Kayan Aikin Juyawa

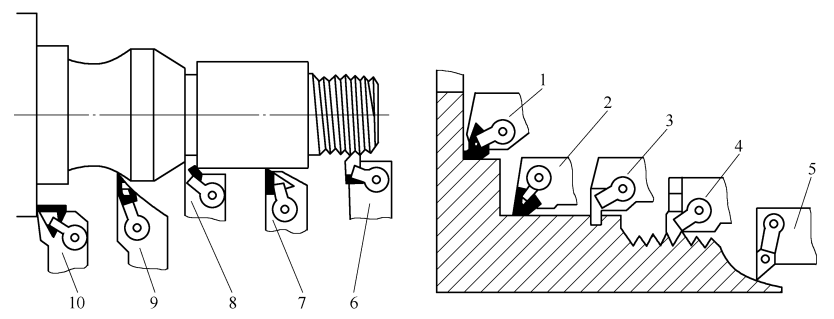

Mafi yawan kayan aiki a cikin yankan karfe shine kayan aiki na juyawa. Ana amfani da kayan aikin juyawa don yanke da'irori na waje, ramuka a tsakiya, zaren, tsagi, hakora, da sauran siffofi akan lathes. Ana nuna manyan nau'ikan sa a cikin hoto na 3-18.

Hoto 3-18 Manyan nau'ikan kayan aikin juyawa

1. 10-Kayan aikin juyawa na ƙarshe 2. 7-Da'irar waje ( kayan aikin juyawa ramin ciki) 3. 8 - Kayan aikin jujjuyawa 4. 6 - Kayan aikin jujjuya zaren 5. 9 - Kayan aikin juyawa

An rarraba kayan aikin jujjuya bisa tsarinsu zuwa ƙwaƙƙwaran juyi, juyi walda, jujjuyawar injin, da kayan aikin ƙididdiga. Kayan aikin jujjuyawa masu ƙididdigewa suna ƙara shahara saboda ƙarin amfani da su. Wannan sashe yana mai da hankali kan gabatar da ƙa'idodin ƙira da dabaru don ƙididdigewa da kayan aikin juya walda.

1. Kayan aikin walda

Kayan aikin juya walda an yi shi ne da wuka na takamaiman siffa da mariƙin da aka haɗa ta hanyar walda. Yawanci ana yin ruwan wukake daga nau'o'i daban-daban na kayan carbide. Kayan kayan aiki gabaɗaya karfe 45 ne kuma an kaifi don dacewa da takamaiman buƙatu yayin amfani. Ingantattun kayan aikin walda da amfani da su sun dogara ne akan matakin ruwa, ƙirar ruwa, sigogin kayan aiki na geometric da siffar da girman ramin. Ingancin niƙa, da sauransu. Ƙimar niƙa, da sauransu.

(1) Akwai fa'idodi da rashin amfani ga kayan aikin walda

Ana amfani da shi sosai saboda sauƙi, tsari mai sauƙi; babban kayan aiki mai ƙarfi; kuma mai kyau juriya na girgiza. Hakanan yana da illoli da yawa, gami da:

(1) Yanke aikin ruwan wurwuri ba shi da kyau. Za a rage aikin yankan ruwa bayan an yi masa walda a babban zafin jiki. Yawan zafin jiki da ake amfani da shi don walda da kaifi yana haifar da damuwa na ciki. Tun da madaidaicin tsawo na layin carbide shine rabin na kayan aikin kayan aiki, wannan na iya haifar da fashewa a cikin carbide.

(2) Ba a sake amfani da mariƙin kayan aiki ba. Ana barar da albarkatun kasa saboda ba za a iya sake amfani da abin riƙe kayan aiki ba.

(3) Lokacin taimako ya yi tsayi da yawa. Canjin kayan aiki da saitin yana ɗaukar lokaci mai yawa. Wannan bai dace da buƙatun injinan CNC ba, tsarin injina ta atomatik, ko kayan aikin injin atomatik.

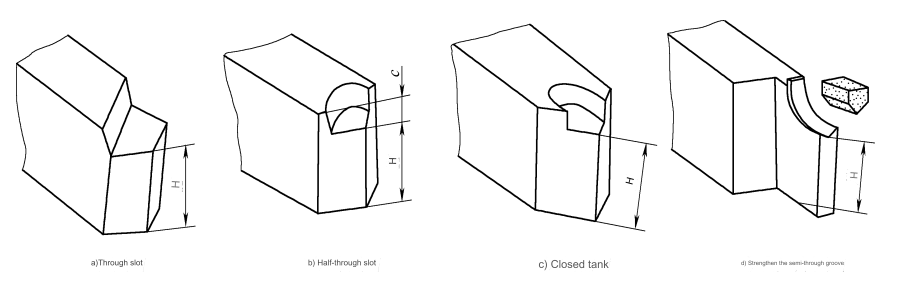

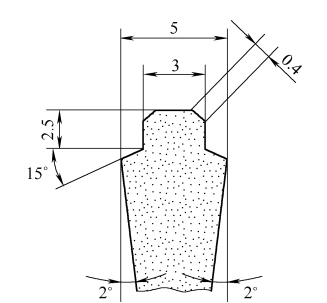

(2) Nau'in tsagi mai riƙe kayan aiki

Don kayan aikin juya walda, kayan aikin shank ya kamata a yi su gwargwadon siffar da girman ruwan wuka. Kayan kayan aiki na shank sun haɗa da ta hanyar tsagi, tsaka-tsakin tsaka-tsakin, rufaffiyar rufaffiyar, da kuma ƙarfafa tsaka-tsakin tsaka-tsakin. Kamar yadda aka nuna a hoto na 3-19.

Hoto na 3-19 Geometry mai riƙe da kayan aiki

Tsagi mai riƙe da kayan aiki dole ne ya cika waɗannan buƙatu don tabbatar da ingancin walda:

(1) Sarrafa kauri. (1) Sarrafa kauri na abin yanka.

(2) Sarrafa rata tsakanin ruwa da tsagi mai riƙe kayan aiki. Rata tsakanin ruwa da tsagi mai riƙe kayan aiki bai kamata ya zama babba ko ƙarami ba, yawanci 0.050.15mm. Haɗin arc ɗin ya kamata ya zama iri ɗaya kamar yadda zai yiwu kuma matsakaicin tazarar gida bai kamata ya wuce 0.3mm ba. In ba haka ba, ƙarfin walda zai shafi.

(3) Sarrafa ƙima-taurin kai na tsagi mai riƙe kayan aiki. Tsagi mai riƙe da kayan aiki yana da ƙarancin ƙasa na Ra=6.3mm. Ya kamata saman ruwa ya zama lebur da santsi. Kafin waldawa, ya kamata a tsaftace tsagi na mariƙin kayan aiki idan akwai mai. Don tsaftace saman wurin walda, zaka iya amfani da fashewar yashi ko barasa ko man fetur don goge shi.

Sarrafa tsayin ruwa. A cikin yanayi na al'ada, ruwan wukake da aka sanya a cikin tsagi mai riƙe kayan aiki ya kamata ya fito da 0.20.3mm don ba da damar yin kaifi. Ana iya yin tsagi mai riƙe kayan aiki ya fi tsayi da 0.20.3mm fiye da ruwan wukake. Bayan walda, jikin kayan aikin yana waldawa. Don kyakkyawan bayyanar, cire duk abin da ya wuce gona da iri.

(3) Tsarin brazing na ruwa

Ana amfani da solder mai ƙarfi don walda igiyoyin siminti na siminti (hard solder ne refractory ko brazing abu wanda yana da narkewar zafin jiki sama da 450degC). Ana ƙona mai siyar har zuwa yanayin narkakkar, wanda yawanci 3050degC sama da wurin narkewa. Juyin yana kare mai siyar daga shiga da yaduwa a saman na'urarkayan aikin injin. Hakanan yana ba da damar hulɗar mai siyar tare da ɓangaren welded. Aikin narkewa yana sa igiyar carbide ta dunkule cikin ramin.

Akwai dabarun dumama brazing da yawa, kamar waldar harshen wuta da walƙiya mai tsayi. Welding lamba na lantarki shine mafi kyawun hanyar dumama. Juriya a wurin haɗuwa tsakanin shingen jan karfe, kuma mai yankewa shine mafi girma, kuma a nan ne za a haifar da babban zafin jiki. Jikin mai yanka ya fara zama ja sannan kuma a canza zafi zuwa ruwa. Wannan yana sa ruwa ya yi zafi a hankali kuma a hankali ya tashi cikin zafin jiki. Hana tsagewa yana da mahimmanci.

Ruwan ba a "ƙonewa" ba saboda an kashe wutar lantarki da zarar kayan ya narke. An tabbatar da waldar hulɗar wutar lantarki don rage tsagewar ruwa da tarwatsawa. Brazing yana da sauƙi kuma barga, tare da inganci mai kyau. Tsarin brazing ɗin ba shi da inganci fiye da manyan walda masu yawa, kuma yana da wahala a goga kayan aikin tare da gefuna masu yawa.

Ingancin brazing yana shafar abubuwa da yawa. Ya kamata a zaɓi kayan brazing, juyi da hanyar dumama daidai. Don kayan aikin brazing na carbide, dole ne abu ya kasance yana da ma'aunin narkewa sama da zafin jiki na yankan. Abu ne mai kyau don yankan saboda yana iya kiyaye ƙarfin haɗin ruwan wuka yayin da yake riƙe da ruwa, daɗaɗɗen ruwa da ƙarancin zafi. Ana yawan amfani da kayan brazing masu zuwa lokacin brazing siminti-carbide ruwan wukake:

(1) The narkewa zafin jiki na tagulla zalla ko jan karfe-nickel gami (electrolytic) ne kamar 10001200degC. Yanayin aiki da aka yarda shine 700900degC. Ana iya amfani da wannan tare da kayan aikin da ke da nauyin aiki mai nauyi.

(2) Copper-zinc ko 105 # ƙarfe mai filler tare da zafin jiki na narkewa tsakanin 900920degC & 500600degC. Ya dace da kayan aiki na matsakaicin nauyi.

Matsakaicin narkewa na gami da azurfa-jan karfe shine 670820. Matsakaicin zafin aiki shine digiri 400. Koyaya, ya dace da kayan aikin jujjuya daidaitattun walda tare da ƙaramin cobalt ko babban carbide titanium.

Ingancin brazing yana tasiri sosai ta zaɓi da aikace-aikacen juzu'i. Ana amfani da juzu'i don cire oxides akan saman wani kayan aikin da za a yi brazed, haɓaka wettability da kare walda daga iskar shaka. Ana amfani da juzu'i biyu don murƙushe kayan aikin carbide: Dehydrated Borax Na2B4O2 ko Dehydrated Borax 25% (massfraction) + boric Acid 75% (massfraction). Matsakaicin zafin jiki ya bambanta daga 800 zuwa 1000 ° C. Borax na iya bushewa ta hanyar narkewar borax, sannan a murƙushe shi bayan sanyaya. Tara Lokacin brazing kayan aikin YG, dehydrated borax yawanci ya fi kyau. Kuna iya samun sakamako mai gamsarwa lokacin brazing kayan aikin YT ta amfani da dabara dehydrated borax (massfraction) 50% + boric (massfraction) 35% + dehydrated potassium (massfraction) fluoride (15%).

Bugu da kari na potassium fluoride zai inganta jika da ikon narkewar titanium carbide. Domin rage damuwa walda lokacin brazing high-titanium alloys (YT30 da YN05), ƙananan zafin jiki tsakanin 0.1 da 0.5mm yawanci ana amfani da su. A matsayin gasket diyya tsakanin ruwan wukake da masu riƙe kayan aiki, ana amfani da ƙarfe na carbon ko ƙarfe-nickel sau da yawa. Don rage damuwa na thermal, ya kamata a sanya ruwan wukake. Yawancin lokaci za a sanya kayan aikin juyawa a cikin tanderun da zafin jiki na 280 ° C. Sanya a cikin tanda na tsawon sa'o'i uku a digiri 320, sa'an nan kuma kwantar da hankali a hankali ko dai a cikin tanderun, ko a cikin asbestos ko bambaro ash foda.

(4) Inorganic bonding

Inorganic bonding yana amfani da maganin phosphoric da foda na jan ƙarfe na inorganic, waɗanda ke haɗa sunadarai, injiniyoyi, da kimiyyar lissafi don haɗa ruwan wukake. Haɗin inorganic yana da sauƙin amfani fiye da brazing kuma baya haifar da damuwa na ciki ko tsaga a cikin ruwa. Wannan hanya tana da amfani musamman ga kayan ruwa waɗanda ke da wahalar walda, kamar yumbu.

Halayen ayyuka da kuma lokuta masu amfani na inji

4. Zaɓin kusurwar ƙwanƙwasa gefe da yanke katako

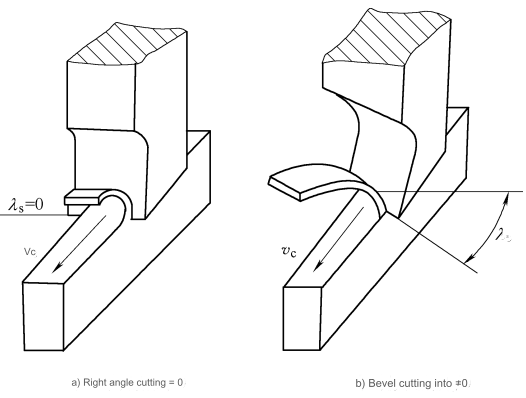

(1) Yanke bevel ra'ayi ne da ya daɗe.

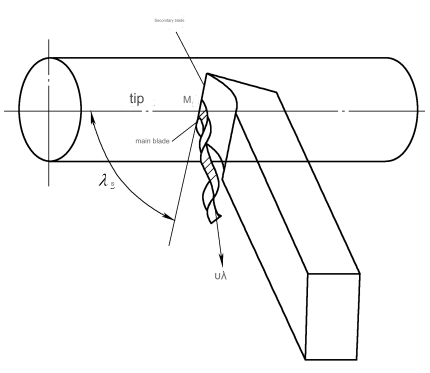

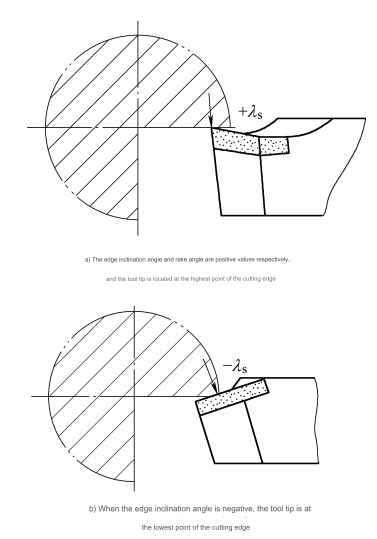

Yanke kusurwar dama yana yankan wanda yankan tsinken kayan aiki yayi daidai da jagorancin yankan motsi zai ɗauka. Yankewar bevel shine lokacin yankan kayan aikin ba daidai ba ne tare da jagorar motsin yankan. A matsayin dacewa, ana iya watsi da tasirin ciyarwar. Yanke wanda yake daidai da babban saurin motsi ko kusurwoyin karkata lss=0 ana ɗaukarsa azaman yankan kusurwar dama. Ana nuna wannan a hoto na 3-9. Yanke da ba daidai ba tare da babban saurin motsi ko kusurwoyin karkata lss0, ana kiransa yankan kusurwa. Misali, Kamar yadda aka nuna a Hoto na 3-9.b, lokacin yankan yankan guda daya ne kawai, ana kiran wannan da yankan kyauta. Yanke bevel ya fi kowa a yankan karfe.

Hoto 3-9 Yanke kusurwar dama da yanke katako

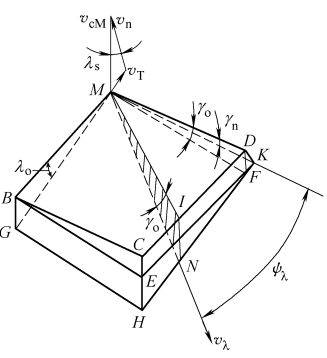

(2) Tasirin yankan bevel akan tsarin yanke

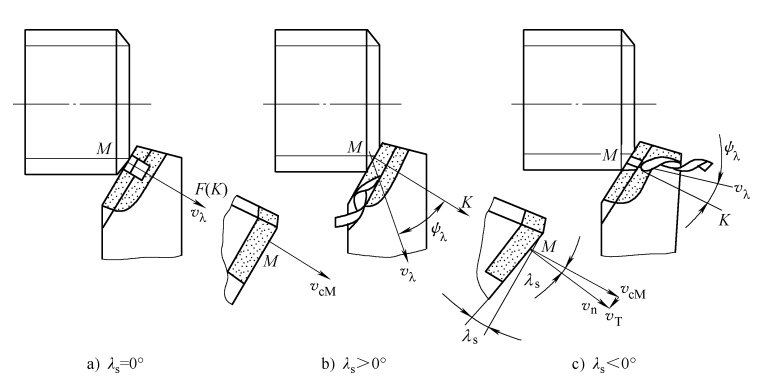

1. Tasiri kan jagorancin guntu fita

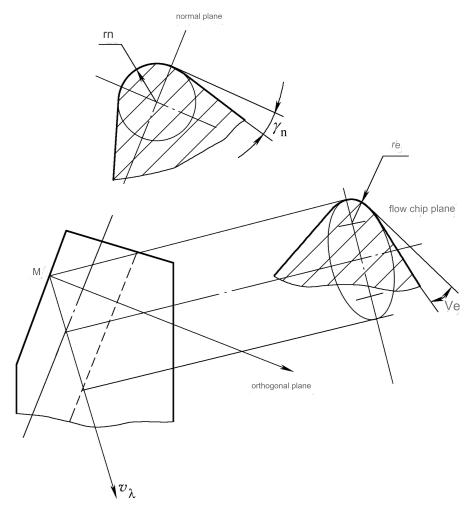

Hoto na 3-10 yana nuna cewa ana amfani da kayan aiki na juyawa na waje don kunna kayan aikin bututu. Lokacin da kawai babban gefen yanke ya shiga cikin yankan, wani barbashi M a cikin yankan Layer (zaton yana da tsayi ɗaya da tsakiyar ɓangaren) ya zama guntu a ƙarƙashin extrusion a gaban kayan aiki kuma yana gudana tare da gaba. Dangantakar da ke tsakanin jagorar kwararar guntu da kusurwar ƙwanƙwasa gefen ita ce ta shiga tsakani naúrar jiki MBCDFHGM tare da jirgin sama na orthogonal da yanke jirgin da jirage biyu daidai da su ta hanyar aya M.

Hoto 3-10 Tasirin λs akan jagorar guntu mai gudana

MBCD shine tushen jirgin sama a Hoto na 3-11. Lokacin da ls = 0, MBEF shine gaba a cikin Hoto 3-11, kuma MDF jirgin sama jirgin sama ne na orthogonal kuma na al'ada. Point M yanzu yana tsaye a gefen yankan. Lokacin da aka fitar da kwakwalwan kwamfuta, M wani yanki ne na saurin gudu tare da gefen yanke. MF yana daidai da daidai gwargwado zuwa yankan gefen. Kamar yadda aka nuna a cikin Hoto na 3-10a, a wannan lokacin, Chips ɗin suna lanƙwasa zuwa siffa mai kama da bazara ko kuma suna gudana cikin layi madaidaiciya. Idan ls yana da ƙima mai kyau to jirgin MGEF yana gaba kuma babban motsi na yanke saurin vcM bai dace da MG ba. The barbashi M guduncnc juya aka gyaravT dangane da kayan aiki a cikin jagorancin maki masu yankewa zuwa MG. Lokacin da maki M ya canza zuwa guntu wanda ke gudana a gaba kuma vT ya shafa shi saurin guntu vl zai karkata daga jirgin sama na al'ada MDK a kusurwar guntu na psl. Lokacin da ls yana da babban darajar, kwakwalwan kwamfuta za su gudana a cikin hanyar sarrafa saman.

Jirgin MIN, kamar yadda aka nuna a Figures 3-10b da 3-11, an san shi da kwararar guntu. Lokacin da ls yana da ƙima mara kyau, ɓangaren saurin vT a cikin hanyar yankan yana juyawa, yana nuna GM. Wannan yana haifar da kwakwalwan kwamfuta don bambanta daga jirgin sama na al'ada. Gudun yana cikin kishiyar hanya zuwa saman injin. Kamar yadda aka nuna a hoto na 3-10.c. Wannan tattaunawar shine kawai game da tasirin ls yayin yankan kyauta. Gudun filastik na karfe a tip na kayan aiki, ƙananan yankan baki, da tsagi na guntu duk za su yi tasiri a kan alkiblar fitar da kwakwalwan kwamfuta a lokacin ainihin aikin mashin ɗin na juya da'ira na waje. Hoto na 3-12 yana nuna bugun ramuka da rufaffiyar ramuka. Tasirin ƙwaƙƙwaran yankewa akan kwararar guntu. Lokacin danna zaren mara rami, ƙimar ls tana da inganci, amma lokacin buga ɗaya da rami, ƙima mara kyau ce.

Hoto 3-11 Madaidaicin yankan guntu jagorar kwarara

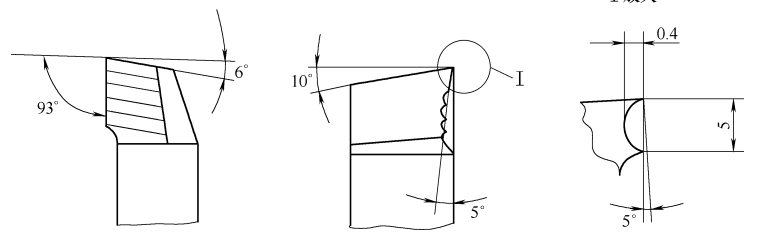

2. Ainihin rake da radius obtuse sun shafi

Lokacin da ls = 0, a cikin yankan kyauta, kusurwar rake a cikin jirgin sama na orthogonal da kuma guntu mai gudana suna da kusan daidai. Idan ls ba sifili ba, yana iya tasiri sosai ga kaifi da juriya lokacin da aka fitar da kwakwalwan kwamfuta. A cikin guntu kwarara jirgin sama, da tasiri rake kwana ge da yankan gefen obtuse radii re dole ne a auna. Hoto 3-13 yana kwatanta lissafi na jirgin sama na al'ada wanda ke wucewa ta wurin M-point na babban gefen tare da radius obtuse re na guntu kwarara jirgin sama. A cikin yanayin kaifi mai kaifi, jirgin sama na al'ada yana nuna arc da aka kafa ta radius obtuse rn. Koyaya, a cikin bayanin martabar guntu kwarara, yankan wani bangare ne na ellipse. Radius na curvature tare da doguwar axis shine ainihin madaidaicin radius obtuse re. Za'a iya ƙididdige madaidaicin dabara mai zuwa daga alkaluman alaƙar lissafi a cikin Figures 3-11 da 3-13.

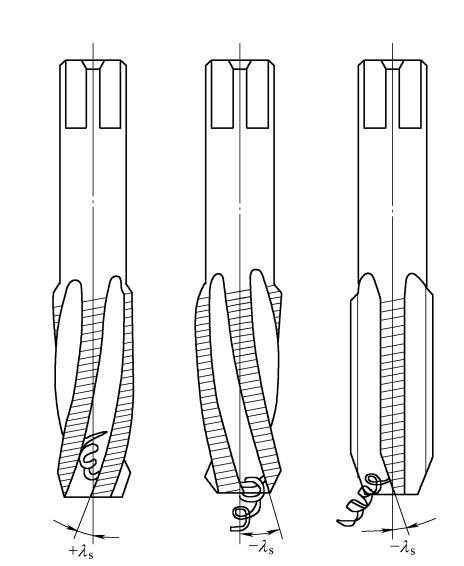

Tsarin da ke sama yana nuna cewa sake yana ƙaruwa yayin da cikakkiyar ƙimar ls ke ƙaruwa, yayin da ge ke raguwa. Idan ls=75deg, da gn=10deg tare da rn=0.020.15mm to ge zai iya zama babba kamar 70deg. re na iya zama ƙarami kamar 0.0039mm. Wannan yana sa ɓangarorin yankan ya zama mai kaifi sosai, kuma yana iya cimma ƙananan yankan (ap0.01mm) ta amfani da ɗan ƙaramin yankan baya. Hoto 3-14 yana nuna matsayi na yanke kayan aiki na waje lokacin da aka saita ls a 75deg. Babban da na biyu gefuna na kayan aiki an daidaita su a cikin layi madaidaiciya. Yanke gefen kayan aiki yana da kaifi sosai. Ba a gyara ɓangarorin yankewa yayin aiwatar da yankewa. Hakanan yana da tangent tare da saman cylindrical na waje. Shigarwa da daidaitawa suna da sauƙi. An yi amfani da kayan aiki cikin nasara don jujjuyawar sauri mai ƙarfi na ƙarfe na carbon. Hakanan za'a iya amfani dashi don gama sarrafa kayan injin mai wahala kamar ƙarfe mai ƙarfi.

Hoto 3-12 Tasirin kusurwar karkata gefe akan alkiblar guntu yayin bugun zaren

Hoto na 3-13 Kwatanta rn da regeometries

3. Tasirin juriya da ƙarfi na tip kayan aiki yana tasiri

Lokacin da ls ba shi da kyau, kamar yadda aka nuna a cikin Hoto 3-15b, tip ɗin kayan aiki zai zama mafi ƙasƙanci tare da yanke. Lokacin yankan gefuna a cikinsamfur sassama'anar farko na tasiri tare da kayan aiki shine kayan aiki (lokacin da tafi yana da ƙimar darajar) ko gaba (lokacin da ba shi da kyau) Wannan ba kawai yana kare da ƙarfafa tip ba, amma kuma yana taimakawa wajen rage haɗarin lalacewa. Yawancin kayan aikin tare da babban kusurwar rake suna amfani da karkata mara kyau. Suna iya haɓaka ƙarfin duka biyu kuma su rage tasiri akan tip ɗin kayan aiki. Ƙarfin baya na Fp yana ƙaruwa a wannan lokaci.

Hoto 3-14 Babban kayan aiki mai jujjuya ruwan wukake ba tare da tsayayyen tukwici ba

4. Yana shafar kwanciyar hankali na yanke ciki da waje.

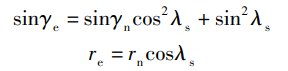

Lokacin da ls = 0, ƙwanƙwasa yana yanke cikin kuma daga cikin aikin kusan lokaci guda, ƙarfin yankewa ya canza ba zato ba tsammani, kuma tasirin yana da girma; lokacin da ls ba zero ba, raguwa a hankali yana yanke cikin kuma daga cikin aikin aiki, tasirin yana da ƙananan, kuma yanke ya fi sauƙi. Misali, manyan masu yankan niƙa na kusurwar helix da injina na ƙarshe suna da mafi girman yankan gefuna da yankan santsi fiye da tsofaffin masu yankan niƙa. Ana haɓaka haɓakar samarwa da sau 2 zuwa 4, kuma ƙimar ƙarancin ƙasa Ra na iya kaiwa ƙasa da 3.2 mm.

5. Yanke siffa

Siffar yankan kayan aiki yana ɗaya daga cikin ainihin abubuwan da ke cikin ma'auni mai ma'ana na geometric na kayan aiki. Canje-canje a cikin siffar ruwa na kayan aiki yana canza tsarin yanke. Abin da ake kira tsarin yankan yana nufin tsari da siffar da aka cire shingen karfe da za a sarrafa ta hanyar yanke. Yana rinjayar girman girman nauyin yankan, yanayin damuwa, rayuwar kayan aiki da ingancin kayan aiki. jira. Yawancin kayan aikin ci-gaba suna da alaƙa ta kut da kut da madaidaicin zaɓi na sifofin ruwa. Daga cikin kayan aikin ci-gaba masu amfani, ana iya taƙaita sifofin ruwa zuwa nau'ikan masu zuwa:

(1) Haɓaka siffar ruwan wuka na yankan gefen. Wannan nau'in nau'i na nau'i na musamman shine don ƙarfafa ƙarfin yankan, ƙara girman kusurwa, rage nauyin da ke kan tsawon naúrar yanke, da inganta yanayin zafi. Bugu da ƙari, da yawa siffofin tip kayan aiki da aka nuna a cikin Hoto 3-8, akwai kuma siffofi na baka (arc gefen juya kayan aiki, arc gefen hobbing fuska milling cutters, arc gefen drill bits, da dai sauransu). , da sauransu)) jira;

(2) Siffar gefen da ke rage saura wurin. Ana amfani da wannan siffa ta gefen gabaɗaya don kayan aikin gamawa, kamar manyan kayan aikin jujjuya abinci da masu yankan fuska tare da wipers, kayan aikin iyo kayan aiki masu ban sha'awa da kayan aiki na yau da kullun tare da wipers na silinda. Reamers, da dai sauransu;

Hoto 3-15 Tasirin kusurwar ƙwanƙwasa a kan tasirin tasiri lokacin yanke kayan aiki

(3) Siffar ruwan wukake wanda ke rarraba gefen yanki mai yankan kuma yana fitar da kwakwalwan kwamfuta a hankali. Siffar irin wannan nau'in siffar ruwa ita ce, tana raba babban yanki mai faɗi da sirara zuwa ƙunƙuntattun kwakwalwan kwamfuta masu yawa, wanda ba wai kawai yana ba da damar fitar da guntuwar ba da kyau, amma kuma yana ƙara ƙimar gaba. Ba da adadin kuma rage ikon yankan naúrar. Misali, idan aka kwatanta da na yau da kullun na yanke yankan baki, wukake masu yankan gefuna masu hawa biyu sun raba babban yankan zuwa sassa uku, kamar yadda aka nuna a hoto na 3-16. Hakanan an raba kwakwalwan kwamfuta zuwa sassa uku daidai da haka. An rage juzu'i tsakanin kwakwalwan kwamfuta da ganuwar biyu, wanda ke hana kullun daga toshewa kuma yana rage girman yankewa. Yayin da zurfin yanke ya karu, raguwar raguwa yana ƙaruwa, kuma tasirin ya fi kyau. A lokaci guda, an rage yawan zafin jiki na yanke kuma an inganta rayuwar kayan aiki. Akwai kayan aikin da yawa na irin wannan nau'in sifar ruwa, irin su masu yankan mataki, masu yankan ƙwanƙwasa ƙwanƙwasa, ƙwanƙolin ƙwanƙwasa gefuna, ƙwanƙwasa ƙwanƙwasa, masu yankan masarar haƙori, da injina na ƙarshen igiyar ruwa. Da kuma bututun da aka yanke da ƙafafu, da dai sauransu;

Hoto 3-16 wuka yankan gefu biyu

(4) Sauran siffofi na musamman. Siffofin ruwan wukake na musamman su ne sifofin ruwa waɗanda aka ƙera don saduwa da yanayin sarrafa sashi da halayen yankansa. Hoto na 3-17 yana kwatanta siffar gaban allo wanda aka yi amfani da shi don sarrafa gubar-tagulla. Babban ɓangarorin yankan wannan ruwa yana da siffa a cikin manyan baka masu girma uku. Kowane batu akan yankan gefen yana da kusurwar karkata wanda ke karuwa daga korau, zuwa sifili sannan zuwa tabbatacce. Wannan yana haifar da matsi da tarkace cikin kwakwalwan kwamfuta masu sifar ribbon.

Anebon alyways yana goyan bayan falsafar "Kasancewa No.1 a cikin babban inganci, kafe akan bashi da amana don haɓaka". Anebon zai ci gaba da yin hidimar baya da sabbin abubuwan da za su biyo baya daga gida da ƙasashen waje gabaɗayan zafafa don Rangwamen Rangwame 5 Axis Precision Custom Rapid Prototype5 axis cnc millingJuya Machining, A Anebon tare da babban inganci don farawa da matsayin taken mu, muna kera samfuran da aka yi gaba ɗaya a Japan, daga sayan kayan zuwa sarrafawa. Wannan yana ba abokan ciniki daga ko'ina cikin ƙasar damar amfani da su tare da kwanciyar hankali.

Ayyukan ƙirƙira na China, sabis na niƙa ƙarfe da sabis na samfur na sauri. Anebon yayi la'akari da "farashi masu ma'ana, ingantaccen lokacin samarwa da kyakkyawan sabis na tallace-tallace" a matsayin tsarin mu. Anebon yana fatan yin haɗin gwiwa tare da ƙarin abokan ciniki don haɓaka juna da fa'idodi. Muna maraba da masu sayayya don tuntuɓar mu.

Lokacin aikawa: Dec-14-2023