Asalin ra'ayi na hakowa

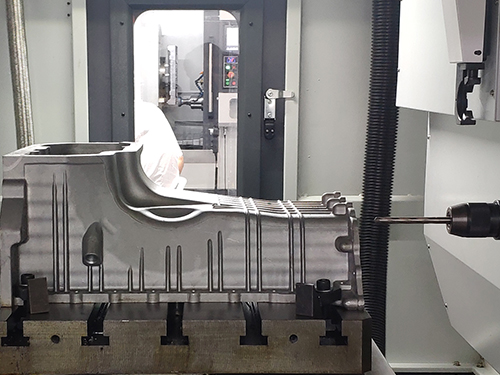

A ƙarƙashin yanayi na al'ada, hakowa yana nufin hanyar sarrafawa inda rawar soja ke yin ramuka a nunin samfurin. Gabaɗaya magana, lokacin da ake haƙa samfur akan injin haƙowa, ɗigon ya kamata ya kammala motsi biyu lokaci guda:CNC machining part

① Babban motsi, wato, motsi na juyawa na rawar motsa jiki a kusa da axis (yanke motsi);

② Motsi na biyu, wato, motsi na linzamin kwamfuta na rawar jiki zuwa aikin aikin tare da axis (motsin ciyarwa).

Lokacin da ake hakowa, saboda kurakuran da ke cikin tsarin na'urar, zai bar alamun a kan sassan da aka sarrafa na samfurin kuma yana shafar ingancin sarrafa kayan aikin. Daidaiton sarrafawa gabaɗaya yana ƙasa da IT10, kuma ƙarancin saman yana kusan Ra12.5μm, wanda ke cikin nau'in sarrafa ƙazamin.

Tsarin aikin hakowa

A jadada

Kafin hakowa, fara fahimtar buƙatun zane. Dangane da ainihin buƙatun hakowa, yi amfani da kayan aiki don zana tsakiyar layin rami. Dole ne layin tsakiya ya kasance a bayyane kuma daidai, kuma mafi ƙaranci shine mafi kyau. Bayan an zana layin, yi amfani da ma'auni na vernier ko mai mulki na karfe. Dauki awo.sashi na inji

Duba murabba'i ko duba da'irar

Bayan an zana layin kuma an wuce binciken, sai a zana grid na dubawa ko da'irar dubawa tare da tsakiyar layin rami a matsayin tsakiyar siminti a matsayin layin dubawa don hakowa na gwaji, ta yadda za a iya dubawa da gyara hanyar hakowa. a lokacin hakowa.

Tabbatarwa

Bayan yin alama daidai filin rajistan ko da'irar, yakamata ku tabbatar da ido a hankali. Yi ɗan ƙaramin tabo da farko, sannan a auna sau da yawa a wurare daban-daban na tsakiyar layin giciye don ganin ko da gaske naushin yana bugun mahadar tsakiyar layin, sannan a buga naushin zuwa dama, zagaye, da kuma zagaye. babba don yin daidai. Wuka a tsakiya.

Matsawa

Yi amfani da rag don tsaftace tebur na inji, daɗaɗɗen daɗaɗɗen kayan aiki, da farfajiyar aikin aikin, sa'an nan kuma matsa kayan aikin. Maƙerin yana da lebur kuma abin dogaro kamar yadda ake buƙata, kuma yana dacewa don tambaya da aunawa a kowane lokaci. Wajibi ne a kula da hanyar clamping na kayan aiki don hana aikin aikin daga lalacewa saboda kullun.

Gwajin rawar jiki

Gwajin hakowa ya zama dole kafin hakowa na yau da kullun: ɗigon rawar yana daidaitawa tare da tsakiyar ramin don haƙa rami mara zurfi, sannan a duba a gani ko rami mara zurfi yana cikin madaidaicin daidaitawa, kuma ana buƙatar ci gaba da gyara don sanya rami mara zurfi coaxial. tare da da'irar dubawa. Idan cin zarafi ya yi ƙanƙanta, zaku iya tilasta ma'aunin aikin don matsawa a gaban gaba na cin zarafi yayin tafiya don isa ga karatun a hankali.

Yin hakowa

Hakowa da injina gabaɗaya ya dogara ne akan aikin ciyarwar da hannu. Lokacin da ake buƙatar daidaiton azimuth na hakowar gwajin, ana iya aiwatar da hakowa. A lokacin ciyarwar da hannu, ƙarfin ciyarwar bai kamata ya sa rawar jiki ta lanƙwasa ba kuma ta guje wa ramin ramin karkata.cnc juya part

Ingantacciyar hanyar hakowa

Ƙaddamar da rawar soja shine farkon komai

Kafin hakowa, zaɓi abin da ya dace don kaifi. Ƙwararren rawar sojan da aka kayyade yana kula da madaidaiciyar kusurwar koli, kusurwar taimako da kusurwar gefuna na chisel, tsayin manyan gefuna guda biyu yana da lebur da daidaitawa zuwa tsakiyar layin rawar rawar sojan, kuma manyan bangarorin biyu suna santsi, domin sauƙaƙe tsakiya da rage girman bangon ramin , Ƙaƙwalwar ƙwanƙwasa da babban yanki ya kamata kuma ya zama ƙasa mai kyau (zai fi dacewa da ƙasa mai laushi a kan grinder da farko, sa'an nan kuma niƙa mai kyau a kan dutse mai).

Daidaitaccen alama shine tushe

Lokacin amfani da mai tsayi mai tsayi don zana layi daidai, abu na farko da za a yi shine tabbatar da daidaiton daidaitattun. Lokacin yin rubutun, sanya kusurwar allurar rubutun da kuma jirgin saman rubutun aikin ya zama kusurwar 40 zuwa 60 digiri (tare da jagorancin rubutun), don haka layin da aka zana ya bayyana kuma har ma.

Kula da zaɓin jirgin saman datum don yin alama, dole ne a sarrafa jirgin datum daidai, kuma dole ne a tabbatar da kwanciyar hankali na kansa da madaidaicin saman da ke kusa. Bayan an zana layin ƙetare na rami, don tabbatar da daidaitawa cikin sauƙi lokacin da ake hakowa, yi amfani da nau'in tsakiya don fitar da tsakiyar tsakiya a kan giciye (yana buƙatar alamar nau'in ya zama ƙarami kuma shugabanci ya zama daidai).

Matsa daidai shine mabuɗin

Gabaɗaya, don ramuka tare da diamita na ƙasa da 6mm, idan daidaito bai yi girma ba, yi amfani da filan hannu don matse kayan aikin don hakowa; ga ramukan 6 zuwa 10mm, idan workpiece ne na yau da kullun kuma har ma, ana iya amfani da filan hanci mai lebur don riƙe kayan aikin, amma aikin aikin ya kamata a ɗaure shi saman yana tsaye da igiya na injin hakowa. Lokacin hako rami tare da diamita mafi girma, dole ne a gyara maƙallan hanci mai lebur tare da farantin latsawa; don manyan workpieces tare da rami diamita na 10mm ko fiye, da latsa farantin clamping hanya da ake amfani da rawar soja rami.

Madaidaicin bincike shine mabuɗin

Bayan aikin da aka clamped, kada ku yi gaggawar sauke rawar sojan, kuma da farko yi jeri.

Daidaitawa yana da daidaitawa a tsaye da daidaitawa. Abin da ake kira a tsaye alignment yana nufin daidaitawa kafin a ƙaddamar da injin hakowa, don haka layin tsakiyar na'ura mai hakowa da layin giciye na workpiece suna daidaitawa. Wannan hanya tana da aminci kuma mai dacewa ga masu farawa da sauƙin fahimta, amma saboda ba'a la'akari da jujjuyawar injin hakowa, alal misali Kuma sauran abubuwan da ba su da tabbas, daidaiton hakowa ya ragu. Ana yin bincike mai ƙarfi bayan an ƙaddamar da injin hakowa. A lokacin daidaitawa, ana la'akari da wasu abubuwan da ba su da tabbas, kuma daidaito yana da girma.

Dubawa a hankali yana da mahimmanci

Ganowa zai iya gano daidai kuma a kan lokaci don gano daidaiton ramin don a iya ɗaukar matakan da suka dace don ramawa.

Don ramukan da ke da madaidaicin hakowa, gabaɗaya muna amfani da hakowa, reaming, da dabarun sarrafa reaming. Bayan hako ƙaramin rami a mataki na farko, yi amfani da caliper don gano kuskuren kuskure daga tsakiyar rami na ƙasa zuwa jirgin sama, kuma ƙididdige matsayi na rami na ƙasa da cibiyar da ta dace bayan ainihin ma'auni. Idan kuskuren bai fi 0.10mm girma ba, ana iya sake gyara shi da kyau ƙara saman kusurwar rawar rawar jiki, raunana tasirin tsakiya ta atomatik, da kyau tura kayan aikin a cikin ingantacciyar hanya, kuma a hankali ƙara diamita na tip ɗin rawar soja don ramawa. . Idan adadin kuskuren ya fi 0.10mm, zaku iya amfani da fayilolin zagaye daban-daban don datsa bangon gefen biyu na ramin ƙasa, kuma ɓangaren trimming ya kamata a haɗa shi tare da sassaucin canjin ramin ƙasa.

We are a reliable supplier and professional in CNC Machining service. If you need our assistance please contact me at info@anebon.com.

Anebon Metal Products Limited na iya samar da CNC Machining, Die Casting, Sheet Metal Fabrication sabis, da fatan za a iya tuntuɓar mu.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Lokacin aikawa: Maris-02-2021