Me kuke tunani shine alaƙar da ke tsakanin saurin yankewa, haɗin gwiwar kayan aiki, da saurin ciyarwa a cikin injinan CNC?

Don ingantaccen aiki, yana da mahimmanci don fahimtar alaƙar da ke tsakanin saurin ciyarwa, saurin yankewa da haɗin kai na kayan aiki a cikin injinan CNC.

Gudun Yankewa:

Gudun yankan shine ƙimar juyawa ko motsi ta cikin kayan. Yawanci ana auna saurin a ƙafar saman ƙasa a minti ɗaya (SFM) ko mita/minti (m/min). An ƙaddara saurin yankewa ta kayan da za a yi amfani da su, kayan aikin yankan, da ƙarewar da ake so.

Shigar Kayan aiki

Haɗin gwiwar kayan aiki shine zurfin abin da kayan aikin yankan ke shiga cikin aikin aiki yayin machining. Abubuwan haɗin gwiwar kayan aiki suna shafar abubuwa kamar yankan lissafi na kayan aiki da ciyarwa da sauri da ingancin saman da ake so da ƙimar cire kayan. Ta hanyar zaɓar girman kayan aiki da ya dace, zurfin yankewa da haɗin gwiwar radial, za ku iya daidaita haɗin gwiwar kayan aiki.

Gudun Ciyarwa

Gudun ciyarwa kuma ana kiransa ƙimar ciyarwa ko ciyarwar kowane haƙori. Yana da ƙimar cewa kayan aikin yankan yana ci gaba da juyin juya hali ta hanyar kayan aikin aikin. Ana auna saurin a millimeters ko inci a cikin minti daya. Adadin ciyarwar yana shafar rayuwar kayan aiki kai tsaye, ingancin saman, da aikin injin gabaɗaya.

Gabaɗaya, mafi girman saurin yankan yana haifar da ƙimar cire kayan abu mafi girma. Duk da haka, suna kuma samar da ƙarin zafi. Ƙarfin yankan kayan aiki don ɗaukar saurin gudu, da ingancin coolant a cikin watsar da zafi sune mahimman abubuwa.

Ya kamata a daidaita haɗin gwiwar kayan aiki bisa ga kaddarorin kayan aiki na kayan aiki, joometry na kayan aikin yankan, da ƙarewar da ake so. Haɗin kai na kayan aiki da ya dace zai tabbatar da ingantaccen ƙaurawar guntu da rage karkatar da kayan aiki. Hakanan zai inganta aikin yankewa.

Ya kamata a zaɓi saurin ciyarwa don cimma ƙimar da ake so na cire kayan da ƙarewa, ba tare da cika kayan aiki ba. Matsakaicin adadin abinci na iya haifar da lalacewa ta kayan aiki da yawa. Duk da haka, ƙananan saurin ciyarwa zai haifar da ƙarancin ƙarewar ƙasa da ƙarancin aiki.

Dole ne mai shirye-shiryen ya rubuta umarnin a cikin shirin CNC don ƙayyade adadin yankan ga kowane tsari. Gudun yankewa, adadin yankan baya, saurin ciyarwa da sauransu duk wani bangare ne na yanke amfani. Ana buƙatar adadin yankan daban-daban don hanyoyin sarrafawa daban-daban.

1. Zaɓin zaɓi na adadin adadin

A lokacin da ake yin roughing, babban abin da aka fi mayar da hankali shi ne gabaɗaya kan haɓaka yawan aiki, amma ya kamata a yi la'akari da tattalin arziki da farashin sarrafawa; lokacin da aka gama kammalawa da ƙarewa, yanke ingantaccen aiki, tattalin arziki, da farashin sarrafawa ya kamata a yi la’akari da su yayin tabbatar da ingancin sarrafawa. Ya kamata a ƙayyade takamaiman ƙimar bisa ga jagorar kayan aikin injin, yankan jagorar amfani, da gogewa.

Farawa daga dorewar kayan aiki, tsarin zaɓin adadin yankan shine: na farko ƙayyade adadin yankan baya, sannan ƙayyade adadin abinci, kuma a ƙarshe ƙayyade saurin yanke.

2. Tabbatar da adadin wuka a baya

Adadin yankan baya yana ƙayyade ta taurin kayan aikin injin, kayan aiki da kayan aiki. Idan taurin ya ba da damar, adadin yankan baya ya kamata ya zama daidai da izinin machining na aikin aikin gwargwadon yiwuwa. Wannan na iya rage adadin izinin kayan aiki da inganta haɓakar samarwa.

Ka'idoji don tantance adadin wuka a baya:

1)

Lokacin da ake buƙatar ƙimar ƙimar aikin aikin ya zama Ra12.5μm ~ 25μm, idan izinin machining naInjin CNCshi ne kasa da 5mm ~ 6mm, daya abinci na m machining iya saduwa da bukatun. Duk da haka, lokacin da gefe ya yi girma, rashin ƙarfi na tsarin tsari ba shi da kyau, ko ikon kayan aikin injin bai isa ba, ana iya kammala shi a cikin abinci da yawa.

2)

Lokacin da surface roughness darajar da workpiece ake bukata ya zama Ra3.2μm ~ 12.5μm, shi za a iya raba biyu matakai: roughing da Semi-kammala. Zaɓin adadin yankan baya a lokacin mashin ɗin yana daidai da da. Bar gefe na 0.5mm zuwa 1.0mm bayan m machining da kuma cire shi a lokacin Semi-kammala.

3)

Lokacin da surface roughness darajar da workpiece ake bukata ya zama Ra0.8μm ~ 3.2μm, shi za a iya raba uku matakai: roughing, Semi-karewa da kuma karewa. Adadin yankan baya yayin kammalawa shine 1.5mm ~ 2mm. A lokacin karewa, adadin yankan baya ya kamata ya zama 0.3mm ~ 0.5mm.

3. Lissafin adadin abinci

An ƙayyade adadin abinci ta hanyar daidaiton ɓangaren da kuma yanayin da ake buƙata, da kuma akan kayan da aka zaɓa don kayan aiki da kayan aiki. Matsakaicin ƙimar ciyarwar ya dogara da tsayayyen injin da matakin aikin tsarin ciyarwa.

Ka'idoji don ƙayyade saurin ciyarwa:

1) Idan ana iya tabbatar da ingancin aikin aiki, kuma kuna son haɓaka haɓakar samarwa, ana ba da shawarar saurin ciyar da sauri. Gabaɗaya, ana saita saurin ciyarwa tsakanin 100m/min da 200m/min.

2) Idan kuna yanke ko sarrafa ramuka masu zurfi, ko amfani da karafa masu sauri, zai fi kyau a yi amfani da saurin ciyarwa a hankali. Wannan ya kamata ya kasance tsakanin 20 da 50m / min.

Lokacin da ake buƙata don daidaito a cikin machining da roughness na saman yana da girma, yana da kyau a zaɓi ƙaramin saurin ciyarwa, yawanci tsakanin 20m/min da 50m/min.

Kuna iya zaɓar matsakaicin ƙimar ciyarwar da tsarin kayan aikin injin CNC ya saita lokacin da kayan aikin ba shi da aiki, kuma musamman "maida sifili" a nesa.

4. Ƙididdigar saurin juzu'i

Ya kamata a zaɓi sandal ɗin bisa madaidaicin saurin yankan da aka yarda da diamita na kayan aikin ku ko kayan aiki. Ƙididdigar ƙididdiga don saurin spindle shine:

n=1000v/pD

Ƙarfafawar kayan aiki yana ƙayyade saurin gudu.

Ana auna saurin juyi a cikin r/min.

D —- Diamita ko girman kayan aiki, wanda aka auna cikin mm.

Ana ƙididdige saurin igiya na ƙarshe ta zaɓar saurin da injin ɗin zai iya cimma ko ya zo kusa da shi, bisa ga littafinsa.

Ba da daɗewa ba, ana iya ƙididdige ƙimar adadin yanke ta hanyar kwatanci, dangane da aikin injin, litattafai, da ƙwarewar rayuwa ta gaske. Ana iya daidaita saurin igiya da zurfin yankan zuwa saurin ciyarwa don ƙirƙirar mafi kyawun adadin yanke.

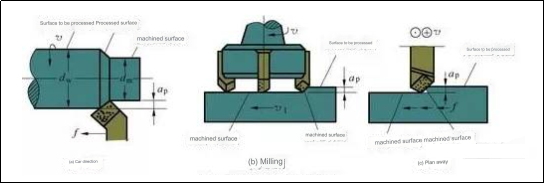

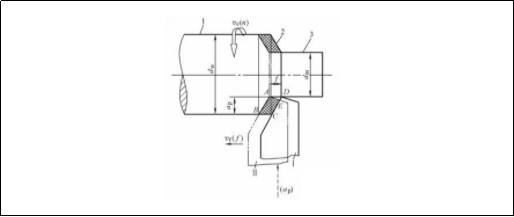

1) Adadin yankan baya (zurfin yanke) ap

Adadin yankan baya shine nisa a tsaye tsakanin saman zuwa injin da saman da aka yi. Yanke baya shine adadin yankan da aka auna daidai gwargwado zuwa jirgin aiki ta wurin tushe. Zurfin yankan shine adadin yankan da kayan aikin jujjuya suke yi a cikin kayan aiki tare da kowane abinci. Ana iya ƙididdige adadin yankan a bayan da'irar waje ta amfani da dabarar da ke ƙasa:

ap = (dw - dm) /2

A cikin dabara, ap —— adadin wuka a baya (mm);

dw——Diamita na saman da za a sarrafa na aikin aikin (mm);

dm (mm) - diamita na kayan aikin injin.

Misali 1:An sani cewa saman diamita na workpiece da za a sarrafa shi ne Φ95mm; yanzu diamita shine Φ90mm a cikin abinci ɗaya, kuma ana samun adadin yankan baya.

Magani: ap = (dw — dm) /2= (95 —90) /2=2.5mm

2) Yawan ciyarwa f

A dangi ƙaura na kayan aiki da workpiece a cikin shugabanci na abinci motsi ga kowane juyi na workpiece ko kayan aiki.

Dangane da kwatancen ciyarwa daban-daban, an raba shi zuwa adadin ciyarwar a tsaye da kuma juzu'in ciyarwar. Adadin ciyarwar mai tsayi yana nufin adadin ciyarwa tare da hanyar dogo jagorar gado, kuma adadin abinci mai jujjuyawa yana nufin madaidaiciyar hanyar dogo jagorar gadon lathe. Yawan ciyarwa.

Lura:Gudun ciyarwar vf yana nufin saurin saurin da aka zaɓa a kan ƙarshen yankan dangane da motsin ciyarwar kayan aikin.

vf=fn

inda vf — — saurin ciyarwa (mm/s);

n——Spindle gudun (r/s);

f——Yawan ciyarwa (mm/s).

3) Yanke gudun vc

Instantaneous gudu a cikin babban motsi a wani takamaiman batu a kan yankan ruwa dangane da workpiece. Ƙididdigar ta:

vc= (pdwn)/1000

Inda vc —-yanke gudu (m/s);

dw = diamita na saman da za a yi magani (mm);

-- Saurin jujjuyawar kayan aikin (r/min).

Ya kamata a yi ƙididdiga bisa matsakaicin saurin yankan. Ya kamata a yi ƙididdiga, alal misali, bisa la'akari da diamita da ƙimar lalacewa na saman da ake yin inji.

Nemo vc. Misali 2: Lokacin juya da'irar waje na abu mai diamita Ph60mm akan lathe, saurin igiya da aka zaɓa shine 600r/min.

Magani:vc=(pdwn)/1000 = 3.14x60x600/1000 = 113 m/min

A cikin samarwa na ainihi, yana da mahimmanci don sanin diamita na yanki. Ana ƙayyade saurin yankewa ta hanyar abubuwa kamar kayan aikin kayan aiki, kayan aiki da buƙatun sarrafawa. Don daidaita lathe, ana canza saurin yankan zuwa saurin igiya na lathe. Ana iya samun wannan dabarar:

n=(1000vc)/pdw

Misali 3: Zaɓi vc zuwa 90m/min kuma nemo n.

Magani: n=(1000v c)/ pdw=(1000×90)/ (3.14×260) = 110r/min

Bayan ƙididdige saurin lathe, zaɓi ƙimar da ke kusa da farantin lamba, misali, n=100r/min azaman ainihin saurin lathe.

3. Taƙaice:

Yanke adadin

1. Adadin wuka na baya ap (mm) ap= (dw – dm) / 2 (mm)

2. Adadin ciyarwa f (mm/r)

3. Yanke gudun vc (m/min). Vc=dn/1000 (m/min).

n=1000vc/d(r/min)

Har zuwa ga kowaCNC aluminum sassasun damu, menene hanyoyin da za a rage nakasar sarrafa sassan aluminum?

Daidaita Daidaitawa:

Gyara kayan aikin daidai yana da mahimmanci don rage murdiya yayin injin. Ta hanyar tabbatar da cewa kayan aikin sun manne a wuri, ana iya rage girgiza da motsi.

Machining Adafta

Ana amfani da martani na firikwensin don daidaita sigogin yankan a hankali. Wannan yana ramawa don bambancin kayan aiki, kuma yana rage nakasawa.

Yanke Ma'auni

Ana iya rage nakasawa ta hanyar inganta sigogi kamar saurin yankewa, ciyarwa, da yanke zurfin. Ta hanyar rage ƙarfin yankewa da samar da zafi ta hanyar amfani da ma'auni masu dacewa, za'a iya rage girman murdiya.

Rage Ƙarfafa Zafi:

Zafin da ake samu a lokacin mashin ɗin na iya haifar da nakasar zafi da faɗaɗawa. Don rage samar da zafi, yi amfani da mai sanyaya ko mai mai. Rage saurin yankewa. Yi amfani da riguna na kayan aiki masu inganci.

Injin A hankali

Yana da kyau a yi ƙetare da yawa lokacin sarrafa aluminum fiye da yanke nauyi ɗaya. Mashin ɗin a hankali yana rage nakasawa ta hanyar rage zafi da yanke ƙarfi.

Yin dumama:

Yin dumama aluminum kafin yin inji na iya rage haɗarin murdiya a wasu yanayi. Preheating yana daidaita kayan kuma yana sa ya zama mai juriya ga murdiya lokacin yin injin.

Taimakon Danniya

Za'a iya yin aikin kawar da damuwa bayan yin injin don rage yawan damuwa. Za a iya daidaita sashin ta dumama shi zuwa wani zafin jiki, sannan a sanyaya shi a hankali.

Zaɓan Kayan Aikin Da Ya dace

Don rage girman lalacewa, yana da mahimmanci don zaɓar kayan aikin yankan daidai, tare da sutura masu dacewa da geometries. Kayan aikin da aka ƙera na musamman don mashin ɗin aluminium suna rage ƙarfin yankewa, haɓaka haɓakar ƙasa, da hana haɓakar gefuna.

Machining a matakai:

Ana iya amfani da ayyukan injina da yawa ko matakai don rarraba runduna a kan hadadduncnc aluminum sassada rage nakasu. Wannan hanya tana hana damuwa a cikin gida kuma yana rage murdiya.

Neman Anebon da manufar kamfani koyaushe shine "Koyaushe biyan bukatun mabukatan mu". Anebon ya ci gaba da samun da salo da kuma ƙirƙira samfura masu inganci masu kyau ga kowane tsofaffin abokan cinikinmu da sabbin abokan cinikinmu da kuma cimma nasarar nasara ga masu amfani da Anebon da kuma mu don Original Factory Profile extrusions aluminum,cnc ya juya part, cnc milling nailan. Muna maraba da abokai da gaske don yin cinikin kasuwancin kasuwanci kuma fara haɗin gwiwa tare da mu. Anebon yana fatan hada hannu da abokai na kud da kud a masana'antu daban-daban don samar da kyakkyawan dogon zango.

Kamfanin kasar Sin mai kera ma'auni mai inganci da karfen karfe na kasar Sin, Anebon na neman samun damar ganawa da dukkan abokai na gida da waje don yin hadin gwiwa don samun nasara. Anebon yana fatan samun hadin kai na dogon lokaci tare da dukkan ku bisa tushen samun moriyar juna da ci gaba tare.

Idan kuna son ƙarin sani, tuntuɓi ƙungiyar Anebon ainfo@anebon.com.

Lokacin aikawa: Nuwamba-03-2023