1. Yanke zare

Gabaɗaya, yana nufin machining thread a kan workpiece tare da forming ko nika kayan aiki, yafi ciki har da juya, milling, tapping da threading nika, nika, guguwa yankan, da dai sauransu Lokacin juya, milling, da nika da zaren, da watsa sarkar na kayan aikin injin yana tabbatar da cewa kayan aikin juyawa, mai yankan niƙa, ko dabaran niƙa suna motsa gubar daidai kuma a ko'ina tare da axial shugabanci na workpiece kowane juyi na workpiece. Lokacin dannawa ko zaren, kayan aikin (matsa ko mutu) yana juyawa dangi zuwa kayan aikin, kuma tsagi na farko da aka kafa yana jagorantar kayan aiki (ko workpiece) don motsawa axially.

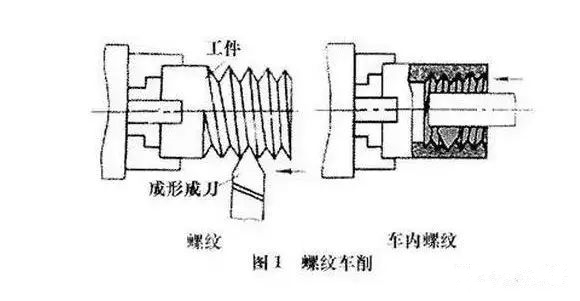

2. Juyawa zare

Ana iya amfani da kayan aikin kati don juya ko zaren zaren akan lathe (duba kayan aikin sarrafa zaren). Juya zaren tare da samar da kayan aikin juyawa shine daidaitaccen hanya don yanki guda ɗaya da ƙaramin tsari na ƙirar zaren aiki saboda tsarin sa mai sauƙi; juya thread tare da thread combing kayan aiki yana da high samar yadda ya dace, amma da tsarin ne hadaddun, don haka shi ne kawai dace da juya short thread workpiece da lafiya hakora a matsakaici da kuma manyan tsari samar. Daidaitaccen filin jujjuya zaren trapezoidal tare da lathe na gaba ɗaya zai iya kaiwa matakan 8-9 kawai (jb2886-81, iri ɗaya a ƙasa); Ana iya inganta yawan aiki ko daidaito sosai yayin yin aikin injin zare akan lathe na musamman na zaren.CNC machining part

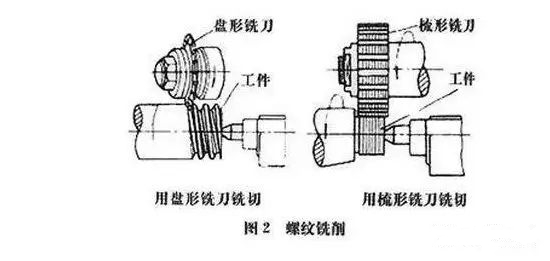

3. Niƙa zare

Ana amfani da abin yankan niƙa faifai ko kuma abin yankan niƙa don niƙa akan na'urar niƙa zaren. The Disc milling abun yanka ana amfani da farko don niƙa trapezoid waje zaren na dunƙule sanduna, tsutsotsi, da sauran workpieces.A combo niƙa abun yanka niƙa ciki da waje gama gari da taper thread. Saboda sashin aikin sa ya fi tsayin zaren da za a sarrafa shi ta mai yankan niƙa da yawa, ana iya sarrafa aikin aikin ta hanyar jujjuyawar 1.25-1.5 kawai, tare da babban yawan aiki. A farar daidaito na thread milling iya isa 8-9 maki, da kuma surface roughness ne r5-0.63 μ M. Wannan hanya ta dace da taro samar da janar daidaici thread workpieces ko m machining kafin nika.CNCc bangaren milling

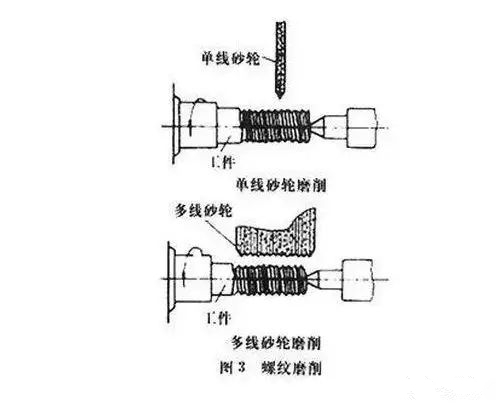

4. Zare nika

An yafi amfani da aiwatar da madaidaicin zaren na taurare workpiece a kan zaren grinder. Dangane da nau'ikan nau'ikan juzu'i daban-daban na dabaran niƙa, ana iya raba shi zuwa nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nika guda biyu ne: dabaran niƙa mai layi ɗaya da dabaran niƙa da yawa. Matsakaicin daidaito na dabaran niƙa mai layi guda ɗaya shine maki 5-6, kuma ƙarancin ƙasa shine r1.25-0.08 μ m, don haka ya dace don gama injin niƙa. Wannan hanya ta dace da niƙa madaidaicin sukurori, ma'aunin zaren, tsutsotsi, ƙananan batches na zaren workpieces, da madaidaicin hobTwot iri na niƙa meth sun wanzu: niƙa mai tsayi da yanke-in niƙa. Faɗin dabaran niƙa tare da hanyar niƙa madaidaiciya bai kai tsayin zaren da za a yi ƙasa ba, kuma zaren na iya ƙasa ƙasa zuwa girman ƙarshe bayan injin niƙa yana motsawa sau ɗaya ko sau da yawa. Nisa daga cikin dabaran niƙa na hanyar yanke-in niƙa ya fi girma fiye da tsawon zaren da za a yi ƙasa. The dabaran nika yanke a cikin saman workpiece radially, da workpiece iya zama ƙasa bayan juya game da 1.25 juyin juya halin. Yawan aiki ya fi girma, amma daidaito ya ɗan ragu kaɗan, kuma suturar ƙafafun niƙa ya fi rikitarwa. Hanyar yankan a cikin niƙa ta dace don yin shebur mai yawa na famfo da niƙa wasu zaren ɗaure.bangaren filastik

5. Nika zare

Nau'in goro ko nau'in dunƙule-nau'in zaren-lapping kayan aiki an yi shi da abubuwa masu laushi kamar baƙin ƙarfe. Sassan zaren da aka sarrafa akan kayan aikin tare da kuskuren farar suna ƙasa ta gaba da juyawa don haɓaka daidaiton farar. Zaren ciki mai tauri yawanci ana kawar da shi ta hanyar niƙa don inganta daidaito.

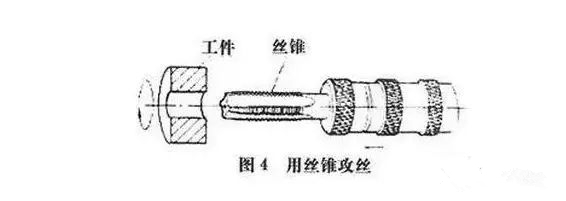

6. Tatsi da zare

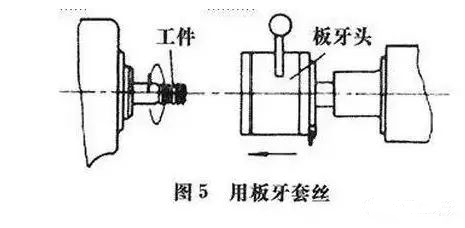

Taɓa shine a yi amfani da ƙayyadaddun juzu'i don murƙushe fam ɗin cikin ramin ƙasa da aka hako akan kayan aikin don aiwatar da zaren ciki.

Threading shine yanke zaren waje akan mashaya (ko bututu) workpiece tare da mutu. Daidaiton mashin ɗin bugun ko zaren ya dogara da daidaiton famfo ko mutu. Ko da yake akwai hanyoyi da yawa don sarrafa zaren ciki da waje, ƙananan ƙananan zaren ciki za a iya sarrafa su ta hanyar famfo. Ana iya yin taɗawa da zare da hannu ko ta latsa, injin hakowa, injin taɗa, da na'urar zare.

7. Zaren mirgina

Hanyar sarrafawa na ƙirƙira da mirgina mutu don samar da nakasar filastik na workpiece don samun zaren mirgina gabaɗaya ana aiwatar da shi akan na'urar mirgina zaren ko lathe ta atomatik a haɗe tare da buɗewa ta atomatik da rufe zaren mirgina kai, wanda ya dace da samarwa da yawa. na waje zaren juna na daidaitattun fasteners da sauran threaded gidajen abinci. Gabaɗaya, diamita na waje na zaren birgima bai wuce 25 mm ba, tsayin bai wuce mm 100 ba, kuma daidaiton zaren zai iya kaiwa matakin 2 (gb197-63). Diamita na blank ɗin da aka yi amfani da shi ya yi kusan daidai da diamita na zaren da za a sarrafa. Gabaɗaya, zaren ciki ba za a iya sarrafa shi ta hanyar birgima ba. Duk da haka, don aikin aiki mai laushi, za a iya amfani da zaren ciki mai sanyi ba tare da famfo extrusion na ramin (matsakaicin diamita na iya kaiwa kusan 30mm), kuma ka'idar aiki tana kama da tapping. Ƙunƙarar da ake buƙata don extrusion sanyi na zaren ciki shine kusan sau 1 ya fi girma fiye da haka don tapping, kuma daidaitattun machining da ingancin saman sun dan kadan fiye da haka don tapping.

Abubuwan da ake amfani da su na rolling thread sune kamar haka:

① rashin ƙarfi na saman bai kai juyi ba, niƙa, da niƙa;

② fuskar zaren bayan mirgina zai iya inganta ƙarfi da ƙarfi saboda aikin sanyi;

③ yawan amfani da kayan yana da yawa;

④ yawan aiki yana ninka sau biyu idan aka kwatanta da tsarin yankewa, kuma yana da sauƙin gane aiki da kai;

⑤ rayuwar sabis na mirgina mutu yana da tsayi sosai. Koyaya, taurin kayan aikin bai wuce hrc40 ba, ana buƙatar daidaiton girman blank don zama babba, kuma daidaito da taurin mirgina shima yana da girma, don haka yana da wahala a kera mutu. Bai dace da zaren da ke da bayanan mirgina asymmetric ba.

Dangane da nau'in mirgina daban-daban, zaren mirgina za a iya raba iri biyu: zare rolling da zare rolling.

Zaren mirgina: faranti guda biyu masu birgima tare da bayanan bayanan zaren suna takure kuma an shirya su da farar 1/2. An gyara farantin a tsaye, kuma farantin mai motsi yana motsawa a cikin madaidaiciyar layi mai jujjuyawa daidai da farantin. Lokacin da workpiece aka aika tsakanin biyu faranti, motsi farantin matsawa gaba don shafa da latsa workpiece, yin da surface nakasar roba da kuma forming wani zare. Mo Mo Q group 373600976

Akwai nau'ikan mirgina iri uku: radial, tangential,g, da mirgina kai.

① Radial thread mirgina: biyu (ko uku) thread-dimbin yawa thread mirgina ƙafafun suna shigar a kan juna a layi daya shafts, da workpiece da aka sanya a kan goyon baya tsakanin biyu ƙafafun, da biyu ƙafafun juya a wannan gudun a cikin wannan shugabanci, daya. wanda kuma yana yin motsin ciyarwar radial. Motsin dabaran yana motsa kayan aikin don juyawa, kuma an fitar da saman radially don samar da zaren. Hakanan za'a iya amfani da irin wannan hanyar mirgina don wasu sukurori tare da ƙananan buƙatu.

② tangential zaren mirgina: wanda kuma aka sani da duniyar zaren mirgina. Kayan aikin birgima ya ƙunshi dabaran jujjuyawar zaren tsakiya mai jujjuyawa da faranti madaidaiciya guda uku. Za a iya ciyar da kayan aikin gabaɗaya yayin mirgina, don haka yawan aiki ya fi na zaren shafa da mirgina radial.

③ Zaren mirgina kai: ana yin shi akan lathe ta atomatik kuma ana amfani dashi gabaɗaya don aiwatar da ɗan gajeren zaren akan kayan aikin. Akwai rollers 3-4 waɗanda aka rarraba iri ɗaya a kusa da kayan aikin. Lokacin mirgina, aikin aikin yana jujjuya, kuma mirgina kai yana ciyarwa axially don mirgine aikin daga zaren.

Anebon Metal Products Limited na iya samar da mashin ɗin CNC, simintin gyare-gyare, sabis na ƙirar ƙarfe, da fatan za a iya tuntuɓar mu.

Tel: +86-769-89802722 Email: info@anebon.com Website : www.anebon.com

Lokacin aikawa: Oktoba-04-2019