Onye ọ bụla maara na threadia. Dịka ndị ọrụ ibe na ụlọ ọrụ mmepụta ihe, anyị na-achọkarị ịgbakwunye eri dị ka mkpa ndị ahịa si dị mgbe ị na-edozi ngwa ngwa ngwa dị kaCNC machining akụkụ, CNC ntụgharị akụkụnaCNC-egwe ọka akụkụ.

1. Gịnị bụ eri?

A eri bụ helix e bee n'ime a workpiece ma si n'èzí ma ọ bụ n'ime. Isi ọrụ nke eriri bụ:

1. Mepụta njikọ n'ibu site na ijikọta ngwaahịa eri n'ime na ngwaahịa eri.

2. Nyefee mmegharị site n'ịgbanwe ntụgharị rotary ka ọ bụrụ usoro kwụ ọtọ na nke ọzọ.

3. Nweta uru igwe.

2. Eriri profaịlụ na okwu okwu

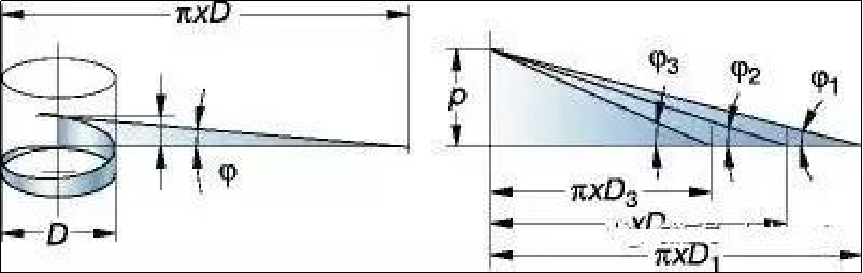

Profaịlụ eri ahụ na-ekpebi geometry nke eri ahụ, gụnyere dayameta workpiece (isi, pitch, na obere dayameta); eri profaịlụ n'akuku; pitch na helix akụkụ.

1. Okwu eri

① N'okpuru: elu ala na-ejikọta eriri eriri abụọ dị n'akụkụ.

② flank: elu akụkụ eri nke jikọtara crest na ala eze.

③Crest: elu elu na-ejikọta akụkụ abụọ ahụ.

P = pitch, mm ma ọ bụ eri kwa inch (tpi)

ß = akụkụ profaịlụ

ϕ = eriri helix akụkụ

d = nnukwu dayameta nke eriri mpụga

D = nnukwu dayameta nke eriri ime

d1 = obere dayameta nke eriri mpụga

D1 = Obere dayameta nke eriri ime

d2 = dayameta pitch nke eriri mpụga

D2 = dayameta eriri olulu dị n'ime

Dayameta oghere, d2/D2

Dayameta nke eri ahụ dị irè. Ihe dị ka ọkara n'etiti dayameta ndị isi na obere.

The geometry nke eri dabeere na eri pitch dayameta (d, D) na pitch (P): axial anya tinyere eri na workpiece si n'otu ebe na profaịlụ na kwekọrọ ekwekọ ọzọ n'ókè. Enwere ike ịhụ nke a dị ka triangle na-agafe na workpiece.

vc = ịkpụ ọsọ (m/min)

ap = mkpokọta eriri omimi (mm)

ụra = mkpokọta eriri omimi (mm)

tpi = eri kwa inch

Nri = pitch

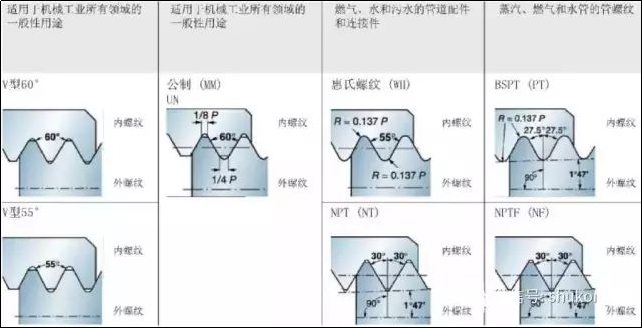

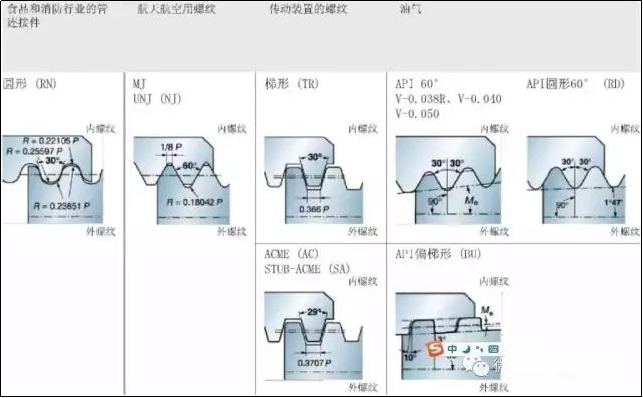

2. Profaịlụ eri nkịtị

1. Ngụkọta na ndidi nke mpụga eri pitch dayameta nke 60° eze ụdị (mba ọkọlọtọ GB197/196)

a. Ngụkọta nke isi size nke pitch dayameta

Nha isi nke dayameta pitch nke eri ahụ = isi dayameta nke eri ahụ - pitch × ọnụọgụ ọnụọgụ.

Nnọchite anya usoro: d/DP×0.6495

2. Ngụkọta na ndidi nke pitch dayameta nke 60° esịtidem eri (GB197/196)

A.6H larịị eri pitch dayameta ndidi (dabere na thread pitch)

Oke oke:

P0.8+0.125P1.00+0.150P1.25+0.16P1.5+0.180

P1.25+0.00P2.0+0.212P2.5+0.224

Uru oke ala bụ "0",

Usoro mgbako oke oke 2+TD2 bụ nha nha + nnabata.

Dịka ọmụmaatụ, dayameta pitch nke eriri ime M8-6H bụ: 7.188+0.160=7.348 Oke oke: 7.188 bụ oke ala.

b. Usoro ngụkọta oge nke dayameta pitch nke eriri dị n'ime bụ otu ihe ahụ nke eriri mpụga

Ya bụ, D2 = DP × 0.6495, ya bụ, n'etiti dayameta nke esịtidem eri hà na isi dayameta nke eri-pitch × ọnụọgụ ọnụọgụgụ uru.

c.6G klas eri pitch pitch dayameta isi deviation E1 (dabere na eriri pitch)

P0.8+0.024P1.00+0.026P1.25+0.028P1.5+0.032

P1.75+0.034P1.00+0.026P2.5+0.042

3. Ngụkọta na ndidi nke isi dayameta nke mpụga eri (GB197/196)

a. Oke elu nke 6h isi dayameta nke eriri mpụga

Ya bụ, eri dayameta uru atụ M8 bụ φ8.00 na elu oke ndidi bụ “0″.

b. Nkwenye nke uru oke ala nke nnukwu dayameta nke klas 6h nke eriri mpụga (dabere na eriri eri)

P0.8-0.15P1.00-0.18P1.25-0.212P1.5-0.236P1.75-0.265

P2.0-0.28P2.5-0.335

Usoro mgbako maka oke ala nke isi dayameta: d-Td bụ akụkụ bụ isi nke dayameta isi nke eri - ndidi.

4. Ngụkọta na ndidi nke obere dayameta nke esịtidem eri

a. Ngụkọta nke isi nha nke obere dayameta nke eriri ime (D1)

Nha isi nke obere dayameta nke eri ahụ = nha isi nke eriri dị n'ime - pitch × ihe

5. Usoro mgbako nke nkewa isi otu ụzọ nkerisi

Usoro ngụkọ nke otu usoro nkewa: n=40/Z

n: ọnụọgụ mgbanwe nke isi nkewa kwesịrị ịtụgharị

Z: Nha nhata nke workpiece

40: ọnụ ọgụgụ a kapịrị ọnụ nke isi nkewa

6. Usoro mgbako nke hexagon nke edere na okirikiri

① Chọta hexagonal chere ihu (S elu) nke okirikiri D

S=0.866D bụ dayameta × 0.866 (ọnụọgụ)

② Gbakọọ dayameta nke gburugburu (D) site na akụkụ nke ọzọ nke hexagon (S elu)

D = 1.1547S bụ akụkụ nke ọzọ × 1.1547 (ọnụọgụ)

7. Ngụkọta usoro nke hexagonal megidere akụkụ na diagonals na oyi na-atụ isi usoro

① Chọta akụkụ na-abụghị e site na akụkụ (S) nke mpụta hexagon

e = 1.13s bụ akụkụ nke ọzọ × 1.13

② Chọta akụkụ na-abụghị (e) site na akụkụ (s) nke ọzọ nke hexagon dị n'ime

e = 1.14s bụ akụkụ nke ọzọ × 1.14 (ọnụọgụ)

③ Chọta dayameta ihe nke isi akụkụ nke ọzọ (D) site n'akụkụ nke ọzọ (s) nke hexagon mpụta.

Ekwesịrị ịgbakọ dayameta nke okirikiri (D) dabere na (usoro nke abụọ na 6) akụkụ akụkụ hexagonal (s elu), yana uru etiti etiti kwesịrị ịba ụba nke ọma, ya bụ, D≥1.1547s. Enwere ike ịme atụmatụ ọnụọgụ etiti etiti.

8. Usoro mgbako nke square edere na okirikiri

① gburugburu (D) ịchọta akụkụ nke ọzọ nke square (S elu)

S=0.7071D bụ dayameta × 0.7071

② Chọta okirikiri (D) site n'akụkụ nke ọzọ nke square (S elu)

D = 1.414S bụ akụkụ nke ọzọ × 1.414

9. Mgbakọ usoro nke square megidere n'akụkụ na-abụghị akụkụ na oyi na-atụ isiokwu usoro

① Chọta akụkụ na-abụghị (e) site na akụkụ nke ọzọ (S) nke square mpụta

e = 1.4s bụ akụkụ nke ọzọ (s) × 1.4 paramita

② Chọta akụkụ na-emegide (e) site na akụkụ (s) nke ọzọ nke square dị n'ime

e = 1.45s bụ akụkụ nke ọzọ (s) × 1.45 ọnụọgụ

10. Usoro maka ịgbakọ olu nke hexagon

s20.866 × H / m / k pụtara n'akụkụ akụkụ × akụkụ dị n'akụkụ × 0.866 × ịdị elu ma ọ bụ ọkpụrụkpụ.

11. Usoro nchịkọta nke olu nke nkụda mmụọ (cone) ahụ

0.262H(D2+d2+D ×d) bụ 0.262× ịdị elu ×(nnukwu isi dayameta × nnukwu isi dayameta+obere isi dayameta ×obere isi dayameta+ nnukwu isi dayameta ×obere isi dayameta).

12. Usoro ngụkọ maka ụda ahụ dị okirikiri (dị ka isi ọkara okirikiri)

3.1416h2 (Rh/3) bụ 3.1416 × ịdị elu × ịdị elu × (radius - ịdị elu ÷ 3).

13. Usoro mgbako maka machining akụkụ nke taps maka esịtidem eri

1. Ngụkọta mgbata isi dayameta D0

D0=D+(0.866025P/8)×(0.5~1.3) bụ isi nha nke mgbata nnukwu dayameta eri + 0.866025 pitch ÷ 8×0.5 ka 1.3.

Rịba ama: Nhọrọ nke 0.5 ruo 1.3 kwesịrị ịkwado dịka nha nke pitch si dị. Ka ọnụ ahịa pitch ka ukwuu, a ga-eji ọnụ ọgụgụ dị nta mee ihe. N'ụzọ megidere nke ahụ, ka ọnụ ahịa pitch dị ntakịrị, a ga-eji ọnụ ọgụgụ buru ibu dabara adaba.

2. Ngụkọta dayameta ụda mgbata (D2)

D2=(3×0.866025P)/8, ya bụ, kpatụ dayameta=3×0.866025×pitch÷8

3. Ngụkọta dayameta mgbata (D1)

D1=(5×0.866025P)/8 bụ mgbata dayameta = 5×0.866025×pitch÷8

14. Usoro mgbako maka ogologo ihe eji eme isiokwu oyi na-akpụ n'ụdị dị iche iche

A maara na usoro olu nke okirikiri bụ dayameta × dayameta × 0.7854 × ogologo ma ọ bụ radius × radius × 3.1416 × ogologo. Ya bụ, d2×0.7854×L ma ọ bụ R2×3.1416×L

Mgbe ị na-agbakọ, olu X÷diameter ÷ dayameta ÷ 0.7854 ma ọ bụ X÷radius÷radius÷3.1416 nke ihe achọrọ maka nhazicnc machining akụkụnacnc ntụgharị akụkụbụ ogologo ihe.

Usoro kọlụm = X/(3.1416R2) ma ọ bụ X/0.7854d2

X na usoro na-anọchi anya uru olu nke ihe achọrọ;

L na-anọchi anya uru ogologo nke nri nri n'ezie;

R/d na-anọchi anya radius ma ọ bụ dayameta nke nri nri n'ezie.

Oge nzipu: Jan-11-2023