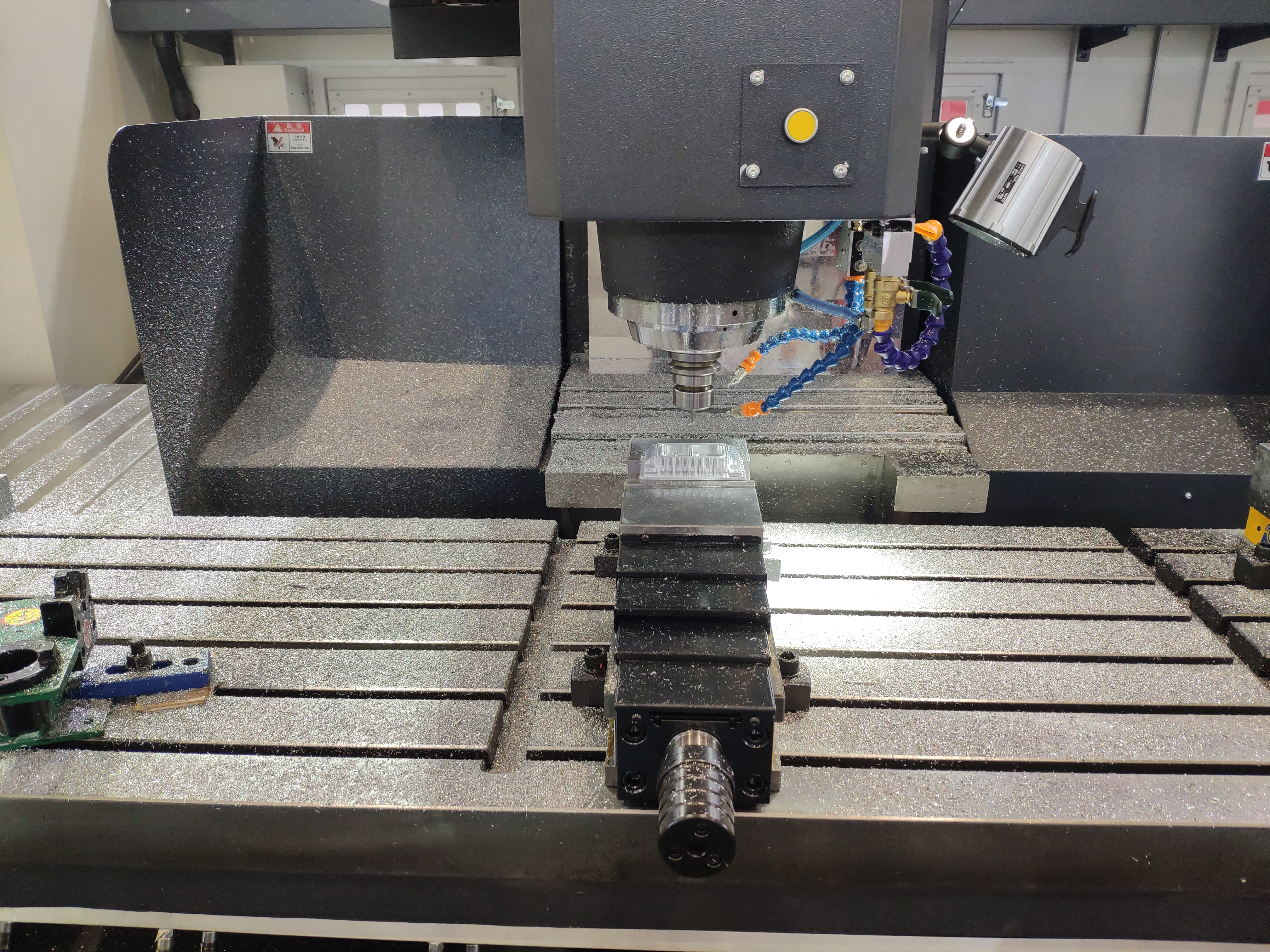

I. Shigar da na'ura mai sarrafa lambobi:

An ƙera na'ura mai sarrafa lambobi gaba ɗaya tare da haɗin inji da na lantarki. Ana jigilar shi azaman cikakken inji ba tare da tarwatsawa da marufi daga masana'anta zuwa mai amfani ba. Don haka, bayan karɓar kayan aikin injin, mai amfani kawai yana buƙatar bin umarnin. Kula da abubuwa masu zuwa:

(1) kwancewa: bayan cire kayan aikin injin, da farko nemo takaddun fasaha masu rakiyar bisa ga alamomin tattarawa kuma ƙidaya kayan haɗi, kayan aiki, kayan gyara, da sauransu, bisa ga lissafin tattarawa a cikin takaddun fasaha. Idan kayan da ke cikin akwatin bai dace da lissafin tattarawa ba, tuntuɓi masana'anta da wuri-wuri. Sa'an nan, da fatan za a karanta umarnin a hankali kuma yi shigarwa bisa ga su.

(2) ɗagawa: bisa ga zanen ɗagawa a cikin littafin koyarwa, toshe katako ko zane mai kauri a daidai wurin da ya dace don hana igiyar waya ta ƙarfe lalata fenti da wurin sarrafawa. A cikin aiwatar da ɗagawa, ya kamata a rage girman tsakiya na kayan aikin injin. Idan kunkuru na lantarki na kayan aikin injin CNC ya rabu, akwai zoben ɗagawa a saman majalisar lantarki don ɗagawa.

(3) Daidaitawa: ana jigilar babban na'ura a matsayin cikakkiyar na'ura don injin milling na CNC, wanda aka gyara kafin bayarwa. A lokacin shigarwa, mai amfani ya kamata ya kula da daidaitawar man fetur, daidaitawar man shafawa ta atomatik, da kuma dubawa mai mahimmanci don hana na'urar zamewa ta tsaye na dandalin ɗagawa daga aiki.

II. Debugging da yarda da CNC milling inji:

Ana jigilar babban na'ura azaman cikakkiyar injin don injin niƙa na CNC na gaba ɗaya, wanda aka gyara kafin bayarwa. Duk da haka, masu amfani har yanzu suna buƙatar kula da abubuwan da ke gaba kafin amfani da su: gyara injin milling na CNC:

(1) daidaita matsa lamba na mai: saboda ana buƙatar matsa lamba mai dacewa don canjin saurin hydraulic, tashin hankali na hydraulic, da sauran hanyoyin bayan an cire kayan aikin injin, cire hatimin mai don tsatsa pprevention wato, cika tafkin mai da mai, fara famfon mai don daidaita matsa lamba mai, gabaɗaya a 1-2pa.juya part

(2) daidaita man shafawa ta atomatik: yawancin injunan niƙa na CNC suna amfani da lokacin atomatik da tashoshi mai ƙididdigewa don wadatar mai. Kafin farawa, bincika ko famfon mai mai mai yana farawa daidai da ƙayyadadden lokacin. Relays yawanci suna yin waɗannan gyare-gyaren lokaci. Yana da mahimmanci don bincika ko na'urar zamewa ta tsaye ta dandalin ɗagawa tana da tasiri. Hanyar dubawa ita ce madaidaiciya. Lokacin da aka kunna kayan aikin injin, gyara ginshiƙi na mita akan gado, nuna alamar bugun kira zuwa teburin aiki, sannan yanke ikon tebur ɗin ba zato ba tsammani, kuma duba ko tebur ɗin yana nutsewa ta hanyar mai nuna bugun kira, tare da canjin canji. 0. 01 - 0. 02mm an yarda, zamewa da yawa zai shafi daidaiton sassan da aka sarrafa a cikin batches. A wannan lokacin, ana iya daidaita na'urar kulle kai.

(3) yarda da injin niƙa CNC: yarda da injunan niƙa CNC ya dogara ne akan ƙa'idodin ƙwararrun da jihar ta bayar. Akwai nau'ikan zbj54014-88 da zbnj54015-88. Kafin barin masana'anta, masana'anta sun bincika kayan aikin injin bisa ga ka'idoji guda biyu na sama, kuma sashen binciken ingancin ya ba da littafin cancantar samfur. Mai amfani zai iya gudanar da binciken samfurin ko duk sake duba daidaito bisa ga abubuwan da ke cikin littafin cancantar, kuma sashin ya mallaki ainihin ma'anar gwaji. Mai amfani zai iya yin shawarwari tare da masana'anta idan akwai wasu abubuwan da basu cancanta ba. Idan bayanan sake dubawa sun cika buƙatun takardar shaidar masana'anta, ana iya yin rikodin shi cikin fayil ɗin don tunani na gaba.CNC machining part

| Bangaren Karfe Bakin Karfe | Filastik Cnc | Ayyukan Juya Lathe |

| Ƙarfe Machining Parts | Ƙirƙirar Ƙungiyoyin Ƙirar Ƙarfafawa | Menene Juyawa CNC |

| CNC Machining Prototype | Ingantattun Kayayyakin Sinanci | Juyawar Aluminum |

www.anebon.com

Anebon Metal Products Limited na iya samar da mashin ɗin CNC, simintin gyare-gyare, sabis na ƙirar ƙarfe, da fatan za a iya tuntuɓar mu.

Tel: +86-769-89802722 Email: info@anebon.com Website : www.anebon.com

Lokacin aikawa: Nov-02-2019