Nawa kuka sani game da hanyar yanke zaren karfe?

Yanke ƙarfe don zaren yawanci ya ƙunshi matakai kamar tapping, zaren niƙa, da zaren wuri ɗaya. Ana amfani da waɗannan hanyoyin da yawa wajen kera don ƙirƙirar zaren ciki ko na waje akan abubuwan ƙarfe.

Taɓa wani tsari ne inda ake amfani da kayan aikin famfo don yanke zaren cikin ramukan da aka riga aka haƙa. An fi amfani dashi don ƙirƙirar zaren ciki. Milling zaren, a gefe guda, yana amfani da kayan aiki mai juyawa tare da hakora da yawa don yanke bayanan zaren a hankali. Ana amfani da wannan hanyar sau da yawa don zaren ciki da na waje.

Zaren maƙasudi ɗaya ya haɗa da yin amfani da kayan aiki mai yankewa tare da yanki guda ɗaya don yanke zaren akan kayan aiki. Ana amfani da wannan hanyar sau da yawa a cikin lathes ko na'ura mai juyayi don ƙirƙirar ainihin zaren.

Zaɓin hanyar ya dogara da dalilai kamar nau'in kayan da aka zare, bayanin martabar zaren da ake so, daidaiton da ake buƙata, da ƙarar samarwa. Ana iya amfani da kayan aiki daban-daban, inji, da dabaru don aikace-aikace daban-daban da buƙatun masana'antu.

1. Muhimmiyar ilimin asali na sarrafa zaren

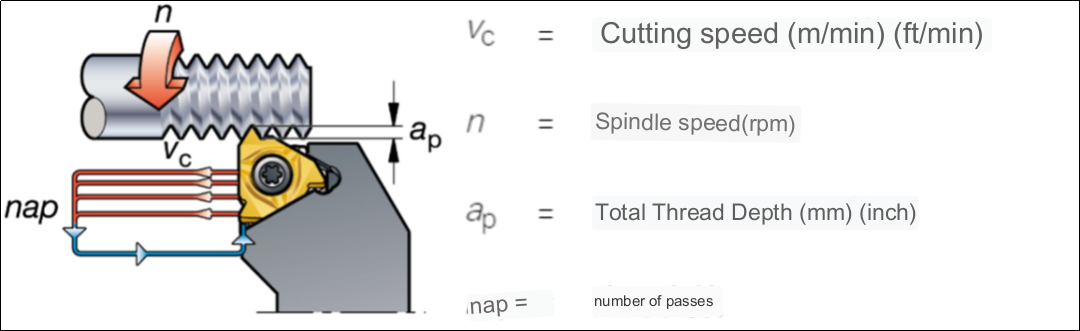

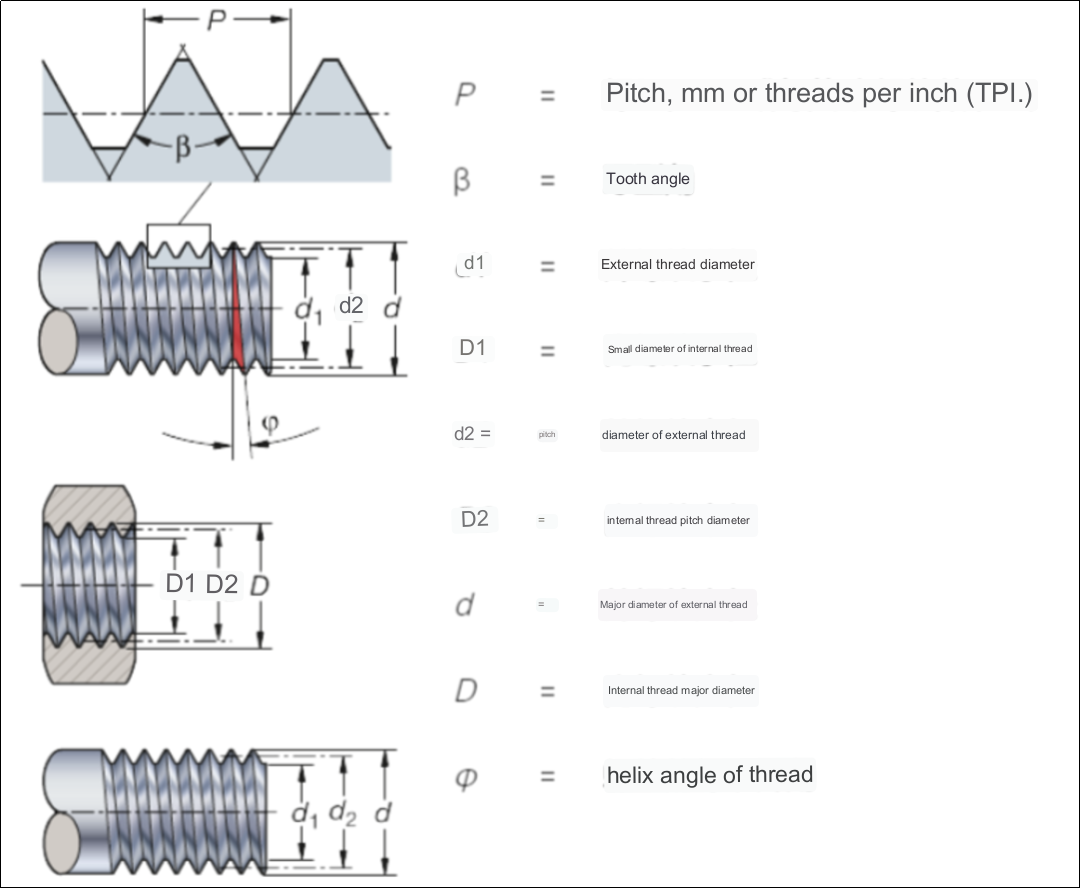

1. Ma'anar sharuddan

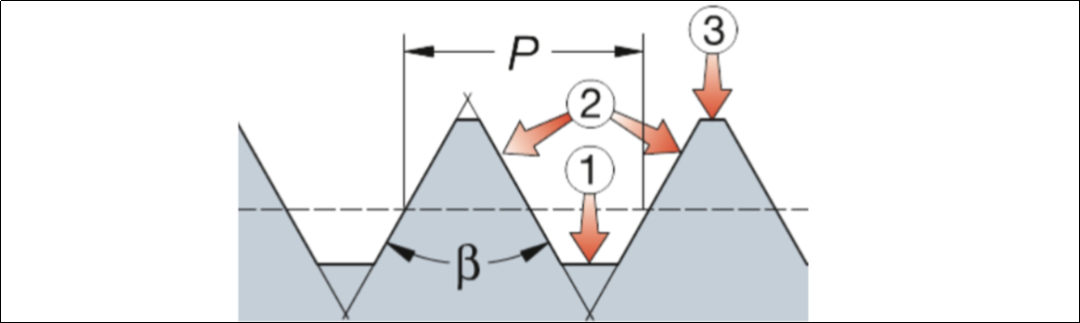

①Kasan hakori ② Gefen hakori ③ saman hakori

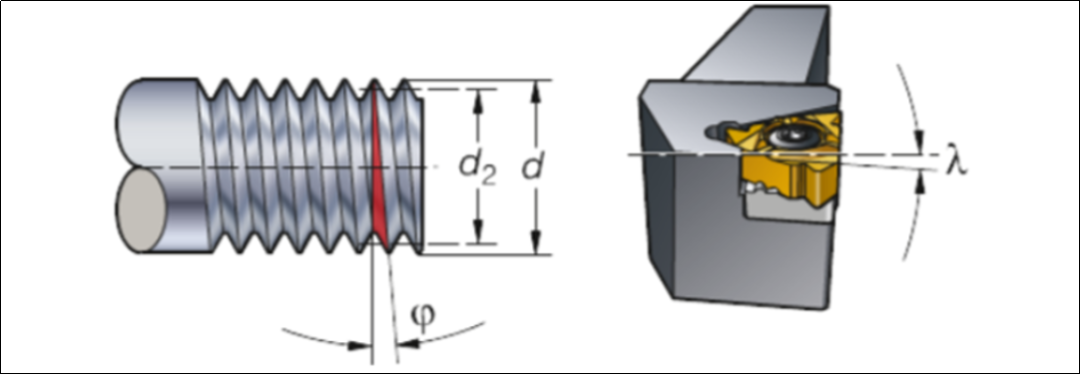

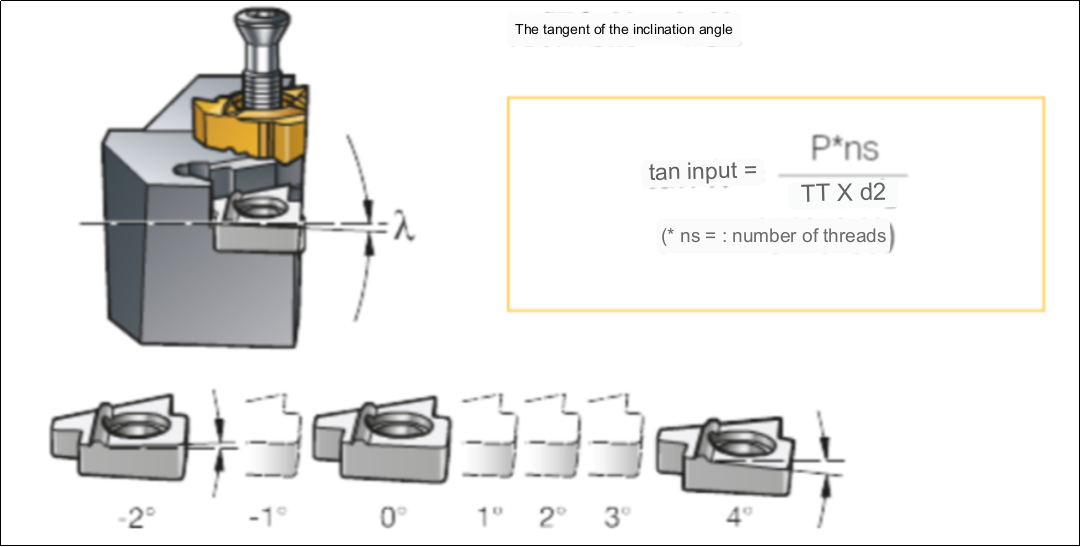

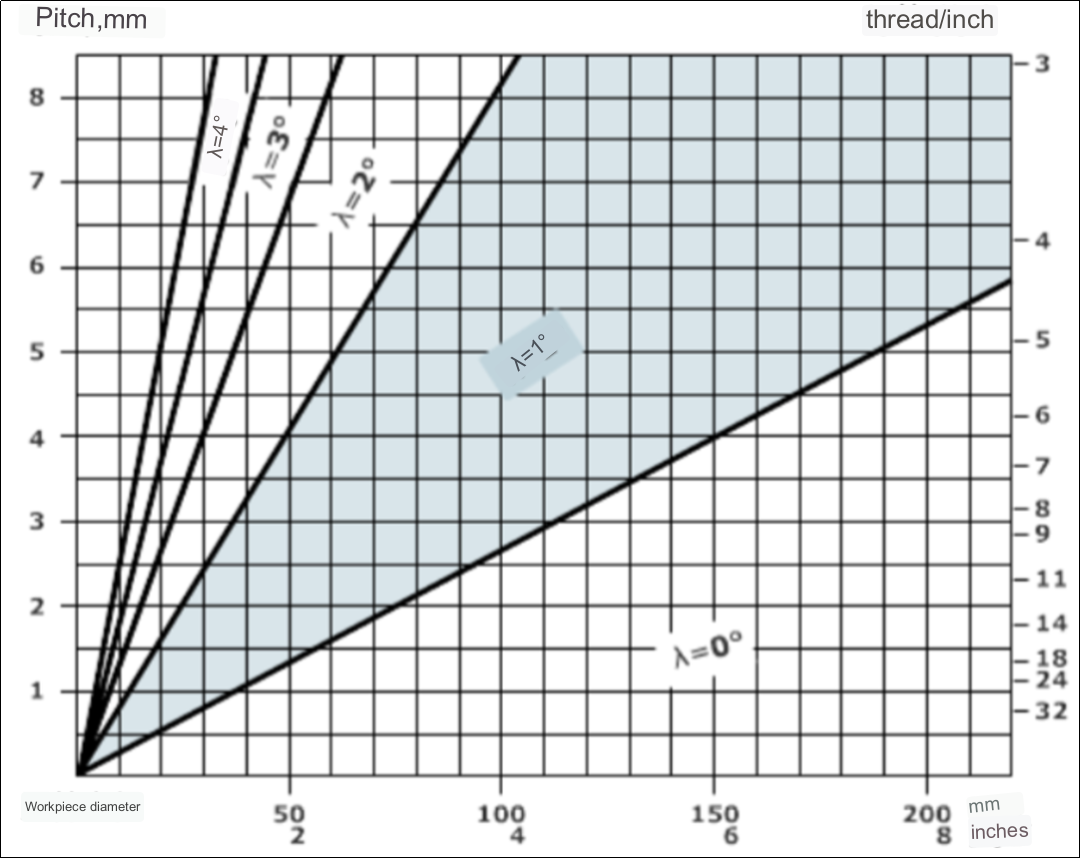

kusurwar Helix:

Matsakaicin kusurwar helix ya dogara da diamita da farar zaren.

Daidaita sassaucin gefen ɓangarorin ta hanyar canza shim.

Matsakaicin karkatar da ruwa shine γ. Mafi yawanci kusurwar bevel shine 1°, wanda yayi daidai da daidaitaccen shim a cikin mariƙin.

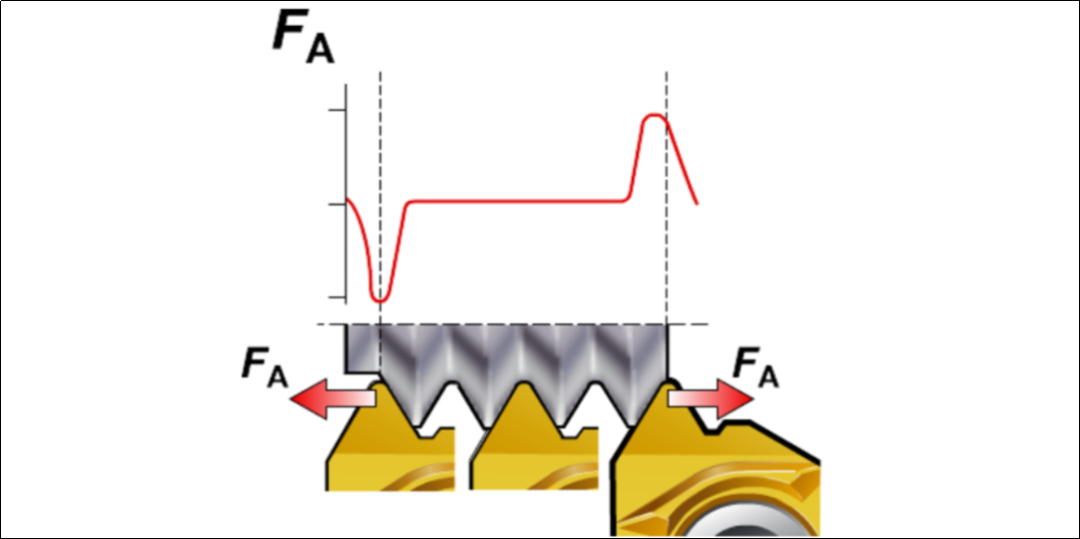

Yanke ƙarfi lokacin shiga da fita zaren:

Mafi girman rundunonin yankan axial a cikin ayyukan zaren suna faruwa yayin shigarwa da fita na kayan aikin yankewa a cikin kayan aiki.

Yanke bayanan da suka yi tsayi da yawa na iya haifar da motsin abin da ba a dogara da shi ba.

karkatar da ruwa don sharewa:

Za'a iya saita kusurwar bevel tare da shim a ƙarƙashin ruwa a cikin hannu. Koma zuwa ginshiƙi a cikin kasidar kayan aiki don zaɓar wane shim don amfani. Duk masu riƙon suna zuwa tare da daidaitattun shims da aka saita a kusurwar rake 1°.

Zaɓi shim bisa ga kusurwar bevel. Diamita na kayan aiki da farar zaren suna shafar kusurwar rake. Kamar yadda za a iya gani daga adadi a kasa, diamita nacnc lathe sassasu ne 40mm kuma farar ya kasance 6mm, shim ɗin da ake buƙata dole ne ya kasance yana da kusurwar bevel 3° (ba za a iya amfani da shims daidai ba).

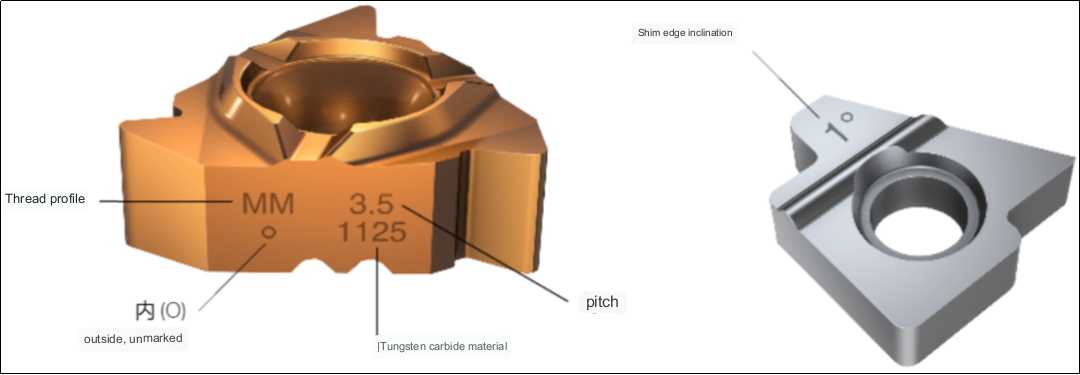

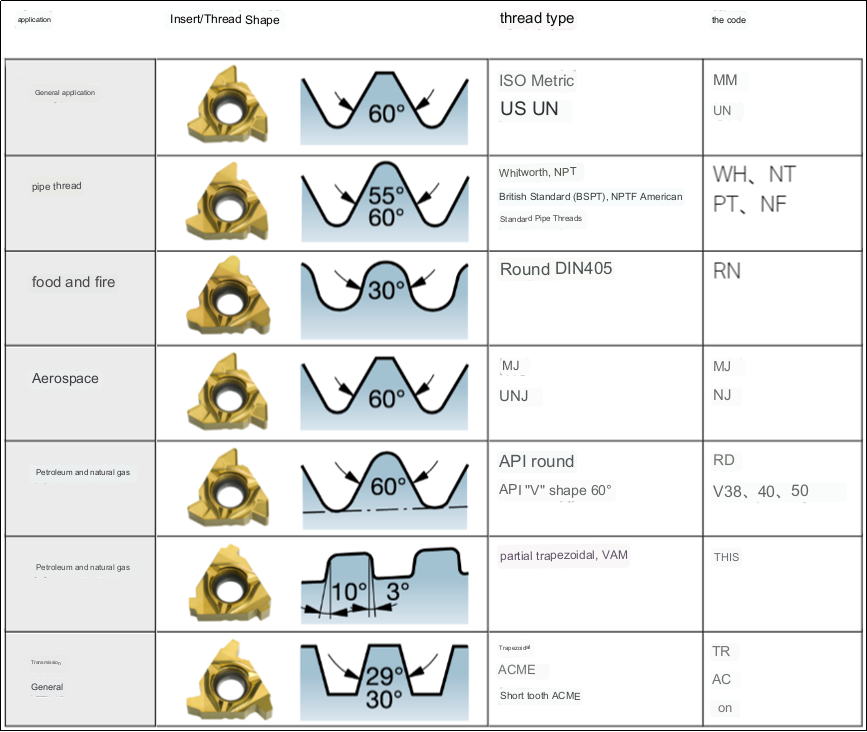

Alamomi don saka zare da shims:

Siffar zaren da aikace-aikacen sa:

2. Nau'in saka zare da makirci

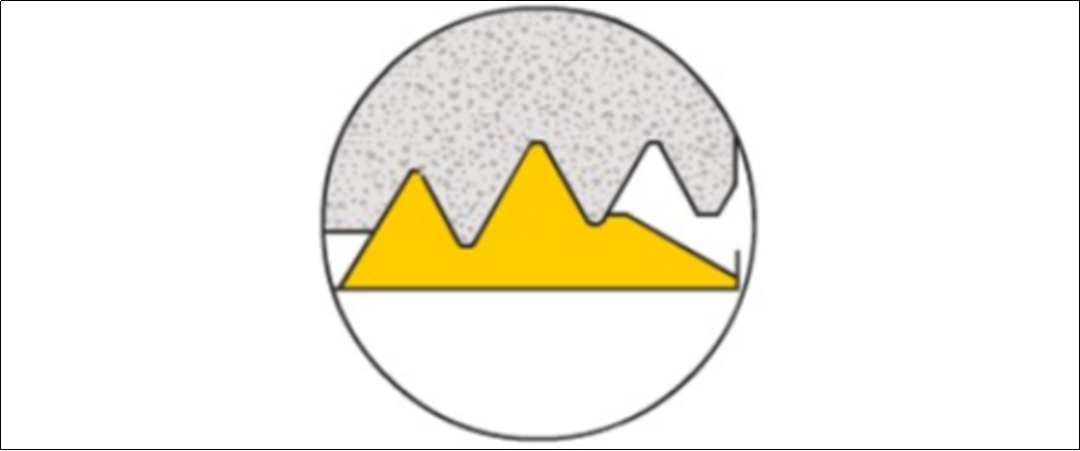

1. Multi hakori ruwa

Amfani:

Rage adadin ciyarwa

Babban yawan aiki

Ragewa:

Bukatar tsayayyiyar matsawa

Ana buƙatar isasshiyar sarari ja da baya bayan zaren

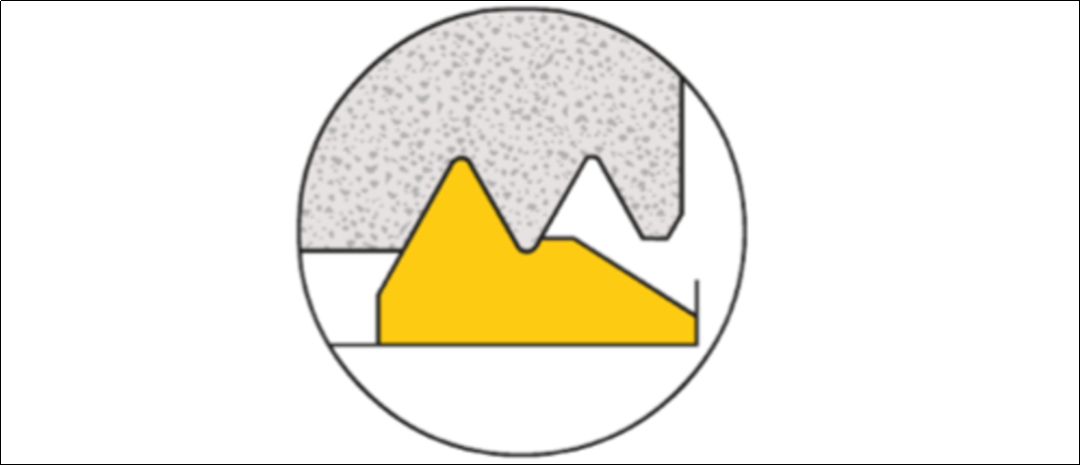

2. Cikakken bayanin martaba

Amfani:

Babban iko akan siffar zaren

ƙananan glitches

Ragewa:

Ruwa ɗaya zai iya yanke farat ɗaya kawai

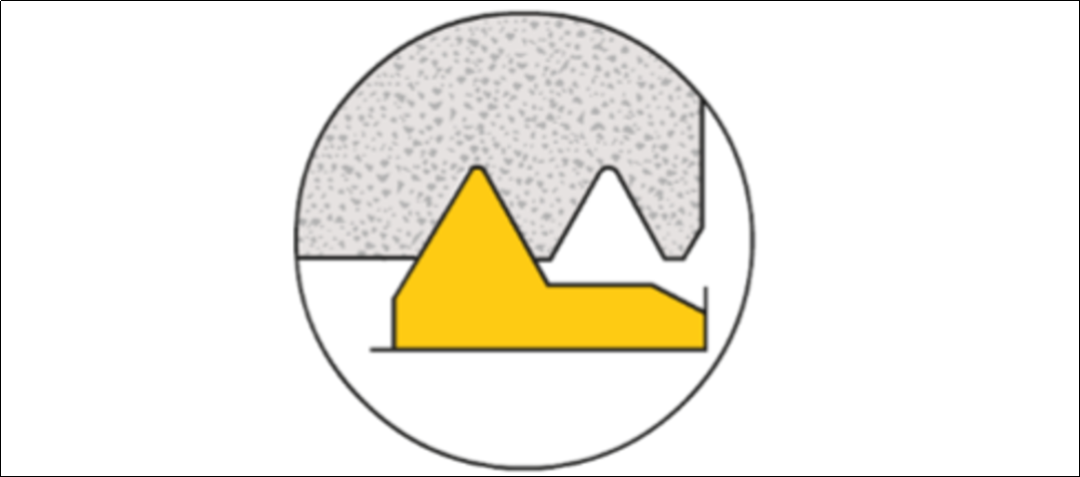

3. V-profile ruwa

Amfani:

Sassauci, irin wannan saka za a iya amfani da shi don filaye da yawa.

Ragewa:

Zai sa burrs su fito kuma suna buƙatar cirewa.

Maganin matsawa i-LOCK:

Zare mai tsauri mai tsauri tare da kafaffen abubuwan sakawa

Jagorar hanyar dogo mai jagora, an sanya ruwan wukake a daidai matsayi

Sukullun yana danna abin da aka saka akan titin jagoran baya zuwa tasha radial a fuska daya (jajayen fuska) a cikin wurin zama

Amintaccen saka dubawa yana tabbatar da tsawon rayuwar kayan aiki da ingancin zaren mafi girma

Hannu daban-daban:

3. Hanyoyin ciyarwa iri-iri uku

Hanyar ciyarwa na iya samun tasiri mai mahimmanci akan zaren proce. Yana rinjayar: Yanke sarrafawa, saka lalacewa, ingancin zaren, rayuwar kayan aiki.

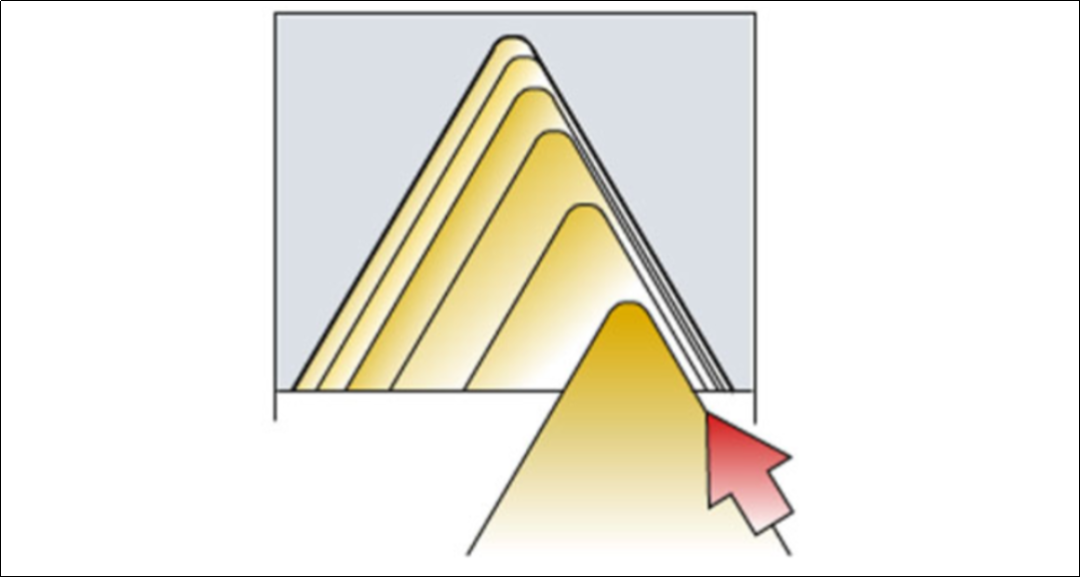

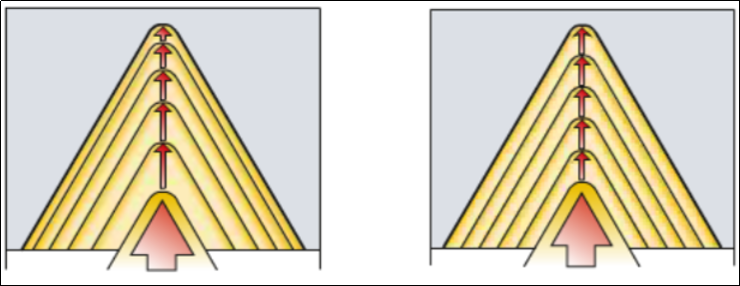

1. Inganta ciyarwar gefe

Yawancin kayan aikin injin CNC na iya amfani da wannan hanyar ciyarwa ta shirye-shiryen sake zagayowar:

Chips tare da nau'ikan juyi na al'ada - mai sauƙin tsari da jagora

Ƙarfin yankan axial yana rage haɗarin girgiza

Chips suna da kauri amma kawai sun taɓa gefe ɗaya na abin da aka saka

Rage canjin zafi zuwa ruwa

Zabi na farko don yawancin ayyukan zare

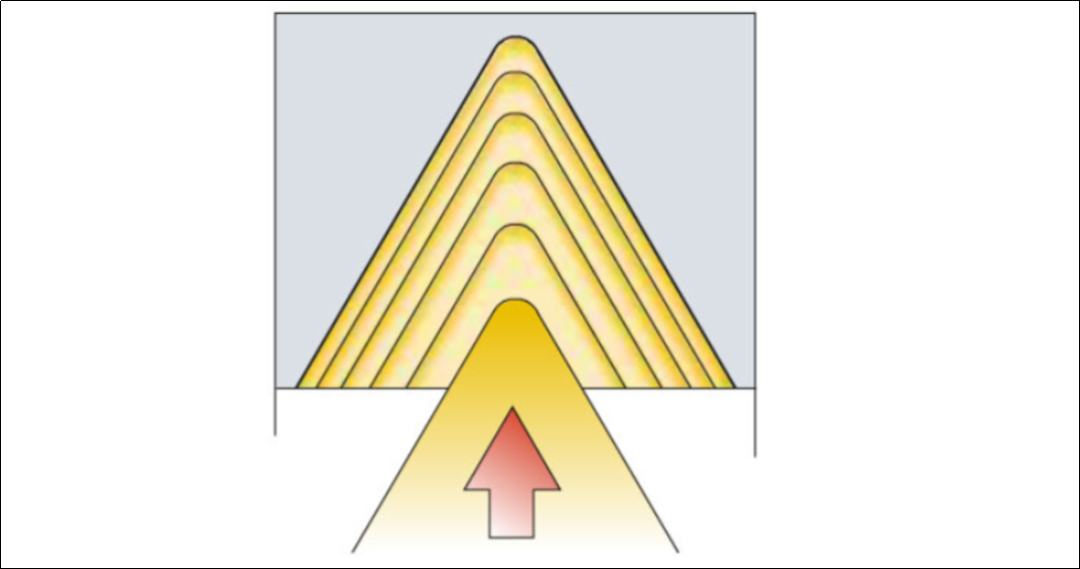

2. Radial infeed

Hanyar gama gari - hanya ɗaya tilo da tsofaffin lathes marasa CNC ke iya amfani da su:

Yana samar da kwakwalwan kwamfuta masu siffar “V” masu wuya

Uniform Blade Wear

Saka Aljihuna suna fuskantar matsanancin zafi, iyakance zurfin abinci

Ya dace da sarrafa zaren mai kyau

Mai yuwuwar girgizawa da rashin kulawar guntu lokacin da ake sarrafa zaren ƙira

Zabi na farko don kayan aiki masu tauri

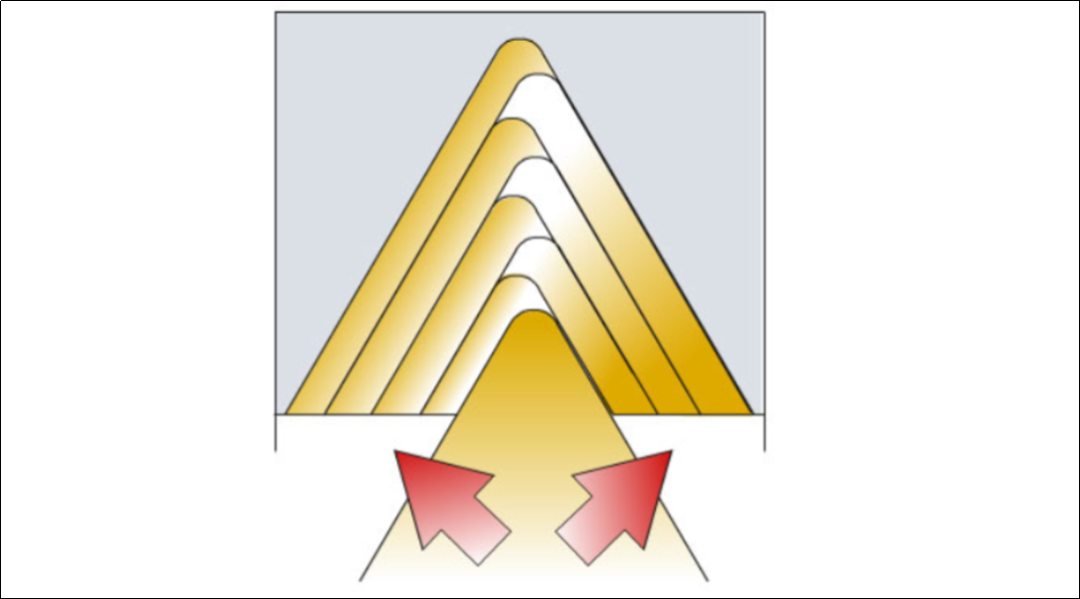

3. Madadin ciyarwa

shawarar ga manyan hakora

Saka rigar Uniform da matsakaicin rayuwar kayan aiki lokacin da ake sarrafa manyan zaren farar gaske

Ana jagorantar guntuwar ta hanyoyi biyu, yana sa su da wuyar sarrafawa

4. Hanyoyi don inganta sakamakon sarrafawa

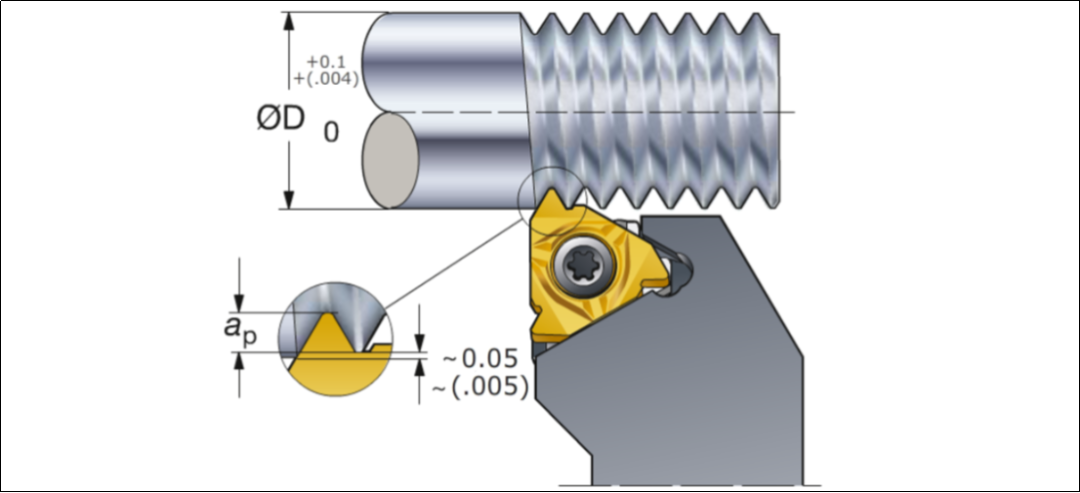

Rage zurfin yanke (hagu), madaidaicin zurfin yanke (dama)

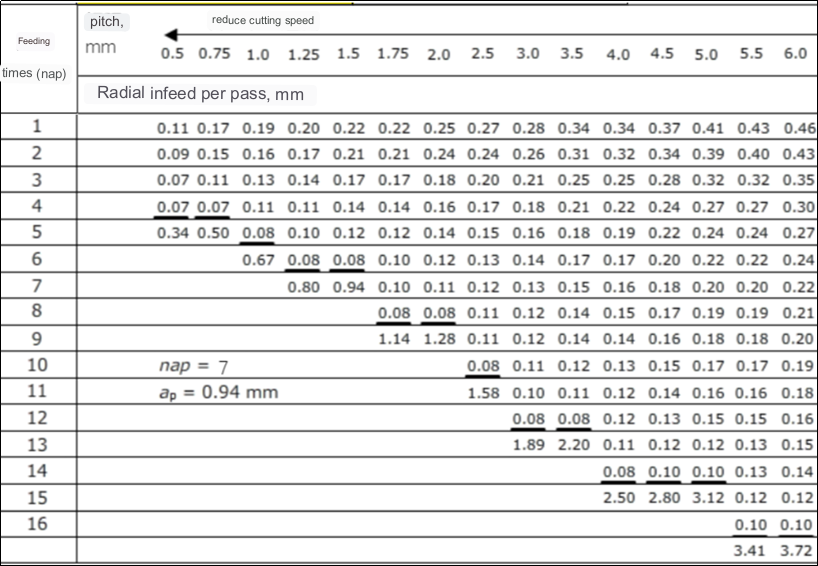

1. Zurfin yanke yana raguwa Layer ta Layer (yankin guntu ya kasance baya canzawa)

Iya cimma wani yanki na guntu akai-akai, wanda shine hanyar da aka fi amfani da ita a cikin shirye-shiryen NC.

Mafi zurfin wucewa ta farko

Bi shawarwarin akan teburin ciyarwa a cikin kasida

Ƙarin yankin guntu "daidaitacce".

Ƙarshen wucewa a zahiri shine kusan 0.07mm

2. Ci gaba da zurfin yanke

Kowane wucewa yana da zurfin iri ɗaya ba tare da la'akari da adadin wucewa ba.

Akwai buƙatu mafi girma akan ruwa

Tabbatar da mafi kyawun sarrafa guntu

Kada a yi amfani da shi lokacin da farar ya fi TP1.5mm ko 16TP

Ƙare zaren zaren da ƙarin haja:

Babu buƙatar juya haja zuwa ainihin diamita kafin zaren, yi amfani da ƙarin haja/kayan abu don gama zaren zaren. Don kammala abubuwan da aka saka crest, tsarin jujjuyawar da ya gabata yakamata ya bar 0.03-0.07mm na abu don ba da damar ƙirƙira da kyau.

Shawarar ƙimar ciyarwar zaren waje (tsarin awo na ISO):

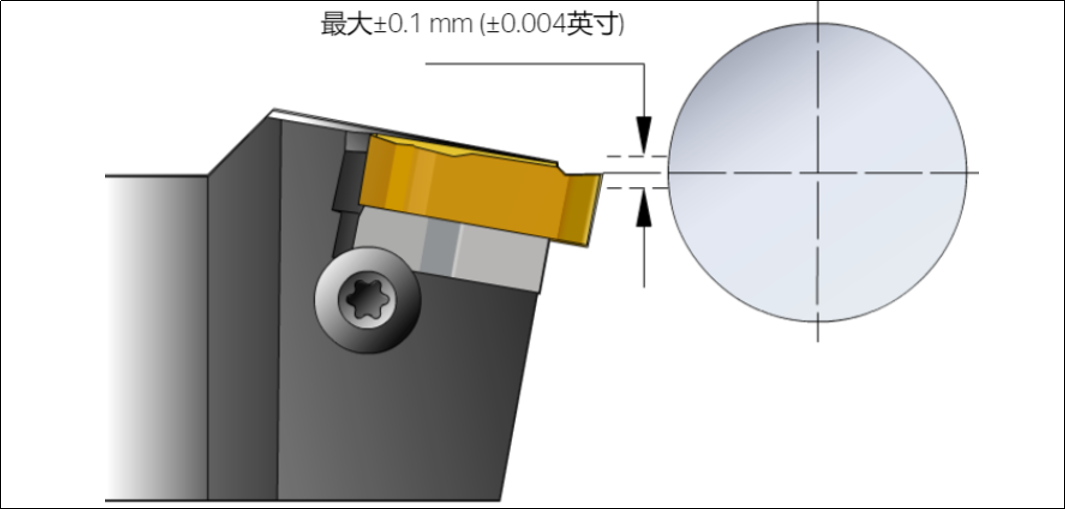

Don tabbatar da daidaiton kayan aiki da kayan aiki:

Yi amfani da madaidaicin karkacewar layin tsakiya na ± 0.1mm. Maɗaukakin matsayi mai mahimmanci kuma kusurwar taimako za ta ragu kuma za a ƙetare iyakar (fashe); ƙananan matsayi mai yankewa kuma bayanin martabar zaren bazai zama daidai ba.

5.zare juya aikace-aikace basira nasara

1) Kafin juya zaren, duba koaluminum machining sassadiamita yana da madaidaicin izinin injin, kuma ƙara 0.14mm azaman izinin kambi.

2) Daidaitaccen matsayi na kayan aiki a cikin kayan aikin injin.

3) Duba saitin yanke yankan dangane da diamita na farar.

4) Tabbatar cewa kayi amfani da madaidaicin juzu'i (A, F ko C).

5) Tabbatar da isasshe babban tsaftataccen ɗaki (shim mai karkata ruwan wukake) ta zaɓin shim ɗin da ya dace don samun madaidaicin share fage.

6) Idan zaren bai cancanta ba, duba duk saitin ciki har da kayan aikin injin.

7) Duba shirye-shiryen NC da ke akwai don juyawa zaren.

8) Inganta hanyar ciyarwa, adadin wucewa da girma.

9) Tabbatar da ingantaccen saurin yanke don biyan buƙatun aikace-aikacen.

10) Idan filin aikin zaren ba daidai ba ne, duba ko filin kayan aikin na'urar daidai ne.

11) Kafin yanke a cikin workpiece, an bada shawarar cewa kayan aiki ya kamata ya fara tare da mafi ƙarancin nisa na sau 3 na farar.

12) Babban madaidaicin sanyaya na iya tsawaita rayuwar kayan aiki da haɓaka sarrafa guntu.

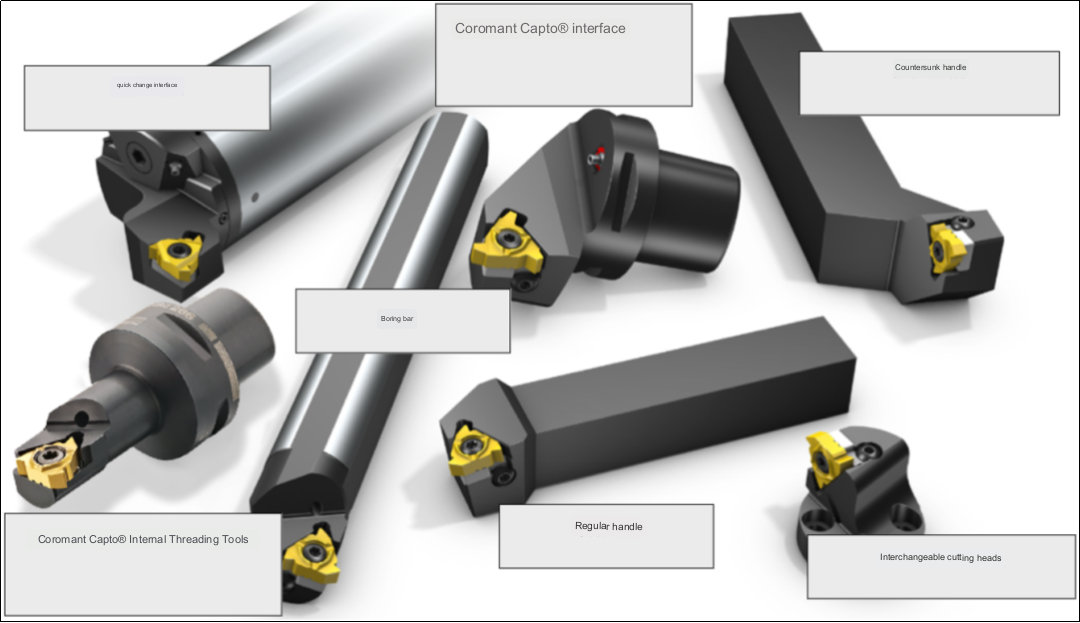

13) Tsarin canji mai sauri yana tabbatar da sauƙi da sauri.

Lokacin zabar kayan aiki don aikin juya zaren, la'akari:

Bincika overhangs da duk wani izini da ake buƙata (misali kafaɗa, ƙananan spindle, da sauransu)

Rage overhang kayan aiki don saiti mai sauri

Don ƙananan saiti masu tsauri, zaɓi abubuwan da aka saka tare da ƙananan ƙarfin yanke

Babban madaidaicin cnc juyawacoolant yana haɓaka rayuwar kayan aiki kuma yana haɓaka sarrafa yanke

Sauƙaƙan samun damar sanyaya tare da adaftar sanyaya-da-wasa

Don tabbatar da yawan aiki da rayuwar kayan aiki, an fi son abubuwan da ake sakawa da yawa, abubuwan da aka haɗa da cikakkun bayanan martaba guda ɗaya sune zaɓi na biyu, kuma V-profile sakawa shine mafi ƙanƙanta yawan aiki da zaɓin rayuwar kayan aiki mafi guntu.

Saka lalacewa da rayuwar kayan aiki:

Hanyar ciyarwa, inganta hanyar ciyarwa, adadin wucewa da zurfin

Ƙaunar ruwa don tabbatar da isasshe babba da tsafta iri ɗaya (shim mai karkatar da ruwa)

Saka geometry, tabbatar da yin amfani da madaidaicin madaidaicin lissafi (A, F ko C geometry)

Kayan ruwa, zaɓi kayan da ya dace daidai da buƙatun kayan da ƙarfi

Yanke sigogi, idan ya cancanta, canza saurin yankewa da adadin wucewa a cikin aiwatar dacnc milling sassa.

Anebon manne wa imanin ku na "Samar da mafita na high quality da kuma samar da abokai tare da mutane daga ko'ina cikin duniya", Anebon ko da yaushe sa sha'awar abokan ciniki don fara da China Manufacturer ga kasar Sin aluminum farantin karfe, milling aluminum farantin, musamman aluminum kananan. sassa cnc, tare da kyakkyawar sha'awa da aminci, suna shirye su ba ku mafi kyawun ayyuka da ci gaba tare da ku don yin kyakkyawar makoma mai haske.

Original Factory China Extrusion Aluminum da Profile Aluminum, Anebon zai bi "Quality farko, , kamala har abada, mutane-daidaitacce , fasahar sabuwar fasahar"kasuwanci falsafa. Yin aiki tuƙuru don ci gaba da samun ci gaba, ƙirƙira a cikin masana'antu, yin kowane ƙoƙari don yin kasuwanci a matakin farko. Muna ƙoƙarin mafi kyawun mu don gina ƙirar sarrafa kimiyya, don koyon ilimin ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun masana'antu, haɓaka kayan aikin samarwa da tsarin samarwa, don ƙirƙirar samfuran inganci na farko, farashi mai ma'ana, babban ingancin sabis, bayarwa mai sauri, don ba ku ƙirƙira. sabon darajar .

Lokacin aikawa: Juni-14-2023