A eri bụ helix bee n'ime a workpiece ma si n'èzí ma ọ bụ n'ime na-eje ozi ọtụtụ mkpa ọrụ. Nke mbụ, eriri na-emepụta njikọ igwe site na ijikọta ngwaahịa nwere eriri n'ime ya na ngwaahịa nwere mpụga. Njikọ a na-eme ka a mata na akụkụ dị iche iche nke workpiece nwere ike jikọọ na ibe ha.

Ọzọkwa, eri na-arụ ọrụ dị mkpa n'ịkwasa ngagharị. Ha nwere ike ịtụgharị ngagharị rotary ka ọ bụrụ ngagharị kwụ ọtọ na ọzọ. Ikike a bara uru karịsịa n'ọtụtụ ngwa, dị ka n'igwe nke chọrọ mmegharị ahịrị iji rụọ ọrụ ụfọdụ.

Na mgbakwunye, eri na-enye uru igwe. Site n'iji eriri eri, enwere ike ịrụ ọrụ igwe dị elu n'akụkụ ọ bụla. Nke a na-agụnye ụbara ikike ibu ibu, nkwalite nkwalite n'ịtọpụ ma ọ bụ ịma jijiji, yana mma nnyefe ike.

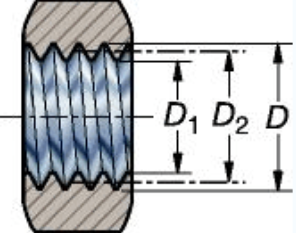

E nwere ụdị eriri dị iche iche, nke ọ bụla n'ime ha na-ekpebi geometry nke eri ahụ. Akụkụ dị mkpa nke profaịlụ eri bụ dayameta workpiece. Nke a na-agụnye nnukwu dayameta (oke dayameta nke eri ahụ) na dayameta pitch ( dayameta na ebe a na-eche echiche ebe obosara eri bụ efu). Ntụle ndị a dị oke mkpa iji hụ na eriri ahụ dabara nke ọma ma rụọ ọrụ nke ọma.

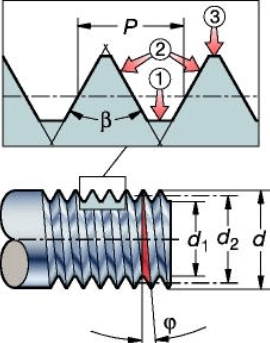

Ịghọta okwu eri dị oké mkpa iji jiri eri eme ihe nke ọma. Ụfọdụ isi okwu gụnyere ndu (ebe dị anya axial nke eri na-aga n'otu mgbanwe zuru oke) na pitch (ebe dị anya n'etiti isi ihe kwekọrọ na eri dị n'akụkụ). Ntụle ndu na pitch dị mkpa iji hụ na nhazi na ndakọrịta eri ziri ezi.

Na nchịkọta, eri na-arụ ọtụtụ ọrụ dị mkpa na ụlọ ọrụ dị iche iche. Ha na-eme ka njikọ ígwè ọrụ dị mfe, na-ebufe mmegharị ma na-enye uru ígwè ọrụ. Ịghọta profaịlụ eri na okwu ndị metụtara ya dị oke mkpa iji eriri eri eme ihe nke ọma yana hụ na arụ ọrụ kacha mma.

Ịdozi ihe omimi nke Pitch: Ịchọgharị ihe ọ pụtara na usoro mgbako

Ngwunye eriri bụ isi ihe na ngalaba nrụpụta na igwe. Ịghọta ihe ọ pụtara na ịgbakọ ya nke ọma dị oke mkpa n'ịmepụta akụkụ dị elu nke igwe. N'ime edemede a, anyị ga-abanye n'ime mgbagwoju anya nke pitch thread, geometry ya, na otu esi amata ya nke ọma. Ọzọkwa, anyị ga-ewebata Anebon, ụlọ ọrụ ọkachamara na prototype CNC machining ọrụ na omenala CNC-egwe ọka, na-enye ngwa ngwa na ntụkwasị obi ruturu online maka CNC machining.

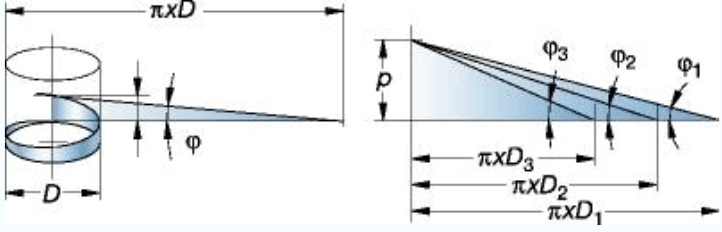

The geometry nke eri dabeere na eri pitch dayameta (d, D) na pitch (P): axial anya tinyere eri na workpiece si n'otu ebe na profaịlụ na kwekọrọ ekwekọ ọzọ n'ókè. Chee ya dị ka triangle na-aga gburugburu workpiece. Ihe owuwu triangular a na-ekpebi ịdị irè na ịrụ ọrụ nke akụrụngwa eri. Ngụkọ ziri ezi nke eriri eri dị oke mkpa iji hụ na ọ dabara nke ọma, nkesa ibu kacha mma yana ịrụ ọrụ nke ọma nke akụkụ igwe.

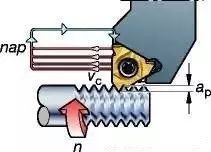

Iji chọpụta ọkwa nke ọma, onye nrụpụta na-eji teknụzụ igwe CNC dị elu. Machining CNC, ma ọ bụ igwe njikwa ọnụọgụ kọmputa, bụ usoro nrụpụta nke na-eji ngwa igwe na-achịkwa kọmpụta iji wepụ ihe sitere na akụrụngwa iji mepụta akụkụ ndị a kpụrụ akpụ. CNC Machining Online Quoting bụ ọrụ nke ọtụtụ ụlọ ọrụ ọkachamara na-enye na-enye ndị ahịa ohere ịnweta atụmatụ ọnụahịa ngwa ngwa na ngwa ngwa maka omenala ha.CNC machining akụkụ.

Anebon bụ ụlọ ọrụ na-eduga na ụlọ ọrụ ngwaike, na-enye prototype CNC machining ọrụ na omenala CNC egwe ọka kemgbe mmalite ya na 2010. Site na otu ọkachamara ọkachamara na akụrụngwa ọgbara ọhụrụ, Anebon na-enye ngwaahịa dị mma, dị elu. . Igwe eji eme ihe eji ebubata na Japan. Igwe igwe igwe CNC ha na lathes yana igwe ihe n'elu na-enyere ha aka ịnapụta nkenke ngwaahịa na ịdị mma pụtara ìhè. Ọzọkwa, Anebon bụ ISO 9001: 2015 kwadoro, na-egosipụta nkwa ha na-edobe ụkpụrụ mmepụta kachasị elu na afọ ojuju ndị ahịa.

Mgbe a na-agbakọ pitch, a na-egosipụtakarị ya na eri kwa inch (TPI) ma ọ bụ millimeters. Maka eriri metric, a na-akọwapụta ọkwa dị ka anya na millimita n'etiti eriri eriri abụọ dị n'akụkụ. N'aka nke ọzọ, maka sistemụ eriri dabere na inch, TPI na-anọchi anya eri kwa inch linear. Ịtụ ụda eriri nke ọma dị oke mkpa iji hụ na ndakọrịta n'etiti akụkụ eriri na izere nsogbu ndị nwere ike ime dị ka ịtọghe, nhịkọ ma ọ bụ nkesa ezughị oke.

CNC igwena-arụ ọrụ dị mkpa n'ịmepụta nha ụda ziri ezi. Site n'iji teknụzụ na-egbutu ọnụ na akụrụngwa nkenke, akụkụ CNC nwere ike imezu ihe kachasị mkpa na nkọwapụta. Mmemme sọftụwia dị elu na-enyere igwe CNC aka ịrụ mgbako eri dị mgbagwoju anya, na-ahụ n'aka na enwetara eriri eri ziri ezi maka ngwa ọ bụla pụrụ iche.

Na nchịkọta, ịghọta mgbagwoju anya nke pitch na ịgbakọ ya n'ụzọ ziri ezi dị oké mkpa iji mepụta akụkụ ndị nwere mma dị elu. Site na iji prototype CNC ọrụ machining na tinye n'ọrụ omenalaCNC-egwe ọka, Nsukka nwere ike nweta ahụkebe nkenke na àgwà na ha ngwaahịa. N'ịbụ ndị gbalịsiri ike na ịdị mma yana akụrụngwa ọgbara ọhụrụ, ụlọ ọrụ ndị dị ka Anebon na-eduga ụzọ n'inye ọrụ ntanetị n'ịntanetị CNC nke a pụrụ ịdabere na ya. Site na ihe ọmụma ziri ezi nke eriri eri, ndị na-emepụta nwere ike ịmepụta akụkụ nke eriri na-ezute ụkpụrụ kachasị elu nke arụmọrụ na arụmọrụ.

1. Ngụkọta na ndidi nke pitch dayameta nke 60° eze n'ụdị mpụga eri (mba ọkọlọtọ GB197/196)

a.Ngụkọta nke pitch dayameta isi size

Nha isi nke dayameta pitch nke eri ahụ = isi dayameta nke eri ahụ - pitch × ọnụọgụ ọnụọgụ.

Nnọchite anya usoro: d/DP×0.6495

Ọmụmaatụ: Ngụkọta dayameta pitch nke eri M8 mpụga

8-1.25×0.6495=8-0.8119≈7.188

b. Ntade dayameta eriri olulu 6h a na-ejikarị (dabere na eriri eriri)

Ọnụ ego kacha elu bụ "0"

Oke ala bụ P0.8-0.095P1.00-0.112P1.25-0.118

P1.5-0.132P1.75-0.150P2.0-0.16

P2.5-0.17

Usoro mgbako mgbako nke elu bụ nha bụ isi, yana usoro mgbako mgbako dị ala d2-hes-Td2 bụ dayameta pitch nke isi nha-iche-iche nwere ike ime.

Uru nnabata nke dayameta ọkwa ọkwa 6h nke M8: uru oke elu 7.188 uru oke ala: 7.188-0.118=7.07.

C. Nke a na-ejikarị 6g ọkwa mpụga eriri pitch dayameta nke ndabere: (dabere na olulu eri)

P0.80-0.024P1.00-0.026P1.25-0.028P1.5-0.032

P1.75-0.034P2-0.038P2.5-0.042

Usoro mgbako kacha elu d2-ges bụ isi nha nha

Usoro mgbako mgbako dị ala d2-ges-Td2 bụ nnabata nnabata nha nha

Ọmụmaatụ, 6g ọkwa pitch dayameta uru ndidi nke M8: elu oke uru 7.188-0.028=7.16 ala ịgba uru: 7.188-0.028-0.118=7.042.

Mara:

① Nkwenye eriri ndị dị n'elu na-adabere na eriri ndị na-adịghị mma, a na-agbanwekwa eriri eriri nke eriri dị mma, ma a na-eme ka njedebe ahụ dịkwuo elu, ya mere njikwa ahụ agaghị agafe oke ọkọlọtọ, n'ihi ya, a naghị akara ha na tebụl. N'elu wee pụta.

② Na mmepụta n'ezie, dị ka nkenke chọrọ site na imewe na ike extrusion nke akụrụngwa nhazi eri, dayameta nke eriri na-egbuke egbuke na-abawanye site na 0.04-0.08 ma e jiri ya tụnyere eriri e mere, nke bụ dayameta nke eriri na-egbuke egbuke. mkpanaka. Dị ka ihe atụ, dayameta nke ụlọ ọrụ anyị M8 mpụga eri 6g eri polished mkpanaka bụ 7.08-7.13, nke dị n'ime nke a nso.

③ N'ịtụle mkpa nke usoro mmepụta ihe, njedebe nchịkwa dị ala nke oghere pitch nke eriri mpụga na-enweghị ọgwụgwọ okpomọkụ na ọgwụgwọ elu na mmepụta n'ezie kwesịrị idobe ya na ọkwa 6h dị ka o kwere mee.

2. Ngụkọta na ndidi nke pitch dayameta nke 60° esịtidem eri (GB197/196)

A.6H larịị eri pitch dayameta ndidi (dabere na thread pitch)

oke oke:

P0.8+0.125P1.00+0.150P1.25+0.16P1.5+0.180

P1.25+0.00P2.0+0.212P2.5+0.224

Uru oke ala bụ "0",

Usoro mgbako oke oke 2+TD2 bụ nha nha + nnabata.

Dịka ọmụmaatụ, dayameta pitch nke eriri ime M8-6H bụ: 7.188+0.160=7.348 oke oke: 7.188 bụ oke ala.

b. Usoro maka ịgbakọ dayameta pitch nke eriri dị n'ime bụ otu ihe ahụ nke eriri dị n'èzí

Ya bụ, D2 = DP × 0.6495, ya bụ, pitch dayameta nke esịtidem eri bụ hà pitch dayameta × ọnụọgụ ọnụọgụgụ uru.

c.6G klas eri pitch pitch dayameta isi deviation E1 (dabere na eriri pitch)

P0.8+0.024P1.00+0.026P1.25+0.028P1.5+0.032

P1.75+0.034P1.00+0.026P2.5+0.042

Ọmụmaatụ: Oke elu nke dayameta pitch nke eriri ime M86G: 7.188+0.026+0.16=7.374

Oke ala: 7.188+0.026=7.214

Usoro oke oke 2+GE1+TD2 bụ nha nha nke dayameta pitch+deviation+ ndidi

Usoro uru oke ala 2+GE1 bụ nha dayameta pitch+deviation

3. Ngụkọta na ndidi nke isi dayameta nke mpụga eri (GB197/196)

a.Upper ịgba nke 6h isi dayameta nke mpụga eri

Ya bụ, eri dayameta uru atụ M8 bụ φ8.00, na elu oke ndidi bụ “0″.

b. Nkwenye nke oke ala nke nnukwu dayameta nke klaasị 6h nke mpụta (dabere na eriri eri)

P0.8-0.15P1.00-0.18P1.25-0.212P1.5-0.236P1.75-0.265

P2.0-0.28P2.5-0.335

Usoro mgbako maka oke ala nke nnukwu dayameta: d-Td bụ isi akụkụ- nnabata nke isi dayameta nke eri ahụ.

Ọmụmaatụ: M8 eri mpụta 6h nnukwu dayameta nha: oke elu bụ φ8, oke ala bụ φ8-0.212=φ7.788

c.Ngbakọ na nnabata nke nnukwu dayameta 6g nke eriri Mpụga

6g Mpụga eriri ederede (dabere na olulu eri)

P0.8-0.024P1.00-0.026P1.25-0.028P1.5-0.032P1.25-0.024P1.75–0.034

P2.0-0.038P2.5-0.042

Usoro mgbako elu nke elu d-ges bụ akụkụ bụ isi nke eri isi dayameta-ntụgharị uche

Usoro mgbako obere ala d-ges-Td bụ akụkụ bụ isi nke eri isi dayameta-baseline deviation-tolerance

Ọmụmaatụ: M8 eri mpụta 6g klas isi dayameta elu oke φ8-0.028=φ7.972.

Oke ala φ8-0.028-0.212=φ7.76

Cheta na: ① A na-ekpebi isi dayameta nke eriri ahụ site na dayameta nke eriri a na-egbu maramara na ogo nke iyi nke eriri na-agbagharị efere/profaịlụ eze, na uru ya na-adaba na dayameta elu na etiti nke eri ahụ. Na ndabere nke otu oghere na threading ngwá ọrụ, nta n'etiti dayameta, ibu nnukwu dayameta, na vice versa, ibu n'etiti dayameta, na nta nke isi dayameta.

② Maka akụkụ ndị chọrọ ọgwụgwọ okpomọkụ na ọgwụgwọ elu, na-atụle mmekọrịta dị n'etiti teknụzụ nhazi na mmepụta n'ezie, a ga-achịkwa isi dayameta nke eri ahụ na njedebe ala nke klas 6h gbakwunyere 0.04mm ma ọ bụ karịa. Dịka ọmụmaatụ, maka eriri mpụga M8, nnukwu dayameta nke eri na-atụgharị (rolling) kwesịrị ịdị n'elu 7.83 na n'okpuru 7.95.

4. Ngụkọta na ndidi nke obere dayameta nke esịtidem eri

a.Ngụkọta nke isi nha nke obere dayameta nke esịtidem eri (D1)

Nha isi nke obere eriri dayameta = nha bụ isi nke eriri ime - pitch × ọnụọgụ

Ọmụmaatụ: Nha isi nke obere dayameta nke eriri ime M8 bụ 8-1.25×1.0825=6.646875≈6.647

b. Ngụkọta nke ime eri 6H obere dayameta ndidi (dabere na thread pitch) na obere dayameta uru

P0.8+0.2P1.0+0.236P1.25+0.265P1.5+0.3P1.75+0.335

P2.0+0.375P2.5+0.48

The ala ịgba deviation usoro D1+HE1 nke esịtidem eri 6H klas bụ isi size nke esịtidem eri obere dayameta + deviation.

Mara: Uru elegara anya bụ “0″ na ọkwa 6H

Usoro mgbako maka oke elu nke 6H larịị nke esịtidem eri = D1+HE1+TD1, ya bụ, isi size nke obere dayameta nke esịtidem eri + deviation + ndidi.

Ọmụmatụ: Oke elu nke obere dayameta nke 6H grade M8 esịtidem eri bụ 6.647+0=6.647

Oke ala nke obere dayameta nke 6H ọkwa M8 ime eri bụ 6.647+0+0.265=6.912

c.Calculation nke isi ndiiche nke obere dayameta nke esịtidem eri 6G (dabere na pitch) na uru nke obere dayameta.

P0.8+0.024P1.0+0.026P1.25+0.028P1.5+0.032P1.75+0.034

P2.0+0.038P2.5+0.042

Usoro mgbako maka oke ala nke obere dayameta nke eriri dị n'ime 6G = D1 + GE1 bụ nha bụ isi nke eriri dị n'ime + iche.

Ọmụmaatụ: Oke ala nke obere dayameta nke 6G grade M8 esịtidem eri bụ 6.647+0.028=6.675

Usoro D1+GE1+TD1 maka uru oke elu nke obere dayameta nke 6G grade M8 internal thread bụ isi nha nke eriri ime + iche + ndidi.

Ọmụmaatụ: Oke elu nke obere dayameta nke 6G grade M8 esịtidem eri bụ 6.647+0.028+0.265=6.94

Mara:

① Ogologo nha nha nke eriri dị n'ime na-ejikọta ya na oge na-ebu nke eriri ime, ya mere oghere kwesịrị ịdị n'ime oke elu nke klas 6H dị ka o kwere mee.

② N'oge a na-arụ ọrụ eriri nke ime, obere obere dayameta nke eriri dị n'ime, na-ebelata arụmọrụ nke ngwaọrụ nhazi - mgbata. Site n'echiche nke iji ya mee ihe, obere ntakịrị ntakịrị, nke ka mma, ma nlebara anya zuru oke, a na-ejikarị obere obosara n'etiti etiti etiti na oke elu, ma ọ bụrụ na a na-agbanye ígwè ma ọ bụ aluminum, a ga-eji ya mee ihe n'etiti oke ala na oke etiti nke obere dayameta.

③Mgbe obere dayameta nke eriri ime bụ 6G, enwere ike ịghọta ya dị ka 6H. The ziri ezi larịị tumadi na-atụle mkpuchi nke pitch dayameta nke eri. Ya mere, a na-atụle naanị dayameta pitch nke mgbata n'oge nhazi eri, na a naghị atụle obere dayameta. Dayameta nke oghere ọkụ.

5. Usoro mgbako nke nkewa isi otu ụzọ nkerisi

Usoro ngụkọta nke otu otu: n=40/Z

n: ọnụ ọgụgụ okirikiri nke isi nkewa kwesịrị ịtụgharị

Z: hà nhata akụkụ nke workpiece

40: Oghere indexing isi nọmba

Ọmụmaatụ: Mgbakọ maka egwe ọka hexagon

Dochie n'ime usoro: n=40/6

Mgbakọ: ① Mee ka ụmụ irighiri ihe dị mfe: chọta nkesa kacha nta 2 wee kewaa site, ya bụ, kewaa ọnụọgụ na ọnụọgụ abụọ n'otu oge iji nweta 20/3. Mgbe ị na-ebelata akara ahụ, nha nha ya ka dị otu.

② Ngụkọta nke ụmụ irighiri ihe: N'oge a, ọ dabere na ụkpụrụ nke ọnụọgụ na ọnụ ọgụgụ; ọ bụrụ na ọnụọgụ na ọnụ ọgụgụ buru ibu, mgbe ahụ, a na-eme ngụkọta oge.

20÷3=6(2/3) bụ uru n, ya bụ, isi nkewa ga-atụgharị 6(2/3) okirikiri. N'oge a, akụkụ ahụ abụrụla ihe dị nta; akụkụ integer nke ọnụọgụgụ 6 bụ isi nkewa kwesịrị ịtụgharị okirikiri isii zuru oke. Ihe ntakiri 2/3 nwere obere ntakiri nwere ike ịbụ naanị 2/3 nke gburugburu ma a ga-agbakọghachi ya n'oge a.

③Nhọrọ na ngụkọ nke efere indexing: ngụkọta nke ihe na-erughị otu okirikiri ga-emerịrị site n'enyemaka nke indexing efere nke isi indexing. Nzọụkwụ mbụ n'ime mgbako bụ ịgbasa akụkụ ahụ n'otu oge site na 2/3. Dịka ọmụmaatụ: ọ bụrụ na a na-ebuli akara ahụ ugboro 14 n'otu oge, ọ bụ 28/42; ọ bụrụ na a na-ebuli ya ugboro 10 n'otu oge, akara bụ 20/30; Ọ bụrụ na a na-ebuli ya elu ugboro iri na atọ n'otu oge, akara ahụ bụ 26/39… Ọnụ ọgụgụ buru ibu kwesịrị ịdị ka ọkpụkpọ ahụ Họrọ ọnụ ọgụgụ oghere na ya.

N'ebe a kwesịrị ịṅa ntị na:

① Ọnụ ọgụgụ nke oghere nke efere indexing ahọpụtara ga-ekewa site na denominator 3. Dịka ọmụmaatụ, na ihe atụ dị n'elu, oghere 42 bụ ugboro 14 nke 3, oghere 30 bụ ugboro 10 nke 3, na oghere 39 bụ ugboro 13 nke 3. .

②Mgbasa nke ụmụ irighiri ihe ga-abụrịrị na agbasawanye ọnụọgụ na ọnụọgụgụ n'otu oge, na nkewa nhata ka na-agbanwe agbanwe, dịka ọmụmaatụ.

28/42=2/3×14=(2×14)/(3×14); 20/30=2/3×10=(2×10)/(3×10);

26/39=2/3×13=(2×13)/(3×13)

28/42 The denominator 42 ga-eji 42 oghere nke index nọmba maka indexing; ọnụọgụgụ 28 na-aga n'ihu na oghere ntinye nke wiil elu, wee tụgharịa oghere 28 ahụ, ya bụ, oghere 29 bụ oghere oghere nke wiil dị ugbu a, 20/30 bụ oghere 10 na-aga n'ihu na ebe ntụgharị nke 30-oghere index efere, na 11th oghere bụ kpọmkwem oghere oghere nke wheel a. 26/39 bụ oghere oghere nke wiil a na efere index nke oghere 39, na oghere 26 nke oghere 27th na-atụgharị n'ihu.

Mgbe a na-egwe ọka hexagon (n'ụzọ isii), oghere dị ka oghere 42, oghere 30, na oghere 39 nke nwere ike ịkewaa site na 3 ka a na-eji dị ka akpịrịkpa: ọrụ ahụ bụ ịtụgharị aka ahụ ugboro 6, wee gaa n'ihu na oghere n'ọnọdu. bụrụ wheel elu n'otu n'otu. Tụgharịa 28+1/10+1/26+ ọzọ! A na-eji oghere dị n'elu 29/11/27 oghere dị ka oghere oghere nke wiil.

Ọmụmaatụ 2: Mgbakọ maka igwe igwe ihe nwere ezé iri na ise.

Dochie n'ime usoro: n=40/15

Gbakọọ n=2(2/3)

Ọ ga-atụgharị okirikiri 2 zuru oke, wee họrọ oghere ntụnye nke enwere ike kewaa site na 3, dịka 24, 30, 39, 42.51. Tinye oghere 1, ya bụ 17, 21, 27, 29, 35, 37, 39, 45 oghere, dị ka oghere maka wiil a.

Ọmụmaatụ 3: Ngụkọ nke indexing maka egwe ọka 82 ezé.

Dochie n'ime usoro: n=40/82

Gbakọọ n=20/41

Nke ahụ bụ: ọ bụrụhaala na a na-ahọrọ efere index nwere oghere 41, gbanwee 20 + 1 na oghere ntinye nke wiil elu, ya bụ, a na-eji oghere 21 dị ka oghere nke wiil nke ugbu a.

Ọmụmaatụ 4: Ngụkọ nke indexing maka egwe ọka 51 ezé

Dochie usoro n = 40/51, ebe ọ bụ na enweghị ike ịgbakọ akara ahụ n'oge a, ị nwere ike họrọ oghere ahụ ozugbo, ya bụ, họrọ efere index nwere oghere 51, wee tụgharịa wiil elu 51+1 na n'ọnọdu. oghere, ya bụ, oghere 52, dị ka wiil nke ugbu a. Ndokwa oghere viz.

Ọmụmaatụ 5: Ngụkọ nke indexing maka egwe ọka 100 ezé.

Dochie n'ime usoro n=40/100

Gbakọọ n=4/10=12/30

Họrọ efere index nke oghere 30 n'ime oge, wee tinye oghere 12+1 ma ọ bụ 13 n'elu oghere n'ọkwa n'elu wheel dị ka oghere nkwụnye wiil ugbu a.

Ọ bụrụ na diski indexing niile anaghị erute ọnụ ọgụgụ nke oghere achọrọ maka ngụkọta oge, a ga-eji usoro ntinye ihe ntinye ihe maka ngụkọta oge, nke na-adịghị etinye na usoro nchịkọta a. N'ime mmepụta n'ezie, a na-ejikarị gia hobbing eme ihe, n'ihi na arụ ọrụ n'ezie mgbe mkpokọta indexing na-arụ ọrụ adịghị mma.

6. Usoro mgbako maka hexagon edere na okirikiri

① Chọta akụkụ nke ọzọ nke hexagon (S elu) nke gburugburu D

S=0.866D bụ dayameta × 0.866 (ọnụọgụ)

② Gbakọọ dayameta (D) nke gburugburu site na akụkụ nke ọzọ nke hexagon (S elu)

D=1.1547S akụkụ nke ọzọ × 1.1547 (ọnụọgụ)

7. Usoro mgbako nke akụkụ dị n'akụkụ na diagonal ahịrị hexagon na usoro isiokwu oyi

① Chọta akụkụ na-abụghị e nke akụkụ (S) nke mpụta hexagon

e = 1.13s akuku × 1.13

② Chọta akụkụ na-abụghị (e) site na akụkụ (s) nke ọzọ nke hexagon dị n'ime

e = 1.14s akụkụ dị iche × 1.14 (ọnụọgụ)

③ Nweta dayameta ihe nke isi diagonal (D) site n'akụkụ (s) nke ọzọ nke hexagon mpụga.

A ga-agbakọ dayameta (D) nke gburugburu dịka akụkụ nke ọzọ (s ụgbọ elu) nke hexagon (usoro nke abụọ na 6), na ọnụ ahịa etiti etiti kwesịrị ịba ụba nke ọma, ya bụ, D≥1.1547s. Enwere ike ịme atụmatụ ego nkwụghachi site na etiti naanị.

8. Usoro mgbako nke square edere na okirikiri

① See okirikiri (D) ka ịchọta akụkụ nke ọzọ nke square (S elu)

S=0.7071D bụ dayameta × 0.7071

② Chọta okirikiri (D) site n'akụkụ nke ọzọ nke square (S elu)

D = 1.414S akụkụ nke ọzọ × 1.414

9. Ngụkọta usoro maka square megidere akụkụ na-emegide akụkụ na oyi isiokwu usoro

① Chọta akụkụ na-abụghị (e) site na akụkụ nke ọzọ (S) nke square mpụta

e = 1.4s bụ akụkụ nke ọzọ (s) × 1.4 paramita

② Chọta akụkụ na-emegide (e) nke akụkụ (s) nke ọzọ nke square dị n'ime

e = 1.45s bụ akụkụ nke ọzọ (s) × 1.45 ọnụọgụ

10. Usoro mgbako olu hexagon

s20.866 × H / m / k pụtara n'akụkụ akụkụ × akụkụ dị n'akụkụ × 0.866 × ịdị elu ma ọ bụ ọkpụrụkpụ.

11. Usoro mgbako maka mkpịrị (cone) olu

0.262H (D2 + d2 + D × d) bụ 0.262 × ịdị elu × (nnukwu isi dayameta × nnukwu isi dayameta + obere isi dayameta × obere isi dayameta + nnukwu isi dayameta × obere isi dayameta).

12. Usoro mgbako maka olu okirikiri (dị ka isi okirikiri)

3.1416h2 (Rh/3) bụ 3.1416 × ịdị elu × ịdị elu × (radius - ịdị elu ÷ 3).

13. Usoro mgbako maka machining akụkụ nke esịtidem eri taps

1. Ngụkọta mgbata isi dayameta D0

D0=D+(0.866025P/8)×(0.5~1.3) bụ isi nha nke mgbata nnukwu dayameta eri + 0.866025 pitch÷8×0.5~1.3.

Rịba ama: Nhọrọ nke 0.5 ~ 1.3 kwesịrị ikpebi dịka ọkwa ọkwa si dị. Ka ọnụ ahịa pitch buru ibu, ka ekwesịrị iji ọnụọgụ ọnụọgụ dị ntakịrị. N'aka nke ọzọ, ka ọnụ ahịa pitch dị ntakịrị, nnukwu ọnụọgụ kwekọrọ kwesịrị ịdị.

2. Ngụkọta dayameta ụda mgbata (D2)

D2=(3×0.866025P)/8, ya bụ, kpatụ dayameta=3×0.866025×pitch÷8

3. Ngụkọta dayameta mgbata (D1)

D1=(5×0.866025P)/8 bụ mgbata dayameta = 5×0.866025×pitch÷8

Iri na anọ,

Usoro mgbako nke ogologo ihe maka isi oyi na-akpụ ụdị dị iche iche

Usoro olu nke okirikiri mara amara bụ dayameta × dayameta × 0.7854 × ogologo ma ọ bụ radius × radius × 3.1416 × ogologo. Ya bụ, d2×0.7854×L ma ọ bụ R2×3.1416×L

Mgbe ị na-agbakọ, olu X÷diameter ÷ dayameta ÷ 0.7854 ma ọ bụ X÷radius÷radius÷3.1416 nke ihe achọrọ bụ ogologo ihe ahụ.

Usoro kọlụm = X/(3.1416R2) ma ọ bụ X/0.7854d2

N'ime usoro ahụ, X na-anọchi anya uru olu nke ihe achọrọ;

L na-anọchi anya uru ogologo nke nri nri n'ezie;

R/d na-anọchi anya radius ma ọ bụ dayameta nri n'ezie.

Ebumnuche Anebon bụ ịghọta nhụsianya dị mma site na nrụpụta ma nye ndị ahịa ụlọ na mba ofesi nkwado kacha elu maka 2022 High Quality Stainless Steel Aluminum High Precision Custom Mere CNC Turning Milling Machining Spare Part for Aerospace, Iji gbasaa ahịa mba ụwa anyị, Anebon tumadi nye anyị oversea ahịa Top àgwà arụmọrụ n'ibu akụkụ, milled akụkụ na cnc mbịne ọrụ.

China wholesale China Machinery Parts na CNC Machining Service, Anebon na-akwado mmụọ nke "ihe ọhụrụ, nkwekọ, otu ọrụ na nkekọrịta, ụzọ ụkwụ, pragmatic ọganihu". Nye anyị ohere, anyị ga-egosipụtakwa ike anyị. Site n'enyemaka obiọma gị, Anebon kwenyere na anyị nwere ike ịmepụta ọdịnihu dị mma na gị ọnụ.

Oge nzipu: Jul-10-2023