Bakin karfe naCNC Machining Partsyana ɗaya daga cikin kayan ƙarfe na yau da kullun a cikin aikin kayan aiki. Fahimtar ilimin bakin karfe zai taimaka wa masu sarrafa kayan aiki mafi kyawun zaɓi da amfani da kayan aikin.

Bakin Karfe shine takaitaccen bakin karfe da karfe mai jure acid. Karfe wanda ke da juriya ga raunin lalata kafofin watsa labarai kamar iska, tururi da ruwa ko kuma yana da kaddarorin bakin karfe ana kiransa bakin karfe; Karfe da ke da juriyar lalata matsakaicin sinadarai (acid, alkali, gishiri da sauran etching sinadarai) ana kiransa karfen da ke jure acid.

Bakin karfe yana nufin karfen da ke jure rashin raunin kafofin watsa labarai kamar iska, tururi da ruwa da kuma sinadarai masu etching irin su acid, alkali da gishiri, wanda kuma aka sani da bakin karfe. A aikace aikace, karfe mai juriya ga matsakaici mai rauni ana kiransa bakin karfe, yayin da karfe mai juriya ga matsakaicin sinadari ana kiransa karfe mai juriya. Saboda bambancin sinadaran sinadaran da ke tsakanin su biyun, na farko ba lallai ba ne ya yi juriya ga lalata matsakaicin sinadarai, yayin da na karshen ya zama bakin karfe. Juriya na lalata bakin karfe ya dogara da abubuwan gami da ke cikin karfe.

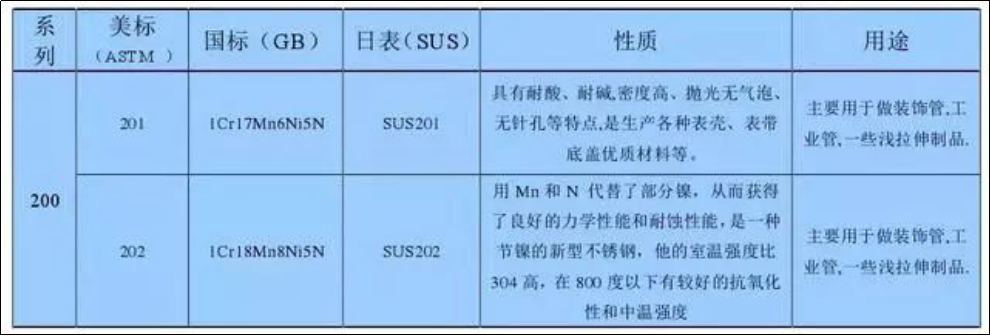

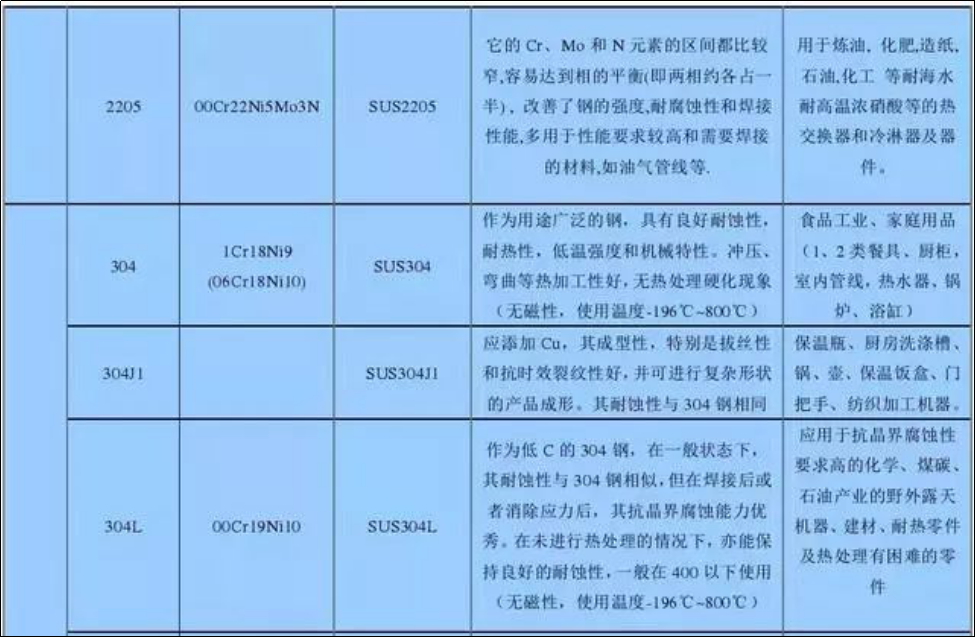

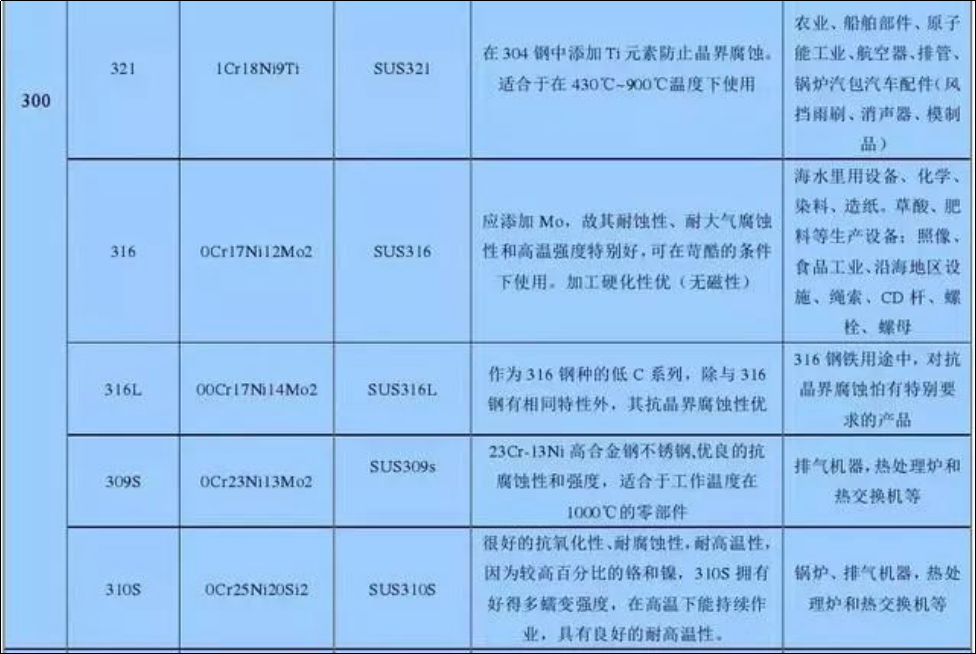

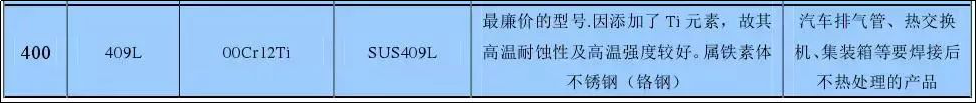

Rarraba gama gari

Gabaɗaya, an raba shi zuwa:

Gabaɗaya, bisa ga tsarin metallographic, talakawa bakin karafa sun kasu kashi uku: austenitic bakin karfe, ferritic bakin karfe da martensitic bakin karfe. A bisa wadannan uku na asali metallographic Tsarin, dual lokaci karfe, hazo hardening bakin karfe da high gami karfe tare da baƙin ƙarfe abun ciki kasa da 50% da aka samu don takamaiman bukatu da dalilai.

1. Austenitic bakin karfe.

Matrix galibi tsarin austenitic ne (CY Phase) tare da tsari mai siffar cubic crystal, wanda ba shi da magnetic, kuma yana da ƙarfi musamman (kuma yana iya haifar da wasu maganadisu) ta aikin sanyi. Cibiyar Ƙarfe da Ƙarfe ta Amurka ana nuna ta da jerin lambobi 200 da 300, kamar 304.

2. Ferritic bakin karfe.

Matrix galibi tsari ne na ferrite (phase a) tare da tsarin kristal na tsakiya na jiki, wanda yake maganadisu, kuma gabaɗaya ba za a iya taurare ta hanyar maganin zafi ba, amma ana iya ƙarfafa shi ta hanyar aikin sanyi. Cibiyar Iron da Karfe ta Amurka tana da alamar 430 da 446.

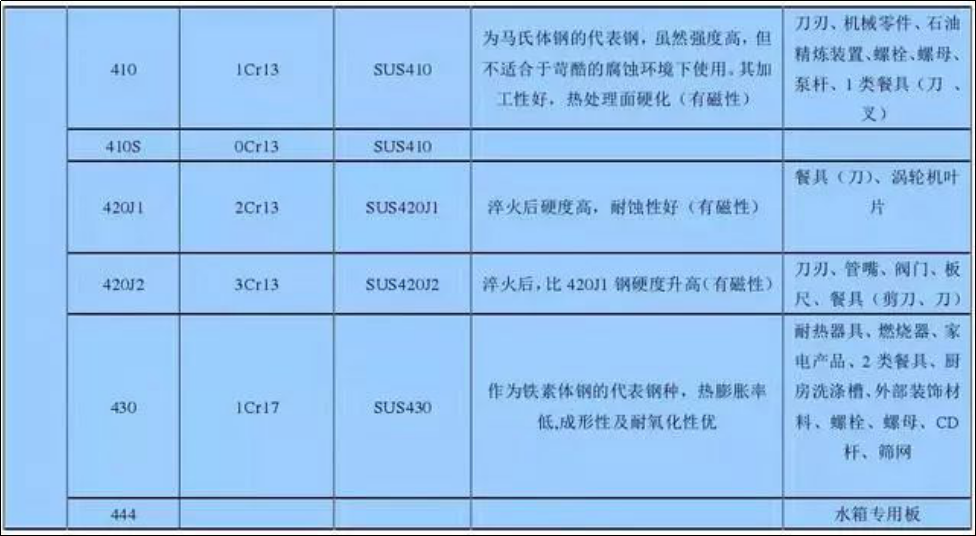

3. Martensitic bakin karfe.

Matrix shine tsarin martensitic (cubic tsakiya ko cubic), maganadisu, kuma ana iya daidaita kayan aikin sa ta hanyar magani mai zafi. Cibiyar Iron da Karfe ta Amurka ana nuna su ta lambobi 410, 420, da 440. Martensite yana da tsarin austenitic a babban zafin jiki. Lokacin da aka sanyaya shi zuwa dakin da zafin jiki a daidai lokacin da ya dace, ana iya canza tsarin austenitic zuwa martensite (watau taurare).

4. Austenitic ferritic (duplex) bakin karfe.

Matrix yana da duka austenite da ferrite tsarin matakai biyu, kuma abun ciki na ƙarancin lokaci matrix gabaɗaya ya fi 15%, wanda shine Magnetic kuma ana iya ƙarfafa shi ta hanyar aikin sanyi. 329 shine bakin karfe na duplex na yau da kullun. Idan aka kwatanta da austenitic bakin karfe, dual lokaci karfe yana da mafi girma ƙarfi, da juriya ga intergranular lalata, chloride danniya lalata da pitting lalata an inganta sosai.

5. Hazo hardening bakin karfe.

Bakin ƙarfe wanda matrix ɗin austenitic ne ko martensitic kuma ana iya taurare ta hanyar hazo mai taurin magani. Cibiyar Iron da Karfe ta Amurka tana da lambobi jerin lambobi 600, kamar 630, watau 17-4PH.

Gabaɗaya magana, ban da gami, bakin karfe austenitic yana da kyakkyawan juriya na lalata. Ferritic bakin karfe za a iya amfani da a cikin yanayi tare da low lalata. A cikin yanayi tare da lalata mai laushi, martensitic bakin karfe da hazo hardening bakin karfe za a iya amfani da idan abu da ake bukata don samun babban ƙarfi ko taurin.

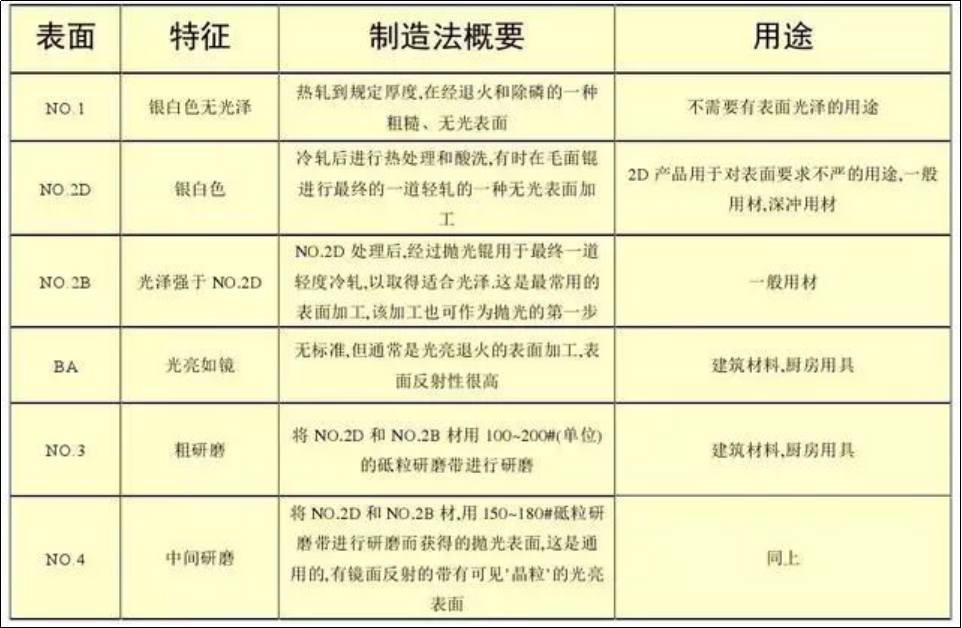

Halaye da manufa

Fasahar sararin samaniya

Bambancin kauri

1. Domin a cikin jujjuyawar injin injin ƙarfe na ƙarfe, juzu'in na'urar ta ɗan lalace saboda dumama, wanda ke haifar da ɓacin rai a cikin kauri na birgima. Gabaɗaya, kauri na tsakiya yana da bakin ciki a bangarorin biyu. Lokacin auna kauri na farantin, za a auna sashin tsakiya na kan farantin bisa ga ka'idodin ƙasa.

2. Haƙuri gabaɗaya an raba shi zuwa babban haƙuri da ƙaramin haƙuri bisa ga kasuwa da buƙatar abokin ciniki:

Misali

Matsayin bakin karfe da aka fi amfani da shi da kaddarorin kayan kida

1. 304 bakin karfe. Yana daya daga cikin mafi yadu amfani austenitic bakin karfe tare da babban adadin aikace-aikace. Ya dace da masana'anta zane mai zurfi da aka kafa, bututun watsa acid, tasoshin, sassan tsarin, jikin kayan aiki daban-daban, da dai sauransu, da kuma kayan aikin da ba na maganadisu ba da ƙarancin zafin jiki da kayan aiki.

2. 304L bakin karfe. Bakin karfe mai ƙarancin ƙarancin carbon austenitic wanda aka haɓaka don magance mummunan yanayin lalata na 304 bakin karfe wanda ya haifar da hazo Cr23C6 a ƙarƙashin wasu yanayi, juriyawar lalatawar tsaka-tsakin sa yana da mahimmanci fiye da 304 bakin karfe. Sai dai ƙananan ƙarfi, sauran kaddarorin iri ɗaya ne da bakin karfe 321. Ana amfani da shi ne don kayan aiki masu juriya da lalata da sassan da ke buƙatar walda amma ba za a iya magance su ba, kuma ana iya amfani da su don kera jikin kayan aiki daban-daban.

3. 304H bakin karfe. Don reshe na ciki na bakin karfe 304, ɓangaren ƙwayar carbon shine 0.04% - 0.10%, kuma babban aikin zafin jiki ya fi 304 bakin karfe.

4. 316 bakin karfe. Bugu da kari na molybdenum a kan tushen 10Cr18Ni12 karfe sa karfe da kyau juriya ga rage matsakaici da pitting lalata. A cikin ruwan teku da sauran kafofin watsa labarai, juriya na lalata ya fi 304 bakin karfe, galibi ana amfani da shi don rarrabuwa da kayan juriya.

5. 316L bakin karfe. Ultra low carbon karfe, tare da mai kyau juriya ga sensitized intergranular lalata, ya dace da masana'anta lokacin farin ciki sashe size waldi sassa da kayan aiki, kamar anti-lalata kayan a petrochemical kayan aiki.

6. 316H bakin karfe. Don reshe na ciki na bakin karfe 316, ɓangaren ƙwayar carbon shine 0.04% - 0.10%, kuma babban aikin zafin jiki ya fi na 316 bakin karfe.

7. 317 bakin karfe. Juriya ga lalata lalata da creep ya fi 316L bakin karfe. Ana amfani da shi don kera kayan aikin petrochemical da Organic acid.

8. 321 bakin karfe. Titanium stabilized austenitic bakin karfe za a iya maye gurbinsu da matsananci-low carbon austenitic bakin karfe saboda inganta intergranular lalata juriya da kyau high zafin jiki inji Properties. Sai dai lokuta na musamman kamar babban zafin jiki ko juriya na lalata hydrogen, gabaɗaya ba a ba da shawarar yin amfani da shi ba.

9. 347 bakin karfe. Niobium ya daidaita austenitic bakin karfe. Ƙarin niobium yana inganta juriya na lalata intergranular. Juriyarsa na lalata a cikin acid, alkali, gishiri da sauran kafofin watsa labarai masu lalata iri ɗaya ne da 321 bakin karfe. Tare da kyakkyawan aikin walda, ana iya amfani dashi azaman abu mai juriya da lalata da ƙarfe mai jure zafi. An fi amfani dashi a cikin wutar lantarki da filayen petrochemical, kamar yin tasoshin, bututu, masu musayar zafi, shafts, bututun tanderu a cikin tanderun masana'antu, da ma'aunin zafi da sanyio tanderu.

10.904L bakin karfe. Super cikakken austenitic bakin karfe babban bakin karfe ne wanda Kamfanin OUTOKUMPU na Finland ya kirkira. Matsakaicin adadin nickel ɗin sa shine 24% - 26%, kuma juzu'in ƙwayar carbon ɗin bai wuce 0.02%. Yana da kyakkyawan juriya na lalata. Yana da kyakkyawan juriya na lalatawa a cikin acid waɗanda ba oxidizing kamar su sulfuric acid, acetic acid, formic acid da phosphoric acid, kazalika da kyau juriya ga crevice lalata da danniya lalata. Yana da amfani ga nau'o'in sulfuric acid daban-daban da ke ƙasa da 70 ℃, kuma yana da kyakkyawan juriya ga acetic acid na kowane taro da zafin jiki a ƙarƙashin matsa lamba na al'ada da gauraye acid na formic acid da acetic acid. Asalin daidaitaccen ASMESB-625 ya ƙirƙira shi azaman alloy na nickel, kuma sabon ma'aunin ya ƙirƙira shi azaman bakin karfe. A kasar Sin, akwai irin wannan nau'in karfe na 015Cr19Ni26Mo5Cu2. Wasu ƴan masana'antun kayan aikin Turai suna amfani da bakin karfe 904L azaman maɓalli. Misali, bututun aunawa na E+H mass flowmeter yana amfani da bakin karfe 904L, kuma yanayin agogon Rolex shima yana amfani da bakin karfe 904L.

11.440C bakin karfe. Taurin bakin karfe na martensitic, bakin karfe da bakin karfe shine mafi girma, kuma taurin shine HRC57. An fi amfani dashi don yin nozzles, bearings, valve cores, bawul kujeru, hannayen riga, bawul mai tushe, da dai sauransu.

12. 17-4PH bakin karfe. Martensitic hazo hardening bakin karfe, tare da taurin na HRC44, yana da babban ƙarfi, taurin da lalata juriya, kuma ba za a iya amfani da a yanayin zafi sama da 300 ℃. Yana da kyakkyawan juriya na lalata yanayi da diluted acid ko gishiri. Juriyar lalatarsa iri ɗaya ce da bakin karfe 304 da bakin karfe 430. Ana amfani da shi don kerawaCNC Machining Parts, turbine ruwan wukake, bawul muryoyin, bawul kujeru, hannayen riga, bawul mai tushe, da dai sauransu.

A cikin sana'a na kayan aiki, a hade tare da al'amuran duniya da farashi, tsarin zaɓi na al'ada na austenitic bakin karfe shine 304-304L-316-316L-317-321-347-904L bakin karfe, wanda 317 ba shi da amfani, 321 ba a yi amfani da shi ba. shawarar, 347 da ake amfani da high zafin jiki lalata juriya, 904L ne tsoho abu ga wasu aka gyara na mutum masana'antun, da kuma 904L ba a zaɓi rayayye ba a cikin ƙira.

A cikin zane da zaɓi na kayan aiki, yawanci akwai lokuta inda kayan kayan aiki ya bambanta da kayan aikin bututu, musamman ma a cikin yanayin aiki mai zafi, ya kamata a biya kulawa ta musamman ga ko zaɓin kayan kayan aiki ya dace da ƙirar ƙira da matsa lamba na ƙira. aiwatar da kayan aiki ko bututu. Misali, bututun karfe ne na chromium molybdenum na zafin jiki, yayin da kayan aikin bakin karfe ne. A wannan yanayin, matsalolin zasu iya faruwa, kuma dole ne ku tuntuɓi ma'aunin zafin jiki da matsa lamba na kayan da suka dace.

A cikin tsarin ƙirar kayan aiki da zaɓin nau'in, sau da yawa muna haɗuwa da bakin karfe na tsarin daban-daban, jerin da alamu. Lokacin zabar nau'in, ya kamata mu yi la'akari da matsaloli daga ra'ayoyi da yawa kamar ƙayyadaddun kafofin watsa labaru na tsari, zafin jiki, matsa lamba, sassan da aka damuwa, lalata da farashi.

Lokacin aikawa: Oktoba-17-2022