1. Yana da fasaha don samun ɗan ƙaramin abinci mai zurfi. A cikin tsarin juyawa, ana amfani da aikin triangular sau da yawa don aiwatar da wasu kayan aiki tare da da'irori na ciki da na waje sama da daidaito na biyu. Saboda zafi yanke, da gogayya tsakanin workpiece da kayan aiki sa kayan aiki lalacewa da kuma maimaita sakawa daidaito na square kayan aiki mariƙin, da dai sauransu, don haka ingancin yana da wuyar garanti. Don warware madaidaicin zurfin zurfin ƙaramin ƙaramin tsari a cikin tsarin juyawa, zamu iya amfani da alaƙar da ke tsakanin kishiyar gefen da madaidaicin gefen alwatika kamar yadda ake buƙata don matsar da ƙaramin mariƙin wuƙa mai tsayi a kusurwa don isa daidai zurfin cin abinci a kwance. micro-motsin kayan aikin juya. Manufa: adana aiki da lokaci, tabbatar da ingancin samfur, da haɓaka ingantaccen aiki. Babban ma'aunin ma'auni mai riƙe kayan aikin lathe lathe shine 0.05mm kowace grid. Idan kuna son samun ƙimar zurfin cin abinci a kwance na 0.005mm, duba teburin aikin sine trigonometric: sine=0.005/0.05=0.1 α=5o44′, don haka matsar da ƙaramin mariƙin wuƙa. Lokacin da yake 5o44', lokacin motsa diski ɗin da aka zana a tsaye akan ƙaramin mariƙin wuƙa, zai iya kaiwa ƙaramin motsi na kayan aikin yankan tare da zurfin ƙimar 0.005mm a cikin shugabanci na gefe.

2. Yin amfani da fasahar jujjuyawar fasaha a cikin ayyukan samarwa na tsawon lokaci guda uku ya tabbatar da cewa a cikin ƙayyadaddun tsari na juyawa, fasahar yankan baya na iya samun sakamako mai kyau. Misalai masu zuwa sune kamar haka:

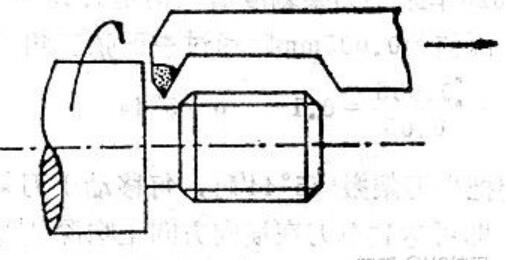

(1) Lokacin da reverse-yanke zaren abu ne martensitic bakin karfe yanki tare da na ciki da kuma waje zaren workpiece tare da farar 1.25 da kuma 1.75 mm tun farar lathe dunƙule an cire da farar na workpiece, da samu darajar. darajar ce mara iyaka. Idan zaren na'ura ne ta hanyar ɗaga hannun goro, zaren yakan karye. Gabaɗaya, lathe na yau da kullun ba shi da na'ura mara ƙarfi, kuma saitin fayafai da aka yi da kansa yana ɗaukar lokaci sosai wajen sarrafa irin wannan farar. Lokacin zaren, yana da yawa. Hanyar da aka yi amfani da ita ita ce hanyar jujjuya mai sauƙi mai sauƙi don ɗaukar sauri mai sauri bai isa ya janye wuka ba, don haka aikin samarwa ya ragu, fayil ɗin yana samuwa a sauƙi a lokacin Juyawa, kuma rashin ƙarfi na sama ba shi da kyau, musamman ma. a sarrafa martensite bakin karfe kamar 1Crl3, 2 Crl3, da dai sauransu Lokacin yankan a cikin ƙananan gudu, abin sickle ya fi shahara. Hanyar yankan juzu'i, juye-juye, da kuma gaba-gaba-kwarya "hanyoyi uku-biya" da aka kirkira a cikin aikin mashin ɗin na iya cimma kyakkyawan sakamako na yanke gabaɗaya saboda hanyar na iya juya zaren a babban saurin, da kuma motsi na kayan aiki. an janye daga hagu zuwa dama, don haka babu wani koma baya cewa kayan aiki ba za a iya janyewa ba lokacin yanke zaren a babban gudun. Hanya ta musamman ita ce kamar haka: Lokacin da ake amfani da zaren waje, niƙa irin wannan kayan aikin juyawa na ciki (Fig. 1);

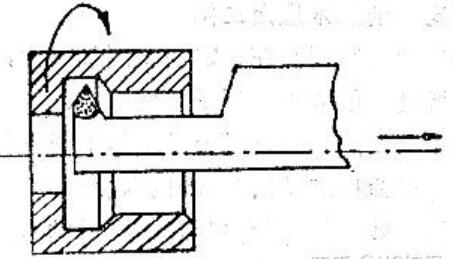

Nika kayan aikin juyar da zaren ciki na baya (Hoto 2).

Kafininji, daidaita sandar farantin juzu'i kaɗan don tabbatar da jujjuya saurin juyawa. Don mai yankan zaren mai kyau, rufe ƙwaya mai buɗewa da rufewa, fara gaba da ƙananan gudu don zuwa sipe mara kyau, sa'an nan kuma sanya kayan aikin juya zaren a cikin zurfin yanke; za ku iya juyar da jujjuyawar. A wannan lokacin, ana barin kayan aikin juyawa a babban gudun. Ta hanyar yanke wuka zuwa dama da yanke adadin wukake bisa ga wannan hanya, zaren zaren da ke da tsayi mai tsayi da tsayin daka zai iya yin inji.

(2) A cikin tsarin ƙullun gargajiya na juzu'i na juzu'i, ana shigar da filaye na ƙarfe da tarkace a tsakanin kayan aiki da wuka mai ɗaure, yana haifar da damuwa da aikin aikin, yana haifar da haɗa layin, an murƙushe ƙirar ko fatalwa, da dai sauransu. Idan an karɓi sabon hanyar aiki na Juyawa da dunƙule sandar lathe, za a iya hana rashin lahani da aikin smoothing ya haifar. kuma ana iya samun tasiri mai kyau.

(3) Juya juyewar zaren bututu na ciki da na waje Lokacin juya zaren bututu na ciki da waje daban-daban tare da ƙarancin daidaito da ƙarancin tsari, yana yiwuwa a yi amfani da yankan juyawa kai tsaye ba tare da na'urar ƙira ba. A cikin sabuwar hanyar aiki, yayin yanke gefen kayan aiki, kayan aiki yana motsawa a kwance daga hagu zuwa dama. Fayil mai jujjuyawa yana sa sauƙin fahimtar zurfin fayil ɗin daga babban diamita zuwa ƙaramin diamita. Dalilin shine fayil. Akwai pre-danniya. Kewayon aikace-aikace na wannan sabon nau'in fasahar aiki ta baya a cikin jujjuyawar fasaha yana ƙara yaɗuwa kuma ana iya yin amfani da su cikin sassauƙa zuwa takamaiman yanayi daban-daban.

3. Sabuwar hanyar aiki da ƙirar kayan aiki don hako ƙananan ramuka A cikin tsarin juyawa, lokacin da ramin ya kasance ƙasa da 0.6mm, diamita na rawar jiki yana da ƙananan, rashin ƙarfi ba shi da kyau, saurin yankewa bai tashi ba, kuma kayan aiki na kayan aiki. shi ne alloy mai jure zafi da bakin karfe, kuma juriya na yanke yana da girma, don haka lokacin hakowa, kamar yin amfani da abinci na watsawa na inji, rawar jiki yana da sauƙin karya, mai zuwa yana bayyana kayan aiki mai sauƙi da inganci da hanyar ciyarwa ta hannu. Da fari dai, ana canza ƙuƙumar rawar soja ta asali zuwa nau'in shank madaidaiciya. Lokacin da aka manne ɗan ƙaramin rawar rawar soja a kan ƙugiya mai iyo, za a iya yin aikin hakowa cikin sauƙi. Saboda bangaren baya na rawar rawar jiki madaidaiciyar zamewar shank, yana iya motsawa cikin yardar kaina a cikin hannun riga. Lokacin da aka haƙa ƙaramin ramin, za a iya kama ƙwanƙwasa a hankali da hannu, za a iya gane micro feed na manual, kuma za a iya fitar da ƙaramin rami da sauri. Quality da yawa da kuma tsawaita rayuwar sabis na ƙananan drills. Hakanan za'a iya amfani da ƙwanƙolin maƙasudin maƙasudi da yawa don ƙaramin diamita na zaren ciki, reaming, da sauransu. (Idan aka haƙa rami mai girma, ana iya saka fil mai iyaka tsakanin hannun ja da madaidaiciyar shank).

4. Anti-vibration a cikin mashigin rami mai zurfi A cikin mashin mai zurfi, saboda ƙananan buɗewa, mashaya kayan aiki mai ban sha'awa yana da siririn. Babu makawa don haifar da girgiza lokacin da diamita na rami ya kasance Φ30 ~ 50mm, kuma rami mai zurfi yana kusan 1000mm. Shi ne mafi inganci da inganci don hana girgizar arbor. Hanyar ita ce haɗa goyan baya guda biyu (ta amfani da abu kamar bakelite na zane) zuwa jikin shank, kuma girman daidai yake da girman buɗewa. A lokacin yankan tsari, arbor ba shi da sauƙi ga girgiza saboda matsayi na slats, kuma ana iya sarrafa sassan rami mai zurfi na inganci mai kyau.

5. Anti-break na ƙananan ƙananan ƙananan ƙananan ƙananan ƙananan ƙananan ƙananan ƙananan ƙananan Φ1.5mm lokacin da hakowa ya kasance ƙasa da rami na tsakiya na Φ1.5mm. Hanya mai sauƙi kuma mai tasiri mai tasiri shine kada a kulle kullun wutsiya lokacin da ake hako rami na tsakiya amma bari tailstock. Ana amfani da nauyin nauyin kai da kuma juzu'in da aka haifar tsakanin saman gadon injin don haƙa rami na tsakiya. Lokacin da juriya na yanke ya yi girma da yawa, dokin wutsiya zai ja da baya da kansa, don haka yana kare rawar tsakiya.

6. Anti-vibration na juya bakin ciki-bango workpieces A lokacin da juya aiwatar da bakin ciki-banga workpieces, vibrations ne sau da yawa generated saboda matalauta karfe Properties na workpieces; musamman lokacinjuya bakin karfeda allura masu jure zafin zafi, girgizar ta fi shahara, yanayin yanayin aikin aikin yana da rauni sosai, kuma rayuwar sabis na kayan aiki yana raguwa. Hanyoyi mafi sauƙi na keɓewar girgiza a yawancin samarwa an kwatanta su a ƙasa.

(1) Lokacin da juya m da'irar na bakin karfe m siriri tube workpiece, da rami za a iya cika da itace kwakwalwan kwamfuta da plugged. A lokaci guda, duka ƙarshen aikin aikin suna toshe tare da filogin bakelite, sa'an nan kuma an maye gurbin katsewar goyan baya akan mariƙin kayan aiki tare da kankana mai goyan bayan kayan bakelite na iya gyara baka da ake buƙata don yin Juyawar bakin karfe mara kyau. siririn sanda. Wannan hanya mai sauƙi na iya hana rawar jiki da nakasar sandar siriri mara kyau yayin aiwatar da yankan.

(2) Lokacin da juya ciki rami na wani zafi-resistant (high-nickel-chromium) gami bakin ciki-bango workpiece, da rigidity na workpiece ne matalauta, da shank ne siriri, da kuma tsanani resonance sabon abu faruwa a lokacin yankan tsari. wanda ke da alhakin lalata kayan aiki da haifar da sharar gida. Idan wani abu mai ɗaukar girgiza, kamar tsiri na roba ko soso, ya sami rauni a kewayen waje na kayan aikin, za a iya samun tasirin girgiza yadda ya kamata.

(3) Lokacin da juya waje da'irar na zafi-resistant gami bakin ciki-banga hannun riga workpiece, saboda da m dalilai kamar high juriya na zafi-resistant gami, yana da sauki don samar da vibration da nakasawa a lokacin yankan. Idan roba rami ko auduga zaren da aka saka a cikin workpiece rami, The tarkace da ake amfani da, sa'an nan da clamping hanya a duka iyakar za a iya amfani da yadda ya kamata hana vibration da nakasawa na workpiece a lokacin yankan tsari, da kuma high quality-. na bakin ciki-banga workpiece za a iya sarrafa.

7. Ƙarin kayan aikin anti-vibration sauƙi yana haifar da rawar jiki saboda rashin ƙarfi na elongated shaft-type workpiece a lokacin da Multi-tsagi yankan tsari, haifar da matalauta surface roughness na workpiece da kuma lalacewa da kayan aiki. Saitin ƙarin kayan aikin anti-vibration na iya magance matsalar girgizar sassan siriri a cikin tsarin tsagi (duba hoto 10). Shigar da kayan aikin da aka yi da kai a cikin matsayi mai dacewa akan ma'auni na murabba'in kafin aiki. Sannan, shigar da kayan aikin jujjuya mai siffa mai ramin da ake buƙata akan madaurin kayan aikin murabba'i, daidaita nisa da adadin matsi na bazara, sannan a yi aiki. Lokacin da kayan aiki na juyawa ya yanke cikin aikin aiki, an sanya ƙarin kayan aikin anti-vibration a saman kayan aiki a lokaci guda, wanda ke da kyau don girgizawa. Tasiri.

8. Abubuwan da ke da wahala-zuwa-inji suna honed kuma sun ƙare. Lokacin da muke cikin kayan aiki masu wahala-zuwa na'ura kamar alloys masu zafin jiki da ƙwanƙwasa ƙarfe, ana buƙatar ƙarancin aikin aikin ya zama Ra0.20-0.05μm, kuma daidaiton girman shima yana da girma. Ƙarshe na ƙarshe yawanci ana aiwatar da shi akan injin niƙa. Yi kayan aikin honing mai sauƙi da dabaran honing, kuma sami kyakkyawan tasirin tattalin arziki ta hanyar honing maimakon aikin niƙa akan lathe.

9. Saurin ɗorawa da saukar da mandaloli sau da yawa suna haɗuwa da nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan juyi a cikin tsarin juyawa. Da'irar waje da jujjuyawar jagorar kusurwar maɗaurin taro. Saboda girman girman batch, lokacin lodi da saukewa ya fi lokacin yankewa. Dogon, ƙarancin samar da inganci. Mandarin mai ɗaukar nauyi da sauri da wuka guda ɗaya (karfe mai wuya) kayan aikin juyawa da aka kwatanta a ƙasa na iya adana lokacin taimako da tabbatar da ingancin samfura cikin sarrafa sassa daban-daban na hannun hannu. Hanyar samarwa shine kamar haka. Yi sauƙi, e ƙaramar taper mandrel. Ƙa'idar ita ce a yi amfani da alamar 0.02mm na taper a bayan mandrel. Ana ɗora saitin ɗamara akan madaidaicin ta hanyar juzu'i, sa'an nan kuma ana amfani da kayan aikin jujjuya wuka mai yawa. Bayan zagaye, kusurwar mazugi na 15 ° yana juyawa, kuma ana yin filin ajiye motoci don cire sassan da sauri da kyau, kamar yadda aka nuna a cikin Hoto.

10. Juya sassa na ƙarfe mai tauri

(1) Daya daga cikin key misalai na taurin karfe juya 1 Sake gina high-gudun karfe W18Cr4V taurare broach (gyara bayan karaya) 2 na gida mara misali thread plug ma'auni (hardening hardware) 3 quenching hardware da sprayingTurningg kashe guda hudu na quenching hardware m surface plugging 5 Zare mirgina famfo sanya da high-gudun karfe kayan aikin Don quenching hardware da kuma sassa daban-daban na kayan aiki masu wuyar gaske da aka fuskanta a cikin samarwa na sama, zaɓi kayan aikin da ya dace da kayan aiki da yankan adadin da kayan aiki Geometric kusurwa da hanyoyin aiki na iya cimma kyakkyawan sakamako na tattalin arziki gaba ɗaya. Misali, bayan an karye kasidar murabba'i, idan aka sake kaddamar da ita don kera kasidar murabba'i, ba wai tsayin da'irar masana'anta ba ne amma kuma farashin yana da yawa. A tushen tushen broach, muna amfani da ruwan wukake na gawa mai wuya YM052 don kaifafa shi zuwa mummunan. Gaban kwana r. = -6°~-8°, za'a iya juyar da yankan gefen ta hanyar nika a hankali tare da dutse mai. Gudun yankan shine V=10 ~ 15m/min. Bayan da'irar waje, an yanke sipe mara kyau, kuma a ƙarshe, an raba zaren zuwa m da lafiya. ), bayan roughing, da kayan aiki dole ne a reamed da kuma kasa bayan sabon kaifafa da nika. Sa'an nan kuma, dole ne a shirya zaren ciki na igiya mai haɗawa, kuma dole ne a gyara haɗin gwiwa. An gyara ma'auni mai fa'ida tare da karyewar tarkace bayan an juyo, kuma ta kasance kamar sabo.

(2) Zaɓin kayan aikin kayan aiki don juyawa da kayan aikin kashewa 1 Sabbin maki kamar su ƙarfi gami da YM052, YM053, YT05, da sauransu, saurin yankan gabaɗaya yana ƙasa da 18m / min, kuma ƙarancin kayan aikin na iya isa Ra1.6 ~0.80m. 2 cubic boron nitride kayan aiki FD na iya aiwatar da kowane nau'in ƙarfe mai ƙarfi da sassa da aka fesa, saurin yankewa har zuwa 100m / min, ƙarancin ƙasa har zuwa Ra0.80 ~ 0.20μm. Kayan aiki mai siffar cubic boron nitride DCS-F wanda Kamfanin Injin Babban Jiha da Kamfanin Guizhou No.6 ke niƙa shi ma yana da wannan aikin. Sakamakon aiki ya fi muni fiye da na siminti carbide (amma ƙarfin ba shi da kyau kamar na kayan aiki mai wuyar gaske, yana da zurfi da rahusa fiye da gwangwani mai wuya, kuma yana da sauƙin lalacewa idan an yi amfani da shi ba daidai ba). Kayan aikin yumbu tara, saurin yankewa na 40 ~ 60m / min, ƙarfin ba shi da kyau. Duk kayan aikin da ke sama suna da halaye nasu a cikin juyawa da quenching sassa kuma ya kamata a zaba bisa ga ƙayyadaddun yanayi na juya kayan daban-daban da taurin daban-daban.

(3) Zaɓin nau'ikan nau'ikan nau'ikan sassa na ƙarfe da kayan aiki daban-daban na sassa daban-daban na sassa na ƙarfe mai ƙarfi a ƙarƙashin taurin guda ɗaya, abubuwan da ake buƙata don aikin kayan aiki sun bambanta gabaɗaya, kamar manyan nau'ikan nau'ikan uku masu zuwa: 1 babban alloy karfe: yana nufin alloying. abubuwa Tool karfe da mutu karfe (yafi daban-daban high-gudun karafa) tare da jimlar taro na fiye da 10%. 2 alloy karfe: yana nufin kayan aiki karfe da mutu karfe tare da alloying kashi abun ciki na 2 ~ 9%, kamar 9SiCr, CrWMn, da kuma high ƙarfi gami tsarin karfe. Uku carbon karfe: ciki har da daban-daban carbon kayan aiki zanen gado na karfe da carburized karfe kamar T8, T10, 15 karfe, ko 20 ma'auni karfe carburizing karfe. Don carbon karfe, da microstructure bayan quenching ne tempered martensite da karamin adadin carbide, wuya gashi HV800 ~ 1000, fiye da taurin WC da TiC a cimined carbide da A12D3 a yumbu kayayyakin aiki. Yana da ƙasa da ƙasa, kuma yana da ƙarancin zafi fiye da martensite ba tare da haɗa abubuwa ba kuma gabaɗaya baya wuce 200 ° C. Kamar yadda abun ciki na alloying abubuwa a cikin karfe karuwa, da carbide abun ciki na karfe bayan quenching da tempering yana ƙaruwa, da kuma irin carbide zama quite rikitarwa. Shan high-gudun karfe a matsayin misali, abun ciki na carbides a cikin microstructure bayan quenching da tempering iya isa 10-15% (girman rabo) da kuma ya ƙunshi carbides na MC, M2C, M6 M3, 2C, da dai sauransu High taurin (HV2800) ya fi girma fiye da taurin lokaci mai wuya a cikin kayan aiki na gaba ɗaya. Bugu da ƙari, saboda kasancewar yawan adadin abubuwan haɗin gwiwa, zafi mai zafi na martensite wanda ya ƙunshi abubuwa daban-daban na alloying za a iya ƙara zuwa kimanin 600 ° C. Ƙarfin aiki mai ƙarfi na ƙarfe mai tauri tare da microhardness iri ɗaya ba iri ɗaya bane, kuma bambancin yana da girma sosai. Kafin juya sassan ƙarfe masu tauri, ana nazarin su don kasancewa cikin wannan rukunin. Jagora halaye kuma zaɓi kayan aikin da suka dace, yankan adadin, da lissafin kayan aiki. The kwana iya smoothly kammala stringing na karfe sassa.

Anebon Metal Products Limited na iya samar da CNC Machining, Die Casting, Sheet Metal Fabrication sabis, da fatan za a iya tuntuɓar mu.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Lokacin aikawa: Agusta-30-2019