Aluminum shine mafi yawan amfani da kayan ƙarfe mara ƙarfe, kuma kewayon aikace-aikacensa har yanzu yana faɗaɗa. Fiye da nau'ikan samfuran aluminium sama da 700,000 ana samarwa ta amfani da kayan aluminium. Bisa kididdigar da aka yi, akwai nau'o'in aluminum fiye da 700,000, kuma masana'antu daban-daban, kamar masana'antun gine-gine da kayan ado, masana'antun sufuri, masana'antar sararin samaniya, da dai sauransu, suna da bukatu daban-daban. A yau, Xiaobian zai gabatar da fasahar sarrafa kayayyakin aluminum da kuma yadda za a guje wa nakasar sarrafawa.CNC machining part

Amfani da halaye na aluminum sune kamar haka:

1. Ƙananan yawa. Girman aluminium yana kusan 2.7 g/cm3. Yawansa shine kawai 1/3 na ƙarfe ko jan ƙarfe.

2. Babban filastik. Aluminum yana da sassauƙa kuma ana iya sanya shi cikin samfura daban-daban ta hanyoyin sarrafa matsa lamba kamar extrusion da mikewa.

3. Juriya na lalata. Aluminum ƙarfe ne da aka caje shi sosai, kuma za a samar da fim ɗin oxide mai kariya a saman ƙasa a ƙarƙashin yanayin yanayi ko anodizing. Yana da mafi kyawun juriya na lalata fiye da ƙarfe.

4, mai sauƙin ƙarfafawa. Aluminum mai tsabta ba shi da ƙarfi sosai, amma ana iya ƙara shi ta hanyar anodizing.

5. Easy surface jiyya. Jiyya na saman na iya ƙara haɓaka ko canza yanayin saman aluminum. A aluminum anodizing tsari ne quite balagagge da kuma barga da kuma yadu amfani don aiwatar da aluminum kayayyakin.

6. Kyakkyawan aiki mai kyau da sauƙin sake yin amfani da shi.

Fasahar sarrafa samfuran aluminum

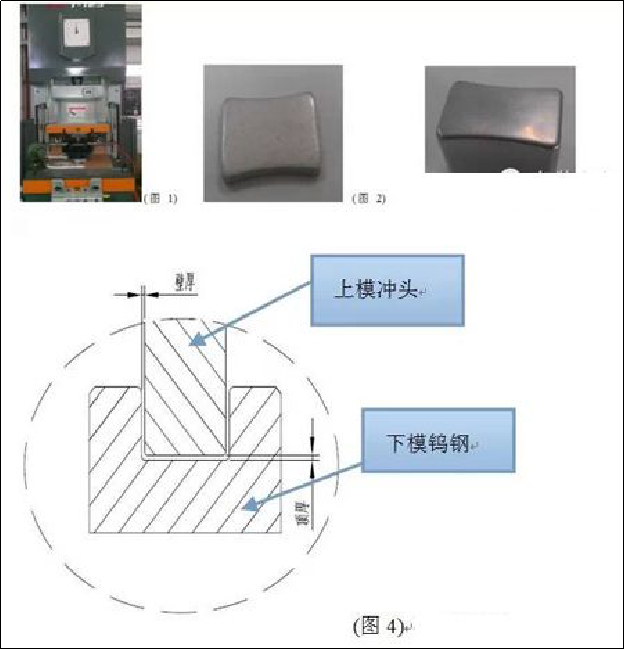

Punching na aluminum kayayyakin

1. Sanyi naushi

Yi amfani da pellet na kayan abu na aluminum. Ana amfani da injin extrusion da mutu don gyare-gyaren lokaci ɗaya kuma sun dace da samfuran cylindrical ko sifofin samfur waɗanda ke da wahalar cimma ta hanyar shimfidawa, kamar samfuran oval, murabba'i, da samfuran rectangular.

Yawan na'urar da aka yi amfani da ita tana da alaƙa da ɓangaren ɓangaren samfurin. Kaurin bangon samfurin shine tazarar dake tsakanin babban mutun mutun da ƙaramin mutun tungsten. Lokacin da aka danna naushi na sama da ƙananan mutun tungsten karfe tare, tazarar tsaye zuwa tsakiyar mataccen ƙasa shine Don saman kauri na samfurin.aluminum part

Abũbuwan amfãni: Zagayewar buɗewar mold gajere ne, kuma farashin ci gaba yana ƙasa da na ƙirar zane.

Rashin hasara: Tsarin samarwa yana da tsayi, girman samfurin yana canzawa sosai, kuma farashin aiki yana da yawa.

2. Miqewa

Yi amfani da fata na kayan aluminum. Ya dace da lalata jikin da ba na cylindrical (kayayyakin aluminum tare da samfurori masu lankwasa), sau da yawa ta yin amfani da ci gaba da injunan mutuwa da ƙira don saduwa da buƙatun siffar.

Abũbuwan amfãni: ƙarin hadaddun da mahara nakasawa kayayyakin da barga girma girma iko a cikin samar da tsari, da samfurin surface ne santsi.

Hasara: babban farashi mai ƙima, in mun gwada da tsayin ci gaba da zagayowar, da babban zaɓi na inji da ainihin buƙatun.

Surface jiyya na aluminum kayayyakin

1. Yashi (shot peening)

Tsarin tsaftacewa da roughening karfe saman ta yin amfani da tasirin yashi mai saurin gudu.

A surface jiyya na aluminum sassa a cikin wannan hanya na iya samun wani mataki na tsabta da kuma daban-daban roughness a kan surface na workpiece domin inji Properties na surface na workpiece suna inganta, don haka inganta gajiya juriya na workpiece da kuma kara rata tsakaninsa da sutura. Adhesion na sutura yana tsawaita ƙarfin fim ɗin da aka rufe kuma yana da kyau ga daidaitawa da kayan ado na sutura. Mun ga a cikin wannan tsari cewa samfuran Apple sune o2. goge baki

Suna amfani da aikin injiniya, sinadarai, ko electrochemical don rage ƙunci na kayan aikin da samun hanyar sarrafa saman ƙasa mai haske. Tsarin goge goge ya kasu kashi na inji, sinadarai, da polishing electrolytic. Bayan injin polishing + electrolytic polishing, sassan aluminum na iya zama kusa da tasirin madubi na bakin karfe. Wannan tsari yana ba wa mutane ma'anar sauƙi mai sauƙi da kuma makomar gaye.

3. Zane

Zane-zanen waya na ƙarfe shine tsarin masana'anta na sake goge takardar aluminum daga layi tare da takarda yashi. Za a iya raba zane zuwa madaidaiciya, bazuwar, karkace, da zare. Tsarin zanen waya na ƙarfe na iya nuna a sarari kowane ƙaramin siliki, don haka gashin gashi mai ladabi ya bayyana a cikin matte na ƙarfe, kuma samfurin yana da ma'anar salo da fasaha.

4. Babban yanke mai sheki

Yin amfani da injin sassaƙa, ana ƙarfafa wuƙar lu'u-lu'u a kan babban mashin ɗin na'urar, tana jujjuyawa cikin sauri (gaba ɗaya 20,000 rpm) don yanke sassan, kuma an samar da wani yanki mai haske a saman samfurin. Hasken fitattun abubuwan yankan yana shafar saurin rawar niƙa. Da sauri gudun rawar soja, da haske da yanke karin bayanai, kuma akasin haka, da duhu da kuma mafi m don samar da yankan Lines. Ana amfani da yankan mai kyalli da sheki sosai a cikin wayoyin hannu kamar iPhones. Wasu firam ɗin ƙarfe na TV masu tsayi kwanan nan sun ɗauki wani babban aikin niƙa mai sheki. Bugu da ƙari, anodizing da tsarin zanen waya suna sa TV ɗin ya cika da salon da fasaha.

5. Anodizing

Anodic hadawan abu da iskar shaka yana nufin electrochemical hadawan abu da iskar shaka iskar shaka ko gami. A karkashin daidaitattun electrolyte da ƙayyadaddun yanayin tsari, aluminum da alloys suna samar da fim din oxide akan samfurin aluminum (anode) saboda aikin da ake amfani da shi a halin yanzu. Anodizing ba zai iya kawai magance lahani na aluminum surface taurin da kuma sa juriya amma kuma tsawaita rayuwar sabis na aluminum da kuma inganta aesthetics. Ya zama wani ɓangaren da ba makawa a cikin jiyya na saman aluminum kuma a halin yanzu shine mafi yawan amfani da shi kuma yana da nasara sosai. sana'a

6. anode mai launi biyu

anodizing launi biyu yana nufin anodizing akan samfur ɗaya da ba da launuka daban-daban zuwa takamaiman wurare. Ba a cika amfani da tsarin anodizing mai launi biyu a cikin masana'antar TV ba saboda tsarin yana da rikitarwa kuma yana da tsada. Duk da haka, bambanci tsakanin launuka biyu na iya

mafi kyawun nuna babban matsayi da na musamman na samfurin.

Ma'auni na tsari da ƙwarewar aiki don rage nakasar sarrafa aluminum

Akwai dalilai da yawa don lalata sassan aluminum, waɗanda ke da alaƙa da kayan, siffar ɓangaren, da yanayin samarwa. Akwai abubuwa da yawa masu zuwa: nakasar da damuwa na cikin gida ke haifarwa, nakasar da ake samu ta hanyar yanke ƙarfi da yanke zafi, da nakasar da ke haifar da matsawa.

Matakan tsari don rage nakasar sarrafawa

1. Rage damuwa na ciki na al'adun gashi

Na halitta ko tsufa na wucin gadi da jiyya na jijjiga na iya kawar da danniya na ciki na sarari. Pre-aiki kuma hanya ce mai inganci. Saboda babban izni, nakasar bayan sarrafawa shima yana da mahimmanci ga mara kyau tare da kai mai kitse da manyan kunnuwa. A ce an riga an riga an aiwatar da abin da ya wuce gona da iri, kuma an rage izinin kowane bangare. A wannan yanayin, zai iya rage nakasar sarrafawa na tsari na gaba kuma ya saki wasu damuwa na ciki bayan an riga an yi aiki na wani lokaci.

2. Inganta ikon yankan kayan aiki

Kayan aiki da sigogi na geometric na kayan aiki suna da tasiri mai mahimmanci akan ƙarfin yankewa da yanke zafi. Madaidaicin zaɓi na kayan aiki ya zama dole don rage lalacewar mashin ɗin ɓangaren.

1) Zaɓin madaidaicin ma'auni na kayan aiki na geometric.

① Rake kwana: A karkashin yanayin kiyaye ƙarfin ruwa, an zaɓi kusurwar rake daidai don zama mafi girma; a daya bangaren kuma yana iya nika kaifi mai kaifi, sannan a daya bangaren kuma yana iya rage nakasar da ake yankewa, da sanya guntuwar da ake cirewa cikin santsi, sannan ta rage karfin yankewa da yanke zafin jiki. Kada a taɓa amfani da kayan aiki tare da kusurwa mara kyau.

②Angle Relief: Girman kusurwar taimakon kai tsaye yana tasiri ga lalacewa da ingancin injin da aka yi. Kaurin yanke shine mahimmancin yanayi don zaɓar kusurwar sharewa. Kayan aiki yana buƙatar ɓarkewar zafi mai kyau yayin niƙa mai ƙazanta saboda ƙimar abinci mai mahimmanci, yankan nauyi mai nauyi, da haɓakar zafi mai yawa. Don haka, yakamata a zaɓi kusurwar sharewa don zama ƙarami. Lokacin da niƙa mai kyau, yankan gefen dole ne ya kasance mai kaifi, an rage juzu'in da ke tsakanin fuskar gefe da saman injin da aka yi, kuma an rage nakasar nakasar. Don haka, kusurwar sharewa ya kamata ya zama mafi mahimmanci.

③ Helix kusurwa: kusurwar helix ya kamata ya zama babba kamar yadda zai yiwu don santsi da rage ƙarfin milling.

④ Babban kusurwar raguwa: Daidaita raguwa na tsakiya na tsakiya zai iya inganta yanayin zafi da kuma rage yawan zafin jiki na yankin sarrafawa.

2) Inganta tsarin kayan aiki.

① Rage adadin haƙoran mai yankan niƙa kuma ƙara sararin guntu. Saboda babban filastik na kayan aluminium da babban nakasar yankewa yayin aiki, ana buƙatar isasshen sarari guntu, don haka radius na ƙasan guntu ya kamata ya zama mahimmanci, kuma adadin haƙoran milling ya zama ƙanana.

② a nika hakora sosai. Ƙimar ƙaƙƙarfan ƙimar yankan hakora ya kamata ya zama ƙasa da Ra=0.4um. Kafin amfani da sabon wuka, ya kamata ku yi amfani da dutse mai kyau don sassaukar gaba da baya na haƙoran wukar sau ƴan lokaci don kawar da bursu da ƴan ƴan ƙwanƙwasa da suka rage yayin da ake kaifi. Ta wannan hanyar, za'a iya rage zafi mai yankewa, kuma yanke nakasar yana da ƙananan ƙananan.

③ Tsananin sarrafa ma'aunin lalacewa na kayan aiki. Bayan da kayan aiki da aka sawa, da surface roughness darajar da workpiece ƙara, da yankan zafin jiki ya tashi, da workpiece nakasawa yana ƙaruwa. Sabili da haka, ban da zaɓin kayan aikin kayan aiki tare da juriya mai kyau, ƙirar kayan aiki kada ta kasance mafi kyau fiye da 0.2mm. In ba haka ba, yana da sauƙi don samar da gefen da aka gina. Lokacin yankan, yawan zafin jiki na workpiece bai kamata ya wuce 100 ℃ don hana nakasawa ba.

3. Inganta hanyar clamping na workpiece

Don kayan aikin aluminum mai bakin ciki tare da rashin ƙarfi, ana iya amfani da hanyoyin matsawa masu zuwa don rage lalacewa:

①Domin bakin ciki-banga bushing sassa, idan uku-jaw kai tsakiya chuck ko spring chuck da ake amfani da radial clamping, da workpiece zai babu makawa nakasu da zarar an sake shi bayan aiki. Ya kamata a yi amfani da hanyar da za a danna ƙarshen axial fuska tare da mafi kyawun rigidity. Sanya rami na ciki na sashin, yi madaidaicin zaren, saka shi a cikin rami na ciki, danna ƙarshen fuska tare da farantin murfin akan sa, sannan ku matsa shi da goro. Ana iya nisantar nakasar matsewa yayin yin aikin da'irar waje don samun gamsasshen daidaito.

② Lokacin sarrafa bakin ciki-bango da bakin ciki-farantin workpieces, yana da kyau a yi amfani da injin tsotsa kofuna don samun ko'ina rarraba clamping karfi sa'an nan aiwatar da wani karamin adadin yankan, wanda zai iya hana workpiece nakasawa.

Bugu da ƙari, ana iya amfani da hanyar tattarawa. Don ƙara girman aiki na bakin ciki-banga workpieces, matsakaici za a iya cika a cikin workpiece don rage nakasawa na workpiece a lokacin clamping da yankan. Alal misali, urea narke mai dauke da 3% zuwa 6% potassium nitrate an zuba a cikin workpiece. Bayan aiki, za a iya nutsar da aikin a cikin ruwa ko barasa, kuma ana iya narkar da filler kuma a zubar da shi.

4. Madaidaicin tsari na matakai

A lokacin babban saurin yankewa, saboda babban izinin injina da yanke yanke, aikin niƙa yakan haifar da girgizawa, wanda ke shafar daidaiton mashin ɗin da ƙarancin ƙasa. Saboda haka, da CNC high-gudun sabon tsari za a iya kullum a raba zuwa roughing-Semi-kammala-kusurwar-share-kammala da sauran hanyoyin. Wani lokaci yakan zama dole ga sassan da ke da madaidaicin buƙatun don yin kammala na biyu da gamawa. Bayan m machining, sassa za a iya sanyaya ta halitta, kawar da damuwa na ciki lalacewa ta hanyar m machining da kuma rage nakasawa. Izinin da aka bari bayan m machining ya kamata ya fi nakasar, gabaɗaya 1 zuwa 2 mm. A lokacin karewa, da karewa surface na sassa ya kamata kula da wani uniform machining izni, kullum 0.2 ~ 0.5mm, don haka da cewa kayan aiki ne barga a lokacin machining tsari, wanda zai iya muhimmanci rage yankan nakasawa, samun mai kyau surface machining ingancin da kuma tabbatar da samfurin daidaito.

Ƙwarewar aiki don rage ɓarna na inji

Baya ga dalilan da ke sama, sassan sassan aluminum sun lalace yayin sarrafawa. Hanyar aiki kuma tana da mahimmanci a ainihin aiki.

1. Don sassan da ke da izinin yin amfani da manyan kayan aiki, don samar da su da mafi kyawun yanayin zafi a lokacin aikin injiniya da kuma guje wa zafi mai zafi, ya kamata a yi amfani da mashigin mashin a lokacin aikin. Idan takarda mai kauri na 90mm yana buƙatar sarrafa shi zuwa 60mm idan an niƙa gefe ɗaya kuma a yi niƙa ɗaya gefen nan da nan, kuma ana sarrafa girman ƙarshe a lokaci ɗaya, lebur ɗin zai kai 5mm; idan an sarrafa shi da ma'ana tare da maimaita ciyarwa, kowane gefe ana sarrafa shi sau biyu zuwa Girman ƙarshe na iya ba da tabbacin fa'ida na 0.3mm.sashin hatimi

2. Idan akwai ramuka da yawa akan sassan farantin, bai dace a yi amfani da tsarin sarrafa tsari na rami ɗaya da rami ɗaya yayin sarrafawa ba, wanda zai haifar da lalacewa da sauri saboda rashin daidaituwa. Ana ɗaukar nau'i-nau'i masu yawa, kuma kowane Layer ana sarrafa shi zuwa dukkan cavities a lokaci guda, sa'an nan kuma a sarrafa Layer na gaba don sanya sassan su daidaita da kuma rage lalacewa.

3. Rage ƙarfin yankewa da yanke zafi ta canza adadin yanke. Daga cikin abubuwa uku na yankan adadin, adadin haɗin gwiwar baya yana tasiri sosai ga yankewa. Idan alawus ɗin injin ɗin ya yi yawa, ƙarfin yankan fas ɗin ɗaya ya yi yawa, wanda ba kawai zai lalata sassan ba amma kuma zai yi tasiri ga ƙaƙƙarfan mashin ɗin na'urar da kuma rage ƙarfin kayan aiki—yawan wuƙaƙen da za a ci. Idan an rage baya, aikin samarwa zai ragu sosai. Koyaya, ana amfani da niƙa mai sauri a cikin injinan CNC, wanda zai iya shawo kan wannan matsala. Yayin da ake rage yawan yankan baya, idan dai an ƙara ciyarwa daidai kuma an ƙara saurin kayan aikin injin, za a iya rage ƙarfin yankewa, kuma ana iya tabbatar da ingantaccen aiki a lokaci guda.

4. Ya kamata kuma a kula da odar motsin wuka. Rough machining yana jaddada haɓaka aiki da kuma bin ƙimar cirewa kowane raka'a na lokaci. Gabaɗaya, ana iya amfani da niƙa da aka yanke. Wato, an cire abubuwan da suka wuce gona da iri a saman blank a cikin sauri mafi sauri da mafi ƙarancin lokaci, kuma an kafa ma'aunin geometric da ake buƙata don kammalawa. Duk da yake karewa yana jaddada babban daidaito da inganci, yana da kyau a yi amfani da milling. Saboda kaurin yankan hakora a hankali yana raguwa daga matsakaicin zuwa sifili yayin saukar da niƙa, matakin ƙarfin aiki yana raguwa sosai, kuma matakin nakasa ɓangaren kuma yana raguwa.

5. Sirin-bango workpieces suna nakasa saboda clamping a lokacin aiki; ko da gamawa ba zai yuwu ba. Don rage nakasawa na workpiece zuwa mafi ƙanƙanta, zaku iya sassauta ɓangaren latsawa kafin kammala girman ƙarshe don aikin aikin zai iya komawa yanayinsa na asali sannan kuma danna shi kaɗan, muddin ana iya matse aikin (gaba ɗaya) . Bisa ga ji na hannu), ana iya samun kyakkyawan sakamako na aiki ta wannan hanya. A wasu kalmomin, aikin batu na clamping karfi zai fi dacewa a kan goyon bayan surface, da kuma clamping karfi ya kamata a yi amfani a cikin shugabanci na mai kyau workpiece rigidity. Don tabbatar da cewa workpiece ba sako-sako da, da karami da clamping karfi, mafi alhẽri.

6. A lokacin da machining sassa tare da wani rami, kokarin kada a bar milling abun yanka kai tsaye nutse cikin part kamar rawar soja lokacin da machining cikin rami, haifar da rashin isasshen sarari ga milling abun yanka don saukar da kwakwalwan kwamfuta da matalauta guntu cire, haifar da overheating, fadadawa. , da rushewar sassan - wukake, karaya, da sauran abubuwan da ba su dace ba. Da farko, a haƙa ramin tare da tuƙi mai girman girman mai yankan niƙa ko kuma girman girmansa, sannan a niƙa shi da abin yankan niƙa. A madadin, ana iya amfani da software na CAM don samar da shirye-shiryen rundunonin karkace.

Anebon Metal Products Limited na iya samar da CNC Machining, Die Casting, Sheet Metal Fabrication sabis, da fatan za a iya tuntuɓar mu.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Lokacin aikawa: Juni-16-2022