1

Tasiri kan yankan zafin jiki: saurin yankan, ƙimar ciyarwa, adadin yankan baya.

Tasiri kan yanke ƙarfi: adadin yankan baya, ƙimar ciyarwa, saurin yankewa.

Tasiri kan ƙarfin kayan aiki: saurin yankan, ƙimar ciyarwa, adadin yankan baya.

2

Lokacin da adadin haɗin baya ya ninka, ƙarfin yanke ya ninka;

Lokacin da adadin abinci ya ninka sau biyu, ƙarfin yankan yana ƙaruwa da kusan 70%;

Lokacin da saurin yankan ya ninka, ƙarfin yankan yana raguwa a hankali;

Wato, idan aka yi amfani da G99, saurin yanke zai karu, amma ƙarfin yanke ba zai canza da yawa ba.

3

Dangane da fitar da filayen ƙarfe, ana iya yanke hukunci ko ƙarfin yankewa da yankan zafin jiki suna cikin kewayon al'ada.

Lokacin da ainihin ƙimar X da diamita Y na zanen ya fi 0.8, kayan aikin juyawa tare da kusurwar juzu'i na biyu na digiri 52 (wato, kayan aikin da aka saba amfani da su tare da ruwan wuka na digiri 35 da babban kusurwar jujjuyawar. 93 digiri) R daga cikin motar na iya goge wukar a wurin farawa.

5

Yanayin zafin jiki wanda aka wakilta ta launi na filayen ƙarfe: fari bai wuce digiri 200 ba

Yellow 220-240 digiri

Dark blue 290 digiri

Blue 320-350 digiri

Baƙar fata mai shuɗi fiye da digiri 500

Ja ya fi digiri 800

6

FUNAC OI mtc gabaɗaya ya sabawa umarnin G:

G69: ba tabbas

G21: Shigar girman awo

G25: An katse gano saurin juzu'i

G80: Soke zagayowar gwangwani

G54: tsoho tsarin daidaitawa

G18: Zaɓin jirgin sama na ZX

G96 (G97): sarrafa saurin mizani akai-akai

G99: Ciyar da kowace juyin juya hali

G40: soke diyya na kayan aiki (G41 G42)

G22: gano bugun jini ON

G67: soke tsarin tsarin macro

G64: ba tabbas

G13.1: Soke yanayin haɗin gwiwar polar coordinate interpolation

7

Zaren waje gabaɗaya 1.3P ne, kuma zaren ciki shine 1.08P.

8

Saurin zaren S1200/pitch* factor aminci (gaba ɗaya 0.8).

9

Manual Tool hanci R dabara dabara: daga kasa zuwa sama, chamfering: Z=R*(1-tan(a/2)) X=R(1-tan(a/2))*tan(a) daga sama zuwa sama Sauka daga chamfer kuma canza ragi zuwa ƙari.

10

Duk lokacin da ciyarwar ta karu da 0.05, saurin yana raguwa da juyi 50-80. Wannan shi ne saboda rage gudun yana nufin cewa kayan aiki yana raguwa, da kumayankan cnckarfi yana ƙaruwa sannu a hankali, don ramawa don haɓakar abincin da ke haifar da ƙarar ƙarfi da kuma yawan zafin jiki. Tasiri

11

Tasirin saurin yankewa da yanke ƙarfi akan kayan aiki yana da matukar mahimmanci, kuma babban dalilin da yasa kayan aikin ya rushe saboda tsananin yankewa. Dangantakar da ke tsakanin saurin yankewa da yanke ƙarfi: lokacin da saurin yanke ya yi sauri, ciyarwar ta kasance ba ta canzawa, kuma ƙarfin yanke yana raguwa sannu a hankali. Mafi girma shine, lokacin da ƙarfin yankewa da damuwa na ciki ya yi girma don shigar da shi, zai yi guntu (hakika, akwai kuma dalilai irin su damuwa da taurin lalacewa ta hanyar canjin yanayin zafi).

12

Yaushemashin daidaiciCNC lathes, ya kamata a ba da hankali na musamman ga waɗannan abubuwan:

(1) Don lathes na CNC na tattalin arziƙi na yanzu a cikin ƙasata, ana amfani da injunan asynchronous na yau da kullun na yau da kullun don gane canjin saurin tafiya ta hanyar masu juyawa. Idan babu raguwar injina, ƙarfin fitarwa na igiya sau da yawa bai isa ba a ƙananan gudu. Idan nauyin yankan ya yi girma, yana da sauƙi don samun gundura Motoci, amma wasu kayan aikin injin suna da matsayi na kayan aiki don magance wannan matsala sosai.

(2) Kamar yadda zai yiwu, kayan aiki na iya kammala sarrafa sashi ɗaya ko sauyin aiki ɗaya. A cikin kammala manyan sassa, ya kamata a biya kulawa ta musamman don kauce wa canza kayan aiki a tsakiya don tabbatar da cewa za'a iya sarrafa kayan aiki a lokaci guda.

(3) Lokacinjuyawazaren tare da lathe CNC, yi amfani da sauri mafi girma kamar yadda zai yiwu don cimma babban inganci da ingantaccen samarwa.

(4) Yi amfani da G96 gwargwadon iko.

(5) Mahimman ra'ayi na mashin mai sauri shine don sa abinci ya wuce saurin tafiyar zafi, don haka ana fitar da zafi mai yankewa tare da filaye na ƙarfe don ware yanke zafi daga kayan aiki, don tabbatar da cewa aikin ya yi aiki. ba zafi ko zafi kadan. Saboda haka, mashin ɗin sauri shine babban zaɓi. An daidaita saurin yankewa tare da babban adadin ciyarwa yayin zaɓar ƙaramin adadin haɗin baya.

(6) Kula da diyya na hancin kayan aiki R.

13

Teburin Grading Machinability Material Workpiece (Ƙananan P79)

Lokacin yankan zaren da aka saba amfani da shi da ma'aunin sa hannu na baya (babban P587)

Ƙididdigar ƙididdiga na adadi na geometric da aka saba amfani da su (babban P42)

Chart Canjin Inci zuwa Millimeters (Babban P27)

14

Vibration da kuma karya kayan aiki sukan faru a lokacin tsagi. Tushen tushen duk wannan shine cewa ƙarfin yanke ya zama ya fi girma kuma rigidity na kayan aiki bai isa ba. Ƙananan tsayin tsawo na kayan aiki, ƙananan kusurwar taimako, kuma mafi girman yanki na ruwa, mafi kyawun rigidity. Tare da mafi girman ƙarfin yankan, amma girman faɗin abin yankan tsagi, ƙarfin yankan da zai iya jurewa zai ƙaru yadda ya kamata, amma ƙarfin yankan kuma zai ƙaru. Akasin haka, ƙarami mai yankan tsagi, ƙarami ƙarfin da zai iya jurewa, amma ƙarfin yankan shima ƙarami ne.

15

Dalilan da ke haifar da vibration a lokacin slotting:

(1) Tsawon tsayin kayan aiki yana da tsayi da yawa, yana haifar da raguwa a cikin rashin ƙarfi.

(2) Yawan ciyarwar yana da jinkirin gaske, wanda zai haifar da ƙarfin yankan naúrar ya karu kuma ya haifar da girgiza mai girma. Ma'anar ita ce: P=F/ adadin yankan baya*f P shine ƙarfin yankan naúrar F shine ƙarfin yankan, kuma gudun yana da sauri Yana kuma girgiza wuka.

(3) Rashin ƙarfin injin bai isa ba, wato, kayan aiki na iya ɗaukar ƙarfin yankan, amma injin ɗin ba zai iya ɗaukarsa ba. Don sanya shi a hankali, kayan aikin injin baya motsawa. Gabaɗaya, sababbin gadaje ba su da irin wannan matsalar. Gado mai irin wannan matsalar ko dai tsoho ne ko kuma tsoho. Ko dai kuna yawan haɗuwa da masu kashe kayan aikin injin.

16

Lokacin da nake tuƙi da kaya, na ga cewa girman yana da kyau a farkon, amma bayan ƴan sa'o'i na aiki, sai na ga girman ya canza kuma girman ba shi da tabbas. Dalili kuwa shi ne, ƙarfin yankan ba shi da ƙarfi sosai saboda wuƙaƙen duk sababbi ne a farkon. Babban, amma bayan wani lokaci, kayan aiki ya ƙare kuma ƙarfin yanke ya zama ya fi girma, yana sa kayan aiki ya canza a kan chuck, don haka girman ya tsufa kuma ba shi da tabbas.

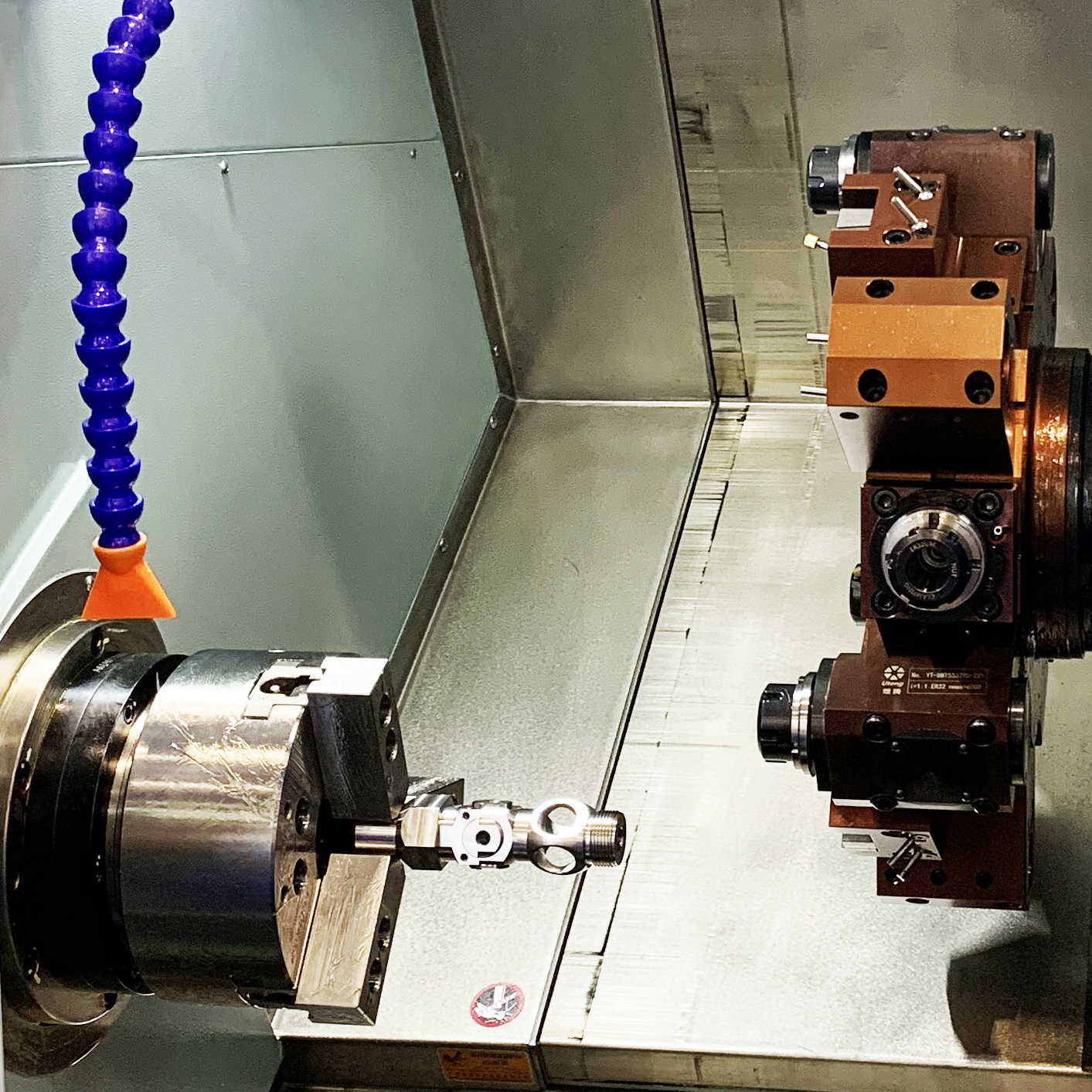

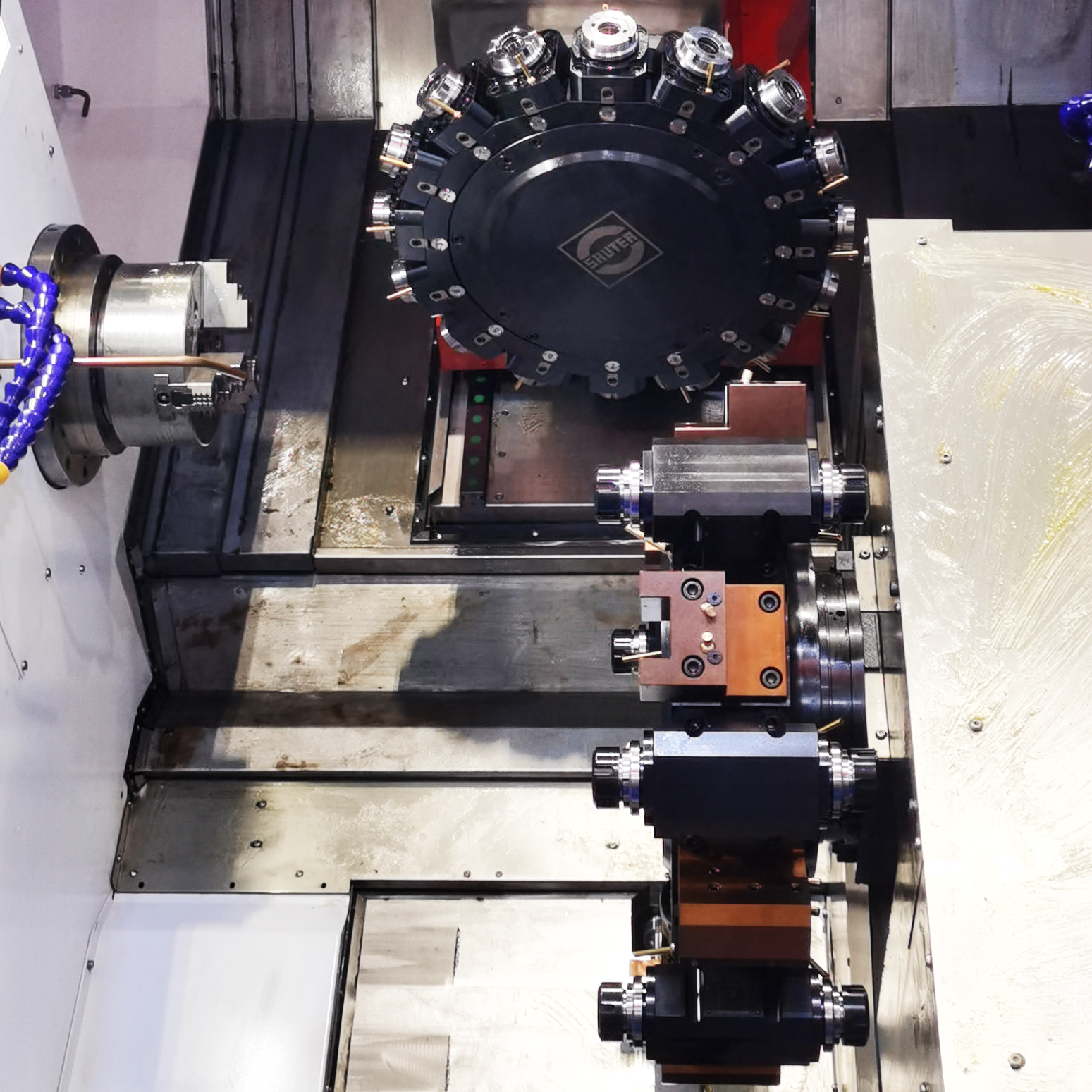

Anebon suna da mafi yawan kayan aikin samarwa, ƙwararrun injiniyoyi da ƙwararrun injiniyoyi da ma'aikata, ingantaccen tsarin kula da inganci da ƙungiyar ƙwararrun tallace-tallacen abokantaka kafin / bayan-tallace-tallace don tallafin China wholesale OEM Plastic ABS / PA / POM CNC Lathe CNC Milling 4 Axis / 5 Axis CNC machining sassa, CNC juya sassa. A halin yanzu, Anebon yana neman gaba don haɓaka haɗin gwiwa tare da abokan cinikin waje bisa ga ribar juna. Da fatan za a fuskanci kyauta don tuntuɓar mu don ƙarin bayani.

2022 Babban ingancin Sin CNC da Machining, Tare da ƙungiyar ƙwararrun ma'aikata da ƙwararrun ma'aikata, Kasuwar Anebon ta rufe Kudancin Amurka, Amurka, Gabas ta Tsakiya, da Arewacin Afirka. Yawancin abokan ciniki sun zama abokan Anebon bayan kyakkyawar haɗin gwiwa tare da Anebon. Idan kuna da buƙatun kowane samfuranmu, ku tuna tuntuɓar mu yanzu. Anebon zai sa ido a ji daga gare ku nan ba da jimawa ba.

Lokacin aikawa: Fabrairu-09-2023