Maka injinia, ihe ndị na-emepụta ihe dị ka crankshafts, camshafts, na cylinder liners na-eji chucks na usoro nhazi ọ bụla. N'oge nhazi, na chucks center, mwekota na ụgbọala na workpiece. Dị ka ike nke chuck jide workpiece na ịnọgide na-enwe n'etiti, ọ na-ekewa n'ime isiike Chuck na sere n'elu chuck. Edemede a na-atụlekarị ụkpụrụ nhọrọ chucks abụọ a na isi ihe ndozi kwa ụbọchị.5aixs CNC machining akụkụ

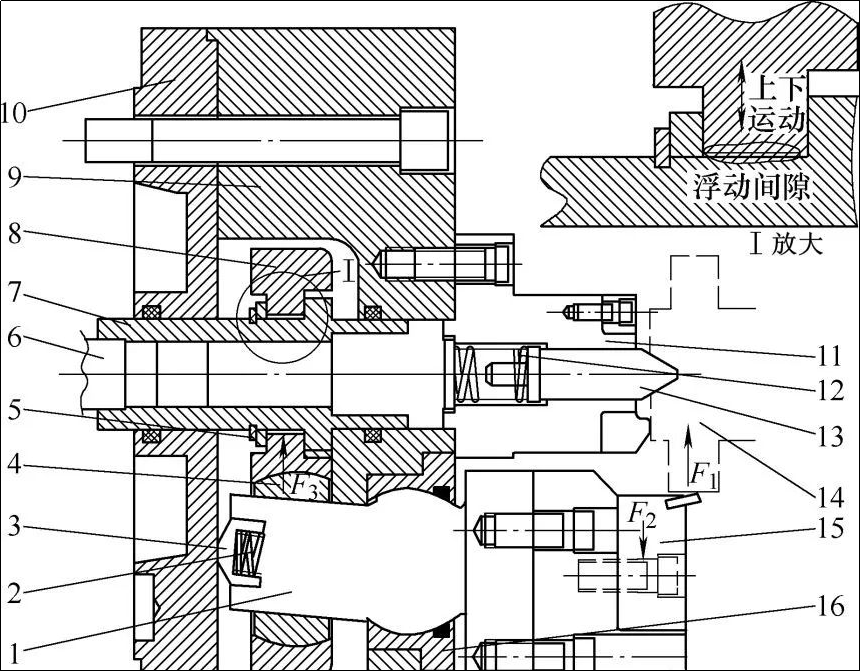

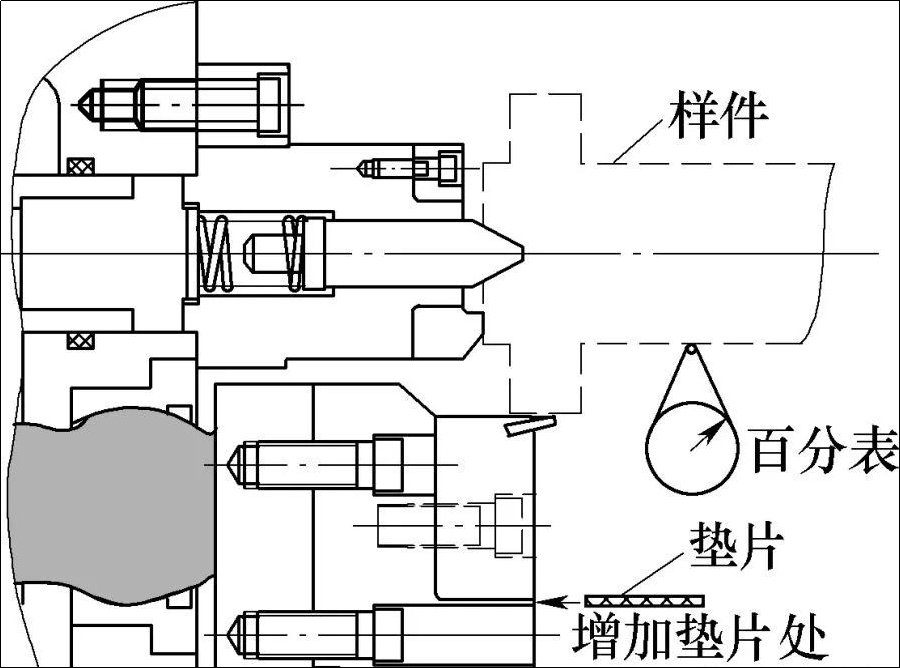

Isi ike na chucks na-ese n'elu mmiri dị nnọọ iche na nhazi na usoro nhazi. Na-ewere usoro nke chucks nke akara Japanese dị ka ihe atụ, ihe osise 1 na-egosi usoro ihe omume nke ihe na-ese n'elu mmiri: workpiece dị n'okpuru ọrụ nke nkwụsị nkwado na n'elu. A na-eme nhazi nke axial na radial na clamping. Mgbe ahụ, chuck cylinder na-ebugharị mkpanaka chuck center tie, efere mgbanwe ọdịiche, efere nkwado agba agba, nkwonkwo okirikiri, na ogwe aka agba site na eriri eriri, n'ikpeazụ na-achọpụta na chuck agba iji kpoo workpiece.

Mgbe enwere mgbanwe dị ịrịba ama nke coaxial n'etiti etiti atọ agba nke chuck na etiti nke workpiece, a ga-edobe agba nke na kọntaktị workpiece mbụ na ike F2, nke a na-ebunye na agba. efere nkwado ogwe aka site na ogwe aka agba na nkwonkwo okirikiri. F3 na-eme ihe na efere nkwado aka aka. Maka chuck na-ese n'elu mmiri, enwere oghere n'etiti mkpanaka mkpara etiti nke chuck na efere nkwado ogwe aka. N'okpuru ọrụ nke ike F3, efere nkwado claw ogwe aka na-eji oghere na-ese n'elu mmiri (efere mgbanwe ọdịiche, mkpanaka etiti nke chuck, na efere nkwado nke agba agba ọnụ na-etolite usoro na-ese n'elu mmiri), nke ga- aga na ntụziaka nke ike ruo atọ jaws mwekota workpiece kpamkpam.

Ọgụgụ 1 Ọdịdị wụ n'elu mmiri

1. Ogwe aka

2. Mmiri akụkụ anọ

3. Spherical n'elu mkpuchi

4. Spherical nkwonkwo

5. Efere mmezi nke mkpochapụ

6. mkpanaka dọkpụrụ cylinder

7. Chuck center dọkpụrụ mkpanaka

8. Efere nkwado ogwe aka

9. Chuck's body 10. Chuck's end cover

10. Nkwadebe nkwado ngọngọ

12. Workpiece ga-esikwa

13. Chuck jaw 16. Nkwado bọọlụ

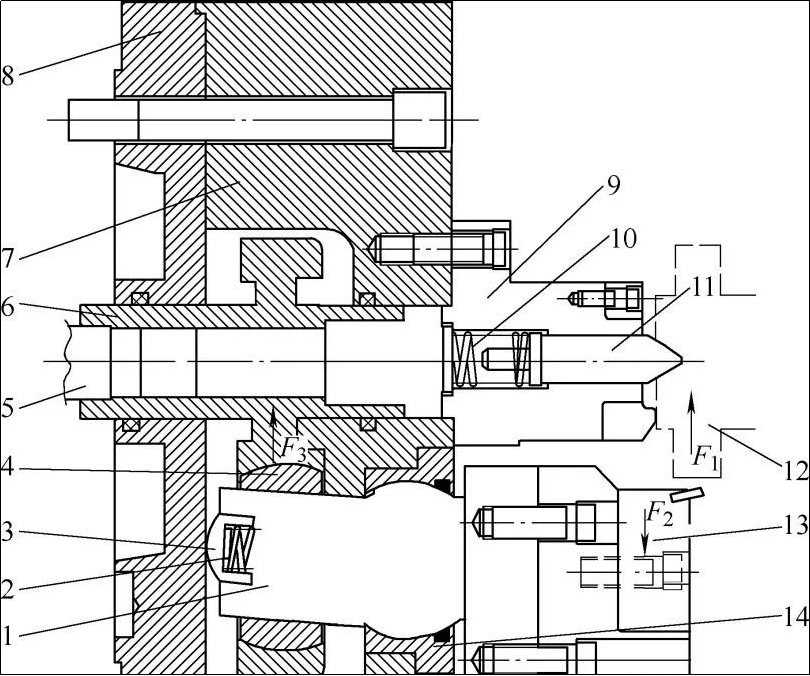

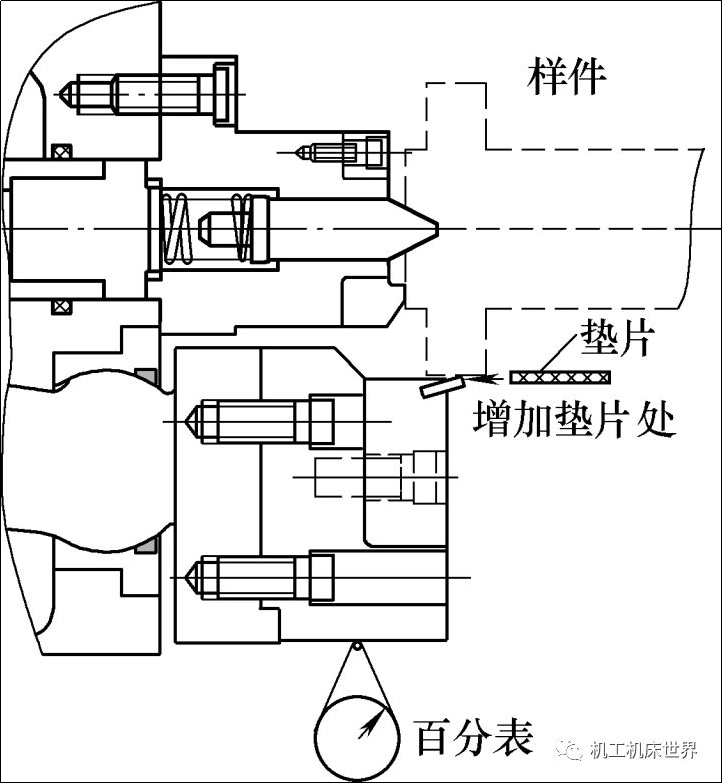

Onyonyo 2 na-egosi usoro mmemme nke chack siri ike

N'okpuru omume nke n'ọnọdu nkwado ngọngọ na n'elu, na workpiece na-positioned na clamped axially na radially, na mgbe ahụ chuck mmanụ cylinder draịva Central sere mkpara, * Tụkwasị na nkwonkwo na agba nke chuck site sere mkpanaka. Ogwe aka na-akpali, na n'ikpeazụ, chuck jaws machie workpiece. Ebe ọ bụ na a na-ejikọta mkpanaka na-adọta etiti nke chuck na nkwonkwo gburugburu na ogwe aka agba, mgbe a na-ejikọta chuck jaws (agba atọ), a ga-emepụta ebe a na-ejikọta ya. Ebe a na-amachi nke a kpụrụ site n'elu anaghị ejikọta ya, na workpiece ga-enwe nrụrụ doro anya clamping mgbe agbachichara. Tupu ejiri chuck mee ihe, ọ dị mkpa iji dozie ihe nkedo n'etiti etiti etiti ahụ na etiti etiti ahụ iji jide n'aka na chuck agaghị apụta nke ọma mgbe ọ gbasịrị. Ọnọdụ ejigidere.

Ọgụgụ 2 Ọdịdị siri ike chuck

1. Ogwe aka

2. 10. Mmiri akụkụ anọ

3. Spherical n'elu mkpuchi

4. Spherical nkwonkwo

5. mkpanaka tie cylinder

6. Chuck etiti tie mkpanaka

7. Chuck ahu

8. Ihe mkpuchi azụ azụ nke Chuck

9. Nkwadebe nkwado ngọngọ

10. N'elu

11. Workpiece ga-esikwa

12. Chuck agba

13. Nkwado okirikiri

Site na nyocha nke usoro nke chuck na Figure 1 na Figure 2, ihe na-ese n'elu mmiri na ihe siri ike nwere ọdịiche ndị a.

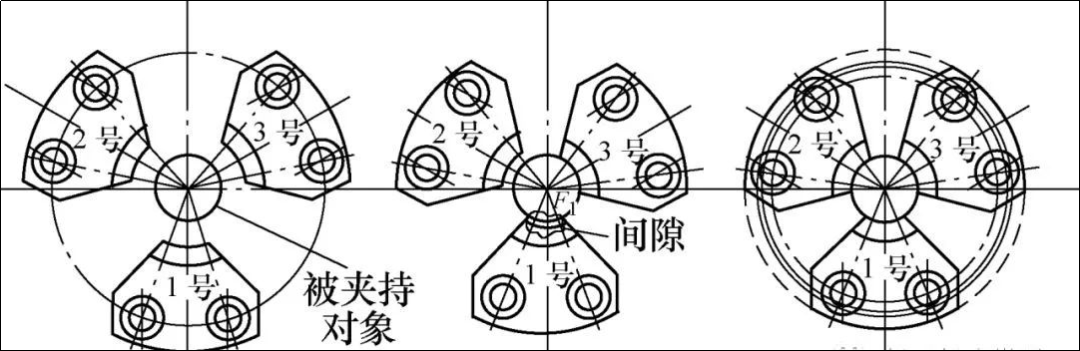

Floating Chuck: Dị ka e gosiri na Figure 3, na usoro nke clamping na workpiece, n'ihi na dị iche iche elu nke workpiece oghere elu ma ọ bụ nnukwu roundness ndidi nke oghere, nke 3 agba ga-abata kọntaktị na workpiece elu na. agba nke 1 na nke 2 ga-apụta. Ọ bụrụ na emetụbeghị workpiece ahụ, n'oge a, usoro na-ese n'elu mmiri na-arụ ọrụ, na-eji elu nke workpiece dị ka nkwado na-ese n'elu 3 agba. Ọ bụrụhaala na ego na-ese n'elu mmiri zuru ezu, a ga-emesịa kụchie agba nke 1 na nke 2. The workpiece nwere obere mmetụta na etiti nke workpiece.

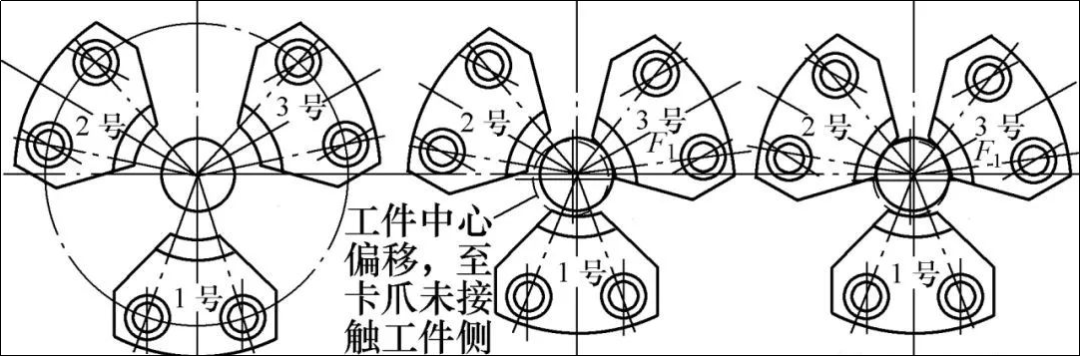

Ọgụgụ 3 Usoro njigide nke agba agba na-ese n'elu mmiri

Isiike Chuck: Dị ka e gosiri na Figure 4, n'oge clamping usoro, ma ọ bụrụ na concentricity n'etiti Chuck na workpiece na-adịghị edozi nke ọma, nke 3 agba ga-akpọtụrụ workpiece, na Nke 1 na Nke 2 jaws agaghị. jikọọ na workpiece. , mgbe ahụ chuck clamping force F1 ga-arụ ọrụ na workpiece. Ọ bụrụ na ike ahụ buru ibu, a ga-ewepụ ọrụ ahụ site na etiti a kara aka, na-amanye workpiece ịkwaga n'etiti chuck; mgbe ike njigide nke chuck dị ntakịrị, ụfọdụ ga-eme. Mgbe jaws enweghị ike ịkpọtụrụ workpiece n'ụzọ zuru ezu, ịma jijiji na-eme n'oge ị na-arụ ọrụ.cnc igwe igwe njikọ

Ọgụgụ 4 Usoro njigide nke agba agba siri ike

Ndozi chọrọ tupu eji chuck: The siri ike chuck ga-etolite clamping center nke chuck n'onwe ya mgbe clamping. Mgbe ị na-eji chuck siri ike, ọ dị mkpa iji dozie ebe nkwụsị nke chuck iji kwekọọ na ebe a na-etinye ya na ntinye nke workpiece, dị ka egosiri na foto 5.cnc machining aluminom akụkụ

Ọgụgụ 5 Ndozi ebe etiti siri ike

Dị ka nyocha nhazi nke dị n'elu, a na-atụ aro ka ị gbasoo ụkpụrụ ndị a na nhazi na nhazi nke chuck: A na-edochi mmanu na griiz nke akụkụ ndị na-ebugharị n'ime chuck mgbe niile. Ntugharị n'etiti akụkụ ndị na-akpụ akpụ n'ime chack bụ esemokwu na-amị amị. Ọ dị mkpa ịgbakwunye na mgbe niile dochie ọkwa a kapịrị ọnụ nke mmanụ lubricating mmanụ / griiz dị ka ihe ndozi chọrọ nke chuck. Mgbe ị na-agbakwunye griiz, ọ dị mkpa ikpochapụ griiz niile ejiri mee ihe n'oge gara aga, wee gbochie ọdụ ụgbọ mmiri mmanụ mgbe ị na-amachichi chuck iji gbochie oghere ime nke chuck ka ọ ghara ijide ya.

Nyocha mgbe niile na ukpụhọde nke clamping center nke isiike Chuck na center nke workpiece: The isiike Chuck kwesịrị ka oge tụọ ma center nke Chuck na etiti nke workpiece spindle bụ agbanwe agbanwe. Tụlee mpụta nke diski ahụ. Ọ bụrụ na ọ gafere oke achọrọ, tinye oghere n'ụzọ kwesịrị ekwesị n'otu agba ma ọ bụ abụọ dabara na ebe dị elu, ma megharịa usoro ndị a dị n'elu ruo mgbe emezuru ihe achọrọ.

Nyocha oge nke ọnụ ọgụgụ na-ese n'elu mmiri na-ese n'elu mmiri (lee foto 6). Na mmezi chuck kwa ụbọchị, ọ dị mkpa iji tụọ ọnụ ọgụgụ na-ese n'elu mmiri mgbe niile na nkenke nke na-ese n'elu mmiri, ma nye nduzi maka nlekọta n'ime ime nke chuck na oge ikpeazụ. Usoro nha nke ziri ezi na-ese n'elu mmiri: mgbe chuck mechiri ihe nlele ahụ, tinye chuck ka a tụọ ya. Tụgharịa nkịrịka ahụ n'ọnọdụ nha dabara adaba, tụọ ihe ngosi ọkpụkpọ (mkpa itinye ntọala mita magnet n'akụkụ ogwe a na-akpụ akpụ), ma kaa akara nrịgo dị ka ebe ebe efu. Mgbe ahụ, jikwaa servo axis iji bugharịa ihe ngosi ọkpụkpọ, mepee chuck, tinye gasket nwere ọkpụrụkpụ nke Amm n'etiti agba ka a tụrụ ya na ihe nlele ahụ, kpachie ihe nlele ahụ na chuck, bugharịa ihe ngosi ọkpụkpọ gaa na ebe efu, ma gosi ma data nke akara ọkpụkpọ pịara ọ bụ gbasara Amm. Ọ bụrụ na ọ bụ, ọ pụtara na izi ezi na-ese n'elu mmiri dị mma. Ọ bụrụ na data ahụ dị iche nke ukwuu, ọ pụtara na enwere nsogbu na usoro na-ese n'elu mmiri nke chuck. Ntụle nke agba ndị ọzọ bụ otu ihe ahụ dị n'elu.

Ọgụgụ 6 Nyochaa ọnụ ọgụgụ na-ese n'elu mmiri na-ese n'elu mmiri

Ndochi anya nke akụkụ ndị dị ka akàrà, gaskets na isi iyi n'ime chuck: isi iyi akụkụ anọ, anụ ahụ chuck, mkpuchi azụ azụ azụ, isi iyi akụkụ anọ, na akàrà na isi iyi na nkwado okirikiri ga-emerịrị dịka ugboro ole ejiri ya na nke dị n'elu. nsonaazụ ule. Dochie mgbe niile. Ma ọ bụghị ya, ike ọgwụgwụ ga-emebi ya, na-eme ka ọnụ ọgụgụ na-ese n'elu mmiri na mmiri siri ike.

Site na nyocha nke dị n'elu nke isi ihe dị mkpa nke nhazi nhazi na nhazi nke chuck, ṅaa ntị na ụkpụrụ ndị a na nhọrọ nke chucks: ma ọ bụrụ na akụkụ nke chuck clamping nke akụkụ ahụ edoziri bụ oghere oghere, a na-ahọrọ ihe na-ese n'elu mmiri, na ihe siri ike. a na-eji arụ ọrụ arụ ọrụ. The chuck clamping elu nke machined akụkụ bụ elu mgbe roughing, ọkara-finishing/finishing. Mgbe ịgbaso iwu ndị dị n'elu, ịme nhọrọ ziri ezi dịka ọnọdụ ọrụ dị iche iche dị mkpa.

Nhọrọ nke chack siri ike:

① Ọnọdụ igwe na-achọ oke nke ịkpụ na nnukwu ike ịkpụ. Mgbe clamped site workpiece na-esichara na-akwado site etiti etiti, a muscular workpiece rigidity, na nnukwu workpiece rotational ịnya ụgbọ ala chọrọ.

② Mgbe ọ nweghị usoro etiti oge, dị ka n'elu, a chọrọ imewe nke chuck centering.

Nhọrọ chack na-ese n'elu mmiri:

① High chọrọ maka centering nke workpiece spindle. Mgbe chuck na-clamped, ya sere n'elu agaghị akpaghasị isi centering nke workpiece spindle.

② Ọnụ ego a na-egbutu abụghị nnukwu, yana ọ dị mkpa naanị ịkwanye spindle workpiece ka ọ gbanwee ma nwekwuo ike nke workpiece.

Ihe dị n'elu na-akọwa ọdịiche nhazi na nhazi na nhọrọ nhọrọ nke chucks na-ese n'elu mmiri na nke siri ike, nke na-enyere aka maka iji na mmezi. Ị chọrọ nghọta miri emi na iji mgbanwe mee ihe; ịkwesịrị ịchịkọta ahụmịhe mgbe niile na iji saịtị na mmezi.

Anebon Metal Products Limited nwere ike ịnye CNC Machining, Die Casting, Sheet Metal Fabrication ọrụ, biko nweere onwe gị ịkpọtụrụ anyị.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Oge nzipu: Mar-31-2022