1. Yi amfani da wayo da ɗanɗano abinci kuma kuyi amfani da ayyukan trigonometric da wayo

Sami ƙananan abinci tare da basira kuma amfani da ayyukan trigonometric yadda ya kamata. A yayin aiwatar da juyawa, kayan aiki tare da da'irori na ciki da na waje waɗanda ke buƙatar babban daidaito ana sarrafa su akai-akai. Kalubale kamar yanke zafi, gogayya da ke haifar da lalacewa na kayan aiki, da maimaita daidaitaccen mai riƙe kayan aikin murabba'in yana da wahala a tabbatar da inganci.

Don magance madaidaicin zurfin ƙarar ci, muna daidaita ma'aunin kayan aiki mai tsayi a kusurwa dangane da alaƙar da ke tsakanin ɓangarorin da ke gaba da ma'aunin alwatika, yana ba da damar ingantaccen zurfin juzu'i yayin aikin juyawa. Wannan tsarin yana nufin adana lokaci da aiki, kula da ingancin samfur, da haɓaka ingantaccen aiki.

Madaidaicin ƙimar ma'auni na kayan aikin lathe C620 shine 0.05mm kowace rarrabuwa. Don cimma zurfin zurfin 0.005mm, yin la'akari da teburin aikin sine trigonometric: sinα=0.005/0.05=0.1 α=5º44′Saboda haka, daidaita mariƙin kayan aiki zuwa 5º44′ yana ba da damar kayan aikin juyawa don cimma ƙaramin zurfin 0.005mm a cikin juzu'i mai jujjuyawa tare da kowane motsi na firam mai tsayi.

2. Abubuwa uku na fasahar tuƙi baya

Ƙwarewar samarwa mai yawa ya nuna cewa yin amfani da fasahar yanke juzu'i a wasu hanyoyin juyawa na iya haifar da sakamako mai kyau. Misalai na yanzu sun haɗa da:

(1) Martensitic bakin karfe sassa ana amfani a matsayin abu domin baya yankan zaren.

Lokacin aiki akan kayan aikin da aka zana tare da filaye na 1.25 da 1.75mm, ya zama ruwan dare don haɗu da batutuwan da suka danganci ja da baya da kayan aiki. Lathes na yau da kullun galibi suna rasa keɓaɓɓen na'urar buckling faifai, yana buƙatar mafita na al'ada mai cin lokaci. Sakamakon haka, zaren sarrafawa tare da waɗannan takamaiman filaye na iya zama mai ɗaukar lokaci kuma ƙananan saurin juyawa na iya zama hanya ɗaya tilo.

Duk da haka, yankan a ƙananan gudu zai iya haifar da cizon kayan aiki da rashin ƙarfi na ƙasa, musamman ma lokacin da ake hulɗa da kayan bakin karfe na martensitic kamar 1Crl3 da 2 Crl3. Don magance waɗannan ƙalubalen, an ƙaddamar da hanyar yankan "uku" a cikin aikin machining.

Wannan tsarin, wanda ya haɗa da lodin kayan aiki na baya, yanke juzu'i, da madaidaicin hanyoyin yanke, ya tabbatar da cewa yana da tasiri wajen cimma yanke zare mai sauri tare da ja da baya mai santsi. Wannan hanyar tana da fa'ida musamman yayin da take ba da izinin yankewa mai inganci kuma tana guje wa yuwuwar al'amurran gnawing kayan aiki da ke da alaƙa da jujjuyawar saurin gudu.

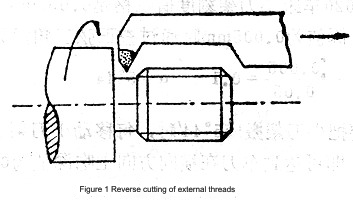

Lokacin da waje na mota, niƙa mai kama da wukar motar zaren ciki (Hoto 1);

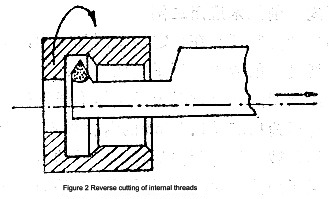

Lokacin da aka niƙa zaren ciki na motar, wuka mai zare na baya (Hoto 2).

Kafin fara aikin, daidaita faifan juzu'i mai jujjuya juzu'i don tabbatar da saurin jujjuyawa yayin fara jujjuyawar. Na gaba, matsayi da amintaccen abin yankan zaren, fara jujjuyawar gaba a ɗan ƙaramin gudu, kuma matsa zuwa madaidaicin kayan aiki mara kyau. Sa'an nan, ci gaba da saka zaren juya kayan aiki zuwa dace zurfin yankan kafin canjawa zuwa baya juyi. A wannan lokaci, kayan aikin juyawa ya kamata ya juya daga hagu zuwa dama a babban gudu. Bayan da yawa cuts bin wannan hanya, yana yiwuwa a cimma wani zare tare da kyau kwarai surface roughness da high daidaito.

(2) Furen nadi na mota

Lokacin amfani da mirgina na gargajiya, ya zama ruwan dare ga barbashi na ƙarfe da tarkace don shigar da kayan aiki da yankan kayan aiki. Yin amfani da sabuwar dabarar aiki tare da sandar lathe na iya magance matsalolin da aka fuskanta yayin aiki na gargajiya da kuma haifar da kyakkyawan sakamako gaba ɗaya.

(3) Juya juyewar zaren bututun ciki da waje

A lokacin da aiki a kan ciki da kuma na waje tapered bututu zaren tare da low daidaici bukatun da kuma a cikin kananan batches, za ka iya kai tsaye amfani da sabuwar hanyar da baya yankan da baya kayan aiki shigarwa ba tare da bukatar samfur na'urar, rike ci gaba da yankan matakai.

Ingancin wuka na gefe na hannun hannu, wanda ke sharewa daga hagu zuwa dama lokacin juya zaren bututun taper na waje, ya ta'allaka ne a cikin ikonsa na sarrafa zurfin wukar yankan yadda ya kamata daga diamita mafi girma zuwa ƙaramin diamita saboda matsa lamba a lokacin. tsarin yankan. Aiwatar da wannan sabuwar fasahar aiki ta baya a cikin juyawa tana ci gaba da girma kuma ana iya daidaita ta da sassauƙa zuwa takamaiman yanayi daban-daban.

3. Sabon aiki da kayan aikin kayan aiki na hako ƙananan ramuka

A yayin aikin juyawa, lokacin hako ramukan ƙasa da 0.6mm, ƙayyadaddun diamita da ƙaƙƙarfan ƙaƙƙarfan rawar sojan sun hana haɓaka saurin yankewa. The workpiece abu, zafi-resistant gami da bakin karfe, nuna high yankan juriya. A sakamakon haka, yin amfani da hanyar ciyar da na'ura mai watsawa yayin hakowa zai iya karya maɗaurin cikin sauƙi. Magani mai sauƙi kuma mai inganci shine yin amfani da hanyar ciyar da hannu da kayan aiki na musamman.

Matakin farko ya ƙunshi gyaggyara ƙugiyar rawar soja ta asali zuwa nau'in iyo madaidaiciya-shank. Ta hanyar maƙale ƙaramin ɗan rawar sojan kan ƙugiya mai iyo, ana samun hakowa mai santsi. Bangaren baya na rawar rawar soja ya haɗa da madaidaiciyar hannu da madaidaicin zamewa, yana ba da damar motsi kyauta a cikin abin jan. A halin yanzu, lokacin hako ƙaramin rami, ƙaramin ciyarwar hannu mai laushi tare da ƙwanƙwasa ƙwanƙwasa na hannu yana sauƙaƙe hakowa cikin sauri, kiyaye inganci da tsawaita rayuwar sabis na ƙananan ramuka.

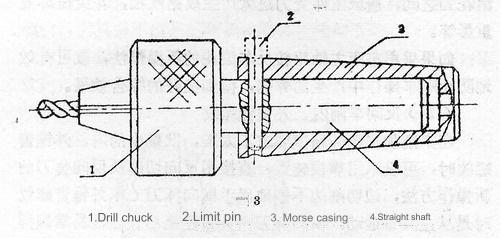

Bugu da ƙari, za a iya amfani da gyare-gyaren maƙasudin maƙasudi da yawa don ƙaramin diamita na zaren ciki, reaming, da makamantan ayyuka. Don manyan ramuka, ana ba da shawarar saka fil mai iyaka tsakanin hannun riga da hannun madaidaiciya. Koma Hoto na 3 don cikakkun bayanai na gani.

4. Shockproof don aikin rami mai zurfi

A lokacin sarrafa rami mai zurfi, haɗuwa da ƙananan diamita na rami da siririn kayan aiki mai ban sha'awa na iya haifar da girgizar da babu makawa lokacin juya sassa tare da diamita na rami daga Φ30 zuwa Φ50mm da zurfin kusan 1000mm. Don rage girgizawa da kuma tabbatar da sarrafa rami mai zurfi mai inganci, madaidaiciyar hanya madaidaiciya kuma mai inganci ta haɗa da haɗa tallafi guda biyu, waɗanda aka gina daga kayan kamar zane da bakelite, zuwa jikin sanda.

Waɗannan goyan bayan ya kamata su dace da girman diamita daidai daidai. Ta hanyar yin amfani da shingen bakelite sandwiched tare da zane a matsayin tallafi na matsayi yayin aiwatar da yanke, kayan aiki yana daidaitawa, yana rage yiwuwar girgizawa da kuma ba da damar samar da sassan rami mai zurfi mai inganci.

5. Rigakafin karyewar ƙananan ayyukan cibiya

A cikin aiwatar da juyawa, hako rami na tsakiya ƙasa da Φ1.5mm yana haifar da babban haɗari na karya rawar tsakiya. Hanya mai mahimmanci don hana karyewa ita ce guje wa kulle tarkacen wutsiya yayin hako rami na tsakiya. Wannan yana ba da damar mataccen nauyin kifin wutsiya da ƙarfin juzu'i da ke tsakaninsa da gadon kayan aikin injin don amfani da shi don hakowa. A cikin yanayin da yanke juriya ya wuce kima, dokin wutsiya zai ja da baya kai tsaye, ta haka zai kare rawar tsakiya.

6. Wahalar sarrafa kayan aikace-aikacen

Lokacin da muke da wahalar sarrafa kayan kamar high-zazzabi gami da quenching karfe, da surface roughness na workpiece ake bukata ya kasance a cikin RA0.20 zuwa 0.05 μm, kuma girman daidaito ne kuma high. A ƙarshe, ana yin aiki mai kyau akan gadon niƙa.

7. Saurin lodawa da sauke sandal

Yayin tafiyar matakai, mukan ci karo da nau'ikan kayan ɗaukar kaya da ke nuna da'irar da'irar waje da jujjuyawar kusurwoyin madaidaicin jagora. Saboda girman girman su, suna buƙatar lodawa da saukewa a duk lokacin sarrafawa. Lokacin da ake buƙata don canjin kayan aiki ya fi tsayi fiye da ainihin lokacin yankewa, yana haifar da rage yawan samar da kayan aiki.

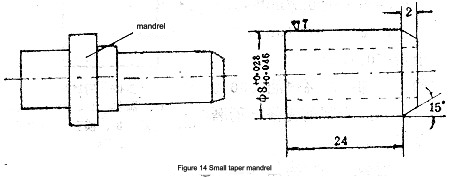

Saurin saukewa da saukewar mandrel, tare da kayan aiki mai juyayi mai yawa (tungsten carbide) da aka kwatanta a kasa, na iya rage lokacin taimako kuma tabbatar da ingancin samfurori yayin sarrafa sassa daban-daban na hannun hannu. Hanyar samar da ita ita ce kamar haka: Don ƙirƙirar ɗan ƙaramin ƙaramin ɗaki mai sauƙi, ana amfani da ɗan ƙaramin 0.02mm a baya.

Da zarar an shigar da igiya, sassan suna amintar da su a kan mandrel ta hanyar juzu'i, sa'an nan kuma ana amfani da kayan aikin jujjuya mai kaifi guda ɗaya don yin aiki a saman. Bayan an gama zagaye, an juyar da kusurwar mazugi zuwa 15°, a nan ne ake amfani da maƙarƙashiya don fitar da sassan cikin sauri da inganci, kamar yadda aka nuna a hoto na 14.

8. Tuki na quenching karfe sassa

(1) Ɗaya daga cikin misalan maɓalli na quenchingcnc inji kayayyakin

① The high-gudun karfe W18CR4V sake fasalin da kuma sabuntawa (gyara bayan hutu)

② Ka'idodin Slocculus Ba -Madaidaicin Gida (Tsarin Ƙarfafawa)

③ Tuki na kayan aiki da kayan feshi

④ Fuskantar hasken kayan aiki

⑤ Tataccen zaren haske ta famfo tare da babban wuka karfe mai sauri

Lokacin da ake hulɗa da kayan aiki mai wuyar gaske da sassa daban-daban na ƙalubale-zuwa-na'ura a cikin samar da mu, zaɓin hankali na kayan aikin da ya dace da ƙananan ƙididdiga, kazalika da kusurwoyi na geometric da hanyoyin aiki, na iya haifar da fa'idodin tattalin arziki. Misali, lokacin da kasidar-baki ta karye kuma aka sake sabunta shi don amfani da shi wajen samar da wani nau'i na bakin murabba'i, ba wai kawai yana tsawaita zagayowar masana'anta ba har ma yana haifar da tsada.

Hanyarmu ta ƙunshi amfani da carbide YM052 da sauran nasihun ruwa don daidaita tushen tushen tushen tushen zuwa kusurwar gaba mara kyau. = -6°~ -8°, kyale ɓangarorin da za'a dawo dasu bayan an yi niƙa sosai tare da dutsen farar fata. An saita saurin yankewa a V = 10 ~ 15m / min. Bayan an juya da'irar waje, an yanke tsagi mara kyau, sa'an nan kuma an juya zaren (wanda ya ƙunshi m da kuma juyi mai kyau). Bayan juye juye, kayan aiki dole ne a kaifi da ƙasa kafin kammala zaren waje, sa'an nan kuma, an shirya wani yanki na zaren ciki don haɗa sandar taye, wanda aka gyara bayan haɗin. A sakamakon waɗannan hanyoyin jujjuyawar, an gyara ɓoyayyen fili da aka jefar kuma an mayar da shi yadda yake a asali.

(2) Zaɓin kayan aikin kayan aiki don sarrafa kayan aiki masu tauri

①New maki na carbide abun da ake sakawa kamar YM052, YM053, da YT05 ana yawanci amfani da yankan gudu a kasa 18m / min, cimma wani workpiece surface roughness na Ra1.6 ~ 0.80μm.

② Kayan aiki na FD cubic boron nitride yana da ikon sarrafa nau'in karfe da aka kashe da kuma sassa masu feshi a yankan saurin har zuwa 100m / min, yana haifar da rashin ƙarfi na Ra0.80 ~ 0.20μm. Kayan aikin DCS-F na hada cubic boron nitride kayan aiki daga masana'antar Babban Injin Jiha da Kamfanin Guizhou No. 6 Grinding Wheel Factory ya raba wannan aikin. Duk da yake tasirinsa ba ya da girma kamar siminti carbide, ba shi da ƙarfi iri ɗaya da zurfin shiga, kuma yana zuwa akan farashi mai girma kuma tare da haɗarin lalacewa mai yanke kai idan aka yi amfani da shi ba daidai ba.

③ Kayan aikin yankan yumbu suna aiki a saurin yankewa na 40-60m / min amma suna da ƙarfi mafi talauci.Kowane ɗayan waɗannan kayan aikin yana ba da halaye na musamman don sarrafa sassan da aka kashe kuma ya kamata a zaɓa bisa ƙayyadaddun yanayi ciki har da bambance-bambancen kayan aiki da taurin.

(3) Abubuwan Bukatun Ayyukan Kayan aiki don Kayayyaki Daban-daban na Ƙarfe Ƙarfe Ƙarfe na sassa daban-daban na kayan aiki daban-daban suna buƙatar aikin kayan aiki daban-daban a ƙarƙashin taurin guda kuma ana iya rarraba su zuwa nau'i uku masu zuwa:

High alloy karfe:Wannan ya shafi kayan aiki karfe da kuma mutu karfe (da farko daban-daban high-gudun karafa) tare da jimlar alloying kashi abun ciki da ya wuce 10%.

Alloy karfe:Wannan ya ƙunshi ƙarfe na kayan aiki kuma ya mutu karfe tare da abun ciki na gami da ke jere daga 2 zuwa 9%, misali, 9SiCr, CrWMn, da ƙarfe mai ƙarfi mai ƙarfi.

Karfe Karfe:Wannan ya hada da daban-daban carbon kayan aiki steels da carburized karfe irin su T8, T10, No. 15 karfe ko No. 20 karfe carburized karfe, da sauransu. Bayan quenching, da microstructure na carbon karfe kunshi tempered martensite da karamin yawa na carbides. Wannan yana haifar da kewayon taurin HV800 ~ 1000, wanda ya fi na WC da TiC a cikin siminti carbide da A12D3 a cikin kayan aikin yumbu.

Bugu da ƙari, taurinsa mai zafi yana ƙasa da na martensite ba tare da abubuwan gami ba, gabaɗaya baya wuce 200 ° C.

Ƙara kasancewar abubuwan haɗakarwa a cikin ƙarfe yana haifar da haɓaka daidaitaccen abun ciki na carbide na ƙarfe bayan quenching da tempering, yana haifar da hadaddun haɗaɗɗun nau'ikan carbide. Ƙarfe mai sauri yana aiki a matsayin misali, inda abun ciki na carbide a cikin microstructure bayan quenching da tempering zai iya kaiwa 10-15% (rabin girma). Wannan ya haɗa da nau'ikan carbides daban-daban kamar MC, M2C, M6, M3, 2C, da sauransu, tare da VC yana nuna babban taurin (HV2800), wanda ya wuce taurin kayan kayan aiki na yau da kullun.

Bugu da ƙari kuma, zafi mai zafi na martensite wanda ya ƙunshi abubuwa masu yawa da yawa ana iya ɗaga shi zuwa kusan 600 ° C. Saboda haka, injin da aka kashe karfe tare da taurin macro iri ɗaya ya bambanta sosai. Kafin yin aikin sashin ƙarfe da aka kashe, yana da mahimmanci a fara bincika nau'insa, fahimtar halayensa, sannan zaɓi kayan aikin da suka dace, yanke sigogi, da lissafin kayan aiki. Tare da la'akari da kyau, za a iya cika jujjuyawar sassa na ƙarfe mai tauri a kusurwoyi daban-daban.

Anebon yana alfahari daga babban cikawar abokin ciniki da kuma karɓuwa mai yawa saboda dagewar da Anebon ya yi na neman babban inganci duka akan samfur da sabis na CE Certificate Customized High Quality Computer Products.CNC Parts MillingKarfe, Anebon ya ci gaba da bin yanayin WIN-WIN tare da abokan cinikinmu. Anebon yana maraba da abokan ciniki daga ko'ina cikin duniya waɗanda ke zuwa sama don ziyarar da kafa dangantakar soyayya mai dorewa.

CE Certificate China CNC machined aluminum aka gyara,CNC Juya Sassanda cnc lathe sassa. Duk ma'aikata a masana'anta, kantin sayar da kayayyaki, da ofishin Anebon suna kokawa don manufa ɗaya don samar da ingantacciyar inganci da sabis. Kasuwanci na gaske shine don samun yanayin nasara. Muna son samar da ƙarin tallafi ga abokan ciniki. Maraba da duk masu siye masu kyau don sadarwa cikakkun bayanai na samfuranmu da mafita tare da mu!

Idan kuna son ƙarin sani ko kuna da tambayoyi, tuntuɓiinfo@anebon.com.

Lokacin aikawa: Fabrairu-18-2024