Me kuka sani game da tsarin jiyya na saman kayan a cikin injin CNC?

Domin CNC machining, surface jiyya shi ne tsarin aiki don inganta bayyanar kazalika da aiki da kuma tsawon da machined kayan. Mafi yawan hanyoyin da ake amfani da su don magance saman da ake amfani da su a cikin injinan CNC sun haɗa da lalata. Wannan hanya ta ƙunshi cire kaifi masu kaifi, bursu, ko duk wani abu da ya wuce gona da iri daga saman abin da aka kera. Deburring yana haɓaka ƙaya da amincin samfurin ƙarshe.

gogewa:Ana iya amfani da goge goge don sassauƙa saman abubuwan da ke haifar da bayyanar haske da haske. Yana haɓaka bayyanar abubuwa kuma yana rage juzu'i akan sassa.

Nika: Ana amfani da shi don kawar da lahani a saman ko samun daidaitattun haƙuri. Wannan ya ƙunshi yin amfani da dabaran niƙa don cire kayan aiki daga wani yanki.

Anodizing:Yanayi wani tsari ne na electrochemical wanda ke haifar da kariya mai kama da oxide akan saman kayan ƙarfe kamar aluminum. Yana haɓaka juriya ga lalata da kuma kayan kwalliya, taurin da.

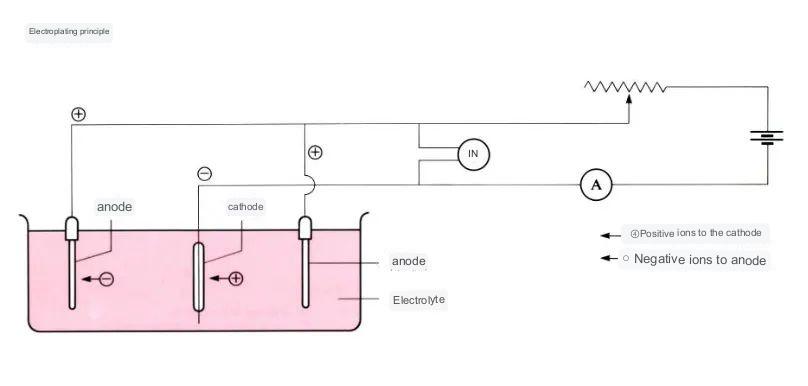

Electroplatingya haɗa da ɗora bakin bakin ƙarfe na ƙarfe a saman saman kayan. Yana inganta juriya ga lalata da kuma conductivity da kamanni.

Tufafi:Shafi na sama shine tsarin yin amfani da Layer anti-corrosion ko fenti a saman kayan. Yana iya ba da juriya ga lalata da juriya. Hakanan zai iya inganta kayan ado.

Maganin zafi:Wannan ya haɗa da fallasa wani abu zuwa matsanancin zafin jiki da sanyi mai sarrafawa don canza kayan injin su. Wannan tsari yana inganta dorewar kayan, taurinsa kuma yana ƙin lalacewa da lalacewa.

Waɗannan jiyya don saman suna iya haɓaka ingancin gabaɗaya, aiki da tsawon rayuwar abubuwan da aka ƙera CNC. Nau'in magani da kuka zaɓa don amfani ya dogara da kayan, aikace-aikacen da aka yi niyya, da sakamakon da ake so.

Maganin saman wani tsari ne don ƙirƙirar abin da ke sama da tushe wanda ke da sifofin sinadarai, na zahiri, da na inji waɗanda suka bambanta da na kayan tushe.

Makasudin jiyya na saman shine don gamsar da juriya ga lalacewa, lalata da sauran buƙatun da kayan. Dabarun da aka fi amfani da su akai-akai don magance saman sun haɗa da injin niƙa, jiyya na sinadarai a saman zafi da feshi a saman. Maganin saman shine tsarin tsaftace saman, share shi, lalata shi da kuma ragewa a waje na yanki. A yau, za mu tattauna hanya na jiyya na surface.

Wadanne fa'idodi na iya haifar da jiyya ta sama zuwa sassan mashin ɗin?

Hanyoyin maganin yankin saman na iya kawo fa'idodi da yawa zuwa gainji sassa, wanda ya ƙunshi: Ingantattun Aesthetics: Hanyoyin da ake amfani da su kamar su sprucing up, anodizing, plating da kuma gamawa na iya haɓaka fara'a na gani na kayan aikin injin. Yana iya ba da santsi, mai sheki ko na'urar da aka keɓance, yana inganta jimillar kamannin abu.

Ingantacciyar juriyar tsatsa: Yawancin hanyoyin kwantar da hankali, irin su anodizing, plating, da ƙarewa, suna haifar da shinge mai kariya a saman kayan. Wannan Layer yana aiki azaman cikas, yana ba da kariya ga ɓangaren daga haɗuwa da saitin lalata, don haka yana haɓaka juriyar lalata.

Ƙarfafa juriyar lalacewa: Magungunan saman sama kamar jiyya mai zafi ko ƙarewa na iya ƙara ƙarfin juriya na sassan injina. Waɗannan hanyoyin na iya haɓaka ƙarfi, tauri da kuma sturdiness na kayan, yana mai da su da yawa rigakafi ga shafa, abrasion kazalika da lalacewa. Haɓaka man shafawa da kuma rage shafa: Wasu jiyya na yanki, kamar goge-goge ko Layer tare da ƙarancin juzu'i, na iya rage juzu'i tsakanin abubuwan motsi. Wannan yana haifar da tsari mai santsi, yana rage lalacewa, kuma yana haɓaka jimillar abubuwan da aka kera.

Mafi kyawun juriya na sinadarai: Ta hanyar jiyya ta sama, ana iya haɓaka juriyar sinadarai na kayan aikin injin. Wannan yana da fa'ida musamman lokacin da abubuwan haɗin gwiwa suka haɗu da sinadarai masu haɗari ko mahadi waɗanda zasu iya rushe samfurin. Haƙuri da Haƙuri da Maɗaukakin Maɗaukaki: Jiyya na sama kamar niƙa ko taimakon goge goge sun sami juriya mai ƙarfi da kuma tabbatar da daidaito mafi girma a cikin sassan injina. Wannan yana da mahimmanci ga aikace-aikacen da ke buƙatar babban daidaito da kuma juriya mai ƙarfi.

Ingantattun mannewa da kuma Haɗin kai: Shirye-shiryen saman na iya ƙirƙirar wuri mai dacewa don adhesives, fenti ko wasu hanyoyin haɗin gwiwa. Wannan yana ba da damar samun ƙarin ƙarfi da kuma kyakkyawar alaƙa tsakanin abubuwa daban-daban, inganta amincin samfur. Gabaɗaya, matakan jiyya na saman suna taka muhimmiyar rawa wajen haɓaka fasalin, tsawon rai da kuma kamanninkayan aikin injin, yana sa su fi dacewa da aikace-aikacen da ake so da kuma inganta yawan su duka.

Hanyoyin jiyya na saman da aka saba amfani da su sune:

Vacuum electroplating, electroplating tsari, anodizing, electrolytic polishing, kushin bugu tsari, galvanizing tsari, foda shafi, ruwa canja wurin bugu, allo bugu, electrophoresis, da dai sauransu

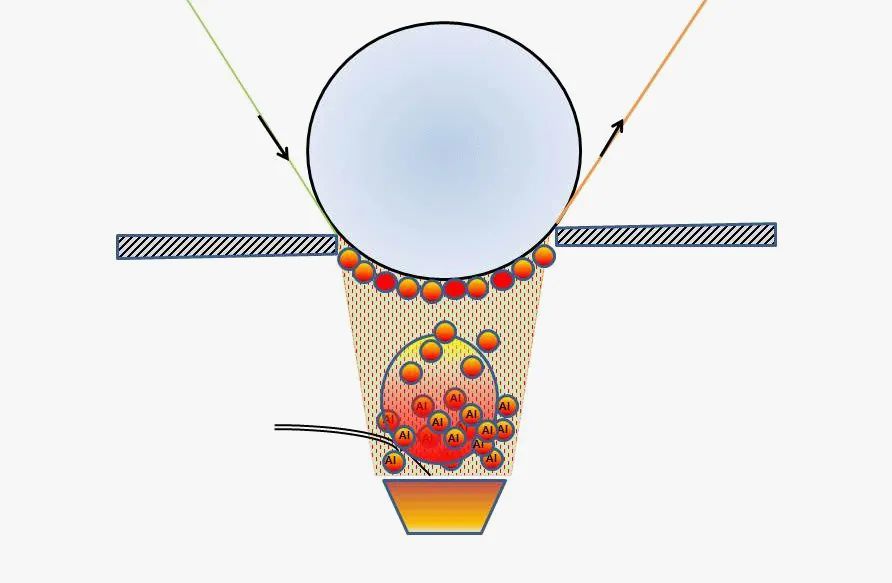

01. Vacuum plating

——Vacuum Metalizing ——

Za'a iya siffanta ƙulla ɓangarorin a matsayin tsarin jijiya ta jiki. A zahiri, ana shigar da iskar argon a cikin yanayi mara kyau, atom ɗin gas ɗin ya buge kayan da aka zaɓa, kuma kayan da aka yi niyya an raba su cikin ƙwayoyin cuta, waɗanda abubuwan da ke motsa jiki suna tsotse su don samar da nau'in nau'in nau'in nau'in kwaikwayi mai santsi. .

Abubuwan da ake buƙata:

1. Za'a iya shafa nau'ikan abubuwa iri-iri, ciki har da ƙarfe mai wuya da robobi masu laushi, yumbu, kayan haɗin gwiwa da gilashi. Hanyar da aka fi amfani da ita ta lantarki ita ce aluminum, wanda ya biyo bayan tagulla da azurfa.

2. Kayayyakin halitta ba su dace da ɗimbin tururi ba saboda gaskiyar cewa danshi a cikin kayan halitta na iya canza yanayin injin.

Kudin aikin shine tsadar tururin kayan da za a fesa a sauke, a loda sannan a mayar da shi a fesa, wanda ke nufin kudin aiki yana da tsada, duk da haka ya danganta ne da girma da hadadden kayan aikin.

Tasirin muhalli: Vacuum electroplating yana haifar da ƙarancin tasirin muhalli, wanda yayi kama da tasirin tsari akan yanayin da ke kewaye.

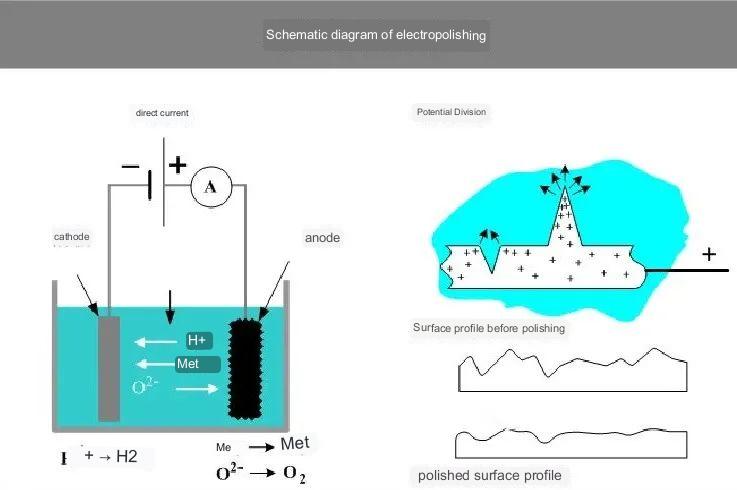

02. Electropolishing

—— Electropolishing ——

Electropolishing yana nufin hanyar electrochemical ta hanyar atom a cikincnc juya sassawanda aka nutsar a cikin na'urar lantarki ana canza su zuwa ions sannan a cire su daga saman ta hanyar cajin wutar lantarki, wanda ke haifar da kawar da buroshi masu kyau da kuma kara haske a saman.

Abubuwan da ake buƙata:

1. Yawancin karafa ana goge su ta hanyar lantarki gami da gogewar saman da bakin karfen da aka yi amfani da shi akai-akai (musamman tare da austenitic bakin sa).

2. Daban-daban kayan ba su iya zama electropolished lokaci guda ko ma a cikin guda sauran ƙarfi ga electrolysis.

Farashin tsarin: Gabaɗayan tsarin gyaran gyare-gyaren lantarki kusan gaba ɗaya ne mai sarrafa kansa, ma'ana farashin aiki yayi ƙasa sosai. Tasiri akan muhalli: Electrolytic polishing yana amfani da sinadarai marasa tasiri. Duk tsarin yana buƙatar ƙaramin adadin ruwa kawai, kuma yana da sauƙin amfani. Bugu da ƙari, yana iya haɓaka kaddarorin bakin karfe da kuma jinkirta lalata bakin karfe.

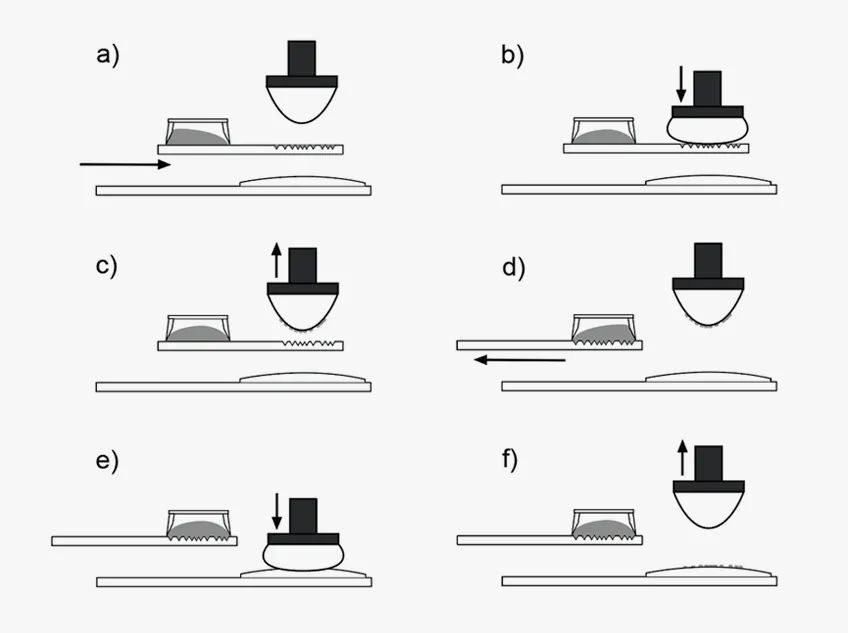

03. Tsarin buga kushin

——Pad Printing——

Ikon buga hotuna, rubutu da zane-zane akan saman abubuwa masu siffa ba bisa ka'ida ba yana zama muhimmin al'amari na bugu na musamman.

Abubuwan da ake buƙata:

Buga kushin wani zaɓi ne mai yuwuwa akan kusan kowane abu, ban da kayan da suka fi karyewa kamar gashin silicone kamar PTFE.

Farashin tsari Ƙananan farashin ƙira da ƙananan farashin aiki.

Tasirin muhalli: Kamar yadda wannan tsari ya keɓe ga tawada masu narkewa (waɗanda suka gurɓace da sinadarai masu cutarwa) kuma yana da tasirin muhalli mai mahimmanci.

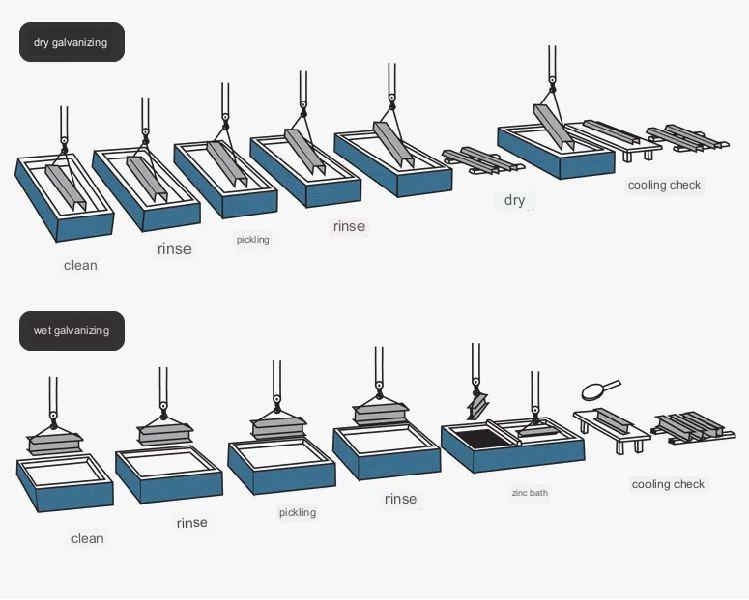

04. Tsarin Galvanizing

—— Galvanizing ——

Fasaha don kula da saman da ke lulluɓe tuffa mai ɗorewa a saman abubuwan gami da aka yi da ƙarfe don ƙayatarwa da fa'idodin tsatsa. Tushen zinc akan saman yana aiki azaman kariyar kariya ta lantarki wanda ke hana lalata ƙarfe. Hanyoyi guda biyu da aka fi amfani da su sune galvanizing mai zafi da galvanized.

Abubuwan da ake buƙata:

Saboda galvanizing ya dogara da haɗin gwiwar ƙarfe wannan tsari ya dace da maganin saman kan ƙarfe da ƙarfe.

Cost na tsari: Babu mold kudin, short sake zagayowar ko matsakaici aiki kudin, tun da ingancin da surface a kan workpiece aka fi mayar da m da surface jiyya yi da hannu kafin galvanizing.

Tasirin muhalli: Kamar yadda tsarin galvanizing zai iya ƙara tsawon rayuwar sassan karfe tsakanin shekaru 40 zuwa 100 kuma yana hana lalata da tsatsa da zai iya faruwa a kan shi, tsarin zai iya yin tasiri ga kare muhalli. Bugu da ƙari kuma za a iya mayar da aikin da aka yi amfani da shi zuwa tankin zinc da zarar lokacin amfani da shi ya ƙare kuma ci gaba da amfani da zinc a cikin ruwa ba ya haifar da sharar jiki ko sinadarai.

05. Electroplating tsari

—— Electrolating ——

Hanyar hašawa wani bakin ciki Layer na karfe fim zuwa saman aka gyara ta hanyar electrolysis, domin tasha karfe hadawan abu da iskar shaka, inganta lalacewa juriya da conductivity na haske tunani lalata juriya, da kuma inganta bayyanar. Za'a iya sanyawa na waje na tsabar tsabar kudi da yawa. .

Abubuwan da ake buƙata:

1. Ƙarfe da yawa ana sanya wuta. Duk da haka, daban-daban karafa zo da daban-daban matakan tsarki da plating tasiri. Shahararru daga cikinsu sune kamar haka: tin da chromium, azurfa, nickel, da rhodium.

2. Mafi mashahuri abu don gudanar da electroplating shine ABS. ABS.

3. Kada a rika amfani da karfen nickel wajen sanya electroplated kayayyakin da suka hadu da fata saboda yana da ban haushi da cutarwa ga fata.

Kudin tsari: Babu farashin ƙira, duk da haka ana buƙatar kayan aiki don amintar sassan farashin lokaci ya dogara ne akan yanayin zafi da nau'in ƙarfe ko ƙimar aiki (matsakaicin matsakaici) ya dogara da takamaiman nau'ikan abubuwan plating, kamar kayan ado da kayan ado. kayan azurfa, wanda ke buƙatar babban matakin ƙwarewa. ƙwararrun ma'aikata ne ke sarrafa shi saboda yawan buƙatu ta fuskar bayyanar da tsawon rai.

Tasirin muhalli na electroating: An yi amfani da babban adadin sinadarai masu guba waɗanda ke aiki a cikin tsari na zaɓaɓɓu wanda shine dalilin da yasa yasa yasa yasa yasa mahimmanci don rage tasirin muhalli.

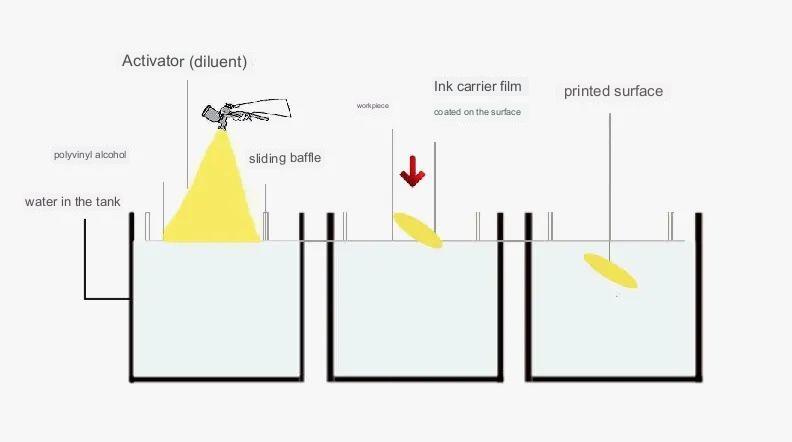

06. Buga canja wurin ruwa

—— Buga Canja wurin Hydro ——

Dabaru ce don buga ƙirar launi akan takardar canja wuri saman samfurin mai girma uku ta amfani da ruwan matsi. Kamar yadda buƙatun mutane na tattara kayayyaki da kayan ado na sama, amfani da buƙatun buƙatun yana ƙara yaɗuwa.

Abubuwan da ake buƙata:

Duk nau'ikan kayan aiki masu wuya sun dace da buguwar canja wurin ruwa kuma kayan da suka dace da fesa dole ne su dace da bugu da ruwa. Shahararru sune sassa na allura da kuma abubuwan ƙarfe.

Farashin tsari: Babu farashin da ke da alaƙa, duk da haka samfuran da yawa dole ne a canja su zuwa ruwa a lokaci guda ta amfani da kayan aiki. jimlar kudin bai wuce adadin lokaci a kowane zagaye ba.

Tasirin muhalli: Idan aka kwatanta da fesa kan samfuran buguwar canja wurin ruwa ya fi dacewa da fentin bugu wanda ke rage yuwuwar yabo da sharar gida.

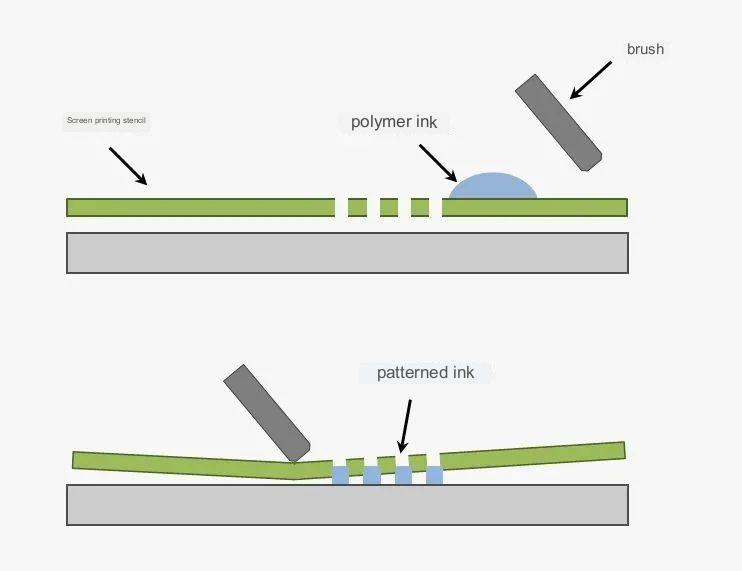

07. Buga allo

—— Buga allo ——

Ta hanyar extrusion na scraper, tawada ana canja shi zuwa saman ta hanyar raga kuma ya samar da ainihin hoton da aka buga a farkon. Firintocin allo suna da sauƙin amfani, kuma masu sauƙin bugawa da yin faranti, tare da ƙarancin farashi da ingantaccen sassauci.

Kayayyakin bugawa da aka saba amfani da su sun hada da fosta na zanen mai kala, katunan kasuwanci, fastoci masu daure fuska, alamun kayayyaki, da rina da bugu.

Abubuwan da ake buƙata:

Kusan kowane abu ana iya buga allo, gami da ƙarfe, filastik, yumbun takarda, gilashi da ƙari.

Kudin tsarin Kuɗin ƙirar yana da ƙarancin ƙima, amma har yanzu ya dogara da adadin launuka da aka yi amfani da su, tunda kowane launi dole ne a ƙirƙira shi da kansa. Kudaden aiki na da tsada sosai, musamman a yanayin buga launi da yawa.

Tasirin Muhalli: Buga allo tare da tawada masu launin haske ba su da wani mummunan tasiri a kan muhalli, duk da haka tawada da aka yi da PVC da formaldehyde sune mahadi masu guba, kuma suna buƙatar sake yin amfani da su sannan a zubar da su a lokacin da ya dace don dakatar da gurɓataccen ruwa. .

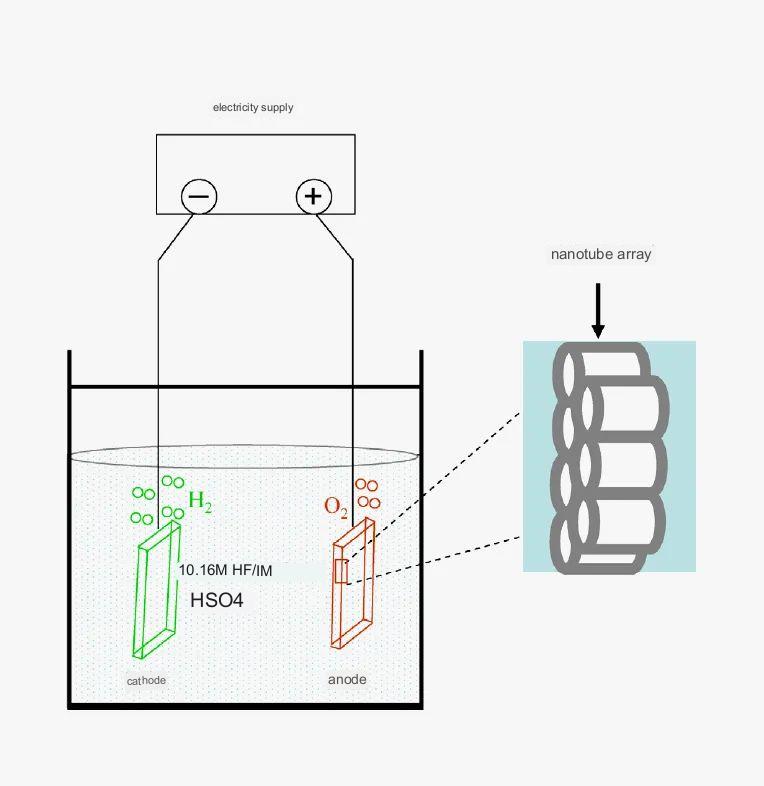

08. Anodizing

--Anodic Oxidation --

A anodic hadawan abu da iskar shaka tsari ga aluminum da farko dogara ne a kan electrochemical ra'ayi don ƙirƙirar wani tushe bakin ciki Layer hada da Al2O3 (aluminum oxide) fim a kan aluminum kazalika da aluminum gami. Oxide yana da halaye daban-daban kamar kariya daga lalata, ado, rufi da juriya ga lalacewa.

Abubuwan da ake buƙata:

Aluminum, aluminum gami da sauran kayayyakin aluminum

Kudin tsari: A cikin tsarin samar da amfani da wutar lantarki da ruwa yana da yawa, musamman a lokacin aiwatar da iskar oxygen. Yawan makamashin da injina ke amfani da shi yana buƙatar ci gaba da sanyaya shi da ruwan gudu. Amfanin wutar lantarki a kowace tonne yawanci yana kusan digiri 1000.

Tasirin muhalli: Anodizing ba ya bambanta dangane da ingancin makamashi. Duk da haka, a kan aiwatar da samar da electrolysis na aluminum da anode dauki yana haifar da iskar gas da ke da illa mai cutarwa akan Layer Ozone na yanayi.

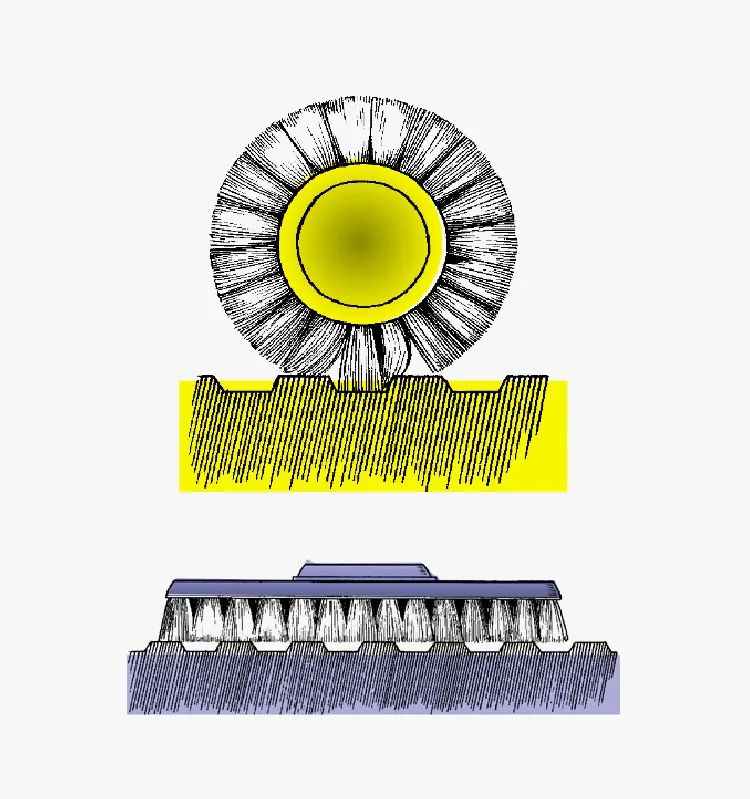

09. Ƙarfe zane

—- Karfe Waya ——

Hanya ce ta magance yanayin da ke haifar da layi a saman saman aikin ta hanyar niƙa abu don samun tasiri mai ban sha'awa. Dangane da nau'ikan sifofi daban-daban bayan kwatancin na USB, ana iya raba shi zuwa: madaidaicin zanen kebul, zanen na USB mara kyau, corrugated, da jujjuyawa.

Abubuwan da suka dace: Kusan duk kayan ƙarfe na iya yin amfani da tsarin zanen igiyar ƙarfe.

Kudaden tsari: Hanyar hanya tana da sauƙi, na'urori masu sauƙi ne, kayan amfani da kayan abu kaɗan ne, an rage farashin daidai, kuma fa'idar kuɗi yana da yawa.

Tasirin muhalli: samfuran ƙarfe mai tsabta, babu fenti ko kowane nau'in kayan sinadarai a saman, digiri 600 mai tsayi mai tsayi ba ya narke, baya haifar da iskar gas mai guba, ya sadu da tsaro na wuta gami da bukatun kare muhalli.

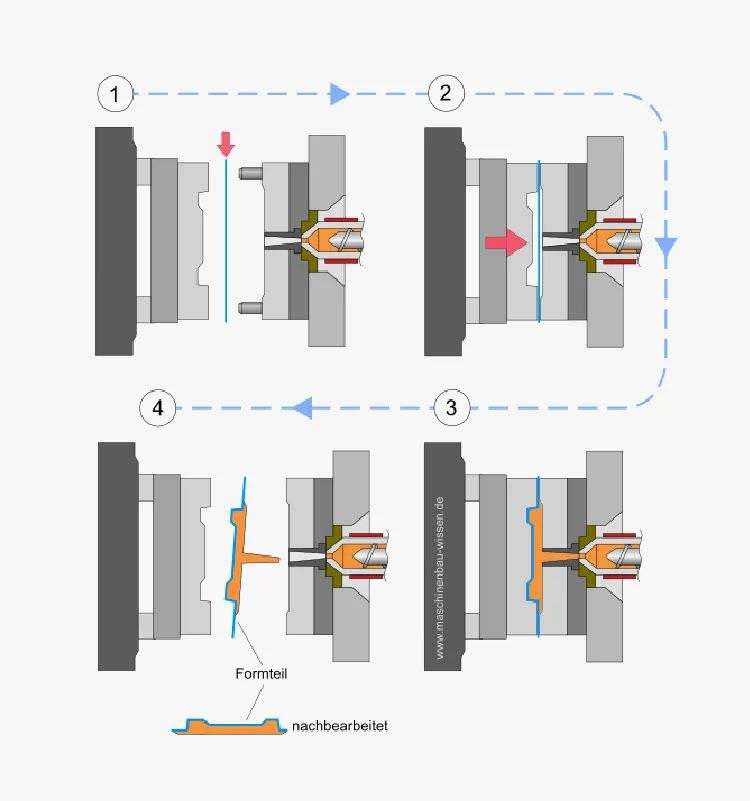

10. In-mold ado

-- In-Mold Decoration-IMD ——

Dabarar gyare-gyare ce wacce ke sanya diaphragm ɗin da aka buga daidai daidai a cikin ƙirar ƙarfe da mildew, yana sanya guduro don yin gyare-gyare daidai cikin ƙirar ƙarfe da mildew kamar yadda ya haɗu da diaphragm, kuma ya sanya diaphragm ɗin da aka buga tare da ƙirar ƙira. resin hade kuma an daidaita shi daidai cikin samfurin da aka gama.

Samfurin da ya dace: yanki na filastik

Tace farashin: kawai buƙatar buɗe tarin mold da mildews, wanda zai iya rage kashe kuɗi da kuma sa'o'in mutum-mutumi, samarwa ta atomatik, ingantaccen tsarin masana'anta, tsarin gyare-gyaren allura na lokaci ɗaya, da samun gyare-gyare da kayan ado a lokaci guda.

Tasirin Muhalli: Wannan fasaha ta zamani ba ta dace da muhalli ba kuma tana da alaƙa da muhalli, tana hana gurɓacewar da zanen al'ada ke haifar da shi da kuma wutar lantarki.

Amfanin Anebon shine rage caji, ƙungiyar samun kuɗi mai ƙarfi, ƙwararrun QC, masana'antu masu ƙarfi, sabis masu inganci don cnc machining sassan aluminum yin sabis da cnc machining juya sassan yin sabis. Anebon ya kafa maƙasudi a ci gaba na tsarin ƙirƙira, ƙirƙira gudanarwa, ƙwararrun ƙididdigewa da haɓaka sassa, ba da cikakkiyar wasa don fa'idodin gabaɗaya, kuma koyaushe yana yin haɓaka don tallafawa mafi kyau.

Anebon New Product China Kulle-Rami Processing Machine da Aluminum Window Kulle Hole Processing Machine, Anebon da cikakken kayan samar line, hada line, ingancin kula da tsarin, da kuma mafi muhimmanci, yanzu Anebon da yawa hažžožin fasahar da gogaggen fasaha & samar da tawagar, gogaggen tallace-tallace sabis. tawagar. Tare da duk fa'idodin mutane, mun kasance za mu ƙirƙira "tabbatacciyar alamar kasa da kasa ta nailan monofilaments", da kuma yada samfuranmu zuwa kowane lungu na duniya. Mun ci gaba da motsawa kuma muna ƙoƙarin yin iya ƙoƙarinmu don hidimar abokan cinikin Anebon.

Lokacin aikawa: Jul-29-2023