Produk CNC

Precision CNC Machining Parts

Kaping pisanan, kualitas produk:

1. Aluminium rod nggunakake 6063, 6061 lan bahan liyane, ora nambah impurities sembarang.

2. Rampung ketemu spesifikasi komposisi kimia lan sifat mekanik saka campuran.

3. Selaras karo syarat standar JIS H 4040/4080/4100.

Kapindho, finishing: Proses jero saka macem-macem profil aluminium (CNC Machining, nglereni kabel. Precision ngowahi. Drilling. Milling. Cutting) kanggo ketemu syarat customer.

Katelu, perawatan permukaan: sandblasting, polishing, anodizing, uyuh, cat semprotan ireng, plating lan liya-liyane.

Papat, kinerja Déwan: kanggo ketemu syarat customer kanggo tujuan nggoleki.

Kelima, Implementasi standar:

Jepang (JIS H4100 Aluminium lan Aluminium Alloy Extrusion Profiles)

China (GBT 6892-2006: Umum industri aluminium lan aluminium alloy extruded GBT_14846-2008: Aluminium lan aluminium alloy extruded ukuran profil penyimpangan).

Enem, karakteristik produk: Pelanggan nyedhiyakake sampel utawa ngatur pangolahan.

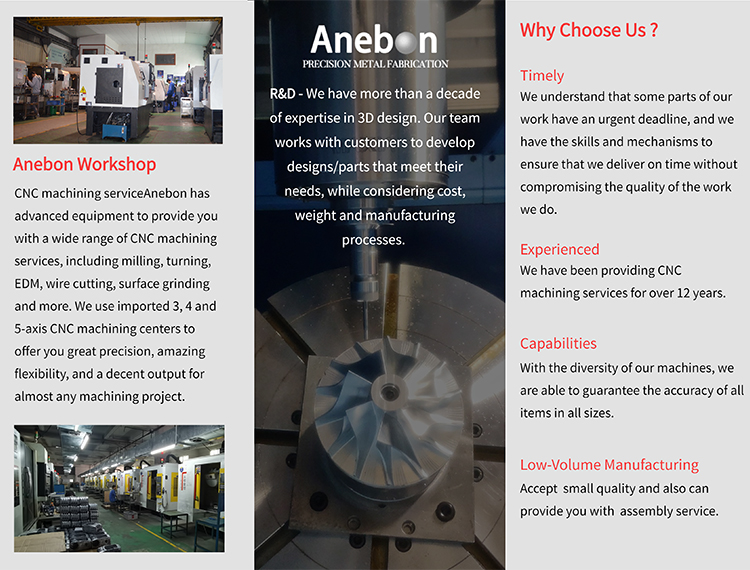

Kapabilitas

| Proses Mesin | CNC Milling, CNC Turning, CNC Drilling, CNC Lathe Machining, CNC grinding. |

| Bahan | Baja Paduan, Aluminium, Kuningan, Paduan Perunggu, Baja Karbon, Besi, Baja Tahan Karat, Titanium, Nilon, PEEK dll. |

| Pangobatan lumahing | Anodizing, Heat treatment, polishing, PVD/CVD Coating, Galvanized, Electroplating, Spraying, Painting, Impregnation lan ing |

| Ngolah prabotan | Pusat mesin CNC, Mesin Nguripake, Mesin Grinding, Mesin Penggilingan, Mesin Bor, Mesin Penggilingan Horizontal, Mesin Chamfering, Mesin pemotong Kawat, Mesin grinding Internal lan Eksternal dll. |

| Axis Mesin | 3 4 |

| Precision | +/- 0,002 mm |

| DrawingFormat | .jpg/.pdf/.dxf/.dwg/.igs./.stp.etc |

| Peralatan Inspeksi | Mesin Ukur Koordinat CMM 3D, Mesin Ukur Gambar Manual 2.5D, Mesin Uji Semprotan Garam, Deteksi Detektor Optik CCD, Arm CMM, Hardness Tester, Tester Dhuwur, Mikrometer, Digital Calliper, Go-No Go Measure Gauge, Ring Gauge, Plug Gauge dll . |

| Kualitas | ISO 9001:2008, TS16949 FA Inspeksi, PPAP, Data CPK lsp. |

Produksi