Kowa ya san zaren. A matsayinmu na abokan aiki a masana'antar masana'anta, yawanci muna buƙatar ƙara zaren gwargwadon buƙatun abokin ciniki lokacin sarrafa kayan haɗi kamarCNC machining sassa, CNC juya sassakumaCNC niƙa sassa.

1. Menene zaren?

Zare wani heliks ne da aka yanke a cikin kayan aiki ko dai daga waje ko daga ciki. Babban ayyukan zaren sune:

1. Samar da haɗin injiniya ta hanyar haɗa samfuran zaren ciki da samfuran zaren waje.

2. Canja wurin motsi ta hanyar juya motsin juyawa zuwa motsi na layi da akasin haka.

3. Sami amfanin inji.

2. Zaren bayanin martaba da kalmomi

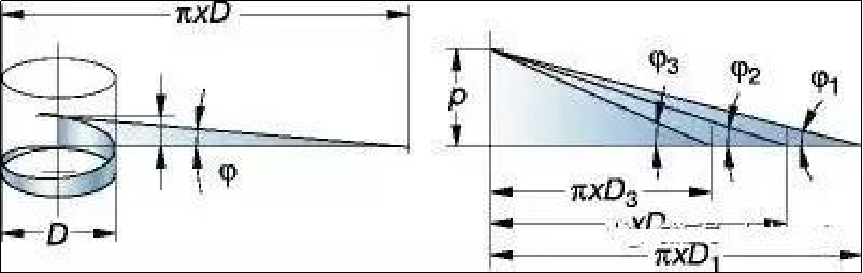

Bayanan martabar zaren yana ƙayyade lissafi na zaren, gami da diamita na aiki (manyan, farar, da ƙananan diamita); kusurwa bayanin martaba; farar da kusurwar helix.

1. Sharuddan zaren

① Kasa: Ƙasar ƙasa tana haɗa flanks guda biyu kusa da zaren.

② flank: saman gefen zaren da ke haɗa kullun da kasan hakori.

③Crest: saman saman da ke haɗa ɓangarorin biyu.

P = farar, mm ko zaren kowane inch (tpi)

ß = kusurwar bayanin martaba

ϕ = kusurwa heliks na zaren

d = babban diamita na zaren waje

D = babban diamita na zaren ciki

d1 = ƙananan diamita na zaren waje

D1 = Ƙananan diamita na zaren ciki

d2 = farar diamita na zaren waje

D2 = diamita farar zaren ciki

Diamita na Pitch, d2/D2

Ingantacciyar diamita na zaren. Kimanin rabin tsakanin manya da ƙananan diamita.

Geometry na zaren yana dogara ne akan diamita na farar zaren (d, D) da farar (P): nisan axial tare da zaren akan kayan aikin daga aya ɗaya akan bayanin martaba zuwa madaidaicin batu na gaba. Hakanan ana iya ganin wannan azaman alwatika yana kewaye da kayan aikin.

vc = saurin yanke (m/min)

ap = jimlar zurfin zaren (mm)

nap = jimlar zurfin zaren (mm)

tpi = zaren kowane inch

Ciyarwa = farar fata

2. Bayanin zare na yau da kullun

1. Lissafi da haƙuri na waje madaurin farar diamita na nau'in haƙori 60 ° (daidaitaccen GB197/196)

a. Lissafi na ainihin girman girman diamita

Matsakaicin girman diamita na zaren = babban diamita na zaren - ƙimar ƙimar ƙimar ƙimar.

Misalin tsari: d/DP×0.6495

2. Ƙididdigewa da juriya na firam diamita na 60° zaren ciki (GB197/196)

A.6H matakin zaren farar diamita haƙuri (dangane da farawar zaren)

Babban iyaka:

P0.8+0.125P1.00+0.150P1.25+0.16P1.5+0.180

P1.25+0.00P2.0+0.212P2.5+0.224

Ƙimar ƙarancin iyaka shine "0",

Ƙididdigar ƙididdiga mafi girma 2+TD2 shine ainihin girman + haƙuri.

Misali, diamita na zaren ciki na M8-6H shine: 7.188+0.160=7.348 Babban iyaka: 7.188 shine ƙananan iyaka.

b. Ƙididdigar ƙididdiga na firam diamita na zaren ciki daidai yake da na zaren waje

Wato D2 = DP × 0.6495, wato, tsakiyar diamita na zaren ciki daidai yake da babban diamita na zaren-pitch × coefficient value.

c.6G aji zaren farar diamita na asali sabawa E1 (dangane da farawar zaren)

P0.8+0.024P1.00+0.026P1.25+0.028P1.5+0.032

P1.75+0.034P1.00+0.026P2.5+0.042

3. Lissafi da juriya na manyan diamita na zaren waje (GB197/196)

a. Iyakar babba na 6h babban diamita na zaren waje

Wato, ƙimar diamita ɗin zaren misali M8 shine φ8.00 kuma haƙurin iyakar babba shine “0″.

b. Haƙuri na ƙananan ƙimar ƙimar babban diamita na aji 6h na zaren waje (dangane da farar zaren)

P0.8-0.15P1.00-0.18P1.25-0.212P1.5-0.236P1.75-0.265

P2.0-0.28P2.5-0.335

Ƙididdigar ƙididdiga don ƙananan iyaka na babban diamita: d-Td shine ainihin girman babban diamita na zaren - haƙuri.

4. Lissafi da haƙuri na ƙananan diamita na zaren ciki

a. Lissafi na ainihin girman ƙaramin diamita na zaren ciki (D1)

Girman asali na ƙananan diamita na zaren = ainihin girman girman zaren ciki - factor × factor

5. Ƙididdigar ƙididdiga ta hanyar rarraba kai guda ɗaya

Ƙididdigar Ƙididdigar hanyar rarraba guda ɗaya: n=40/Z

n: adadin juyin da ya kamata mai raba kan ya juya

Z: Daidaitaccen juzu'i na kayan aiki

40: kafaffen adadin raba kai

6. Ƙididdigar ƙididdiga na hexagon da aka rubuta a cikin da'irar

① Nemo gefen hexagonal kishiyar (S surface) na da'irar D

S=0.866D diamita ne × 0.866 (daidaitacce)

② Yi lissafin diamita na da'irar (D) daga ɓangarorin hexagon (S saman)

D = 1.1547S yana gaba da gefe × 1.1547 (daidaitacce)

7. Ƙididdigar ƙididdiga na tarnaƙi hexagonal masu gaba da juna da diagonals a cikin tsari mai sanyi

① Nemo kishiyar kwana e daga kishiyar gefen (S) na hexagon na waje

e = 1.13s yana gefe × 1.13

②Nemo kishiyar kwana (e) daga kishiyar gefen (s) na hexagon ciki

e = 1.14s yana gefe ɗaya × 1.14 (ƙididdigewa)

③ Nemo diamita abu na kan kishiyar kusurwa (D) daga gefe (s) na waje hexagon

Ya kamata a lissafta diamita na da'irar (D) bisa ga (tsari na biyu a cikin 6) gefen hexagonal kishiyar (s surface), kuma ya kamata a ƙara darajar tsakiyar diyya daidai, wato, D≥1.1547s. Za'a iya ƙididdige adadin cibiyar biya kawai.

8. Ƙididdigar ƙididdiga na murabba'i da aka rubuta a cikin da'irar

① Da'irar (D) don nemo kishiyar gefen murabba'in (S saman)

S=0.7071D diamita ne × 0.7071

② Nemo da'irar (D) daga bangarori daban-daban na murabba'in (S saman)

D = 1.414S yana gefe ɗaya × 1.414

9. Ƙididdigar ƙididdiga na ɓangarorin murabba'i masu gaba da juna da kusurwoyi dabam-dabam a cikin tsarin taken sanyi

① Nemo kishiyar kwana (e) daga kishiyar gefen (S) na filin waje

e=1.4s shine kishiyar gefen (s) × 1.4 siga

② Nemo kishiyar kwana (e) daga kishiyar gefen (s) na murabba'in ciki

e = 1.45s shine kishiyar gefen (s) × 1.45 ƙididdiga

10. Dabarar ƙididdige ƙarar hexagon

s20.866 × H/m/k yana nufin kishiyar gefe × gefe × 0.866 × tsawo ko kauri.

11. Ƙididdigar ƙididdiga na ƙarar jiki (mazugi).

0.262H(D2+d2+D×d) shine 0.262× tsayi ×(babban diamita na kai × babban diamita + ƙarami diamita × ƙaramin kai diamita + babban kai diamita × ƙaramin kai diamita).

12. Ƙididdigar ƙididdiga don ƙarar jiki mai siffar siffar (kamar kai mai madauwari)

3.1416h2(Rh/3) shine 3.1416× tsawo× tsawo×(radius -tsawo÷3).

13. Ƙididdigar ƙididdiga don machining girman famfo don zaren ciki

1. Lissafin babban diamita na famfo D0

D0=D +(0.866025P/8)×(0.5~1.3) shine ainihin girman famfo babban zaren diamita + 0.866025 farar ÷ 8×0.5 zuwa 1.3.

Lura: Zaɓin 0.5 zuwa 1.3 yakamata a tabbatar da girman girman filin. Girman darajar farar, ya kamata a yi amfani da ƙaramin ƙima. Akasin haka, ƙarami ƙimar farar, yakamata a yi amfani da madaidaicin madaidaicin ƙima.

2. Lissafin diamita na fam ɗin famfo (D2)

D2=(3×0.866025P)/8, wato matsa diamita=3×0.866025×pitch÷8

3. Lissafin diamita na famfo (D1)

D1=(5×0.866025P)/8 shine diamita ta famfo=5×0.866025×pitch÷8

14. Ƙididdigar ƙididdiga na tsawon kayan da aka yi amfani da su don yin rubutun sanyi a cikin nau'i daban-daban

An sani cewa ƙarar dabarar da'irar shine diamita × diamita × 0.7854 × tsayi ko radius × radius × 3.1416 × tsayi. Wato d2×0.7854×L ko R2×3.1416×L

Lokacin ƙididdigewa, ƙarar X÷ diamita ÷ diamita ÷ 0.7854 ko X÷radius÷radius÷3.1416 na kayan da ake buƙata don sarrafawacnc machining sassakumacnc juya sassashine tsawon kayan.

Ƙimar ginshiƙi = X/(3.1416R2) ko X/0.7854d2

X a cikin dabara yana wakiltar ƙimar ƙarar kayan da ake buƙata;

L yana wakiltar tsawon ƙimar ainihin ciyarwa;

R/d yana wakiltar radius ko diamita na ainihin ciyarwa.

Lokacin aikawa: Janairu-11-2023