Menene siririn axle na mota?

Siriririyar gatari mota nau'i ne da ake amfani da shi a cikin motoci kuma an tsara shi don ya zama haske. Slender axles yawanci ana amfani da su a cikin motoci tare da mai da hankali kan ingancin mai da ƙarfin aiki. Suna rage nauyin abin hawa gaba ɗaya tare da inganta yadda ake sarrafa shi. Wadannan axles yawanci ana yin su ne daga sassauƙa, kayan ƙarfi kamar aluminum ko ƙarfe mai ƙarfi. An gina waɗannan aksulu don su iya ɗaukar ƙarfin tuƙi, kamar ƙarfin wutar lantarki da injin ke haifarwa, kuma har yanzu suna kiyaye ƙaƙƙarfan ƙira mai sauƙi. Siririr axles suna da mahimmanci don watsa wutar lantarki daga injin zuwa ƙafafun.

Me yasa yake da sauƙin lanƙwasa da nakasa yayin sarrafa siririyar sandar motar?

Zai yi wuya a lanƙwasa ko gurɓata igiyar da ke da sirara. Abubuwan da ake amfani da su don kera mashinan mota (wanda kuma aka sani da tuƙi ko axles) galibi suna da ƙarfi da ɗorewa, kamar haɗaɗɗun fiber carbon ko karfe. An zaɓi kayan da aka yi amfani da su don ƙarfin ƙarfin su, wanda ake buƙata don tsayayya da juzu'i da ƙarfin da aka haifar da watsawa da injin motar.

A lokacin masana'anta, shafts suna bi ta hanyoyi daban-daban, kamar ƙirƙira da jiyya na zafi, don kiyaye tsayin daka da ƙarfin su. Wadannan kayan, tare da fasaha na masana'antu, suna hana shafts daga lankwasa a karkashin yanayi na al'ada. Koyaya, matsananciyar ƙarfi kamar karo da haɗari na iya lanƙwasa ko nakasu ga kowane ɓangaren motar, gami da ramuka. Yana da mahimmanci a gyara ko musanya duk wani ɓangarorin da suka lalace don tabbatar da aminci da ingantaccen aiki na abin hawan ku.

Tsarin injina:

Yawancin sassan shaft suna da rabon al'amari na L / d> 25. A kwance siriri axis yana da sauƙin lankwasa ko kuma zai iya rasa kwanciyar hankali a ƙarƙashin rinjayar nauyi, yankan ƙarfi da manyan rundunonin clamping. Matsalolin danniya a kan siriri mai siriri dole ne a rage lokacin da ake juya shaft.

Hanyar sarrafawa:

Ana amfani da jujjuyawar ciyarwa, tare da matakan ingantattun matakai, kamar zaɓin sigogin lissafi na kayan aiki, yankan adadi, na'urori masu tayar da hankali, da kayan aikin bushewa.

Binciken Abubuwan da ke Haɓaka Nakasar Juya Siriri

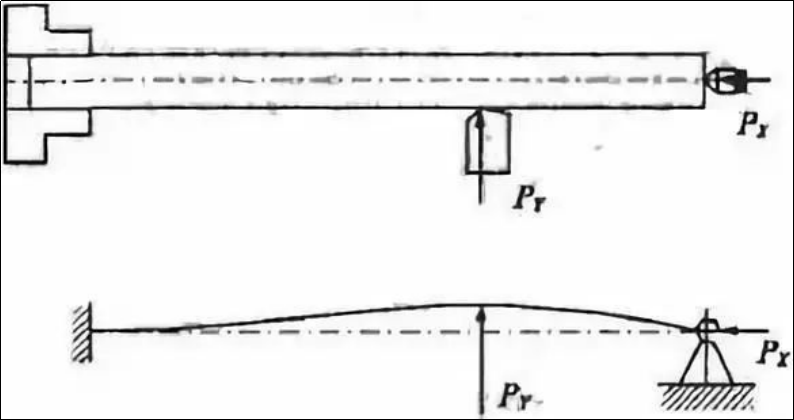

Ana amfani da dabarun manne na gargajiya guda biyu don juya siririyar ramuka a cikin lathes. Hanya ɗaya tana amfani da matse ɗaya tare da shigarwa na sama ɗaya, ɗayan kuma shine manyan shigarwa biyu. Za mu fi mai da hankali kan dabarun manne guda ɗaya da saman. Kamar yadda aka nuna a hoto 1.

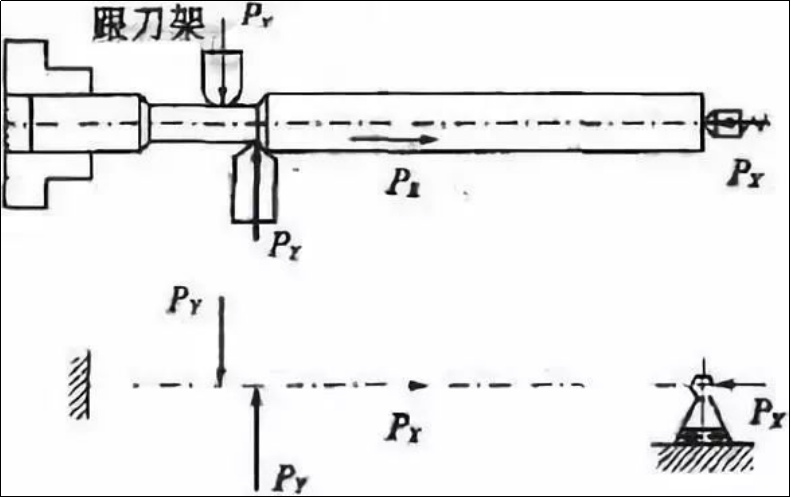

Hoto 1 Ɗayan matsa ɗaya da hanya ɗaya na matsewa da bincike mai ƙarfi

Babban abubuwan da ke haifar da nakasar lankwasawa da ke haifar da juyar da siririyar shaft sune:

(1) Yanke ƙarfi yana haifar da nakasu

Za a iya raba ƙarfin yanke zuwa sassa uku: ƙarfin axial PX (ƙarfin axial), ƙarfin radial PY (ƙarfin radial) da ƙarfin tangential PZ. Lokacin juya sandunan bakin ciki, rundunonin yankan daban-daban na iya yin tasiri daban-daban akan nakasar lankwasawa.

1) Tasirin sojojin yanke radial PY

Ƙarfin radial yana yanke a tsaye ta hanyar axis. Ƙarfin yankan radial yana lanƙwasa siririyar shaft ɗin cikin jirgin sama a kwance saboda rashin ƙarfi. Hoto yana nuna tasirin yankan ƙarfi akan lanƙwasawa na siriri. 1.

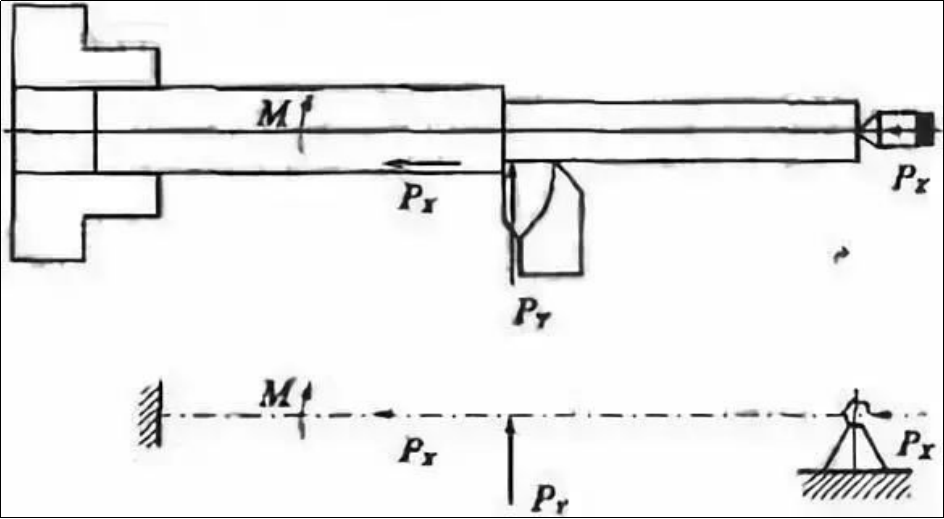

2) Tasirin ƙarfin yankan axial (PX)

Ƙarfin axial yana layi ɗaya da axis akan bakin bakin ciki kuma yana samar da lokacin lanƙwasawa a cikin aikin aiki. Ƙarfin axial ba shi da mahimmanci ga juyowar gaba ɗaya kuma ana iya yin watsi da shi. Saboda rashin tsaurinsa, igiyar ba ta da ƙarfi saboda rashin kwanciyar hankali. Sirin siriri yana lanƙwasa lokacin da ƙarfin axial ya fi wani adadi. Kamar yadda aka nuna a hoto na 2.

Hoto 2: Sakamakon yankan ƙarfi akan ƙarfin axial

(2) Yanke zafi

Thermal nakasawa na workpiece zai faru saboda yankan zafi samar da aiki. Nisa tsakanin chuck, saman rearstock da workpiece an gyara shi saboda an gyara chuck. Wannan yana iyakance haɓakar axial na shaft, wanda ke haifar da lankwasa shaft saboda extrusion axial.

A bayyane yake cewa inganta daidaito na machining na bakin ciki shaft shine ainihin matsala na sarrafa damuwa da nakasar thermal a cikin tsarin tsari.

Matakan don Inganta Ingantacciyar Injiniya Na Slender Shaft

Don inganta daidaito na machining siriri siriri, wajibi ne a dauki matakai daban-daban bisa ga yanayin samarwa.

(1) Zaɓi hanyar matsewa daidai

Matsa tsaka-tsaki sau biyu, ɗayan hanyoyin matsi guda biyu da ake amfani da su a al'adance don juya siriri, ana iya amfani da su don daidaita kayan aikin daidai yayin tabbatar da coaxiality. Wannan hanyar manne siririyar hannun riga tana da rashin ƙarfi mara kyau, babban nakasar lankwasa, kuma tana da saurin girgiza. Saboda haka kawai ya dace da shigarwa tare da ƙaramin tsayi zuwa diamita rabo, ƙaramin izinin machining da manyan buƙatun coaxial. Doguwamadaidaicin kayan aikin injin.

A mafi yawan lokuta, ana yin mashin ɗin ɓangarorin bakin ciki ta hanyar amfani da tsarin ƙugiya wanda ya ƙunshi sama da ɗaki ɗaya. A cikin wannan fasaha na clamping, duk da haka, idan kana da tip wanda ya yi tsayi sosai ba zai lanƙwasa sandar ba kawai amma kuma ya hana shi daga elongating lokacin da aka juya sandar. Wannan na iya haifar da matsi da sandar axially da lankwasa ba ta da siffa. Ƙila ba za a daidaita farfajiyar matsawa tare da rami na tip ba, wanda zai iya haifar da lanƙwasa bayan an manne shi.

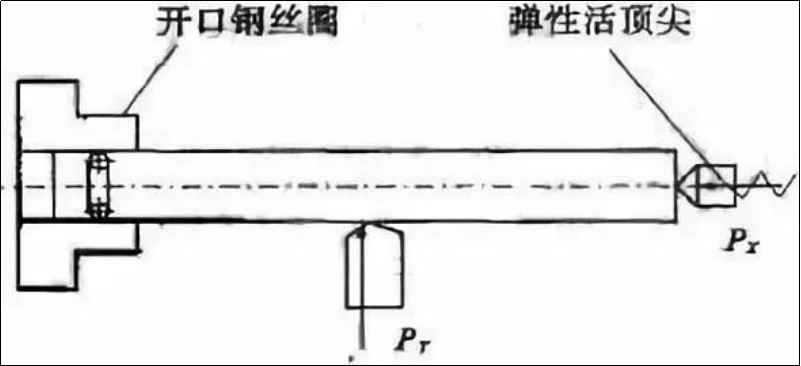

Lokacin amfani da dabarar matse guda ɗaya tare da saman ɗaya, dole ne saman yayi amfani da wuraren zama na roba. Bayan dumama siririyar hannun riga, ana iya yin elongated da yardar kaina don rage murdiya. A lokaci guda kuma ana shigar da matafiyi na ƙarfe mai buɗewa tsakanin jaws zuwa siririyar hannun riga don rage axial lamba tsakanin jaws zuwa siririyar hannun riga da kuma kawar da kan matsayi. Hoto na 3 yana nuna shigarwa.

Hoto na 3: Hanyar ingantawa ta amfani da matse ɗaya da matsi na sama

Rage ƙarfin nakasawa ta hanyar rage tsayin shaft.

1) Yi amfani da madaidaicin diddige da firam ɗin tsakiya

Ana amfani da matse ɗaya da saman ɗaya don juya siriri mai siriri. Don rage tasirin ƙarfin radial akan nakasar da siriri ta haifar, ana amfani da kayan aiki na gargajiya da firam ɗin tsakiya. Wannan daidai yake da ƙara tallafi. Wannan yana ƙaruwa da ƙarfi kuma zai iya rage tasirin tasirin radial akan shaft.

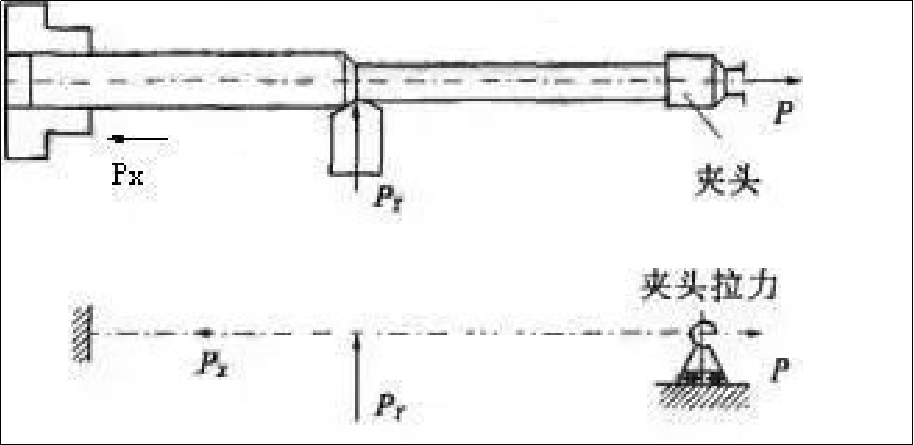

2) Hannun siririn yana jujjuyawa ta hanyar dabarar ƙulla axial

Yana yiwuwa a ƙara ƙarfin hali da kuma kawar da tasirin radial a kan aikin aiki ta amfani da ragowar kayan aiki ko cibiyar tsakiya. Har yanzu ba zai iya magance matsalar da ƙarfin axial lankwasa da workpiece. Wannan gaskiya ne musamman ga siriri mai santsi mai tsayi mai tsayi. Don haka siririyar ramin yana iya juyawa ta amfani da dabarar clamping axial. Axial clamping yana nufin cewa, domin a juya sirararen sirara, ana manne ƙarshen sandar ɗaya tare da ƙugiya da sauran ƙarshensa ta hanyar maɗaɗɗen kai na musamman. Maƙarƙashiyar kai tana amfani da ƙarfin axial zuwa shaft. Hoto na 4 yana nuna manne kai.

Hoto 4 Ƙunƙarar axial da yanayin damuwa

Hannun siririn yana fuskantar tashin hankali na axial akai-akai yayin aikin juyawa. Wannan yana kawar da matsalar ƙarfin yankan axial yana lankwasa shaft. Ƙarfin axial yana rage nakasar lanƙwasa da sojojin yanke radial suka haifar. Hakanan yana rama tsayin axial saboda yanke zafi. daidaito.

3) Juya yanke igiya don juya shi

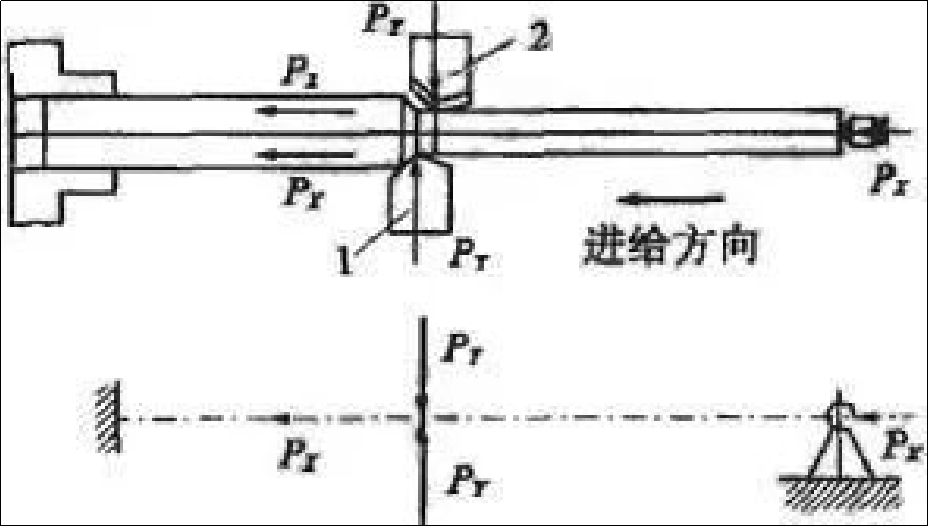

Kamar yadda aka nuna a cikin Hoto na 5, hanyar yanke baya ita ce lokacin da aka ciyar da kayan aiki ta cikin igiya zuwa wutsiyar wutsiya yayin aiwatar da juya bakin bakin ciki.

Hoto na 5 Nazari na Ƙarfin Ƙirƙira da Ƙirƙira ta Hanyar Yanke Juya

Ƙarfin axial wanda aka samar a lokacin sarrafawa zai tayar da shaft, yana hana nakasar lankwasawa. Kwancen wutsiya na roba kuma na iya ramawa ga tsawo na thermal da nakasar matsawa da aikin aikin ya haifar yayin da yake motsawa daga kayan aiki zuwa kan wutsiya. Wannan yana hana nakasa.

Kamar yadda aka nuna a hoto na 6, ana gyara farantin faifan tsakiya ta hanyar ƙara mariƙin kayan aiki na baya da juya duka kayan aikin gaba da na baya lokaci guda.

Hoto 6 Binciken Ƙarfi da injin wuƙa biyu

An shigar da kayan aiki na gaba a tsaye, yayin da kayan aiki na baya ya ɗora a baya. Ƙungiyoyin yankan da kayan aikin biyu suka haifar sun soke juna yayin juyawa. The workpiece ba nakasassu ko rawar jiki, da kuma aiki daidaici ne sosai high. Wannan shine manufa don samar da taro.

4) Dabarar yankan Magnetic don juya bakin bakin ciki

Ka'idar da ke bayan yankan maganadisu tana kama da yanke yanke baya. Ana amfani da ƙarfin maganadisu don shimfiɗa shaft, rage nakasawa yayin aiki.

(3) Iyakance adadin yankan

Yawan zafin da aka yi ta hanyar yankewa zai ƙayyade dacewa da adadin yanke. Nakasar da ke faruwa ta hanyar jujjuya siraren bakin ciki shima zai bambanta.

1) Zurfin Yanke (t)

Bisa ga tsammanin cewa tsarin tsarin ya ƙayyade tsayin daka, yayin da zurfin yanke ya karu, haka ma ƙarfin yanke, da zafi da aka haifar lokacin da aka juya. Wannan yana haifar da damuwa da yanayin zafi na bakin ciki ya karu. Lokacin juya sanduna na bakin ciki, yana da mahimmanci don rage girman zurfin yanke.

2) Adadin ciyarwa (f).

Ƙara yawan adadin ciyarwa yana ƙara yanke ƙarfi da kauri. Ƙarfin yankan yana ƙaruwa, amma ba daidai ba. A sakamakon haka, ƙarfin nakasar ƙarfin don shinge na bakin ciki ya ragu. Dangane da haɓaka haɓakar yankan, yana da kyau a ƙara yawan adadin abinci fiye da ƙara zurfin yankan.

3) Yanke gudun (v).

Yana da fa'ida don ƙara saurin yankewa don rage ƙarfi. Yayin da saurin yankan yana ƙara yawan zafin jiki na kayan aikin yankan, rikici tsakanin kayan aiki, kayan aiki, da shaft zai ragu. Idan saurin yankan ya yi yawa, to, shaft ɗin zai iya sauƙi lanƙwasa saboda sojojin centrifugal. Wannan zai lalata kwanciyar hankali na tsari. The yankan gudun workpieces cewa su ne in mun gwada da manyan a tsawon da diamita ya kamata a rage.

(4) Zaɓi kusurwa mai ma'ana don kayan aiki

Don rage nakasar lanƙwasa wanda aka haifar ta hanyar jujjuya shinge na bakin ciki, ƙarfin yankewa yayin juyawa dole ne ya zama ƙasa kaɗan. Rake, jagora da kusurwoyin karkata sun fi tasiri akan yanke ƙarfi a tsakanin kusurwoyin geometric na kayan aikin.

1) kusurwar gaba (g)

Girman kusurwar rake (g) yana tasiri kai tsaye da ƙarfi, zafin jiki da ƙarfi. Ana iya rage ƙarfin yankewa sosai ta hanyar haɓaka kusurwoyin rake. Wannan yana rage lalacewar filastik kuma yana iya rage adadin ƙarfe da ake yankewa. Don rage ƙarfin yankan, ana iya ƙara kusurwar rake. Matsalolin rake gabaɗaya suna tsakanin 13deg da 17deg.

2) kusurwar jagora (kr)

Babban jujjuyawar (kr), wanda shine mafi girman kusurwa, yana rinjayar daidaito da girman dukkan sassa uku na yanke ƙarfi. Ƙarfin radial yana raguwa yayin da kusurwar shigarwa ya karu, yayin da ƙarfin tangential yana ƙaruwa tsakanin 60deg da 90deg. Dangantakar daidaituwa tsakanin sassa uku na yanke ƙarfi ya fi kyau a cikin kewayon 60deg75deg. Babban kusurwa mafi girma 60deg yawanci ana amfani dashi lokacin juya ramukan bakin ciki.

3) Hankalin ruwa

Ƙaunar ruwa (ls), yana rinjayar kwararar kwakwalwan kwamfuta da ƙarfin tip kayan aiki, da kuma dangantakar da ke tsakanin ukun.juya aka gyarana yanke a lokacin aikin juyawa. Ƙarfin radial na yanke yana raguwa yayin da sha'awar ya karu. Duk da haka, axial da tangential sojojin karuwa. Dangantakar daidaituwa tsakanin sassa uku na yanke ƙarfi yana da ma'ana lokacin da karkatar da ruwa ta kasance cikin kewayon -10deg+10deg. Domin samun kwakwalwan kwamfuta don gudana zuwa saman sandar yayin da ake juya bakin bakin ciki, yawanci ana amfani da kusurwa mai kyau tsakanin 0deg da +10deg.

Yana da wuya a cika ka'idodin ingancin siriri mai siriri saboda rashin ƙarfi. Ana iya tabbatar da ingancin sarrafa siriri ta hanyar ɗaukar hanyoyin sarrafawa na ci-gaba da dabarun ɗaurewa, da zabar madaidaitan kusurwoyin kayan aiki da sigogi.

Manufar Anebon ita ce gane ingantacciyar ƙarancin masana'antu da samar da mafi kyawun sabis ga abokan cinikinmu na gida da na ƙasashen waje gaba ɗaya don 2022 Babban ingancin Bakin Aluminum High Madaidaicin CNC Juya Injin Niƙa Sashe na Aerospace don faɗaɗa kasuwarmu ta duniya, Anebon galibi yana samar da abokan cinikinmu na ketare. tare da manyan injuna, niƙa guda daCNC juya sabis.

Sassan Injin China na China da Sabis na Mashin ɗin CNC, Anebon yana kiyaye ruhun "ƙayi da haɗin kai, aikin haɗin gwiwa, rabawa, sawu, ci gaba mai amfani". Idan kun ba mu dama, za mu nuna iyawarmu. Tare da goyon bayan ku, Anebon ya yi imanin cewa za mu iya gina kyakkyawar makoma a gare ku da dangin ku.

Lokacin aikawa: Agusta-28-2023