Nawa kuka sani game da rarraba kayan aikin injin CNC?

Rarraba kayan aikin injin CNC ya dogara ne akan aiki, tsari da aikace-aikace.

Yanzu za mu kalli rarrabuwa daban-daban:

Bisa Aiki

Injin juyawa:Waɗannan injunan suna aiwatar da aikin jujjuya musamman akan abubuwan cylindrical ko conical.

Ana iya amfani da waɗannan injunan don niƙa filaye mai faɗi ko hadaddun.

Dangane da Tsarin

Cibiyoyin Injin Asali:Ana sanya sandal da kayan aiki a kwance akan tebur.

Cibiyoyin Injin Injiniya Tsaye:Ana sanya sandal da kayan aiki a tsaye akan tebur.

Na'urori masu axis:Waɗannan injunan suna sanye da gatari da yawa (3 ko fiye), suna ba su damar yin daidaitattun ayyuka masu rikitarwa.

Dangane da Aikace-aikacen

Injin hakowa inji ne da ke aiwatar da ayyukan hakowa da farko.

Injin niƙa:Ana iya amfani da waɗannan injina don niƙa da goge ƙarfe.

Injin Yankan Laser:Ana amfani da fasahar Laser don yanke abubuwa daban-daban.

Injin Ciki Electro (EDM):Waɗannan injuna suna siffata kuma suna haƙa kayan aikin lantarki.

Hanyoyin rarrabuwa don injunan CNC sun bambanta. Akwai nau'o'i da ƙayyadaddun bayanai da yawa. Ana iya rarraba ta ta amfani da hanyoyin rarrabawa da ke sama, da kuma ka'idodin aiki da tsari guda huɗu.

1. Rarraba kayan aikin inji bisa ga yanayin sarrafa su

1) Ma'aunin sarrafa CNC inji

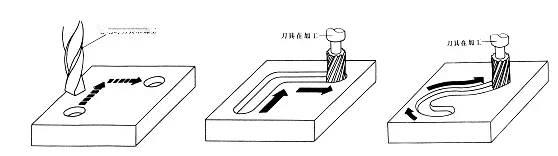

Abinda kawai ake buƙata don sarrafa batu shine daidaitaccen matsayi na sassa masu motsi daga kayan aikin injin zuwa wani. Abubuwan da ake buƙata na yanayin tsakanin maki don motsi ba su da tsauri sosai. A lokacin motsi, ba a yin aiki. Ba shi da mahimmanci yadda motsi ke faruwa tsakanin kowace axis daidaitawa. Don cimma daidaitattun matsayi da sauri, yana da mahimmanci don fara motsa nisa tsakanin maki biyu da sauri, sa'an nan kuma sannu a hankali kusa da matsayi don tabbatar da daidaito. Ana nuna yanayin motsi a ƙasa.

Injin niƙa na CNC da injuna CNC misalai ne na kayan aikin injin waɗanda ke da ikon sarrafa maki. Tsarin CNC da ake amfani da shi kawai don sarrafa batu ya zama mai wuya saboda ci gaban fasahar CNC.

(2) Kayan aikin injin CNC mai linzamin linzamin kwamfuta

Na'urorin CNC masu daidaitawa ana kuma san su da na'urorin CNC na linzamin kwamfuta. Yana da siffa cewa yana sarrafa ba kawai daidaitaccen matsayi tsakanin maki ba amma har da saurin motsi da hanya (hanyoyi), tsakanin maki biyu. Motsin sa yana da alaƙa kawai da kayan aikin injin yana daidaita gatura masu motsi a layi daya. Wannan yana nufin cewa haɗin kai ɗaya ne kawai ake sarrafa shi a lokaci guda. Ana iya amfani da kayan aiki don yanke a ƙimar ciyarwar da aka ƙayyade a lokacin tsarin sauyawa. Za a iya amfani da shi gabaɗaya don aiwatar da abubuwan da aka gyara na rectangular da taku.

Farashin CNCtare da mikakke iko ne yafi CNC milling inji da CNC grinders. Wannan tsarin CNC na kayan aikin injin ana kuma san shi da tsarin CNC mai sarrafa linzamin kwamfuta. Hakazalika, injinan CNC waɗanda ake amfani da su na musamman don sarrafa layin ba safai ba ne.

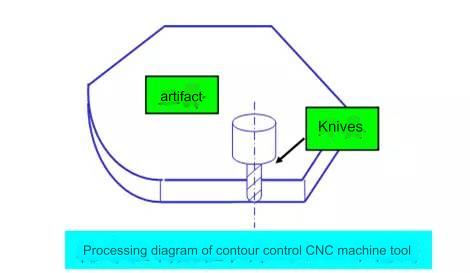

(3) 3D kwane-kwane iko kayan aikin injin CNC

Ci gaba da sarrafa injunan CNC kuma ana san su da na'urorin sarrafa kwanukan CNC. Siffar sarrafa wannan injin shine ikon sarrafa mahaɗar motsi biyu ko fiye a lokaci ɗaya.

Don tabbatar da cewa dangi motsi na kayan aiki a kan kwane-kwane na workpiece daidai da machining kwane-kwane na workpiece, shi wajibi ne don daidai daidaita gudun hijira da kuma gudun kowane hadewa motsi bisa ga daidai gwargwado dangantakar.

Domin amfani da wannan hanyar sarrafawa, dole ne na'urar CNC ta sami aikin haɗin gwiwa. Interpolation yana kwatanta siffar madaidaiciyar layi ko baka ta hanyar sarrafa lissafi da masu aiki a cikin tsarin CNC suka yi. Wannan yana dogara ne akan ainihin bayanan da shirin ya shigar, kamar daidaitawa don ƙarshen maki madaidaiciya, daidaitawa don ƙarshen maki na baka, ko radius ko haɗin cibiyar. Yayin ƙididdigewa, sanya bugun jini ga kowane mai kula da axis ɗin daidaitawa bisa ga sakamakon. Wannan yana sarrafa ƙaurawar haɗin gwiwa don kowane haɗin gwiwa don dacewa da kwandon da ake so. A lokacin motsi, kayan aikin yana ci gaba da yanke saman kayan aikin, wanda ke ba da izinin sarrafawa daban-daban kamar madaidaiciyar layi, lanƙwasa, da baka. Dabarun inji mai sarrafa kwane-kwane.

Wadannan kayan aikin injin sun hada da injinan lathes na CNC da injin niƙa da na'urorin yankan waya na CNC, wuraren injina, da dai sauransu. Na'urorin CNC da suka dace da su ana kiran su tsarin kula da kwane-kwane. Ana iya rarraba shi zuwa nau'i uku bisa ga adadin gatari da yake sarrafawa: form

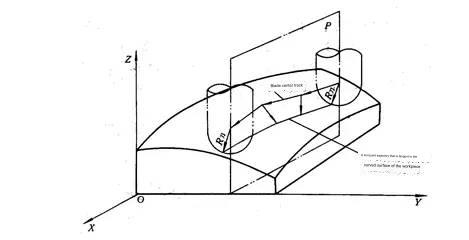

1 Haɗin axis guda biyu:ana amfani da shi musamman don lathes na CNC waɗanda ke sarrafa filaye masu jujjuyawar, ko injunan niƙa na CNC waɗanda ke sarrafa saman silinda mai lankwasa.

2 Semi-linkage 2 gatura:Ana amfani da wannan musamman don sarrafa kayan aikin injin da ke da gatura sama da 3. Ana iya haɗa gatari biyu kuma axis na uku na iya yin ciyarwa lokaci-lokaci.

3 Haɗin axis uku:Wannan haɗin gwiwa ne wanda ya ƙunshi gatari guda uku masu linzamin kwamfuta, yawanci X/Y/Z, kuma injinan milling na CNC, cibiyoyin injin, da dai sauransu ke amfani da su. Nau'in na biyu yana ba ku damar sarrafa haɗin kai guda biyu a lokaci guda a cikin X/Y/Z, kamar yadda haka kuma da axis coordinate axis wanda ke juyawa a kusa da gatura daidaitawa na madaidaiciya.

A cikin cibiyar jujjuya, alal misali, haɗin kai tsakanin gatura daidaitawa guda biyu na layi (X-axis da Z-axis a cikin madaidaiciyar hanya) dole ne a sarrafa su lokaci guda tare da haɗin kai zuwa igiya (C-axis), wanda ke juyawa kusa da axis Z. .

4 Haɗin axis huɗu:Sarrafa madaidaitan daidaitawa guda uku X, Y da Z lokaci guda don haɗa su tare da axis ɗin daidaitawa guda ɗaya.

Haɗin axis guda biyar:Wannan yana ba ku damar sarrafa haɗin haɗin gatura guda uku a lokaci ɗaya, X/Y/Z. Har ila yau, kayan aikin yana sarrafa guda biyu na AB da C masu daidaita gatura waɗanda ke juyawa a kusa da waɗannan gatura masu layi. Wannan yana ba da jimlar gatari biyar. Yanzu ana iya sanya kayan aiki a ko'ina cikin sarari.

Ana iya sarrafa kayan aikin don jujjuya duka biyun gatari x da y lokaci guda, don haka koyaushe yana yanke ta hanya ɗaya da saman kwandon shara. Wannan yana tabbatar da santsi da daidaito na farfajiya. Wurin da aka yi amfani da shi yana da santsi, yana ƙaruwa da inganci.

2. Rarraba tsarin sarrafa servo

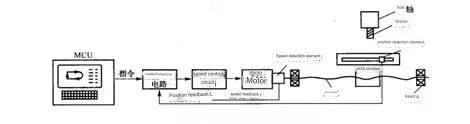

1) Kayan aikin injin CNC mai buɗewa

Irin wannan kayan aikin injin yana da servo feed-loop feed, wanda ke nufin cewa babu na'urar gano ra'ayi. Motar tafiyarsa yawanci mataki ne. Babban fasalin motar stepper shine cewa yana jujjuya cikakken mataki duk lokacin da tsarin sarrafawa ya canza siginar bugun jini. Motar tana da fasalin kulle kai kuma ana iya amfani dashi don daidaita kusurwar nesa.

Mai rarraba bugun jini yana sarrafa da'irar tuƙi ta amfani da siginar umarnin ciyarwa daga tsarin CNC. Ana iya canza adadin bugun bugun jini da mitar bugun jini don sarrafa mahaɗar daidaitawa, saurin ƙaura, ko ƙaura. hanya.

Babban fasali na wannan hanya shine sauƙi, sauƙin amfani, da ƙananan farashi. Babu matsala rashin kwanciyar hankali tare da tsarin kulawa saboda tsarin CNC kawai yana aika sigina guda ɗaya. Daidaiton ƙaura yana da ƙasa, duk da haka, saboda kuskuren watsawa na inji ba a gyara ta hanyar amsawa ba.

An yi amfani da wannan hanyar sarrafawa ta duk injinan CNC na farko, amma yana da ƙarancin gazawa. Duk da ingantuwar da'irar tuƙi, wannan hanyar sarrafawa har yanzu ana amfani da ita sosai a yau. Ana amfani da wannan hanyar sarrafawa, musamman a cikin ƙasarmu don tsarin tsarin CNC na gaba ɗaya wanda ke da tattalin arziki da kuma canza kayan aiki na tsofaffi ta amfani da CNC. Wannan hanyar sarrafawa kuma tana ba da damar saita kwamfuta guda ɗaya ko kwamfutar allo a matsayin injin CNC, wanda ke rage farashin tsarin.

Kayan aikin inji tare da rufaffiyar madauki

Irin wannan kayan aikin injin CNC yana amfani da sarrafa madauki. Motar ɗin na iya zama ko dai DC ko AC kuma dole ne ya sami amsawar matsayi biyu da kuma daidaita martanin saurin gudu don gano duk wani motsi na ɓangaren motsi a kowane wuri yayin aiki. Tsarin CNC yana ciyar da adadin baya a ainihin lokacin zuwa mai kwatanta. Ana samun siginar umarni ta hanyar haɗin gwiwa kuma idan aka kwatanta da adadin. Ana amfani da bambancin don sarrafa servodrive, wanda ke tafiyar da ɓangaren ƙaura don kawar da kuskuren.

Dangane da wuri da na'urar amsawa na mai gano ra'ayin matsayi, akwai hanyoyi guda biyu: rufaffiyar madauki (cikakken) da madaidaicin madauki (madaidaicin madauki).

1 Rufe madauki iko

Na'urar mayar da martani, kamar yadda aka nuna a cikin adadi yana amfani da sashin gano nesa mai layi. (A halin yanzu, ana amfani da ƙa'idar grating mafi yawanci) Ana ɗora wannan akan sirdin kayan aikin injin. Yana gano ƙaura kai tsaye a cikin daidaitawar kayan aikin injin. Ana iya kawar da siginar daga motar ta hanyar amsawa. Kuskuren watsawa yana raguwa a cikin sarkar watsawa na inji, wanda ke haifar da babban daidaito don matsayar injin.

Amsa mai ƙarfi na sarkar watsawar injin gabaɗaya ya fi tsayi fiye da amsawar lantarki. Duk tsarin kula da madauki yana da matukar wahala a daidaita shi, kuma ƙira da gyare-gyarensa suna da sarƙaƙiya. Wannan rufaffiyar-madauki Hanyar sarrafawa da ake amfani da farko ga CNC daidaita inji, CNC daidaici nika inji, da dai sauransu Wannan na bukatar high daidaici.

2 Semi-rufe madauki iko

Ra'ayin matsayi ya dogara ne akan abubuwan gano kusurwa, waɗanda a halin yanzu galibi masu ɓoye ne. Motocin servo ko sukurori suna sanye da abubuwan gano kusurwa (a halin yanzu galibi masu ɓoyewa). Halayen sarrafawa na tsarin sun fi kwanciyar hankali saboda yawancin hanyoyin sadarwa na inji ba a cikin rufaffiyar madauki ba. Ƙimar ƙayyadadden ƙimar software na iya inganta daidaiton kurakuran watsa injin inji, kamar kuskuren dunƙule. Yawancin injunan CNC suna amfani da yanayin madauki na kusa.

3 Dimensional hybrid iko inji CNC

Don ƙirƙirar tsarin kula da matasan, halayen kowane hanyar sarrafawa za a iya tattara su cikin zaɓi. Don saduwa da buƙatun wasu kayan aikin injin da rama bambance-bambancen da ke tsakanin hanyoyin biyu, ana ba da shawarar cewa a yi amfani da tsarin sarrafa matasan. Hanyoyi guda biyu na gama-gari sune nau'in ramawa mai buɗewa da nau'in biyan diyya mai rufaffiyar madauki.

3. CNC Systems an rarraba bisa ga matakin aikin su

An rarraba tsarin CNC zuwa kashi uku bisa ga matakin aikin su: ƙananan, matsakaici, da babba. Ana amfani da wannan hanyar rarrabawa sosai a cikin ƙasarmu. Ma'auni na rarrabuwa sun bambanta daga lokaci ɗaya zuwa na gaba. Dangane da matakin ci gaba na yanzu, nau'ikan tsarin CNC daban-daban sun kasu kashi uku bisa wasu ayyuka da alamomi. Matsakaici da tsarin CNC masu tsayi ana kiransu da cikakken aiki ko daidaitaccen CNC.

(1) Yankan Karfe

Yana nufin injinan CNC waɗanda ke aiwatar da ayyukan yanke daban-daban kamarcnc juya & niƙa. Ana iya raba wannan zuwa manyan sassa biyu.

Injin CNC irin su lathes da injin niƙa.

Babban fasalin cibiyar mashin ɗin shine ɗakin karatu na kayan aiki, wanda ke da injin canza kayan aiki ta atomatik. Yana wuce aikin aikin ta cikin injin sau ɗaya kawai. Bayan clamping da workpiece, da yankan kayan aikin ana maye gurbinsu ta atomatik. Daban-daban matakai, ciki har da niƙa (juyawa), maɓalli, reaming (hakowa), da zaren taping ana ci gaba da yin a kan kowane surface na yanki a kan wannan inji, misali, (gini/nika). Cibiyar, cibiyar juyawa, cibiyar hakowa, da dai sauransu.

(2) Karfe Forming

Yana nufin injunan CNC waɗanda ake amfani da su don extrusion, naushi da latsawa, gami da zane, da sauran ayyukan ƙirƙira. Wasu daga cikin injinan CNC da aka fi amfani da su sun haɗa da matsi na CNC da masu bututun CNC.

(3) Rukunin Gudanarwa na Musamman

CNC waya EDM inji ne na kowa, bi da bicnc karfe yankaninji da CNC Laser sarrafa inji.

(4) Aunawa da zane

Ƙunshe a cikin wannan rukuni sun haɗa da na'urori masu aunawa masu girma uku, masu saita kayan aiki na CNC, CNC mãkirci, da dai sauransu.

Babban manufar Anebon ita ce ba ku abokan cinikinmu kyakkyawar alaƙar kasuwanci, da ba da kulawa ta keɓaɓɓu ga duka don Sabbin Zane-zane na OEM Shenzhen Madaidaicin Hardware Fabrication.Farashin CNCtsari, daidaitaccen simintin gyare-gyare, sabis na samfur. Kuna iya buɗe mafi ƙarancin farashi anan. Hakanan zaku sami samfuran inganci da mafita da sabis mai ban mamaki anan! Kada ku yi jinkirin kama Anebon!

Sabuwar Zane-zane don Sabis ɗin Mashin ɗin CNC na China da Sabis ɗin Mashin ɗin CNC na Al'ada, Anebon yana da lambobi na dandamali na kasuwancin waje, waɗanda su ne Alibaba, Kasuwan Duniya, Kasuwar Duniya, Made-in-china. "XinGuangYang" HID samfurori da mafita suna sayar da su sosai a Turai, Amurka, Gabas ta Tsakiya da sauran yankuna fiye da kasashe 30.

Lokacin aikawa: Oktoba-06-2023