HV, HB, da HRC duk ma'auni ne na taurin da ake amfani da su wajen gwajin kayan. Bari mu karya su:

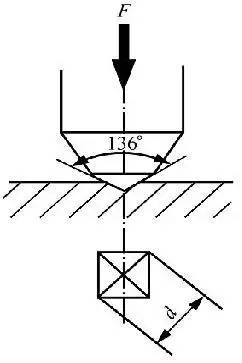

1.HV Hardness (Vickers Hardness): Taurin HV ma'auni ne na juriya na abu ga shigar ciki. An ƙaddara ta hanyar yin amfani da wani sanannen kaya a saman kayan ta amfani da alamar lu'u-lu'u da kuma auna girman sakamakon da aka samu. Ana bayyana taurin HV a cikin raka'a na taurin Vickers (HV) kuma galibi ana amfani dashi don kayan bakin ciki, sutura, da ƙananan sassa.

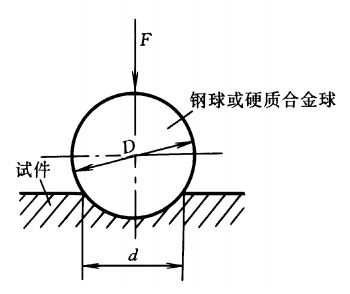

2)HB Hardness (Brinell Hardness): HB taurin wani ma'auni ne na juriya na abu ga shigar ciki. Ya haɗa da yin amfani da sanannen kaya zuwa kayan ta amfani da tauraruwar ƙwallon ƙwallon ƙarfe da auna diamita na sakamakon shigar. Ana bayyana taurin HB a cikin raka'a na taurin Brinell (HB) kuma galibi ana amfani da shi don manyan abubuwa masu girma da girma, gami da karafa da gami.

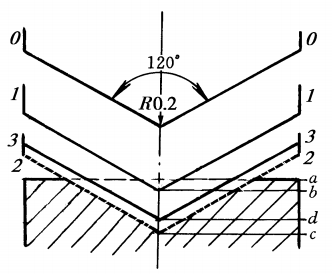

3)HRC Hardness (Rockwell Hardness): Taurin HRC ma'auni ne na juriya na abu don shiga ko shiga. Yana amfani da ma'auni daban-daban (A, B, C, da dai sauransu) bisa ƙayyadaddun hanyar gwaji da nau'in indenter da aka yi amfani da shi (mazugi na lu'u-lu'u ko ƙwallon ƙarfe mai taurin). Ana yawan amfani da ma'aunin HRC don auna taurin kayan ƙarfe. Ana wakilta ƙimar taurin azaman lamba akan sikelin HRC, kamar HRC 50.

Teburin kwatanta taurin HV-HB-HRC da aka saba amfani dashi:

| Teburin kwatancen taurin ƙarfe na gama gari (kimanin ƙarfin juyi) | ||||

| Rarraba taurin | Ƙarfin ƙarfi N/mm2 | |||

| Rockwell | Vickers | Brinell | ||

| HRC | HRA | HV | HB | |

| 17 | - | 211 | 211 | 710 |

| 17.5 | - | 214 | 214 | 715 |

| 18 | - | 216 | 216 | 725 |

| 18.5 | - | 218 | 218 | 730 |

| 19 | - | 221 | 220 | 735 |

| 19.5 | - | 223 | 222 | 745 |

| 20 | - | 226 | 225 | 750 |

| 20.5 | - | 229 | 227 | 760 |

| 21 | - | 231 | 229 | 765 |

| 21.5 | - | 234 | 232 | 775 |

| 22 | - | 237 | 234 | 785 |

| 22.5 | - | 240 | 237 | 790 |

| 23 | - | 243 | 240 | 800 |

| 23.5 | - | 246 | 242 | 810 |

| 24 | - | 249 | 245 | 820 |

| 24.5 | - | 252 | 248 | 830 |

| 25 | - | 255 | 251 | 835 |

| 25.5 | - | 258 | 254 | 850 |

| 26 | - | 261 | 257 | 860 |

| 26.5 | - | 264 | 260 | 870 |

| 27 | - | 268 | 263 | 880 |

| 27.5 | - | 271 | 266 | 890 |

| 28 | - | 274 | 269 | 900 |

| 28.5 | - | 278 | 273 | 910 |

| 29 | - | 281 | 276 | 920 |

| 29.5 | - | 285 | 280 | 935 |

| 30 | - | 289 | 283 | 950 |

| 30.5 | - | 292 | 287 | 960 |

| 31 | - | 296 | 291 | 970 |

| 31.5 | - | 300 | 294 | 980 |

| 32 | - | 304 | 298 | 995 |

| 32.5 | - | 308 | 302 | 1010 |

| 33 | - | 312 | 306 | 1020 |

| 33.5 | - | 316 | 310 | 1035 |

| 34 | - | 320 | 314 | 1050 |

| 34.5 | - | 324 | 318 | 1065 |

| 35 | - | 329 | 323 | 1080 |

| 35.5 | - | 333 | 327 | 1095 |

| 36 | - | 338 | 332 | 1110 |

| 36.5 | - | 342 | 336 | 1125 |

| 37 | - | 347 | 341 | 1140 |

| 37.5 | - | 352 | 345 | 1160 |

| 38 | - | 357 | 350 | 1175 |

| 38.5 | - | 362 | 355 | 1190 |

| 39 | 70 | 367 | 360 | 1210 |

| 39.5 | 70.3 | 372 | 365 | 1225 |

| 40 | 70.8 | 382 | 375 | 1260 |

| 40.5 | 70.5 | 377 | 370 | 1245 |

| 41 | 71.1 | 388 | 380 | 1280 |

| 41.5 | 71.3 | 393 | 385 | 1300 |

| 42 | 71.6 | 399 | 391 | 1320 |

| 42.5 | 71.8 | 405 | 396 | 1340 |

| 43 | 72.1 | 411 | 401 | 1360 |

| 43.5 | 72.4 | 417 | 407 | 1385 |

| 44 | 72.6 | 423 | 413 | 1405 |

| 44.5 | 72.9 | 429 | 418 | 1430 |

| 45 | 73.2 | 436 | 424 | 1450 |

| 45.5 | 73.4 | 443 | 430 | 1475 |

| 46 | 73.7 | 449 | 436 | 1500 |

| 46.5 | 73.9 | 456 | 442 | 1525 |

| 47 | 74.2 | 463 | 449 | 1550 |

| 47.5 | 74.5 | 470 | 455 | 1575 |

| 48 | 74.7 | 478 | 461 | 1605 |

| 48.5 | 75 | 485 | 468 | 1630 |

| 49 | 75.3 | 493 | 474 | 1660 |

| 49.5 | 75.5 | 501 | 481 | 1690 |

| 50 | 75.8 | 509 | 488 | 1720 |

| 50.5 | 76.1 | 517 | 494 | 1750 |

| 51 | 76.3 | 525 | 501 | 1780 |

| 51.5 | 76.6 | 534 | - | 1815 |

| 52 | 76.9 | 543 | - | 1850 |

| 52.5 | 77.1 | 551 | - | 1885 |

| 53 | 77.4 | 561 | - | 1920 |

| 53.5 | 77.7 | 570 | - | 1955 |

| 54 | 77.9 | 579 | - | 1995 |

| 54.5 | 78.2 | 589 | - | 2035 |

| 55 | 78.5 | 599 | - | 2075 |

| 55.5 | 78.7 | 609 | - | 2115 |

| 56 | 79 | 620 | - | 2160 |

| 56.5 | 79.3 | 631 | - | 2205 |

| 57 | 79.5 | 642 | - | 2250 |

| 57.5 | 79.8 | 653 | - | 2295 |

| 58 | 80.1 | 664 | - | 2345 |

| 58.5 | 80.3 | 676 | - | 2395 |

| 59 | 80.6 | 688 | - | 2450 |

| 59.5 | 80.9 | 700 | - | 2500 |

| 60 | 81.2 | 713 | - | 2555 |

| 60.5 | 81.4 | 726 | - | - |

| 61 | 81.7 | 739 | - | - |

| 61.5 | 82 | 752 | - | - |

| 62 | 82.2 | 766 | - | - |

| 62.5 | 82.5 | 780 | - | - |

| 63 | 82.8 | 795 | - | - |

| 63.5 | 83.1 | 810 | - | - |

| 64 | 83.3 | 825 | - | - |

| 64.5 | 83.6 | 840 | - | - |

| 65 | 83.9 | 856 | - | - |

| 65.5 | 84.1 | 872 | - | - |

| 66 | 84.4 | 889 | - | - |

| 66.5 | 84.7 | 906 | - | - |

| 67 | 85 | 923 | - | - |

| 67.5 | 85.2 | 941 | - | - |

| 68 | 85.5 | 959 | - | - |

| 68.5 | 85.8 | 978 | - | - |

| 69 | 86.1 | 997 | - | - |

| 69.5 | 86.3 | 1017 | - | - |

| 70 | 86.6 | 1037 | - | - |

HRC/HB Kimanin Tukwici Juyin Juya

Taurin ya fi 20HRC, 1HRC≈10HB,

Taurin ya yi ƙasa da 20HRC, 1HRC≈11.5HB.

Bayani: Don yankan aiki, ana iya canza shi daidai 1HRC≈10HB (taurin kayan aikin yana da kewayon canzawa)

Taurin kayan ƙarfe

Taurin yana nufin iyawar abu don tsayayya da nakasar gida, musamman nakasar filastik, shigar ko karce. Ma'auni ne don auna laushi da taurin kayan.

Dangane da hanyoyin gwaji daban-daban, taurin ya kasu kashi uku.

①Cire taurin. An fi amfani dashi don kwatanta laushi da taurin ma'adanai daban-daban. Hanyar ita ce zabar sanda mai tsayi ɗaya mai ƙarfi, ɗayan kuma mai laushi, wuce kayan da za a gwada tare da sandar, kuma ƙayyade taurin kayan da za a gwada daidai da matsayi na karce. A cikin magana mai inganci, abubuwa masu wuya suna yin doguwar tarkace kuma abubuwa masu laushi suna yin gajeriyar karce.

②Taurin shigar ciki. Mafi yawan amfani da kayan ƙarfe, hanyar ita ce a yi amfani da wani nau'i mai nauyi don danna ƙayyadadden mai shiga cikin kayan da za a gwada, da kwatanta laushi da taurin kayan da za a gwada ta hanyar girman nakasar filastik na gida a saman. kayan. Saboda bambance-bambancen mai shiga, kaya da tsawon lokacin kaya, akwai nau'ikan taurin shigar da yawa, musamman ciki har da taurin Brinell, taurin Rockwell, taurin Vickers da microhardness.

③Taurin sake dawowa. An fi amfani da shi don kayan ƙarfe, hanyar ita ce yin ƙaramin guduma na musamman ya faɗi cikin yardar kaina daga wani tsayin tsayi don tasiri samfurin kayan da za a gwada, da amfani da adadin kuzarin da aka adana (sannan kuma a sake shi) a cikin samfurin yayin tasiri (ta hanyar dawowar ƙaramin guduma) tsayin tsayi tsayi) don ƙayyade taurin kayan.

Mafi yawan taurin Brinell, taurin Rockwell da taurin Vickers na kayan ƙarfe suna cikin taurin shigar. Ƙimar taurin yana nuna ikon saman abu don tsayayya da nakasar filastik da wani abu ya haifar; C) don auna taurin, kuma ƙimar taurin yana wakiltar girman aikin nakasar ƙarfe na ƙarfe.

Brinell Hardness

Yi amfani da ƙwallon ƙarfe da aka kashe ko ƙwallon gami mai ƙarfi tare da diamita na D azaman mai shiga, danna shi a saman ɓangaren gwajin tare da ƙarfin gwajin daidai F, kuma bayan ƙayyadadden lokacin riƙewa, cire ƙarfin gwajin don samun shiga tare da diamita d. Rarraba ƙarfin gwajin ta wurin farfajiyar shigarwar, kuma ƙimar da aka samu ita ce ƙimar taurin Brinell, kuma alamar tana wakiltar HBS ko HBW.

Bambanci tsakanin HBS da HBW shine bambanci a cikin mai shiga. HBS yana nufin cewa indenter ne mai taurin karfe, wanda ake amfani da shi don auna kayan tare da ƙimar taurin Brinell ƙasa da 450, kamar ƙarfe mai laushi, baƙin ƙarfe mai launin toka da ƙarfe mara ƙarfe. HBW yana nufin cewa mai simintin siminti ne carbide, wanda ake amfani dashi don auna kayan tare da ƙimar taurin Brinell ƙasa da 650.

Don toshe gwajin guda ɗaya, lokacin da sauran yanayin gwajin daidai suke, sakamakon gwaje-gwajen guda biyu sun bambanta, kuma ƙimar HBW sau da yawa tana girma fiye da ƙimar HBS, kuma babu wata ƙa'ida ta ƙididdigewa da za a bi.

Bayan shekara ta 2003, ƙasara ta yi daidai da ƙa'idodin ƙasashen duniya, soke na'urorin ƙwallon ƙarfe na ƙarfe, da dukkan kawunan ƙwallon carbide da aka yi amfani da su. Don haka, an daina HBS, kuma ana amfani da HBW don wakiltar alamar taurin Brinell. A yawancin lokuta, taurin Brinell ana bayyana shi ne kawai a cikin HB, yana nufin HBW. Duk da haka, ana ganin HBS daga lokaci zuwa lokaci a cikin takardun wallafe-wallafe.

Hanyar ma'aunin taurin Brinell ya dace da simintin ƙarfe, gami da ba na ƙarfe ba, ƙarfe daban-daban da aka kashe da kashewa, kuma bai dace da samfura ko gwaji ba.cnc juya sassawaɗanda suke da wuya, ƙanƙanta, kuma sirara, ko waɗanda ba sa ƙyale manyan indents a saman.

Rockwell Hardness

Yi amfani da mazugi na lu'u-lu'u tare da kusurwar mazugi na 120 ° ko Ø1.588mm da Ø3.176mm ƙwallan ƙarfe masu kashewa a matsayin mai sakawa da kaya don yin aiki tare da shi. Nauyin farko shine 10kgf kuma nauyin duka shine 60, 100 ko 150kgf (wato nauyin farko da babban kaya). An bayyana taurin ta hanyar bambance-bambance tsakanin zurfin shigarwa lokacin da aka cire babban kaya da kuma zurfin ƙaddamarwa lokacin da aka riƙe babban nauyin da kuma zurfin shigarwa a ƙarƙashin nauyin farko bayan an yi amfani da nauyin duka.

Gwajin taurin Rockwell yana amfani da rundunonin gwaji uku da indenters uku. Akwai haɗuwa guda 9 daga cikinsu, daidai da ma'auni 9 na taurin Rockwell. Aiwatar da waɗannan masu mulki guda 9 ya ƙunshi kusan duk kayan ƙarfe da aka saba amfani da su. Akwai HRA guda uku da aka fi amfani da su, HRB da HRC, daga cikinsu akwai HRC da aka fi amfani da su.

Teburin ƙayyadaddun gwajin taurin Rockwell da aka fi amfani dashi:

| Tauri | | | Tauri | |

| | | | | Carbide, gishiri, |

| | | | | Annealed, al'ada karfe, aluminum gami |

| | | | | karfe mai tauri, quenched da hushi karfe, zurfi |

Matsakaicin amfani da sikelin HRC shine 20 ~ 70HRC. Lokacin da taurin darajar kasa da 20HRC, saboda conicalaluminum CNC machining partna mai shiga yana danna da yawa, hankali yana raguwa, kuma yakamata a yi amfani da sikelin HRB maimakon; lokacin da taurin samfurin ya fi 67HRC, matsa lamba akan tip na indenter ya yi girma sosai, kuma lu'u-lu'u yana da sauƙin lalacewa. Za a gajarta rayuwar mai shigar da ƙara, don haka ya kamata a yi amfani da ma'aunin HRA gabaɗaya maimakon.

Gwajin taurin Rockwell mai sauƙi ne, mai sauri, kuma ƙarami, kuma yana iya gwada saman ƙãre kayayyakin da kayan aiki masu wuya da bakin ciki. Saboda ƙananan indentation, don kayan da ba daidai ba tsari da taurin, ƙimar taurin yana canzawa sosai, kuma daidaito bai kai girman taurin Brinell ba. Ana amfani da taurin Rockwell don tantance taurin karfe, karafa marasa tafe, gami da sauran su.

Vickers Hardness Vickers Hardness

Ka'idar ma'aunin taurin Vickers yayi kama da na taurin Brinell. Yi amfani da madaidaicin dala mai murabba'in lu'u-lu'u tare da an haɗa kusurwar 136° don danna cikin saman kayan tare da ƙayyadadden ƙarfin gwaji F, kuma cire ƙarfin gwajin bayan kiyaye ƙayyadadden lokacin. Ana bayyana taurin ta matsakaicin matsa lamba akan yanki na yanki na murabba'in dala. Darajar, alamar alamar ita ce HV.

Ma'aunin ma'aunin taurin Vickers yana da girma, kuma yana iya auna kayan tare da taurin daga 10 zuwa 1000HV. Shigar yana ƙarami, kuma ana amfani dashi gabaɗaya don auna kayan sirara da taurare yadudduka kamar carburizing da nitriding.

Leeb Hardness Leeb Hardness

Yi amfani da jiki mai tasiri tare da wani taro na tungsten carbide ball head don tasiri saman yanki na gwajin ƙarƙashin aikin wani ƙarfi, sa'an nan kuma sake dawowa. Saboda taurin kayan daban-daban, saurin dawowa bayan tasiri shima ya bambanta. Ana shigar da maganadisu na dindindin akan na'urar tasiri. Lokacin da tasirin jikin ya motsa sama da ƙasa, na'urar da ke gefenta za ta haifar da siginar lantarki daidai da gudun, sannan ta canza ta zuwa ƙimar taurin Leeb ta hanyar da'irar lantarki. An yiwa alamar alama a matsayin HL.

Na'urar gwajin taurin ta Leeb baya buƙatar na'ura mai aiki, kuma firikwensin taurinsa ƙanƙanta ne kamar alkalami, wanda za'a iya sarrafa shi da hannu kai tsaye, kuma ana iya gano shi cikin sauƙi ko babban aiki ne, mai nauyi ko kuma kayan aiki mai sarƙaƙƙiya na geometric.

Wani fa'idar taurin Leeb shine cewa yana da ƙarancin lalacewa a saman samfurin, kuma wani lokacin ana iya amfani dashi azaman gwaji mara lalacewa; yana da na musamman a cikin gwaje-gwajen taurin a duk kwatance, kunkuntar wurare da na musammansassan aluminum.

Anebon ya bi ka'idar "Mai gaskiya, ƙwararren ƙwararren ƙwararren ƙwararren ƙwararren ƙwararren ƙwararren ƙwararren ƙwararren ƙwararren ƙwararru "don samun sabbin hanyoyin warwarewa gabaɗaya. Anebon ya ɗauki al'amura, nasara a matsayin nasarar sa na sirri. Bari Anebon ya gina ingantacciyar hannu da hannu ta gaba don ɓangarorin injin tagulla da Complex titanium cnc sassa / kayan hatimi. Anebon yanzu yana da cikakkiyar wadatar kayayyaki kuma farashin siyarwa shine fa'idarmu. Barka da zuwa don tambaya game da samfuran Anebon.

Trending Products kasar Sin CNC machining Part da daidaici Part, da gaske ya kamata kowane daga cikin wadannan abubuwa zama sha'awar a gare ku, da fatan za a sanar da mu. Anebon zai yi farin cikin ba ku zance a lokacin da aka sami cikakkun bayanai na mutum. Anebon yana da injinan R&D ƙwararrun mu don biyan kowane buƙatun. Anebon yana fatan samun tambayoyinku nan ba da jimawa ba kuma yana fatan samun damar yin aiki tare da ku a nan gaba. Barka da zuwa duba ƙungiyar Anebon.

Lokacin aikawa: Mayu-18-2023