Ma'anar Ilimin Injiniya ta Anebon

Ilimin injina shine ikon fahimta da amfani da dabaru, ƙa'idodi da ayyuka daban-daban. Ilimin injina ya haɗa da fahimtar injuna, dabaru da kayan aiki da kayan aiki da matakai. Wannan ya haɗa da sanin ƙa'idodin inji, kamar ƙarfi da motsi, makamashi da tsarin kayan aiki da jakunkuna. Ilimin injiniyan injiniya ya haɗa da ƙira, kulawa da dabarun magance matsala, da ƙa'idodin injiniyan injiniya. Ilimin injiniya yana da mahimmanci ga yawancin sana'o'i da masana'antu waɗanda ke aiki tare da tsarin injiniya. Waɗannan sun haɗa da aikin injiniya, masana'antu da gine-gine.

1. Menene hanyoyin gazawar sassa na inji?

(1) Jimillar karyewa

(2) Matsanancin dawwama

(3) Lalacewar sashe

(4) Rashin aiki saboda rushewar yanayin aiki na yau da kullun

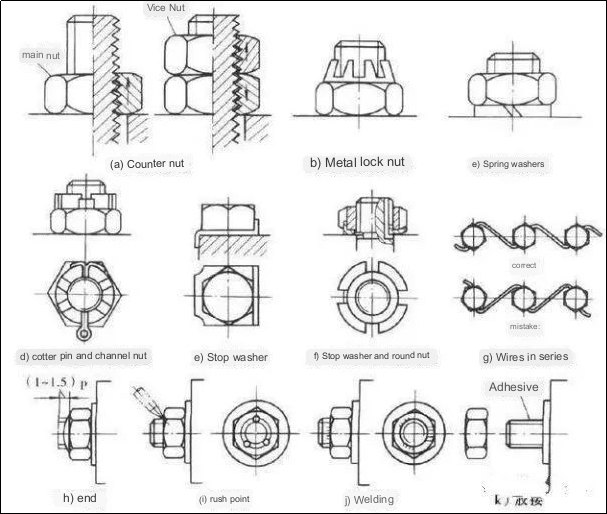

Menene ma'anar bayan buƙatu akai-akai na hana kwance-kwance don haɗin zaren?

Menene ainihin ma'anar anti-unscrewing?

Wadanne hanyoyi daban-daban ake da su don hana sassautawa?

Martani:

Gabaɗaya, haɗin zaren na iya cika ka'idojin kulle kai kuma ba za ta sassauta ba. Koyaya, a cikin yanayi da suka haɗa da girgiza, nauyi mai tasiri, ko matsanancin yanayin zafi, akwai yuwuwar goro mai haɗawa a hankali a hankali. Babban dalilin warware zaren ya ta'allaka ne a cikin jujjuyawar dangi tsakanin nau'ikan zaren. Saboda haka, yana da mahimmanci a haɗa matakan hana sassautawa a cikin ainihin ƙira.

Hanyoyin da aka saba amfani da su sun haɗa da:

1. Gwagwarmaya-tushen anti-loosening - rike gogayya tsakanin zaren nau'i-nau'i don hana sassautawa, kamar yin amfani da spring washers da biyu kwayoyi a kan babba gefe;

2. Mechanical anti-loosening - amfani da obstructivekayan aikin injindon ba da garantin hana sako-sako, yawanci yin amfani da ƙwaya mai ramuka da filaye, da sauransu;

3. Maƙarƙashiya na tushen ɓarna na zaren nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in kifi)" da nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i))" na lalatawa da lalacewa - gyare-gyare da canza dangantaka tsakanin nau'i-nau'i na zaren, kamar ta hanyar amfani da fasaha mai tasiri.

Menene maƙasudin ƙarfafawa a cikin haɗin zaren?

Psamar da hanyoyi da yawa don sarrafa ƙarfin aiki.

Amsa:

Manufar da ke bayan ƙarfafawa a cikin hanyoyin haɗin yanar gizo shine don ba da damar kusoshi don samar da ƙarfin ƙarfafawa. Wannan tsari na riga-kafi yana ƙoƙari don haɓaka dogara da ƙarfin haɗin gwiwa don hana duk wani rata ko motsi na dangi tsakanin sassan da aka haɗa a ƙarƙashin yanayin kaya. Hanyoyi guda biyu masu tasiri don sarrafa ƙarfin ƙarfafawa suna amfani da maƙarƙashiya mai ƙarfi ko madaidaicin maƙarƙashiya. Da zarar karfin da ake buƙata ya kai, ana iya kulle shi a wuri. A madadin, za a iya auna elongation na ƙugiya don daidaita ƙarfin da aka rigaya.

Ta yaya zamewar roba ta bambanta da tsalle-tsalle a cikin bel ɗin tuƙi?

A cikin ƙirar tuƙi na V-belt, me yasa akwai iyakance akan mafi ƙarancin diamita na ƙaramin ja?

Amsa:

Zamewa na roba yana wakiltar siffa ta asali ta bel ɗin tuƙi waɗanda ba za a iya guje wa ba. Yana faruwa lokacin da akwai bambanci a cikin tashin hankali kuma kayan bel ɗin kanta shine elastomer. A daya bangaren kuma, tsallake-tsallake wani nau'in gazawa ne da ke tasowa saboda yawan lodin da ya kamata a hana shi ko ta halin kaka.

Musamman, tsalle-tsalle yana faruwa a kan ƙaramin ja. Ƙara yawan nauyin waje yana haifar da babban bambanci a cikin tashin hankali tsakanin bangarorin biyu, wanda hakan ya haifar da fadada wurin da zamewar roba ke faruwa. Zamewar roba tana wakiltar canji mai ƙididdigewa, yayin da tsalle-tsalle na nuna canji mai ƙima. Saboda haka, don hana ƙetare, akwai iyakance akan mafi ƙarancin diamita na ƙaramin ɗigon, saboda ƙananan diamita na jan hankali yana haifar da ƙananan kusurwoyi da raguwar wuraren hulɗa, yana sa zamewa ya fi faruwa.

Ta yaya saurin zamewar saman haƙori yake da alaƙa da ƙyale ƙarfin hulɗa da baƙin ƙarfe mai launin toka da turbin ƙarfe-ƙarfe na tagulla?

Amsa:

Matsakaicin matsi na tuntuɓar baƙin ƙarfe mai launin toka da injin turbin tagulla na aluminum-iron yana tasiri ta zamewar saurin saman haƙori saboda babban yanayin gazawar da aka sani da mannewar saman haƙori. Mannewa yana tasiri kai tsaye ta hanyar saurin zamewa, don haka yana shafar halayya da damuwa na lamba. A daya bangaren kuma, babban yanayin gazawar simintin tin tagulla turbines shine ramukan saman hakori, wanda ke haifar da matsananciyar lamba. Don haka, damuwan lamba da aka yarda ba shi da alaƙa da saurin zamewa.

Enumkawar da ƙa'idodin motsi na yau da kullun, halayen tasiri, da kuma yanayin da suka dace don mabiyin injin cam.

Amsa:

Dokokin motsi don mabiyin injin kamara sun haɗa da motsin motsi akai-akai, dokokin motsi daban-daban, da motsin jituwa mai sauƙi (dokar haɓaka motsin cosine). Dokar motsi akai-akai tana nuna tasiri mai tsauri kuma ta sami aikace-aikace a cikin yanayin ƙananan sauri da nauyi mai nauyi.

Dokokin motsi na raguwa, gami da ci gaba da sauri, suna da tasiri mai sassauƙa kuma sun dace da matsakaita zuwa ƙananan yanayi. Sauƙaƙan motsin jituwa (dokar haɓaka motsi na cosine 4-chord) yana ba da tasiri mai laushi lokacin da aka sami tazara ta tsayawa, yana mai da shi fa'ida ga yanayin yanayin matsakaici zuwa ƙananan sauri. A cikin yanayin yanayi mai sauri ba tare da tazarar hutu ba, babu wani tasiri mai sassauƙa, yana sa ya dace da waɗannan yanayi.

Taƙaitaccen ƙa'idodin ƙa'idodin da ke tafiyar da bayanan bayanan haƙori.

Amsa:

Duk inda bayanan bayanan hakori suka yi tuntuɓar, layin gama gari na yau da kullun da ke wucewa ta wurin tuntuɓar dole ne ya haɗa wani takamaiman batu akan layin tsakiya. Wannan yanayin yana tabbatar da daidaiton rabon watsawa.

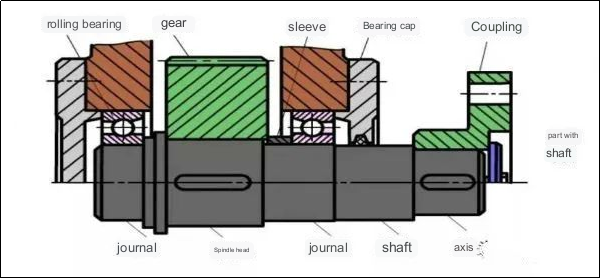

Wadanne hanyoyi ne daban-daban don gyara sassa na kewaye a kan shaft? (ba da fiye da hanyoyi huɗu)

Amsa:

Yiwuwar gyare-gyaren da'irar sun haɗa da yin amfani da haɗin maɓalli, haɗin da aka katse, haɗin da ya dace da tsangwama, saita dunƙule, haɗin fil, da haɗin haɗin gwiwa.

Wadanne nau'ikan dabarun gyaran axial ne na farko don haɗa sassa zuwa shaft?

Menene bambance-bambancen kowannensu? (ambaci fiye da hudu)

Amsa:

Hanyoyin gyara axial don haɗa sassa zuwa sandal sun ƙunshi nau'ikan maɓalli da yawa, kowannensu yana da halaye na musamman. Waɗannan sun haɗa da gyaran ƙwanƙwasa, gyare-gyaren zaren, gyaran gyare-gyaren hydraulic, da gyaran flange. Gyaran ƙwanƙwasa ya ƙunshi amfani da abin wuya ko manne da aka ɗaure a kusa da sandar don tabbatar da sashin axially. Gyaran zaren ya haɗa da amfani da zaren a kan shaft ko sashi don ɗaure su da ƙarfi. Gyaran hydraulic yana amfani da matsa lamba na hydraulic don ƙirƙirar haɗin gwiwa tsakanin sashi da shaft. Gyaran flange ya haɗa da amfani da flange wanda aka kulle ko aka yi masa waldacnc machining sassada shaft, yana tabbatar da abin da aka makala axial amintacce.

Me yasa ya wajaba don yin lissafin ma'auni na zafi don abubuwan tafiyar tsutsa?

Amsa:

Abubuwan tuƙi na tsutsa suna nuna zamewar dangi da manyan matakan gogayya. Saboda ƙarancin ƙarancin zafin su da haɓakar abubuwan da suka shafi adhesion, gudanar da lissafin ma'auni na zafi ya zama mahimmanci.

Wadanne ka'idojin lissafin ƙarfi guda biyu ne ake aiki da su a lissafin ƙarfin kayan aiki?

Wadanne kasawa ne suke nufi?

Idan watsa kayan aiki yana amfani da rufaffiyar saman haƙori mai laushi, menene ma'aunin ƙirar sa?

Amsa:

Ƙididdiga ƙarfin kayan aiki ya ƙunshi ƙayyade ƙarfin gajiyawar lamba na saman haƙori da ƙarfin lanƙwasawa na tushen hakori. Ƙarfin gajiyar hulɗa yana da nufin hana gazawar gajiya a saman haƙori, yayin da ƙarfin gajiyar lanƙwasa yana magance karayar gajiya a tushen hakori. Watsawar kayan aiki da ke amfani da rufaffiyar gefen haƙori mai laushi yana biye da ma'aunin ƙira na la'akari da ƙarfin gajiyawar fuskar haƙori da kuma tabbatar da ƙarfin gajiyawar tushen hakori.

Menene ayyuka daban-daban na haɗin gwiwa da clutches?

Ta yaya suka bambanta da juna?

Amsa:

Dukansu haɗin gwiwa da clutches suna aiki da manufar haɗa raƙuman ruwa biyu don ba da damar watsa karfin juyi da jujjuyawar aiki tare. Duk da haka, sun bambanta dangane da iyawarsu na rabuwa yayin aiki. Couplings suna haɗa ramukan da ba za a iya raba su yayin amfani ba; cire haɗin su yana yiwuwa ne kawai ta hanyar tarwatsajuya sassabayan rufewa. A gefe guda, clutches suna ba da damar yin aiki ko kawar da ramukan biyu a kowane lokaci yayin aikin injin.

Bayyana mahimman abubuwan da ake buƙata don ɗaukar fim ɗin mai don yin aiki da kyau.

Amsa:

Fuskokin biyu da ke jujjuya motsin dangi dole ne su kafa tazara mai siffa; gudun zamiya tsakanin saman dole ne ya ba da tabbacin shigowar mai daga babban tashar jiragen ruwa da fita daga ƙaramar tashar jiragen ruwa; Dole ne mai mai mai ya mallaki takamaiman danko, kuma isassun mai ya zama dole.

Bayar da taƙaitaccen bayani game da abubuwan da suka faru, banbance fasali, da aikace-aikace na yau da kullun na samfurin ɗaukar hoto 7310.

Amsa:

Fassarar lamba: Lambar “7″ tana wakiltar maƙallan ƙwallon ƙafa na kusurwa. Sunan “(0)” yana nufin daidaitaccen faɗin, tare da “0″ kasancewa na zaɓi. Lambar “3″ tana nuna matsakaiciyar jeri dangane da diamita. A ƙarshe, "10" yayi daidai da diamita na ciki na 50mm.

Siffofin da aikace-aikace:

Wannan samfurin ɗaukar hoto zai iya jure wa radial da axial lodi a lokaci guda a cikin hanya guda. Yana ba da saurin iyaka mai girma kuma yawanci ana amfani dashi cikin nau'i-nau'i.

A cikin tsarin watsawa wanda ya haɗa da watsa kayan aiki, watsa bel, da watsa sarkar, wane nau'in watsawa ake sanyawa a mafi girman matakin gudu?

Sabanin haka, wanne ɓangaren watsawa aka shirya a cikin mafi ƙanƙancin gear matsayi?

Bayyana dalilin da ke tattare da wannan tsari.

Amsa:

Gabaɗaya, bel ɗin yana sanya shi a matakin mafi girman gudu, yayin da sarkar ɗin ke sanya shi a cikin mafi ƙasƙanci matsayi. Tushen bel ɗin yana ɗaukar halaye kamar barga watsawa, kwantar da hankali, da ɗaukar girgiza, yana mai da shi fa'ida ga motar a cikin mafi girman gudu. A gefe guda, masu sarrafa sarkar suna haifar da hayaniya yayin aiki kuma sun fi dacewa da yanayin ƙananan sauri, don haka yawanci ana keɓance su zuwa ƙaramin matakin kayan aiki.

Menene ke haifar da rashin daidaituwar gudu a cikin watsa sarkar?

Wadanne abubuwa ne na farko da ke tasiri ta?

A waɗanne yanayi rabon watsa shirye-shiryen nan take zai iya kasancewa akai?

Amsa:

1) Gudun da ba daidai ba a cikin watsawar sarkar ya samo asali ne ta hanyar tasirin polygonal wanda ke cikin tsarin sarkar; 2) Mabuɗin abubuwan da ke tasiri ta sun haɗa da saurin sarkar, sarkar sarkar, da ƙididdigar haƙori; 3) Lokacin da adadin haƙora akan duka manya da ƙanana sprockets sun daidaita (watau z1=z2) kuma tazara tsakanin su shine ainihin ma'aunin farar (p), rabon watsawa nan take ya kasance mai dorewa a 1.

Me yasa fadin hakori (b1) na pinion ya dan fi girma fiye da fadin hakori (b2) na babban kaya a raguwar kayan aiki na silindi?

Lokacin ƙididdige ƙarfi, yakamata madaidaicin faɗin hakori (ψd) ya dogara akan b1 ko b2? Me yasa?

Amsa:

1) Don hana axial misalignment na gears saboda kurakuran taro, meshing hakori nisa ya rage, haifar da ƙara aiki load. Don haka, faɗin hakori (b1) na ƙaramin kayan ya kamata ya zama ɗan girma fiye da b2 na babban kayan. Ya kamata lissafin ƙarfin ya dogara ne akan faɗin hakori (b2) na babban kayan aiki saboda yana wakiltar ainihin faɗin lamba lokacin da nau'ikan gear cylindrical guda biyu suka shiga.

Me yasa diamita na ƙaramin abin jan karfe (d1) zai zama daidai ko girma fiye da ƙaramin diamita (dmin) da kusurwar kunsa na abin tuƙi (α1) ya zama daidai ko girma fiye da 120° a cikin bel ɗin ragewa?

Gabaɗaya, saurin bel ɗin shawarar yana tsakanin 5 zuwa 25 m/s.

Menene clokuta idan gudun bel ya wuce wannan kewayon?

Amsa:

1) Karamin diamita na ƙaramin ɗigon ja yana haifar da matsananciyar lanƙwasawa akan bel. Don hana matsananciyar lanƙwasawa, ya kamata a kiyaye mafi ƙarancin diamita na ƙaramin ɗigon.

2) Ƙaƙƙarfan kusurwa (α1) na motar motar yana rinjayar iyakar tasiri mai tasiri na bel. Karamin α1 yana haifar da ƙaramin ƙarfin ja mai inganci mai ƙarancin ƙarfi. Don haɓaka iyakar ƙarfin ja mai tasiri da hana zamewa, ana ba da shawarar kusurwar kundi na α1≥120° gabaɗaya.

3) Idan saurin bel ɗin ya faɗi a waje da kewayon 5 zuwa 25 m/s, ana iya samun sakamako. Gudun da ke ƙasa da kewayon na iya buƙatar babban ƙarfin ja mai ƙarfi (Fe), wanda zai haifar da haɓaka adadin bel (z) da babban tsarin tuƙi na bel. Sabanin haka, saurin bel ɗin da ya wuce kima zai haifar da ƙarin ƙarfin centrifugal (Fc), yana buƙatar taka tsantsan.

Ribobi da rashin lahani na mirgina helical.

Amsa:

Amfani

1) Yana nuna ƙarancin lalacewa, kuma ana iya amfani da dabarar daidaitawa don kawar da sharewa da haifar da wani matakin nakasar da aka rigaya, ta haka yana haɓaka tsauri da samun daidaiton watsawa mai girma.

2) Ba kamar tsarin kulle kai ba, yana da ikon juyar da motsi na linzamin kwamfuta zuwa motsi na juyawa.

Rashin amfani

1) Tsarin yana da rikitarwa kuma yana haifar da kalubale a masana'antu.

2) Wasu hanyoyi na iya buƙatar ƙarin hanyar kulle kai don hana juyawa.

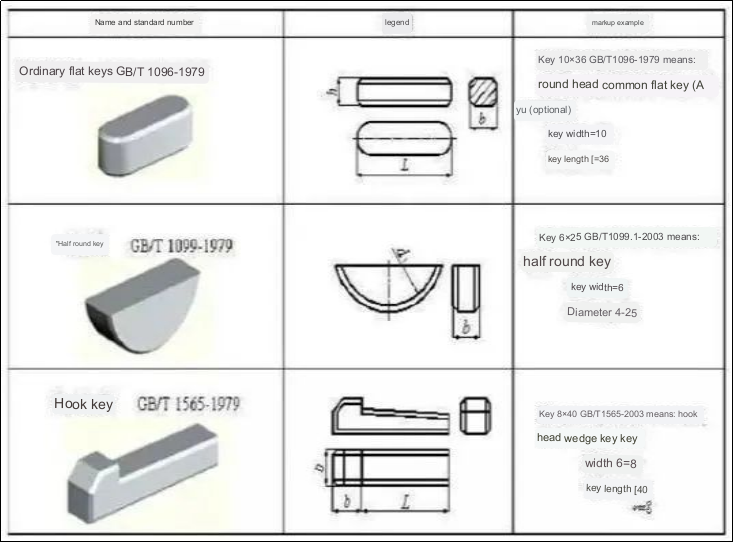

Menene ainihin ka'ida don zabar maɓalli?

Amsa:

Lokacin zabar maɓalli, akwai mahimman la'akari guda biyu: nau'in da girman. Zaɓin nau'in ya dogara da dalilai kamar sifofin tsarin haɗin maɓalli, buƙatun amfani, da yanayin aiki.

A gefe guda, zaɓin girman ya kamata ya bi daidaitattun ƙayyadaddun bayanai da buƙatun ƙarfin. Girman maɓallin ya ƙunshi girma-ɓangaren giciye (maɓallin girman B * Matsa L. gabaɗaya za a ƙayyade bisa tsayin cibiya, ma'ana cewa tsayin maɓallin L kada ya wuce tsayin cibiya. Bugu da ƙari, don maɓallan lebur ɗin jagora, tsayin cibiya L' yawanci yana kusa da (1.5 -2) sau diamita na shaft d, la'akari da tsawon cibiya da tazarar zamewa.

Anebon ya dogara da ƙarfin fasaha mai ƙarfi kuma yana ci gaba da haɓaka fasahar ci gaba don biyan buƙatun sarrafa ƙarfe na CNC,5 axis cnc milling, da simintin mota. Muna daraja duk shawarwari da ra'ayoyi sosai. Ta hanyar kyakkyawar haɗin gwiwa, za mu iya samun ci gaban juna da kyautatawa.

A matsayin mai kera ODM a kasar Sin, Anebon ya ƙware wajen keɓance sassan hatimin aluminium da kayan aikin masana'anta. A halin yanzu, an fitar da samfuranmu zuwa ƙasashe sama da sittin da yankuna daban-daban na duniya, gami da kudu maso gabashin Asiya, Amurka, Afirka, Gabashin Turai, Rasha, da Kanada. Anebon ya himmatu wajen samar da babbar hanyar sadarwa tare da abokan ciniki masu yuwuwa a kasar Sin da sauran sassan duniya.

Lokacin aikawa: Agusta-16-2023