Muhimmancin jiyya na saman ƙarfe:

Ƙarfafa juriyar lalata: Magungunan saman kan karafa na iya kare su daga lalacewa, ta hanyar ƙirƙirar shingen da ke raba karfe da yanayinsa. Yana ƙara tsawon rayuwar sifofin ƙarfe da abubuwan haɗin gwiwa. Haɓaka kayan ado - Jiyya na saman ƙarfe kamar plating, shafi, da gogewa na iya inganta haɓakar gani na ƙarfe.

Yana da mahimmanci a yi la'akari da wannan don kayan gine-gine ko kayan masarufi inda kayan ado ke taka muhimmiyar rawa. Jiyya na sama kamar maganin zafi, nitriding ko taurin yana ƙara taurin ƙarfe da juriya, yana sa ya fi dacewa da aikace-aikacen da suka haɗa da juzu'i, lalacewa ko matsananciyar yanayin aiki.

Jiyya na saman ƙasa kamar fashewar yashi da etching na iya samar da ƙarancin rubutu wanda zai inganta mannewa ga fenti, adhesives da sutura. Wannan yana inganta haɗin gwiwa, kuma yana rage yuwuwar bawo ko ɓarna. Yana inganta haɗin gwiwa: Jiyya na saman ƙarfe, kamar yin amfani da na'ura mai mahimmanci ko masu tallata mannewa, na iya taimakawa wajen haɓaka ƙaƙƙarfan alaƙa tsakanin karafa da sauran kayan kamar su composites ko robobi. A cikin masana'antu kamar na kera motoci da sararin samaniya, tsarin gauraye sun zama ruwan dare gama gari. Sauƙi don tsaftacewa: Jiyya na sama kamar ƙarewar sawun yatsa ko sauƙin tsaftacewa na iya sa filayen ƙarfe ya zama mafi tsafta da sauƙin kulawa. Wannan yana rage yawan ƙoƙari da albarkatun da ake buƙata don kulawa.

Electroplating da anodizing su ne saman jiyya da zai iya ƙara wani karfe ta conductivity. Wannan yana ba shi damar zama mafi inganci a aikace-aikacen da ke buƙatar aiki mai kyau kamar kayan aikin lantarki. Ana iya samun ingantacciyar brazing da mannewar walda ta wasu jiyya na sama kamar tsaftacewa, cire yadudduka oxide ko wasu jiyya na saman. Wannan yana haifar da mafi ƙarfi da ingantaccen tsarin ƙarfe ko sassa.

Ana amfani da jiyya na saman ƙarfe a cikin masana'antar kiwon lafiya da masana'antar kiwon lafiya don haɓaka haɓakar halittu. Yana rage yuwuwar wani mummunan dauki ko ƙin yarda daga jiki lokacin da saman ƙarfen ya haɗu. Keɓancewa da yin alama suna yiwuwa: Ƙarfe yana ba da zaɓuɓɓukan gyare-gyare, kamar su zane, zane ko alama. Waɗannan gyare-gyaren suna da mahimmanci don bambancewa, keɓancewa, ko sanya alama.

1. Anodizing

Yin amfani da ka'idodin electrochemical, anodizing aluminum shine tsari wanda da farko ke samar da fim na Al2O3 (aluminum dioxide) a saman. Wannan fim din oxide yana da halaye na musamman, irin su rufi, kariya, ado da juriya.

Tsari kwarara

Launi ɗaya, launi mai gradient: gogewa / sandblasting / zane - ragewa - anodizing - neutralizing - rini - rufewa - bushewa

launuka biyu:

1 goge / sandblasting / zane - ragewa - masking - anodizing 1 - anodizing 2 - rufewa - bushewa

2 goge / sandblasting / zane - cire mai - anodizing 1 - zanen laser - anodizing 2 - rufewa - bushewa

Siffofin:

1. Ƙarfafa tsokoki

2. Duk wani launi amma fari

3. Turai, Amurka, da sauran ƙasashe suna buƙatar hatimin da ba shi da nickel.

Matsalolin fasaha da wuraren ingantawa:

Farashin anodizing ya dogara da yawan amfanin aikin. Don inganta yawan amfanin ƙasa na anodizing, masana'antun dole ne su bincika mafi kyawun sashi, zazzabi, da yawa na yanzu. Kullum muna neman ci gaba. Muna ba da shawarar ku bi asusun Twitter na "Injin Injiniya" da wuri-wuri don samun ilimi mai amfani da bayanai game da masana'antar.

Samfurin da aka ba da shawarar: E + G masu lanƙwasa iyawa, waɗanda aka yi daga kayan anodized, waɗanda ke da alaƙa da muhalli kuma masu dorewa.

2. Electrophoresis

Ana iya amfani dashi a cikin alluran aluminium da bakin karfe don sanya samfuran su zama launuka daban-daban, kula da ƙyalli na ƙarfe da haɓaka kaddarorin ƙasa.

Tsarin tsari: Pretreatment - Electrophoresis da bushewa

Amfani:

1. Launuka masu wadata

2. Babu karfe. Ana iya amfani dashi don yashi da gogewa. ;

3. Ana iya samun maganin saman ta hanyar aiki a cikin ruwa.

4. Fasaha ya balaga kuma an samar da shi da yawa.

Ana buƙatar Electrophoresis donabubuwan da suka mutu-simintin gyare-gyare, wanda ke buƙatar manyan buƙatun sarrafawa.

3. Micro-arc oxidation

Wannan shine tsarin yin amfani da babban ƙarfin lantarki zuwa electrolyte mai rauni mai rauni don ƙirƙirar shimfidar yumbu. Wannan tsari ya samo asali ne daga tasirin haɗin gwiwar electrochemical oxidation da fitarwa ta jiki.

Tsarin tsari: Kafin magani - wanke ruwan zafi - MAO - bushewa

Amfani:

1. Rubutun yumbu tare da ƙarancin ƙarewa, ba tare da babban haske ba, tare da taɓawa mai laushi da rigar yatsa.

2. Al, Ti da sauran kayan tushe kamar Zn, Zr Mg, Nb da dai sauransu;

3. Pre-maganin samfurin yana da sauƙi. Yana da kyakkyawan juriya na lalata da juriya na yanayi.

Launuka da ake da su a halin yanzu suna iyakance ga baki, launin toka da sauran inuwar tsaka tsaki. Launuka masu haske suna da wuya a cimma a halin yanzu, saboda fasahar ta girma. Babban amfani da wutar lantarki ya shafi farashin kuma yana ɗaya daga cikin mafi tsadar jiyya a saman.

4. PVD injin plating

Turin jiki shine cikakken sunan hanyar kera masana'antu wanda ke amfani da galibin matakai na zahiri don saka fim na bakin ciki.

Tsari kwarara: Tsaftacewa kafin PVD - Vacuuming a cikin tanderu - Wankewar manufa da tsabtace ion - Rufi - Ƙarshen sutura, sanyaya, da fitarwa - Bayan aiwatarwa, (polishing, AAFP) Muna ba da shawarar ku bi asusun aikin injiniya na injiniya don sabon sabo. ilimin masana'antu da bayanai.

Siffofin:Ana iya amfani da PVD don shafa saman ƙarfe a cikin wani abin ado mai ɗorewa da wuyar ƙwanƙwasa.

5. Electroplating

Wannan fasaha tana haɗa fim ɗin ƙarfe na bakin ciki akan saman ƙarfe don haɓaka juriya na lalata, juriya, haɓakawa da kuma tunani. Har ila yau, yana haɓaka ƙayatarwa.

Tsari ya kwarara: Pretreatment - Cyanide-free Alkali Copper - Cyanide-free Cupronickel Tin - Chromium plating

Amfani:

1. Rubutun yana nunawa sosai kuma yana da ƙarfe a bayyanar.

2. SUS, Al Zn Mg da dai sauransu sune kayan tushe. Farashin PVD bai kai na SUS ba.

Mummunan kariyar muhalli da ƙara haɗarin gurɓata yanayi.

6. Fasa foda

Ana fesa kayan kwalliyar foda a saman kayan aikin da injin fesa electrostatic. The foda ne ko'ina adsorbent a kan surface don samar da wani shafi. Lebur yana warkar da gashi na ƙarshe tare da tasiri daban-daban (sakamakon nau'in foda daban-daban).

Tsarin tsari:loading-electrostatic kura cire-spraying-ƙananan zafin jiki matakin-baking

Amfani:

1. Babban mai sheki ko matte gama;

2. Low-cost, manufa domin furniture da kuma radiators bawo. ;

3. Abokan muhalli, babban amfani da ƙimar amfani da 100% amfani;

4. Zai iya rufe lahani da kyau; 5. Zai iya kwaikwayon tasirin ƙwayar itace.

A halin yanzu ba kasafai ake amfani da shi a cikin kayayyakin lantarki ba.

7. Zane Waya Karfe

Wannan hanya ce ta jiyya ta ƙasa inda ake amfani da samfuran niƙa don ƙirƙirar layi akan farfajiyar aikin don cimma kyan gani na ado. Ana iya rarraba shi zuwa nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'_o'i_nau'i) kasa da su: zanen hatsi madaidaiciya (wanda kuma aka sani da hatsin bazuwar), hatsin dala da hatsi mai karkace.

Siffofin:Maganin gogewa na iya haifar da ƙulli na ƙarfe wanda ba ya haskakawa. Hakanan za'a iya amfani da gogewa don kawar da rashin lahani akan saman ƙarfe.

Shawarwarin samfur: Riƙe LAMP tare da jiyya na Zwei L. Kyakkyawan fasahar niƙa da aka yi amfani da ita don haskaka dandano.

8. Yashi

Tsarin yana amfani da iska mai matsewa don ƙirƙirar katako mai sauri na kayan fesa wanda aka fesa akan saman kayan aikin a cikin babban gudu. Wannan yana canza siffa ko kamannin farfajiyar waje, da ma matakin tsafta. .

Siffofin:

1. Kuna iya samun matte daban-daban ko tunani.

2. Yana iya cire burrs daga saman kuma ya daidaita yanayin, rage lalacewar da burrs ke haifarwa.

3. Aikin aikin zai zama mafi kyau, kamar yadda zai kasance da launi mai launi da kuma m surface. Muna ba da shawarar ku bi asusun “Injiniya Injiniya” da wuri-wuri don samun ilimi mai amfani da bayanai game da masana'antu.

Shawarar samfur: E+G Classic Gada Handle, Sandblasted Surface, High-End and Classy.

9. goge baki

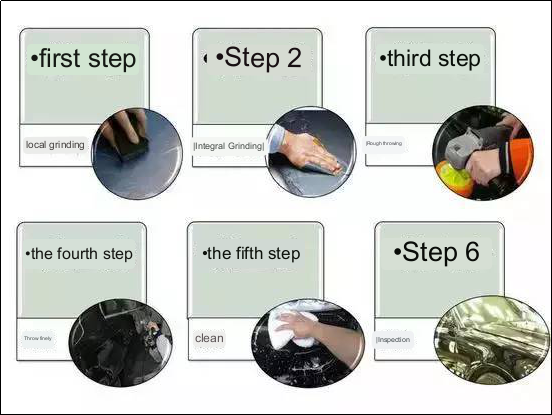

gyaggyarawa saman wani workpiece ta amfani da sassauƙan kayan aikin goge goge da abrasive ko wasu matsakaicin gogewa. Zaɓin madaidaicin dabaran gyaran gyare-gyare don matakai daban-daban, irin su m polishing ko asali polishing, matsakaici polishing ko karewa tsari da lafiya polishing / glazing iya inganta polishing yadda ya dace da kuma cimma sakamako mafi kyau.

Tsarin tsari:

Siffofin:Za a iya yin aikin da ya fi dacewa dangane da girmansa ko siffarsa, ko kuma yana iya samun saman madubi. Hakanan yana yiwuwa a kawar da sheki.

Shawarar samfur: E+G Dogon rikewa, goge goge. Mai sauƙi da m

10. Fitowa

Ana kuma kiransa photochemical etching. Wannan ya haɗa da cire Layer na kariya daga wurin da za a cire, ta hanyar amfani da faranti da tsarin haɓakawa, sa'an nan kuma tuntuɓar maganin sinadarai don narkar da lalata.

Tsari kwarara

Hanyar bayyanawa: Aikin yana shirya kayan bisa ga zane - shirye-shiryen kayan aiki - tsaftacewa kayan aiki - bushewa - fim ko bushewa da bushewa - bushewa haɓaka haɓaka - etching _ tsiri - Yayi kyau.

Buga allo: yankan, tsaftace farantin (bakin da sauran karafa), bugu na allo, etching, tsiri.

Amfani:

1. Fine sarrafa karfe saman yana yiwuwa.

2. Ba da ƙarfe na ƙarfe wani tasiri na musamman

Yawancin ruwayen da ake amfani da su a cikin etching (acids, alkalis, da sauransu), suna da illa ga muhalli. Magungunan etching suna da haɗari ga muhalli.

Muhimmancin kashe ƙarfe:

-

Ana iya amfani da Quenching don sanyaya ƙarfe da sauri don isa matakin taurin da ake so. Ana iya daidaita kayan aikin injiniya na ƙarfe daidai ta hanyar sarrafa ƙimar sanyaya. Ana iya yin ƙarfe mai ƙarfi da ƙarfi ta hanyar quenching, wanda ya sa ya dace don aikace-aikacen da ke buƙatar ƙarfi da ƙarfi.

-

Ƙarfafawa: Ƙarfafawa yana ƙara ƙarfin ƙarfe ta hanyar canza ƙananan tsarin. Alal misali, an kafa martensite a cikin karfe. Wannan yana inganta ƙarfin ɗaukar nauyin ƙarfe da aikin injina.

-

Inganta tauri. Quenching da fushi na iya inganta tauri ta rage damuwa na ciki. Wannan yana da mahimmanci musamman ga aikace-aikace waɗanda ƙarfen ke fallasa ga kaya kwatsam ko tasiri.

-

Sarrafa girman hatsi. Quenching yana da ikon rinjayar girman da tsarin hatsi a cikin karfe. Saurin kwantar da hankali zai iya inganta samuwar tsari mai kyau, wanda zai iya inganta kayan aikin injiniya na karafa, kamar ƙara ƙarfin ƙarfi da juriya ga gajiya.

-

Quenching hanya ce ta sarrafa canje-canjen lokaci. Ana iya amfani da wannan don cimma wasu matakan ƙarfe kamar su danne hazo maras so ko cimma ƙananan ƙananan abubuwa waɗanda ake so don takamaiman aikace-aikace.

-

Quenching yana rage murdiya da warping yayin maganin zafi. Haɗarin ɓata fuska ko canje-canje a siffa za a iya rage girman ta ta amfani da sanyaya da sarrafawa iri ɗaya. Wannan zai tabbatar da mutunci da daidaito nadaidai sassan karfe.

-

Kiyaye ƙarewar saman: Quenching yana taimakawa don adana ƙarewa ko bayyanar da ake so. Haɗarin canza launin saman, iskar oxygen ko sikelin za a iya rage ta hanyar rage tsayin daka zuwa yanayin zafi.

-

Quenching yana ƙara juriya na lalacewa ta hanyar ƙara tauri da ƙarfin ƙarfe. Karfe ya zama mai juriya ga lalacewa da tsagewa, lalata, da gajiyar hulɗa.

-

Menene quenching?

Maganin zafi da ake kira quenching ya haɗa da dumama karfe sama da zafin jiki mai mahimmanci na ɗan lokaci kuma sanyaya shi da sauri fiye da sanyaya mai mahimmanci don samar da tsari mara daidaituwa tare da mamaye martensite (ana iya samar da bainite, ko austinit lokaci ɗaya kamar yadda ake buƙata). Mafi na kowa tsari a cikin karfe magani magani ne quenching.

Maganin zafi na ƙarfe yana dogara ne akan manyan matakai guda huɗu: daidaitawa, annealing da quenching.

Ana amfani da Quenching don kashe ƙishirwar dabbobi.

Ana canza karfen daga supercooled austenite zuwa martensite, ko bainite, don samar da tsarin martensite, ko bainite. An haɗa wannan tare da zafin jiki, a yanayin zafi daban-daban, don inganta ƙarfinsa, taurinsa da juriya. Don saduwa da buƙatun sassa daban-daban na inji da kayan aiki, ana buƙatar ƙarfi da ƙarfi. Hakanan ana amfani da Quenching don haɓaka kayan aikin jiki da sinadarai, kamar juriya na lalata da feromagnetism, na ƙarfe na musamman.

A kan aiwatar da zafi zalunta karafa a cikin abin da workpiece ne mai tsanani har zuwa wani takamaiman zafin jiki, kiyaye na wani lokaci, sa'an nan immersed a cikin wani quenching kafofin watsa labarai ga m sanyaya. Kafofin watsa labarai masu kashe wuta da aka saba amfani da su sun haɗa da mai, ruwa, brine da iska. Quenching yana inganta taurin da juriya ga lalacewa na sassan ƙarfe. Don haka ana amfani da shi sosai don kayan aiki daban-daban, gyare-gyare da kayan aunawa dacnc machining sassa(irin su gears, rolls da carburized sassa) waɗanda ke buƙatar juriya na saman. Haɗa quenching tare da zafin rai na iya haɓaka tauri, juriyar gajiya, da ƙarfin ƙarfe.

Quenching kuma yana ba da damar ƙarfe don samun wasu sinadarai da kaddarorin jiki. Quenching, alal misali, na iya inganta juriya na lalata da feromagnetism a cikin bakin karfe. Ana amfani da Quenching galibi akan sassan karfe. Idan karfe da aka saba amfani da shi yana zafi zuwa zafin jiki sama da mahimmanci, zai canza zuwa austenite. Bayan an nutsar da karfe a cikin mai ko ruwa, yana da sauri sanyaya. Austenite sannan ya canza zuwa martensite. Martensite shine tsari mafi wuya a cikin karfe. Saurin sanyaya da ke haifarwa ta hanyar quenching yana haifar da damuwa na ciki a cikin kayan aiki. Da zarar ya kai wani matsayi, kayan aikin na iya zama naƙasasshe, fashe, ko karkacewa. Wannan yana buƙatar zaɓin hanyar sanyaya mai dacewa. Ana iya rarraba tsarin kashewa zuwa nau'i daban-daban guda huɗu dangane da hanyar sanyaya: ruwa ɗaya, matsakaicin dual, martensite graded, da bainite thermal quenching.

-

Hanyar Quenching

Matsakaicin matsakaici guda ɗaya

Kayan aikin yana sanyaya a cikin ruwa, kamar ruwa ko mai. Sauƙaƙan aiki, sauƙi na injiniyoyi da aikace-aikace masu fa'ida sune fa'idodi. Rashin hasara na quenching shine babban danniya da sauƙi nakasawa da fatattaka wanda ke faruwa lokacin da kayan aikin ya ƙare a cikin ruwa. Lokacin kashewa tare da mai, sanyaya yana jinkirin kuma girman quenching yana da karami. Manyan kayan aiki na iya zama da wahala a kashe su.

Dual matsakaici quenching

Yana yiwuwa a kashe hadaddun sifofi ko sassan giciye marasa daidaituwa ta hanyar fara sanyaya aikin aikin zuwa 300degC ta amfani da matsakaicin matsakaici wanda ke da ƙarfin sanyaya. Sa'an nan, workpiece za a iya sake sanyaya a cikin wani matsakaici na low sanyaya iya aiki. quenching ruwa sau biyu yana da lahani wanda yana da wahalar sarrafawa. Ƙunƙarar ba zai yi wahala ba idan kun canza ruwa da wuri, amma idan kun canza shi a makare, ƙarfe zai iya tsagewa kuma a kashe shi. Don shawo kan wannan rauni, an ɓullo da hanyar da aka ƙima.

A hankali quenching

Ana kashe kayan aikin ta amfani da wankan gishiri ko wankan alkali a ƙananan zafin jiki. Yanayin zafin jiki a cikin alkali ko wankan gishiri yana kusa da wurin Ms. Bayan 2 zuwa 5 min, an cire kayan aikin kuma an sanyaya shi ta iska. Wannan dabarar sanyaya ana kiranta da quenching graded. Sannu a hankali sanyaya kayan aikin hanya ce ta daidaita yanayin zafi a ciki da waje. Wannan zai iya rage damuwa mai kashewa, hana tsagewa, kuma ya sa ya zama iri ɗaya.

-

A baya can, da rarrabuwa zafin jiki da aka kafa dan kadan mafi girma fiye da Ms. A martensite yankin ne kai lokacin da yawan zafin jiki na workpiece da kewaye iska ne uniform. An inganta darajar a yanayin zafi kaɗan ƙasa da zafin Ms. A aikace, an gano cewa ƙididdigewa a yanayin zafi kusa da zafin Ms yana haifar da kyakkyawan sakamako. Yana da na kowa zuwa sa high carbon karfe kyawon tsayuwa a cikin wani alkali bayani a 160degC. Wannan yana ba su damar ɓata kuma a taurare tare da ƙananan nakasawa.

-

Isothermal Quenching

Ana amfani da wankan gishiri don kashe kayan aikin. Yanayin zafin wankan gishiri ya ɗan fi na Ms (a cikin ƙananan bainite zone). Ana adana kayan aikin isothermally har sai bainite ya cika sannan an cire shi don sanyaya iska. Don karafa sama da matsakaicin carbon, ana iya amfani da quenching isothermal don rage bainite da haɓaka ƙarfi, taurin ƙarfi, da juriya. Ba a amfani da Austempering akan ƙananan karafan carbon.

Tauraruwar saman

quenching surface, wanda kuma aka sani da partial quenching, hanya ce ta quenching wanda kawai ke kashe saman saman sassan karfe. Babban ɓangaren ya kasance ba a taɓa shi ba. quenching saman yana ƙunshe da saurin dumama don kawo yanayin zafi da sauri na wani sashi har zuwa yanayin zafi. Ana sanyaya saman nan da nan don hana zafi shiga cikin ainihin kayan aikin.

induction hardening

Induction dumama hanya ce ta dumama da ke amfani da induction na lantarki.

Han Ku

Yi amfani da ruwan kankara azaman matsakaiciyar sanyaya.

Yankewar ɓarna

Sai kawai sassan taurara na kayan aikin suna kashewa.

Yankewar iska

Yana nufin dumama da kashe iskar gas mai tsaka-tsaki da rashin aiki a ƙarƙashin matsi mara kyau, matsi na al'ada ko matsa lamba mai girma a cikin iskar gas mai sauri.

Tauraruwar saman

Quenching da ake yi a kan saman kayan aikin kawai. Wannan ya haɗa da induction quenching (launi juriya dumama), wuta quenching (laser quenching), lantarki katako quenching (laser quenching), da dai sauransu.

Yankewar iska

Ana samun sanyayawar kashewa ta hanyar amfani da matsi ko iska mai kwarara a matsayin matsakaiciyar sanyaya.

Gishiri quenching

Maganin gishiri mai ruwa da aka yi amfani da shi azaman matsakaici mai sanyaya.

Maganin halitta quenching

Matsakaicin sanyaya shine maganin polymer mai ruwa.

Fesa quenching

Jet ruwa kwarara sanyaya a matsayin mai sanyaya matsakaici.

Fesa sanyaya

Ana amfani da hazo mai fesa cakuda iska da ruwa don kashewa da sanyaya kayan aikin.

Zafafan wanka mai sanyaya

Ana kashe kayan aikin a cikin wanka mai zafi, wanda zai iya zama narkakken mai, ƙarfe, ko alkali.

Ruwa biyu quenching

Bayan dumama da austenitizing da workpiece, an nutsar da farko a cikin wani matsakaici cewa yana da karfi sanyaya iya aiki. Lokacin da tsarin ya shirya don yin canje-canje na martensitic, nan da nan an koma shi zuwa matsakaici wanda ke da raunin sanyi.

Matsewar matsi

Za a yi zafi, a inganta aikin, sannan kuma a kashe shi a ƙarƙashin na'ura ta musamman. An yi niyya don rage murdiya yayin sanyaya da kashewa.

Ta hanyar kashewa

Quenching shine tsari na taurara kayan aikin gaba daya daga saman sa zuwa ainihin sa.

Isothermal Quenching

Dole ne a sanyaya kayan aikin da sauri zuwa kewayon zafin jiki na bainite sannan a riƙe shi a cikin isothermally.

A hankali quenching

Bayan da workpiece da aka mai tsanani da kuma austenitized an nutsar da shi don dacewa lokaci a cikin wani alkali ko gishiri wanka a zazzabi da ya dan kadan sama ko kasa da M1. Da zarar workpiece ya kai matsakaicin zafin jiki an cire shi don sanyaya iska domin a cimma martensite quenching.

Ƙarƙashin zafin jiki

An inganta aikin aikin hypoeutectoid tsakanin AC1 da AC3 yanayin zafi, sannan a kashe shi don samar da tsarin martensite ko ferrite.

quenching kai tsaye

Kayan aikin yana kashe kai tsaye bayan an shigar da shi ta hanyar carbon.

quenching sau biyu

Bayan aikin da aka yi carburized, dole ne a inganta shi, sannan a sanyaya shi a mafi girman zafin jiki fiye da Ac3, don daidaita tsarin sa. Daga nan sai a dan kashe shi sama da Ac3, don tace burbushinsa.

Yankewar kai

Zafin zafi daga ɓangaren mai zafi yana canjawa ta atomatik zuwa ɓangaren da ba a yi zafi ba, wanda ke sa yanayin da aka inganta ya yi sanyi kuma ya mutu da sauri.

Anebon ya bi ka'idar "Mai gaskiya, ƙwararren ƙwararren ƙwararren ƙwararren ƙwararren ƙwararren ƙwararren ƙwararren ƙwararren ƙwararren ƙwararru "don samun sabbin hanyoyin warwarewa gabaɗaya. Anebon ya ɗauki al'amura, nasara a matsayin nasarar sa na sirri. Bari Anebon ya gina ingantacciyar hannu da hannu ta gaba don ɓangarorin injin tagulla da Complex titanium cnc sassa / kayan hatimi. Anebon yanzu yana da cikakkiyar wadatar kayayyaki kuma farashin siyarwa shine fa'idarmu. Barka da zuwa don tambaya game da samfuran Anebon.

Trending Products ChinaCNC Machining Partda Daidaitaccen Sashe, da gaske ya kamata kowane ɗayan waɗannan abubuwan ya kasance da sha'awar ku, da fatan za a sanar da mu. Anebon zai yi farin cikin ba ku zance a lokacin da aka sami cikakkun bayanai na mutum. Anebon yana da injinan R&D ƙwararrun mu don biyan kowane buƙatun. Anebon yana fatan samun tambayoyinku nan ba da jimawa ba kuma yana fatan samun damar yin aiki tare da ku a nan gaba. Barka da zuwa duba ƙungiyar Anebon.

Lokacin aikawa: Satumba-20-2023