Takaitacciyar hanyoyin sarrafa zaren guda takwas dole ne ku sani lokacin yin injina.

.Kalmar Turanci daidai da Screw shine Screw. Ma'anar wannan kalma ta canza da yawa a cikin 'yan shekarun nan. Akalla a cikin 1725, yana nufin "mating".

Ana iya gano aikace-aikacen ka'idar zaren zuwa kayan aiki mai karkata ruwa wanda masanin Girka Archimedes ya kirkira a shekara ta 220 BC.

A cikin karni na 4 AD, ƙasashen Bahar Rum sun fara amfani da ka'idar kusoshi da goro ga matsi da ake amfani da su wajen yin giya. A lokacin, zaren na waje ya raunata da igiya zuwa sandar silinda sannan a sassaƙa shi bisa ga wannan alamar, yayin da zaren na ciki yakan yi sau da yawa ta hanyar buga zaren waje tare da abu mai laushi.

Kusan 1500, a cikin zane na na'urar sarrafa zaren da Italiyanci Leonardo da Vinci ya zana, an yi tunanin yin amfani da Screw na mata da kayan musayar don sarrafa zaren tare da filaye daban-daban. Tun daga wannan lokacin, hanyar yanke zaren injina ta haɓaka a cikin masana'antar kera agogon Turai.

A shekara ta 1760, ’yan’uwan Birtaniya J. Wyatt da W. Wyatt sun sami takardar shaidar yankan itace da wata na’ura. A shekara ta 1778, J. Ramsden dan kasar Burtaniya ya taba kera na'urar yankan zare da wani nau'in tsutsotsin gear guda biyu ke tukawa, wanda zai iya sarrafa dogon zaren da madaidaicin gaske. A cikin 1797, Bature H. Maudsley ya yi amfani da Screw na mata da musayar kayan aiki don juya zaren ƙarfe na filaye daban-daban akan ingantaccen lathe ɗinsa, wanda ya aza hanyar farko ta juya zaren.

A cikin 1820s, Maudsley ya samar da famfo na farko kuma ya mutu don zaren.

A farkon karni na 20, ci gaban masana'antar kera motoci ya kara inganta daidaiton zaren da samar da ingantattun hanyoyin sarrafa zaren daban-daban. An ƙirƙira wasu kawunan mutuƙar buɗewa ta atomatik da kuma famfunan rage ta atomatik ɗaya bayan ɗaya, kuma an fara amfani da zaren niƙa.

A farkon 1930s, zaren niƙa ya bayyana.

Duk da cewa fasahar birgima da zaren an yi haƙƙin mallaka ne a farkon ƙarni na 19, saboda wahalar masana'antar ƙira, an tsawaita ci gaban har zuwa yakin duniya na biyu (1942-1945) saboda buƙatar samar da makamai da haɓaka fasahar niƙa. Matsalolin madaidaicin ƙirar ƙira ya haɓaka cikin sauri.CNC juya part

Ana rarraba zaren zuwa zaren haɗawa da zaren watsawa.

Hanyoyin sarrafawa na tsakiya don haɗa zaren su ne tapping, zaren, zaren, zaren rolling, zaren mirgina, da dai sauransu.

Hanyoyin sarrafawa na tsakiya don zaren watsawa suna da ƙaƙƙarfan juyi mai kyau --- niƙa, milling --- m da kyau juyi, da dai sauransu.

Kashi na farko shine yanke zaren

Gabaɗaya yana nufin machining workpiece zaren tare da kafa ko abrasive kayan aikin, yafi ciki har da juya, milling, tapping da zare nika, nika, da whirling yanke. Lokacin juyawa, niƙa, da zaren niƙa, sarkar tuƙi na kayan aikin injin yana tabbatar da cewa kayan aikin juyawa, abin yankan niƙa, ko dabaran niƙa suna motsawa daidai kuma daidai da jagora ɗaya tare da axis na workpiece don kowane juyi na workpiece. Lokacin tapping ko threading, da kayan aiki (matsa ko mutu) da workpiece juya dangi da juna, da kuma a baya kafa thread tsagi shiryar da kayan aiki (ko workpiece) don matsawa axially.

1. Juyawa zare

Ana iya kunna zaren kunna lathe tare da ƙirƙirar kayan aikin juyawa ko tsefe zaren. Juya zaren tare da samar da kayan aikin juyawa shine daidaitaccen hanya don guda ɗaya da ƙananan samar da kayan aikin da aka yi da zaren saboda tsarin kayan aiki mai sauƙi; juya zaren tare da zaren combing kayan aiki yana da babban samar da inganci, amma tsarin kayan aiki yana da rikitarwa, kawai ya dace da matsakaici da manyan samar da tsari. Suna juya gajeren zaren workpieces tare da farar kyau. Daidaiton farar lathes na yau da kullun don juya zaren trapezoidal gabaɗaya na iya kaiwa maki 8 zuwa 9 kawai (JB2886-81, iri ɗaya a ƙasa); mashin ɗin zaren akan lathes na musamman na zaren na iya inganta haɓaka aiki ko daidaito sosai.

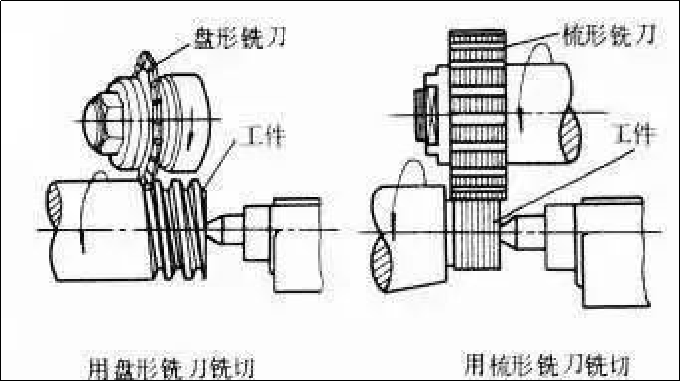

2. Niƙan zare

Ina niƙa da faifai ko mai yanke tsefe akan injin zare.

Disc milling yankan ake yafi amfani ga milling trapezoidal waje zaren a kan workpieces kamar sukurori da tsutsotsi tsefe-dimbin yankan niƙa da ake amfani da nika ciki da waje gama gari da tapered zaren. Tun lokacin da aka niƙa shi da mai yankan niƙa da yawa kuma tsawon sashin aikin sa ya fi tsayin zaren, aikin aikin kawai yana buƙatar juyawa 1.25 zuwa 1.5 don sarrafa kuma a yi tare da babban yawan aiki. Daidaiton farar niƙa na zaren zai iya kaiwa gabaɗaya maki 8 zuwa 9, kuma ƙarancin saman shine R5 zuwa 0.63 microns. Wannan hanya ya dace da taro-samar Threaded workpieces na general daidaici ko roughing kafin nika.

Zaren niƙa abun yanka don sarrafa zaren ciki

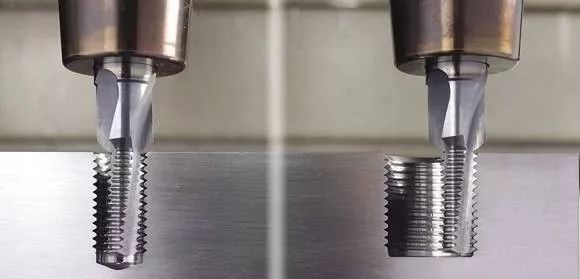

3. Zare nika

Ana amfani da shi musamman don aiwatar da madaidaicin zaren kayan aiki masu tauri akan injunan niƙa zaren. Siffar giciye-sashe na nika dabara za a iya raba biyu iri: guda-line nika dabaran da Multi-line nika dabaran. Daidaiton farar da aka samu ta hanyar niƙa dabaran niƙa mai layi ɗaya shine maki 5 zuwa 6, kuma ƙaƙƙarfan saman shine R1.25 zuwa 0.08 microns, wanda ya fi dacewa don miya ta dabaran. Wannan hanya ta dace da niƙa madaidaicin sukurori, ma'aunin zaren, tsutsotsi, ƙananan batches na kayan aikin da aka yi da zaren, da madaidaicin hobs na niƙa. Multi-line nika dabaran nika ne zuwa kashi a tsaye da kuma plunge nika hanyoyin. A cikin hanyar niƙa mai tsayi, faɗin dabaran niƙa ya fi tsayin zaren da za a niƙa, kuma injin niƙa yana motsawa sau ɗaya ko sau da yawa don niƙa zaren zuwa girman ƙarshe. Nisa daga cikin dabaran nika na hanyar niƙa plunge ya fi tsayin zaren da za a yi ƙasa. The dabaran nika da aka yanke radially a cikin saman workpiece, kuma workpiece iya zama ƙasa da kyau bayan 1.25 juyin juya halin. Yawan aiki yana da girma, amma daidaito ya ɗan ragu kaɗan, kuma miya ta dabaran niƙa ya fi rikitarwa. Nikawar plunge ya dace da niƙa manyan batches na famfo da kuma niƙa takamaiman zaren don ɗaurewa.aluminum extrusion sassa

4. Zare nika

Nau'in goro ko nau'in zare mai nau'in dunƙule an yi shi da abubuwa masu laushi kamar simintin ƙarfe, kuma sassan da zaren yana da kuskuren farar a kan kayan aikin ana jujjuya niƙan juyawa da juyawa don haɓaka daidaiton farar. Tauraren zaren ciki galibi ana ƙasa don kawar da nakasu da haɓaka daidaito.

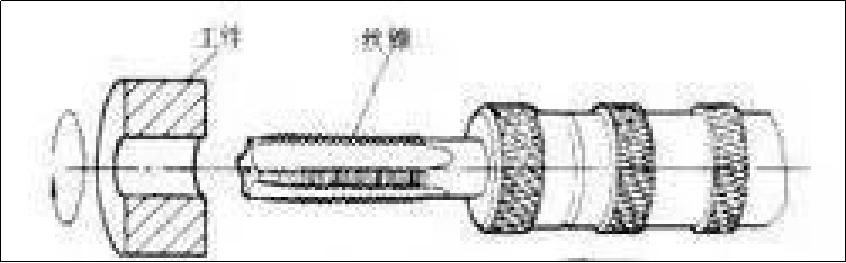

5. Tatsi da zare

Taɓa

Shi ne don murƙushe fam ɗin a cikin ramin ƙasa da aka riga aka hako akan aikin tare da takamaiman juzu'i don aiwatar da zaren ciki.

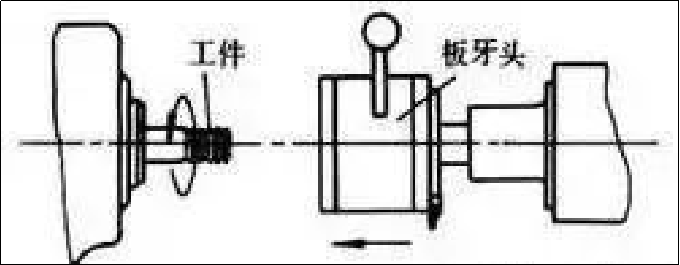

Zare

Yanke zaren waje akan mashaya (ko bututu) workpiece tare da mutu. Daidaiton mashin ɗin bugun ko zaren ya dogara da daidaiton famfo ko mutu.sassan aluminum

Ko da yake akwai hanyoyi da yawa don sarrafa zaren ciki da waje, ƙananan ƙananan zaren ciki za a iya sarrafa su ta hanyar famfo. Ana iya yin taɗawa da zare da hannu, da kuma ta hanyar lathes, injin matsewa, na'urorin buga, da injin zare.

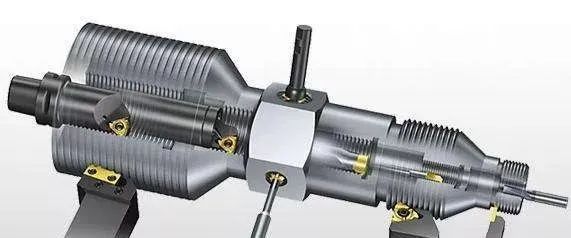

Nau'i na biyu: Zare na'ura

Hanyar sarrafawa na lalata kayan aikin filastik tare da yin birgima mutu don samun zaren. Ana yin jujjuyawar zaren gabaɗaya akan na'ura mai jujjuyawar zaren ko lathe ta atomatik tare da buɗewa ta atomatik da rufe zaren mirgina kai, zaren waje don samar da yawan adadin maɗauran ɗamara, da sauran zaren haɗin gwiwa. Diamita na waje na Zaren da aka yi birgima ba shi da kyau fiye da 25 mm, tsayin bai wuce 100 mm ba, daidaiton zaren zai iya kaiwa matakin 2 (GB197-63), kuma diamita na blank ɗin da aka yi amfani da shi kusan daidai yake da diamita na farar. na Zaren da aka sarrafa. RThread gabaɗaya ba zai iya aiwatar da zaren ciki ba, amma don kayan aiki tare da kayan laushi, ana iya amfani da fam ɗin extrusion mara ƙarfi don fitar da zaren ciki mai sanyi (matsakaicin diamita na iya kaiwa kusan mm 30). Ka'idar aiki tana kama da na bugawa. Ƙunƙarar da ake buƙata don extrusion sanyi na zaren ciki shine kusan sau 1 ya fi girma fiye da tapping, kuma daidaiton machining da ingancin saman ya dan kadan sama da na tapping.

Abvantbuwan amfãni na zaren mirgina:

①Raunin ƙasa ya fi na juyawa, niƙa, da niƙa;

② Fuskar Zaren Zare na iya inganta ƙarfi da ƙarfi saboda aikin sanyi;

③ Yawan amfani da kayan yana da yawa;

④ Yawan aiki yana ninka sau biyu idan aka kwatanta da yankan, kuma yana da sauƙin gane aiki da kai;

⑤ Rayuwar mirgina tana da tsayi sosai. Koyaya, mirgina Zaren Sake karantawa cewa taurin kayan aikin bai wuce HRC40 ba; daidaiton ma'auni na blank yana da girma; daidaici da kauri na birgima suma suna da yawa, kuma yana da wahala a kera mutu; bai dace da zaren mirgina tare da siffar haƙori asymmetric ba.

Dangane da nau'in mirgina daban-daban, Za a iya raba zaren zuwa nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan za a iya kasu kashi biyu.

6. Zaren mirgina

An shirya faranti biyu masu jujjuya zare tare da sifofin haƙora masu zare da juna tare da farar 1/2; A tsaye farantin yana daidaitawa, kuma farantin motsi yana motsawa a cikin motsi na madaidaiciya mai maimaita daidai da farantin. Lokacin da aka aika da aikin tsakanin faranti biyu, farantin motsi yana motsawa gaba kuma yana goge aikin don lalata saman don samar da zaren (Hoto 6 [Screwing]).

7. Zaren mirgina

Akwai nau'ikan radial Thread roThread iri uku, tangential Thread roThread, da mirgina zaren kai.

①Radial Threathreadad 2 (ko 3) zaren mirgina ƙafafun tare da bayanan bayanan zaren an sanya su akan ramukan layi ɗaya; Ana sanya kayan aikin a kan goyon baya tsakanin ƙafafun biyu, kuma ƙafafun biyu suna juyawa a cikin wannan shugabanci da kuma gudu guda (Figure 7). [Radial Thread rolling]), ɗayan zagayen, kuma yana yin motsin ciyarwar radial. The thread mirgina dabaran yana juya workpiece, da kuma surface ne radially extruded don samar da zaren. Ga wasu skru na gubar waɗanda basa buƙatar daidaitattun daidaito, ana kuma iya amfani da irin wannan hanyar don yin nadi.

②Tangential Thread roThread Wanda kuma aka sani da planetary Thread roThread, kayan aikin birgima ya ƙunshi madaidaicin zaren birgima mai jujjuyawa da faranti guda uku kafaffen zaren zaren (Fig. 8 [Tangential Thread rolling]). Ana iya ci gaba da ciyar da aikin aikin yayin zaren zaren, don haka yawan aiki ya fi na Zaren roThreadand radial Thread thread.

③ Rethreaded: Ana yin shi akan lathe ta atomatik kuma ana amfani dashi gabaɗaya don aiwatar da gajerun zaren akan kayan aikin. Akwai 3 zuwa 4 zaren mirgina ƙafafun a ko'ina a kan m gefe na workpiece a cikin mirgina kai (Fig. 9 [Thread rethreaded mirgina]). A lokacin zaren mirgina, aikin aikin yana jujjuya, kuma mirgina kai yana ciyar da axially don mirgine aikin daga cikin Zaren.

Zaren zaren

Gudanar da zaren yau da kullun yana amfani da cibiyoyin injina ko kayan aiki da kayan aiki; wani lokaci, ana kuma iya taɓa hannu. Duk da haka, a wasu lokuta na musamman, hanyar da ke sama ba ta da sauƙi don samun sakamako mai kyau, kamar buƙatar inji zaren bayan maganin zafi na sassa saboda sakaci ko saboda matsalolin kayan aiki, kamar buƙatar matsawa kai tsaye a kan kayan aikin carbide. . A wannan lokacin, wajibi ne a yi la'akari da hanyar sarrafa pEDM.

Idan aka kwatanta da hanyar mashin, tsarin EDM yana cikin tsari guda ɗaya: rami na ƙasa yana buƙatar farawa da farko, kuma diamita na ramin ƙasa ya kamata a ƙayyade bisa ga yanayin aiki. Ana buƙatar na'urar lantarki zuwa siffar zaren, kuma wutar lantarki tana buƙatar iya jujjuya yayin aikin injin.

Anebon Metal Products Limited na iya samar da CNC Machining, Die Casting, Sheet Metal Fabrication sabis, da fatan za a iya tuntuɓar mu.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Lokacin aikawa: Afrilu-15-2022