Otu ịkpụ eri

N'ozuzu, ọ na-ezo aka machining eri na workpiece na a akpụ ma ọ bụ egweri ngwá ọrụ, tumadi gụnyere mbịne, egwe ọka, tapping na threading egweri, egweri, oké ifufe ọnwụ, wdg Mgbe mbịne,-egwe ọka, na-egweri na eri, nnyefe yinye nke. Ngwá ọrụ igwe na-ahụ na ngwaọrụ ntụgharị, onye na-egwe ọka, ma ọ bụ wiil egweri na-ebugharị ụzọ n'ụzọ ziri ezi na nke ọma n'akụkụ axial nke workpiece ọ bụla ntụgharị. Mgbe ọpịpị ma ọ bụ threading, ngwá ọrụ (tap ma ọ bụ anwụ) na-atụgharị ikwu na workpiece, na nke mbụ kpụrụ eri uzo na-eduzi ngwá ọrụ (ma ọ bụ workpiece) ịkwaga axially.

Na-atụgharị eriri abụọ

Enwere ike iji ngwaọrụ kaadị atụgharị ma ọ bụ eri eri na lathe (lee ngwaọrụ nhazi eriri). Agbanye eri na-akpụ mbịne ngwá ọrụ bụ ọkọlọtọ usoro maka otu ibe na obere ogbe mmepụta nke thread workpiece ruru ya mfe Ọdịdị; mbịne eri na eri combing ngwá ọrụ nwere elu mmepụta arụmọrụ, ma ya Ọdịdị bụ mgbagwoju, n'ihi ya, ọ bụ naanị adabara mbịne mkpụmkpụ eri workpiece na ezi ezé na ọkara na nnukwu ogbe mmepụta. Izi ezi nke ịgbanye eriri trapezoidal na lathe n'ozuzu nwere ike iru ọkwa 8-9 (jb2886-81, otu n'okpuru); Enwere ike imeziwanye arụpụtaghị ihe ma ọ bụ izi ezi nke ọma mgbe ị na-eme eri na eriri eriri pụrụ iche.

Egwe ọka atọ

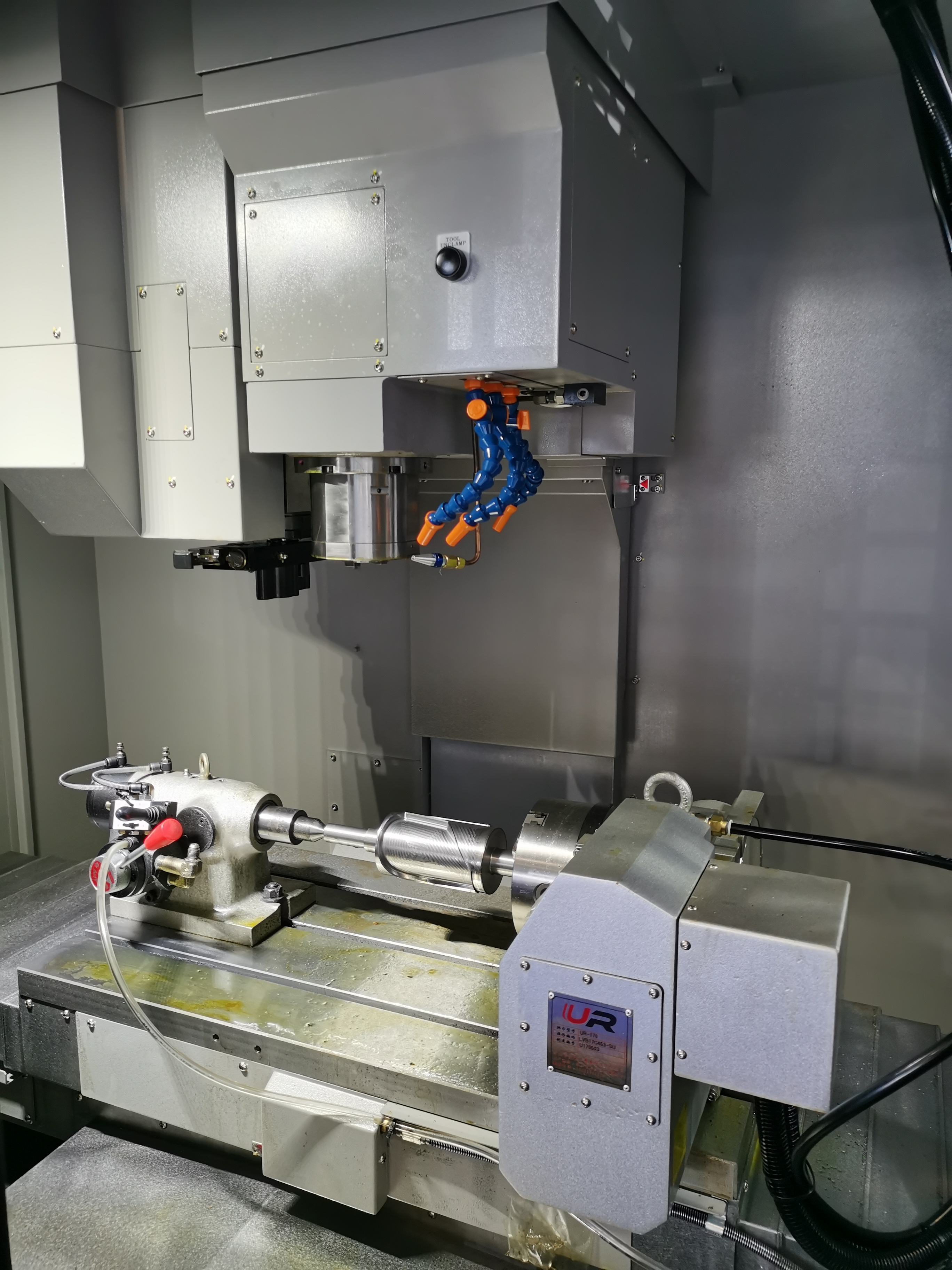

A na-eji ihe na-egwe ọka diski ma ọ bụ mbo egwe ọka egwe ọka n'igwe egwe ọka. A na-eji ihe na-egwe ọka diski eme ihe bụ isi maka egwe ọka trapezoid mpụga nke mkpanaka ịghasa, ikpuru, na ihe ndị ọzọ na-arụ ọrụ. Ngwa igwe igwe ihe igwe ihe dị n'ime na mpụga nkịtị eri na taper. N'ihi na akụkụ ya na-arụ ọrụ dị ogologo karịa ogologo eri ka a ga-edozi ya site na onye na-egwe nri dị iche iche, enwere ike ịhazi workpiece naanị site na ntụgharị 1.25-1.5 na-atụgharị, na-arụ ọrụ dị elu. The pitch ziri ezi nke eri egwe ọka nwere ike iru 8-9 akara ule, na elu roughness bụ r5-0.63 μ M. Usoro a dabara maka uka mmepụta nke izugbe nkenke eri workpieces ma ọ bụ ike ike machining tupu egweri.

Anọeri egweri

A na-eji ya eme ihe nke ọma maka eriri nke workpiece siri ike na igwe ihe. Dị ka ihe dị iche iche cross-ngalaba shapes nke egweri wheel, ọ nwere ike kewaa abụọ ụdị: otu-akara egweri wheel na multi-line egweri wheel. Izi ezi nke otu ahịrị na-egweri wiil bụ 5-6 akara ule, na elu roughness bụ r1.25-0.08 μ m, n'ihi ya, ọ na-adaba n'ime imecha egweri wheel. Usoro a dabara adaba nkenke kposara, eri gauges, ikpuru, obere batches nke eri workpieces, na nkenke hobTwotwo ụdị egweri meth adị: longitudinal egweri na bee-na-egweri. The obosara nke egweri wheel na longitudinal egweri usoro bụ ihe na-erughị ogologo nke eri na-ala, na eri nwere ike ịbụ ala na ikpeazụ size mgbe egweri wheel na-akpali longitudinally otu ugboro ma ọ bụ ọtụtụ ugboro. Obosara nke igwe na-egweri nke usoro ịkpụ-na-egweri dị ukwuu karịa ogologo eri ka ọ bụrụ ala. The egweri wheel bee n'ime elu nke workpiece radially, na workpiece nwere ike n'ala mgbe ọ tụgharịa banyere 1.25 revolutions. Nrụpụta ahụ dị elu, mana nkenke dị ntakịrị ala, na mgbakwasa nke wiil egweri dị mgbagwoju anya. Usoro ịkpụ-na-egweri kwesịrị ekwesị maka shọvel buru ibu nke taps na-egweri ụfọdụ fastening eri. Nhazi ígwè kwesịrị nlebara anya!

Eriri eri ise

Ụdị nut-ụdị ma ọ bụ skru-ụdị eri-lapping ngwá ọrụ na-eji ihe dị nro dị ka nkedo ígwè. Akụkụ nke eri edoziri na workpiece nwere njehie pitch na-agbada site n'ihu na ntụgharị ntụgharị iji kwalite izi ezi. A na-ekpochapụ eriri dị n'ime ahụ siri ike site n'igweri iji meziwanye izi ezi.

Mpịaji isii na eri

Ịpịpị bụ iji otu torque kpọbatara mgbata ahụ n'ime oghere ala a kpụrụ akpụ na workpiece iji hazie eri dị n'ime.

Threading bụ bee mpụga eri na mmanya (ma ọ bụ tube) workpiece na-anwụ anwụ. Izi ezi machining nke ịpị ma ọ bụ eri na-adabere na izi ezi nke mgbata ma ọ bụ nwụọ. N'agbanyeghị na enwere ọtụtụ ụzọ isi hazie eriri dị n'ime na nke dị n'èzí, eriri dị n'ime obere dayameta nwere ike ịhazi naanị site na mgbata. Enwere ike ịme ọpịpị na eriri site na aka ma ọ bụ lathe, igwe na-egwuputa ihe, igwe na-akụ, na igwe eri.

Asaaeri na-atụgharị

A na-eme usoro nhazi nke ịkpụ ma na-atụgharị anwụ iji mepụta nrụrụ plastik nke workpiece iji nweta eriri na-atụgharị na igwe na-akpụgharị eri ma ọ bụ akpaka lathe jikọtara ya na oghere akpaka na mmechi eri na-atụgharị isi, nke dabara maka mmepụta oke. nke mpụga eri ụkpụrụ nke ọkọlọtọ fasteners na ndị ọzọ threaded nkwonkwo. N'ozuzu, dayameta dị n'èzí nke eriri na-atụgharị abụghị ihe karịrị 25 mm, ogologo ya erughị 100 mm, na eriri ziri ezi nwere ike iru ọkwa 2 (gb197-63). Dayameta nke oghere ahụ ejiri mee ihe ruru dayameta pitch nke eri a ga-ahazi. N'ozuzu, enweghị ike ịhazi eri dị n'ime site na ịtụgharị. N'agbanyeghị nke ahụ, maka ọrụ ahụ dị nro, enwere ike iji eriri dị n'ime ikuku extrusion oyi na-enweghị oghere extrusion mgbata (oke dayameta nwere ike iru ihe dịka 30mm), ụkpụrụ ọrụ yiri nke ịpị. The torque chọrọ maka oyi extrusion nke esịtidem eri bụ banyere 1 ugboro ibu karịa nke ahụ maka ịme ọpịpị, na machining ziri ezi na elu àgwà dị ubé elu karịa nke ịme ọpịpị.

Uru ndị dị n'okirikiri eri bụ ndị a:

① Ọkpụkpụ dị n'elu dị obere karịa ntụgharị, igwe-egwe ọka, na igwe;

② Elu nke eri mgbe ị na-atụgharị nwere ike imeziwanye ike na ike n'ihi ịrụ ọrụ oyi;

③ ọnụ ọgụgụ ojiji ihe onwunwe dị elu;

④ arụpụtaghị ihe okpukpu abụọ ma e jiri ya tụnyere usoro ịkpụ, ọ dịkwa mfe ịghọta akpaaka;

⑤ ndụ ọrụ nke rolling die dị ogologo. Otú ọ dị, ike nke ihe na-arụ ọrụ abụghị ihe karịrị hrc40, a na-achọ ihe ziri ezi nke oghere oghere ka ọ dị elu, na izi ezi na ike nke ịnwụ anwụ dịkwa elu, n'ihi ya, ọ na-esiri ike ịmepụta anwụ. Ọ dịghị mma maka eri nwere profaịlụ ntụgharị asymmetric.

Dị ka ndị dị iche iche na-atụgharị na-anwụ anwụ, e nwere ike kewaa eriri na-atụgharị n'ụdị abụọ: eriri na-atụgharị na eriri.

Efere eri abụọ a na-atụgharị na profaịlụ eri na-agbagharị site na 1/2 pitch, a na-edozi efere static, na efere na-akpụ akpụ na-agagharị n'ahịrị kwụ ọtọ na-emegharị na efere static. Ọ bụrụ na ị chọrọ ịmụta UG mmemme na otu 565120797, ọ nwere ike inyere gị aka mgbe workpiece na-etinye n'ime efere abụọ, na-akpali efere n'ihu na-ete na pịa workpiece, na-eme ka elu plastic deformation n'ime eri.

Enwere ụdị mpịakọta atọ: radial, tangential, na mpịakọta isi.

① eriri radial na-atụgharị:A na-etinye wiil abụọ (ma ọ bụ atọ) nke yiri eri na-agbagharị agbagharị n'otu akụkụ, a na-etinye workpiece na nkwado n'etiti wiil abụọ ahụ, wiil abụọ ahụ na-atụgharị n'otu ọsọ ahụ n'otu ụzọ ahụ, otu n'ime ha na-arụkwa ọrụ radial. nri ngagharị. Wheel na-agbagharị agbagharị na-eme ka ihe ahụ rụọ ọrụ ka ọ tụgharịa, a na-agbapụkwa elu ya radially ka ọ bụrụ eri. Enwere ike iji usoro mpịakọta yiri nke ahụ maka skru ụfọdụ nwere ezigbo ihe achọrọ.

eriri tangential na-atụgharị:makwaara dị ka planetary thread rolling. Ngwá ọrụ a na-atụgharị na-agụnye eriri etiti etiti na-agbagharị agbagharị na efere eri nwere ụdị arc atọ edoziri. Enwere ike inye nri na-arụ ọrụ na-aga n'ihu n'oge a na-atụgharị, ya mere arụpụtaghị ihe dị elu karịa nke eriri eri na radial rolling.

③ Eriri na-atụgharị isi eri na-atụgharị isi:a na-eme ya na lathe akpaka ma na-ejikarị eme ihe na-edozi obere eri na workpiece. Enwere rollers 3-4 na-ekesa n'otu n'otu n'akụkụ ebe a na-arụ ọrụ. Mgbe ị na-atụgharị, workpiece na-atụgharị, isi na-atụgharị na-eri nri axially iji tụgharịa workpiece na eri ahụ.

| Ngwa CNC Machining | Ịrụ ọrụ CNC dị ịtụnanya | Ọrụ ntanetị Cnc |

| Akụkụ Aluminom Machining | Akụkụ ụgbọ elu igwe | Omenala Metal Manufacturing |

| Nhazi CNC | Akụkụ Brass Machined | Akụkụ agba CNC Brass |

www.anebon.com

Anebon Metal Products Limited nwere ike ịnye igwe CNC, nkedo anwụ, ọrụ igwe mpempe akwụkwọ, biko nweere onwe gị ịkpọtụrụ anyị.

Tel: +86-769-89802722 Email: info@anebon.com Website : www.anebon.com

Oge nzipu: Ọktoba 04-2019