Drilling, ja, reaming, m... Me suke nufi? Wadannan zasu koya muku sauƙin fahimtar bambanci tsakanin waɗannan ra'ayoyin.

Idan aka kwatanta da sarrafa saman waje, yanayin sarrafa ramuka ya fi muni, kuma yana da wahala a sarrafa ramuka fiye da sarrafa da'irar waje. Wannan saboda:

1) Girman kayan aikin da aka yi amfani da shi don gyaran ramuka yana iyakance da girman ramin da za a yi amfani da shi, kuma rashin ƙarfi ba shi da kyau, wanda ke da wuyar lanƙwasa nakasawa da girgiza;

2) Lokacin da ake yin rami tare da agyarawa-size kayan aiki, Girman ramin sau da yawa yana ƙayyade kai tsaye ta hanyar daidaitattun kayan aiki, kuma kuskuren masana'anta da lalacewa na kayan aiki zai shafi daidaitattun mashin din ramin;

3) Lokacin da machining ramukan, da yankan yanki ne a cikin workpiece, guntu kau da zafi dissipation yanayi ne matalauta, da machining daidaito da kuma surface ingancin ba sauki don sarrafa.

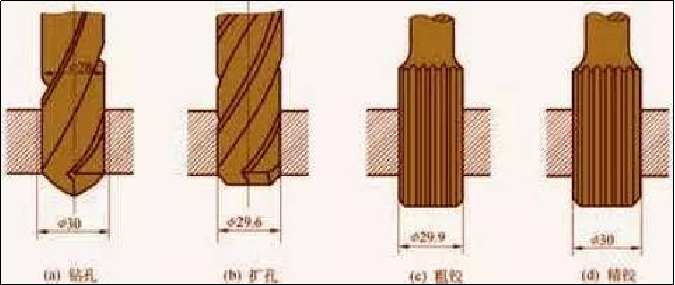

1. Hakowa da reaming

1. Hakowa

Hakowa shine tsarin farko na kera ramuka a cikin daskararrun kayan, kuma diamita na ramukan gaba daya bai wuce 80mm ba. Akwai hanyoyi guda biyu na hakowa: daya ita ce jujjuyawar aikin; ɗayan shine jujjuyawar kayan aikin. Kurakurai da hanyoyin hakowa biyu na sama suka haifar sun bambanta. A cikin hanyar hakowa tare da juzu'i mai jujjuyawa, lokacin da ƙwanƙwasa ya karkata saboda asymmetry na yankan gefen da rashin isasshen tsattsauran ramin, za a karkatar da layin tsakiyar rami na inji. Ba madaidaiciya ba ne, amma diamita na ramin ba ya canzawa; akasin haka, a cikin hanyar hakowa wanda ke jujjuya aikin aikin, ɓacin ɓacin rai zai haifar da diamita na rami don canzawa, yayin da rami na tsakiya ya kasance madaidaiciya.

Kayan aikin hakowa da aka saba amfani da su sun haɗa da: ƙwanƙwasa ƙwanƙwasa, ƙwallon tsakiya, rami mai zurfi, da sauransu.

Saboda ƙayyadaddun tsari, ƙaddamarwar lanƙwasa da ƙaƙƙarfan torsional na rawar sojan duka suna da ƙasa, haɗe tare da tsaka-tsaki mara kyau, daidaiton hakowa yana da ƙasa, gabaɗaya kawai kai IT13 ~ IT11; roughness na saman kuma babba ne, kuma Ra shine gabaɗaya 50 ~ 12.5μm; amma adadin cire ƙarfe na hakowa yana da girma, kuma aikin yankan yana da yawa. Ana amfani da hakowa galibi don aiwatar da ramuka tare da ƙananan buƙatun buƙatun, kamar ramuka na kulle, ramukan ƙasa, ramukan mai, da sauransu. machining na gaba. 2. Ragewa

Reaming shine ci gaba da sarrafa ramukan da aka tono, jefa ko kuma ƙirƙira tare da reaming rawar soja don faɗaɗa buɗewa da haɓaka ingancin sarrafa ramukan.Ƙarshe machiningna ramuka masu ƙarancin buƙata. Ƙwaƙwalwar motsa jiki yana kama da rawar motsa jiki, amma tare da ƙarin hakora kuma babu gefuna.

Idan aka kwatanta da hakowa, reaming yana da halaye masu zuwa: (1) yawan hakora na reaming yana da girma (3 ~ 8 hakora), jagora yana da kyau, kuma yanke yana da inganci; (2) reaming rawar soja ba shi da guntu, kuma yanke yanayin yana da kyau; (3) Izinin injin ɗin ƙananan ne, aljihun guntu za a iya yin ƙasa mai zurfi, za a iya yin kauri mai ƙarfi, kuma ƙarfi da tsaurin jikin mai yankan ya fi kyau. Madaidaicin ramin ramuka gabaɗaya IT11 ~ IT10, kuma ƙarancin saman Ra shine 12.5 ~ 6.3μm. Ana amfani da reaming sau da yawa don injin ramuka tare da diamita ƙasa da . Lokacin hako rami mai girman diamita (D ≥ 30mm), ana amfani da ƙaramin rami (diamita shine sau 0.5 ~ 0.7 diamita na ramin) sau da yawa don fara haƙo ramin, sa'an nan kuma girman daidai girman ramin ramin. ana amfani da shi don ream ramin, wanda zai iya inganta ingancin ramin. Gudanar da inganci da ingancin samarwa.

Baya ga sarrafa ramukan cylindrical, reaming kuma na iya amfani da wasu nau'ikan reaming na musamman (wanda kuma aka sani da countersinks) don sarrafa ramukan kujeru daban-daban da kiftawa. Ƙarshen gaba na countersink sau da yawa yana da ginshiƙan jagora, wanda ke jagorantar rami mai injin.

2. Ragewa

Reaming yana daya daga cikin hanyoyin gamawa na ramuka, wanda ake amfani dashi sosai wajen samarwa. Don ƙananan ramuka, reaming hanya ce ta tattalin arziki da aiki fiye da niƙa na ciki da kuma m.

1. Ma'aurata

Gabaɗaya an kasu masu reamers zuwa nau'i biyu: reamers na hannu da na'urar reamers. Hannun reamer na hannun hannu shine madaidaiciya madaidaiciya, sashin aiki ya fi tsayi, kuma aikin jagora ya fi kyau. The hand reamer yana da nau'i biyu na haɗin kai da diamita mai daidaitacce. Akwai nau'ikan injin reamers iri biyu, nau'in shank da nau'in hannun riga. Reamers ba za su iya aiwatar da ramukan madauwari kawai ba, har ma ana iya sarrafa ramukan tafe tare da taper reamers. 2. Reaming tsari da aikace-aikace

Izinin reaming yana da babban tasiri akan ingancin reaming. Idan izinin ya yi girma da yawa, nauyin reamer zai zama babba, ƙwanƙwasa za ta yi sauri da sauri, ba shi da sauƙi don samun kayan aiki mai laushi, kuma juriya mai girma ba shi da sauƙi don tabbatarwa; idan alawus ɗin ya yi ƙanƙanta, Idan alamun kayan aikin da aka bari ta hanyar da ta gabata ba za a iya cire su ba, a zahiri ba za ta inganta ingancin sarrafa rami ba. Gabaɗaya, ƙyalli mai ƙaƙƙarfan ƙyalli shine 0.35 ~ 0.15mm, kuma madaidaicin hinge shine 01.5 ~ 0.05mm.

Don guje wa samuwar ginin gefe, ana yin reaming yawanci a ƙananan saurin yankan (v <8m/min don manyan maƙallan ƙarfe na ƙarfe da baƙin ƙarfe). Darajar ciyarwar tana da alaƙa da buɗewar da za a sarrafa. Mafi girman budewar, mafi girman darajar ciyarwar. Lokacin da babban-gudun karfe reamer tafiyar da karfe da jefa baƙin ƙarfe, ciyarwa yawanci 0.3 ~ 1mm/r.

Lokacin da ake reaming ramukan, dole ne a sanyaya, mai da kuma tsaftace shi tare da yankan ruwan da ya dace don hana ginannun gefen da cire guntu cikin lokaci. Idan aka kwatanta da niƙa da m, reaming yana da babban yawan aiki kuma yana da sauƙi don tabbatar da daidaito na rami; duk da haka, reaming ba zai iya gyara kuskuren matsayi na ramin rami ba, kuma daidaitaccen matsayi na rami ya kamata a tabbatar da shi ta hanyar da ta gabata. Reaming bai kamata ya sarrafa ramukan tako da ramukan makafi ba.

Matsakaicin girman ramin reaming gabaɗaya IT9 ~ IT7 ne, kuma ƙarancin saman Ra shine gabaɗaya 3.2 ~ 0.8 μm. Don matsakaitan ramuka tare da madaidaicin buƙatun (kamar daidaitattun ramukan IT7), tsarin haɓaka-faɗaɗɗen ramuka shine tsarin sarrafawa na yau da kullun da ake amfani da shi wajen samarwa.

3. Ban sha'awa

M hanya ce ta sarrafawa wacce ke amfani da kayan aikin yanke don faɗaɗa ramukan da aka riga aka kera. Ana iya aiwatar da aikin ban sha'awa akan na'ura mai ban sha'awa ko lathe.

1. Hanyar ban sha'awa

Akwai hanyoyi daban-daban na machining guda uku don m.

(1) The workpiece juya da kayan aiki ciyarwa. Mafi yawan m a kan lathe nasa ne ga wannan m hanya. The tsari fasali su ne: axis line na rami bayan machining ne m tare da juyawa axis na workpiece, da roundness na rami yafi dogara a kan juyi daidaito na inji kayan aiki spindle, da kuma axial lissafi kuskure na rami yafi dogara. a kan ciyarwar shugabanci na kayan aiki dangi da juyawa axis na workpiece. daidaiton matsayi. Wannan hanya mai ban sha'awa ta dace don sarrafa ramukan da ke da buƙatun coaxial tare da farfajiyar waje.

(2) Kayan aiki yana juyawa kuma kayan aikin yana yin motsin ciyarwa. Ƙarƙashin na'ura mai ban sha'awa yana motsa kayan aiki mai ban sha'awa don juyawa, kuma kayan aiki yana motsa kayan aiki don yin motsin ciyarwa.

(3) Lokacin da kayan aiki ya juya kuma yayi motsin ciyarwa, ana amfani da hanyar mai ban sha'awa don m. An canza tsayin tsayin sandar mai ban sha'awa, kuma ana canza nakasar ƙarfi na mashaya mai ban sha'awa. Diamita na ramin karami ne, yana samar da rami mai matsewa. Bugu da kari, da overhang tsawo na m mashaya yana ƙaruwa, da lankwasawa nakasawa na babban shaft saboda nasa nauyi shi ma yana ƙaruwa, kuma za a lankwasa axis na machined rami daidai. Wannan hanya mai ban sha'awa kawai ta dace da gajeren ramuka.

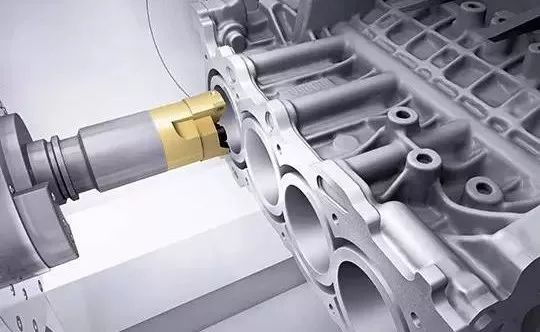

2. Diamond m

Idan aka kwatanta da talakawa m, lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u luku, nahan a sôn sôn sôn, da ɗo sləmawa. Yana iya samun daidaitaccen machining (IT7 ~ IT6) kuma yana da santsi sosai (Ra shine 0.4 ~ 0.05 μm). Tun da farko ana sarrafa shi da kayan aikin lu'u-lu'u masu ban sha'awa, kuma a yanzu ana sarrafa shi da siminti carbide, CBN da kayan aikin lu'u-lu'u na roba. An fi amfani dashi don sarrafa kayan aikin ƙarfe mara ƙarfe, amma kuma don sarrafa simintin ƙarfe da ƙarfe.

Yawan yankan da aka saba amfani da shi don ƙarancin lu'u-lu'u sune: adadin da aka yanke baya na pre-m shine 0.2 ~ 0.6mm, kuma ƙarancin ƙarshe shine 0.1mm; Yawan ciyarwa shine 0.01 ~ 0.14mm / r; da yankan gudun ne 100 ~ 250m / min a lokacin da machining jefa baƙin ƙarfe, da kuma machining 150 ~ 300m / min ga karfe, 300 ~ 2000m / min don sarrafa wadanda ba ferrous karafa.

Domin tabbatar da cewa lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu'u lu re. Babban mashin kayan aikin injin yawanci ana goyan bayan madaidaicin madaidaicin lamba ball bearings ko na zamewar hydrostatic, da sassa masu juyawa masu sauri. Dole ne ya zama daidai daidai; Bugu da ƙari, motsi na hanyar ciyarwa dole ne ya kasance mai ƙarfi sosai don tabbatar da cewa tebur na aiki zai iya yin motsin ciyarwa da sauri da sauri.

Diamond m yana da kyau sarrafa ingancin da high samar yadda ya dace, kuma ana amfani da ko'ina a karshe aiki na daidaici ramukan a taro samar, kamar engine Silinda ramukan, piston fil ramukan, da kuma sandal ramukan a kan inji kayan aiki spindle kwalaye. Duk da haka, ya kamata a lura cewa yayin amfani da lu'u-lu'u mai ban sha'awa don sarrafa kayan ƙarfe na ƙarfe, kayan aikin da aka yi da siminti na siminti da CBN kawai za a iya amfani da su, kuma ba za a iya amfani da kayan aiki masu ban sha'awa da aka yi da lu'u-lu'u ba, saboda carbon atom a cikin lu'u-lu'u yana da dangantaka mai yawa. tare da abubuwan rukuni na ƙarfe. , rayuwar kayan aiki yana da ƙasa.

3. M kayan aiki

Za a iya raba kayan aiki masu ban sha'awa zuwa kayan aiki masu ban sha'awa guda ɗaya da kayan aiki masu ban sha'awa biyu.

4. Halayen fasaha da kewayon aikace-aikacen m

Idan aka kwatanta da tsarin hakowa-fadada-reaming, diamita na ramin ba'a iyakance shi da girman kayan aiki ba, kuma m yana da ƙarfin gyara kuskuren kuskure. Filaye masu ban sha'awa da matsayi suna kula da daidaitattun matsayi.

Idan aka kwatanta da m da'irar na m rami, saboda matalauta rigidity da kuma babban nakasawa na kayan aiki mariƙin tsarin, da zafi watsawa da guntu kau yanayi ba su da kyau, da thermal nakasawa na workpiece da kayan aiki ne in mun gwada da manyan. A machining ingancin da kuma samar da inganci na m rami ba kamar yadda high kamar yadda m da'irar mota. .

Dangane da binciken da aka yi a sama, ana iya ganin cewa m yana da kewayon sarrafawa mai faɗi, kuma yana iya aiwatar da ramuka masu girma dabam da matakan daidaito daban-daban. Don ramuka da tsarin ramuka tare da manyan diamita da girman girma da buƙatun daidaito na matsayi, m shine kusan kawai sarrafawa. hanya. Daidaiton machining na m shine IT9 ~ IT7. Ana iya aiwatar da gundura akan kayan aikin injin kamar injunan ban gajiya, lathes, da injunan niƙa. Yana da abũbuwan amfãni na sassauƙa kuma ana amfani dashi sosai wajen samarwa. A cikin samar da taro, don inganta ingantaccen aiki, ana amfani da mutuwar m.

4. honing ramuka

1. Honing ka'ida da honing shugaban

Honing wata hanya ce ta gama rami tare da honing kai tare da sandar niƙa (whitstone). A lokacin honing, da workpiece yana gyarawa, kuma honing kai ne kora da sandar na'ura don jujjuya da kuma yin reciprocating mikakke motsi. A cikin aikin honing, sandar niƙa tana aiki a saman kayan aikin tare da wani matsi, kuma yana yanke wani abu mai bakin ciki sosai daga saman kayan aikin, kuma yanayin yanke shi ne raƙuman ƙetare. Domin a sa yanayin motsi na ɓangarorin ɓangarorin yashi ba maimaituwa ba, jujjuyawar juyi a minti ɗaya na motsin shugaban honing da adadin bugun bugun jini a cikin minti na honing ya kamata su zama manyan lambobi na juna.

Matsakaicin kusurwar waƙar honing yana da alaƙa da saurin maimaituwa da saurin gefen kan honing. Girman kusurwa yana rinjayar ingancin aiki da ingancin honing. Gabaɗaya, ana ɗaukar shi azaman ° don ƙaƙƙarfan honing da kuma kyakkyawan honing. Domin sauƙaƙe fitar da ɓarna na ɓarna da kwakwalwan kwamfuta, rage yawan zafin jiki da haɓaka ingancin sarrafawa, yakamata a yi amfani da isasshen ruwan yankan yayin honing.

Domin yin bangon ramin da za a sarrafa shi daidai, bugun yashi ya kamata ya wuce adadin da ya wuce gona da iri a ƙarshen ramin. Domin tabbatar da ba da izinin honing iri ɗaya da rage tasirin kuskuren jujjuya kayan aikin inji akan daidaiton mashin ɗin, yawancin shuwagabannin honing da igiya na na'ura suna haɗe ta hanyar iyo.

Ƙwararren radial da daidaitawar ƙwanƙwasa na honing head nika mashaya yana da nau'i daban-daban na tsari irin su manual, pneumatic da na'ura mai aiki da karfin ruwa.

2. Halayen tsari da kewayon aikace-aikacen honing

1) Honing na iya samun daidaito mai girma da daidaiton siffar. Daidaitaccen mashin ɗin shine IT7 ~ IT6, kuma ana iya sarrafa zagaye da kurakuran cylindricity na ramuka a cikin kewayon , amma honing ba zai iya inganta daidaiton matsayi na ramukan injina ba.

2) Honing iya samun high surface quality, da surface roughness Ra ne 0.2 ~ 0.25μm, da kuma zurfin metamorphic lahani Layer na surface karfe ne musamman kananan 2.5 ~ 25μm.

3) Idan aka kwatanta da saurin niƙa, kodayake saurin juzu'i na shugaban honing bai yi girma ba (vc = 16 ~ 60m / min), amma saboda babban yanki na lamba tsakanin sandar yashi da aikin aiki, saurin maimaituwa yana da inganci. (va=8~20m/min). min), don haka honing har yanzu yana da babban aiki.

Ana amfani da honing sosai a cikin injin injin silinda ramukan da madaidaicin ramukan a cikin na'urorin hydraulic daban-daban a cikin samarwa da yawa. Koyaya, honing bai dace da sarrafa ramuka akan kayan aikin ƙarfe mara ƙarfe ba tare da babban filastik, kuma ba zai iya sarrafa ramuka tare da maɓalli ba, ramukan spline, da sauransu.

5. Ja rami

1. Batsa da batsa

Hole broaching hanya ce ta gamawa mai matuƙar amfani da ake yi akan na'ura mai ɗaukar hoto tare da tambari na musamman. Akwai nau'ikan gado guda biyu: gadon lallashi a kwance da gadon lallashi a tsaye, tare da gadon lallashi wanda ya fi yawa.

Lokacin ba da labari, ƙaho yana yin motsin layi marar sauri (babban motsi). Yawan hakora na broach da ke aiki a lokaci guda ya kamata ya zama ƙasa da 3, in ba haka ba broach ba zai yi aiki da kyau ba, kuma yana da sauƙi don samar da ripples na annular a saman kayan aikin. Don hana ɓarna daga karyewa saboda tsananin ƙarfi da ƙarfi, lokacin da broach ɗin ke aiki, adadin haƙoran aiki bai kamata ya wuce 6 zuwa 8 ba.

Akwai hanyoyi guda uku daban-daban na batsa na batsa, waɗanda aka siffanta su kamar haka:

1) Siffar tatsuniyoyi Siffar wannan hanyar yin ba da labari ita ce, ƙasidar tana yanke alawus ɗin alawus ɗin kayan aikin kayan aiki ta layi a jere. Domin sauƙaƙa watsewar guntu, haƙoran masu yankan suna ƙasa tare da tsagi na rabuwa guntu. Kasuwar da aka ƙera bisa ga hanyar da aka ɗora shi ana kiranta broach na yau da kullun.

2) Toshe broaching Siffar wannan hanyar ba da labari ita ce, kowane Layer na ƙarfe a saman injin ɗin ya ƙunshi rukuni na hakora masu girman gaske amma haƙoran haƙora (yawanci kowane rukuni ya ƙunshi hakora 2-3) an cire su. Kowane haƙori yana yanke wani yanki ne na ƙarfe kawai. Kasidar da aka ƙera bisa ga hanyar toshewa ana kiranta ƙaho mai yankan ƙafafu.

3) Cikakken bayani Wannan hanyar tana mai da hankali kan fa'idodin leƙen asiri da rabe-rabe. Bangaren haƙori yana ɗaukar ɓoyayyen ɓoyayyen ɓoyayyen ɓoyayyiyar haƙori, kuma ɓangaren haƙori yana ɗaukar lallausan tsintsaye. Ta wannan hanyar, ana iya rage tsawon broach ɗin, ana iya haɓaka yawan aiki, kuma ana iya samun ingantaccen ingancin ƙasa. Kasidar da aka ƙera bisa ga ƙayyadaddun hanyoyin watsa labarai ana kiranta da m broach.

2. Halayen tsari da kewayon aikace-aikace na jan rami

1) The broach ne Multi-blade kayan aiki, wanda zai iya sequentially kammala roughing, karewa da kuma gama da rami a daya broaching bugun jini, tare da high samar da inganci.

2) Daidaiton labaran ya dogara ne akan daidaiton labaran. A karkashin yanayi na al'ada, daidaitattun buƙatun na iya isa IT9 ~ IT7, kuma ƙarancin ƙasa Ra na iya kaiwa 6.3 ~ 1.6 μm.

3) Lokacin ja da rami, da workpiece ne a matsayi ta machined rami da kanta (jagorancin na broach ne matsayi kashi na workpiece), kuma ba shi da sauki don tabbatar da daidaito matsayi na ramin da sauran saman; A cikin sarrafa sassan jiki, sau da yawa ana zana ramuka da farko, sa'an nan kuma ana sarrafa sauran saman ta hanyar amfani da ramukan azaman matsayi. 4) Broach ba zai iya aiwatar da ramukan zagaye kawai ba, har ma ya samar da ramuka da ramukan spline.

5) Broach shine kayan aiki mai mahimmanci tare da siffa mai mahimmanci da farashi mai girma, wanda bai dace da machining manyan ramuka ba.

Ana amfani da ramukan ja da yawa a cikin samar da yawa don aiwatarwa ta hanyar ramuka akan ƙananan ƙananan sassa masu girma tare da diamita na Ф10 ~ 80mm da zurfin rami wanda bai wuce 5 sau diamita na rami ba.

Lokacin aikawa: Agusta-29-2022