Ci gaba mutu stamping

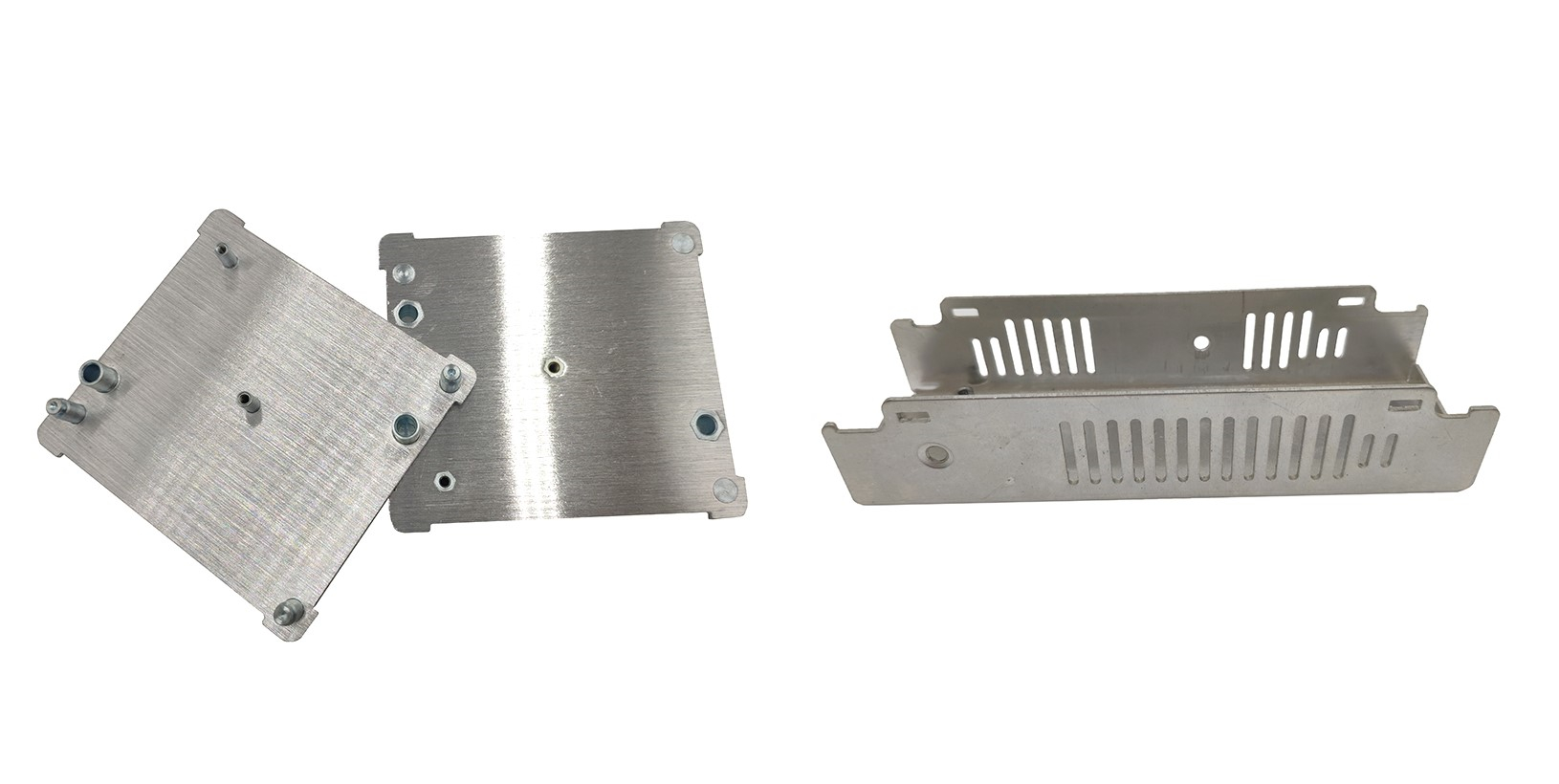

Matsakaicin masu mutuƙar ci gaba suna amfani da motsi a tsaye lokacin sarrafa tsagewar ƙarfen coil. Ana yin aikin lanƙwasawa da yankan lokaci ɗaya a cikin ƙirar don kammala aƙalla sashi ɗaya a cikin kowane bugun na'ura. Ana ciyar da kayan da aka nannade ta hanyar tsari kuma ana sarrafa su mataki-mataki. Dangane da rikitaccen ɓangaren, mutuwar ci gaba na mutuwa na iya zama kaɗan kamar mataki ɗaya ko kuma kamar matakai 40. Saboda yanayin tsarin yana buƙatar kayan da za a tura zuwa tashar ta gaba a yayin kowane bugun jini na kayan aiki, mutuwa mai ci gaba dole ne ya fara jagorantar kayan don sanya kayan aiki a cikin mutuwar kafin yankewa da kafawa. Buƙatar ramukan matukin jirgi a cikin ɗigon kayan ci gaba wani lokaci yana haifar da juzu'i mai yawa ko sharar gida a cikin tsari.sashin hatimi

Koyaya, lokacin shigarwa na mutuwa mai ci gaba yana raguwa da 38% idan aka kwatanta da mutuƙar zamewa huɗu ko mutuƙar zamewa da yawa. Wannan yana bawa masana'antun damar samar da ƙananan batches da ƙarin sassauci a cikin shirye-shiryen samarwa, suna samar da samfuran da suke buƙata kawai lokacin da ake buƙata. Ƙa'idar da mashahurin injiniyan masana'antar Jafananci Shigeo Shingo ya fara aiki: SMED (canjin mutuwa na minti ɗaya) ana iya amfani da shi ga matsi na mutuwa masu ci gaba, wanda shine daidaitaccen aikin Keats. Mutuwar ci gaba kuma na iya haifar da sassa da yawa a kowane bugun jini, yana mai da su manufa don samarwa da yawa:

rami

madogara

Firam ɗin jagora

Bas

Garkuwa

Hudu-slider / Multi-slider stamping

Kamar yadda sunan ke nunawa, na'urar tambarin ƙarfe mai rahusa zamiya huɗu tana da allo masu motsi guda huɗu. Sabanin haka, latsawar mutun faifai da yawa na iya samun mutuwar zamewar motsi sama da huɗu. Tambarin ƙarfe na zame-zane huɗu ko zamewa da yawa suna aiki a kusurwoyi madaidaici a kwance, kuma nunin faifai ( raguna) a cikin injin suna tasiri kayan nada don samar da samfurin da aka gama.karfe stamping

Motoci na Servo ko kyamarorin injina da ke aiki akan faifan na iya samar da hadaddun gwiwar hannu da siffofi. Tare da wannan nau'in na'ura, za'a iya ƙara zaren, saka dunƙule, riveting, da sauran ayyukan haɗin gwiwa masu ƙima.bangaren lankwasawa

Idan aka kwatanta da tambarin mutun na ci gaba, slider-hudu da slider stamping yana rage sharar gida da matsakaicin kashi 31%. Ana samun wannan ta hanyar kawar da buƙatar rami mai jagora da maye gurbin aikin jagora tare da madaidaicin madaidaicin ramin, wanda ya ba da damar ɓangaren ya canza daga naushi zuwa kafa ba tare da buƙatar jagora ba. Keats kuma na iya siyan kayan albarkatun ƙasa bisa madaidaicin faɗin ɓangaren kuma kawar da datsa. Tunda samar da silsilai guda hudu yana ba da damar amfani da jiragen sama da gatari marasa iyaka, yana iya samar da sassa 375 a cikin minti daya, yana mai da shi manufa don samar da yawan hadaddun sassa kamar:

Short film

matsa

Mai ɗaure

bushewa

jaw

Yoke

Anebon Metal Products Limited na iya samar da mashin ɗin CNC, simintin gyare-gyare, sabis na ƙirar ƙarfe, da fatan za a iya tuntuɓar mu.

Tel: +86-769-89802722 Email: info@anebon.com Website : www.anebon.com

Lokacin aikawa: Janairu-15-2020