Kedu ihe ị maara gbasara usoro ọgwụgwọ elu nke ihe na CNC machining?

Maka CNC machining, ọgwụgwọ elu bụ usoro a na-arụ ọrụ iji meziwanye ọdịdị yana ọrụ na ogologo oge nke ihe ndị a na-emepụta. Usoro ndị a na-ejikarị emeso elu ala ejiri na CNC machining gụnyere deburring. Usoro a na-agụnye iwepụ ọnụ ọnụ dị nkọ, ọnyà, ma ọ bụ ihe ọ bụla karịrị akarị n'elu ihe eji arụ ọrụ. Deburring na-akwalite mma na nchekwa nke ngwaahịa ikpeazụ.

Nchacha:Enwere ike iji polishing mee ka ihe dị nro dị nro nke na-ebute ọdịdị na-egbuke egbuke ma na-egbuke egbuke. Ọ enhances ọdịdị nke components na mbelata esemokwu na akụkụ.

Na-egweri: A na-eji ya wepụ ezughị okè n'elu ma ọ bụ nweta nnabata ziri ezi. Nke a na-agụnye iji wheel grinder wepụ ihe na mpempe ọrụ.

Anodizing:Ọ bụ usoro electrochemical nke na-emepụta oyi akwa mkpuchi dị ka oxide n'elu ihe ọla dị ka aluminom. Ọ enhances iguzogide corrosion yana aesthetics, ike na.

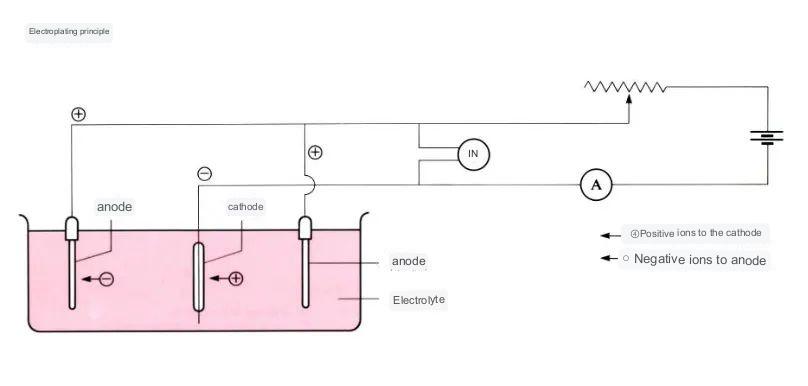

Electroratingna-agụnye idobe oyi akwa ọla n'elu ihe ahụ. Ọ na-eme ka iguzogide corrosion ka mma yana conductivity na anya.

Mkpuchi:Mkpuchi elu bụ usoro nke itinye ihe mgbochi corrosion oyi akwa ma ọ bụ agba n'elu ihe. Ọ nwere ike inye iguzogide corrosion yana mgbochi iyi. Ọ nwekwara ike melite mma.

Ọgwụgwọ okpomọkụ:Nke a gụnyere ikpughe ihe na oke okpomoku yana mma na-achịkwa iji gbanwee akụrụngwa ha. Usoro a na-eme ka ihe ahụ dịkwuo ogologo oge, ike siri ike ma na-eguzogide iyi na nrụrụ.

Ngwọta ndị a maka elu elu nwere ike ịkwalite ịdịmma, arụmọrụ na ogologo ndụ nke akụrụngwa CNC arụnyere. Ụdị ọgwụgwọ ị na-ahọrọ iji mee ihe dabere na ihe ahụ, ngwa e bu n'obi, na nsonaazụ achọrọ.

Ngwọta dị n'elu bụ usoro ịmepụta ihe n'elu isi ihe nwere kemịkalụ, anụ ahụ, na n'ibu dị iche na nke ihe ndabere.

Ebumnuche nke ọgwụgwọ elu bụ imeju iguzogide iyi, corrosion na mkpa ndị ọzọ nke ngwa ahịa ahụ. Usoro a na-ejikarị eme ihe maka ọgwụgwọ elu gụnyere igwe igwe, ọgwụgwọ kemịkalụ ọgwụgwọ elu okpomọkụ na ịgbasa n'elu. Ngwọta dị n'elu bụ usoro ihicha elu, kpochaa ya, mebie ya na iwetu ya na mpụta nke ibe ahụ. Taa, anyị ga-atụle usoro ọgwụgwọ elu.

Kedu uru ọgwụgwọ elu nwere ike iweta akụkụ ndị na-emepụta ihe?

Usoro ọgwụgwọ mpaghara dị n'elu nwere ike iweta ọtụtụ uru naakụkụ igwe, esịnede: Mma Aesthetics: N'elu usoro ọgwụgwọ dị ka sprucing elu, anodizing, plating na nakwa imecha nwere ike ịkwalite mma anya nke machined components. Ọ nwere ike weta mmecha dị nro, na-egbuke egbuke ma ọ bụ ahaziri ahazi, na-eme ka ọdịdị nke ihe ahụ dịkwuo mma.

Enwekwukwa nchara nchara: Ọtụtụ usoro ọgwụgwọ dị n'elu, dị ka anodizing, plating, na finishing, na-emepụta ihe nchebe n'elu ihe ahụ. Igwe oyi akwa a na-arụ ọrụ dị ka ihe mgbochi, na-echebe megide akụkụ ahụ site na ịbanye na kọntaktị na ntọala corrosive, ya mere na-eme ka nguzogide corrosion ya dịkwuo elu.

Nkwụsi ike iyi agbagoro agbagoro: Usoro ọgwụgwọ dị n'elu dị ka ọgwụgwọ ọkụ ma ọ bụ imecha nwere ike ịbawanye nkwụsi ike nke akụkụ ndị a kpụrụ akpụ. Usoro ndị a nwere ike imeziwanye nkwụsi ike, isi ike na kwa ike nke ihe, na-eme ka ha nwee ọtụtụ ihe na-egbochi ikpochapu, abrasion yana iyi. Mee mmanu mmanu ma belatakwa ịhịa aka n'ahụ: Ụfọdụ ọgwụgwọ mpaghara dị n'elu, dị ka ihicha ma ọ bụ oyi akwa nwere ihe ndị na-adịghị obere, nwere ike belata esemokwu n'etiti ihe ndị na-akpụ akpụ. Nke a na-eme ka usoro dị nro dị nro, na-ebelata iyi, ma na-eme ka arụ ọrụ zuru ezu nke akụkụ ndị a kpụrụ akpụ.

Mgbochi kemịkalụ ka mma: Site na ọgwụgwọ elu, enwere ike ịkwalite nguzogide kemịkalụ nke akụrụngwa igwe. Nke a bara uru karịsịa mgbe akụrụngwa batara na kemịkalụ ọjọọ ma ọ bụ ogige nwere ike imebi ngwaahịa ahụ. Nkwekọrịta siri ike yana nkenke dị elu: ọgwụgwọ dị n'elu dị ka ichicha ma ọ bụ enyemaka nchacha na-enweta nkwụsi ike n'akụkụ ma hụkwa na izi ezi ka ukwuu n'akụkụ arụpụtara. Nke a dị mkpa maka ngwa chọrọ oke nkenke yana nnabata siri ike.

Adhesion emelitere yana nkekọ: Nkwadebe dị n'elu nwere ike ịmepụta ebe elu kwesịrị ekwesị maka nrapado, agba ma ọ bụ ụzọ njikọ ndị ọzọ. Nke a na-enye ohere maka njikọ dị ike na nke ọma karịa n'etiti ihe dị iche iche, na-eme ka iguzosi ike n'ezi ihe ngwaahịa. N'ozuzu, usoro ọgwụgwọ elu na-arụ ọrụ dị oke mkpa n'ịkwalite njirimara, ogologo ndụ na anya nkeakụrụngwa igwe, na-eme ka ha dịkwuo mma maka ngwa ha chọrọ ma na-emeziwanye àgwà ha niile.

Usoro ọgwụgwọ elu nke a na-ejikarị eme ihe bụ:

Vacuum electroplating, electroplating process, anodizing, electrolytic polishing, pad printing process, galvanizing process, powder cover, water transfer printing, screen printing, electrophoresis, etc.

01. Ihe mkpuchi oghere

—— Vacuum Metalizing ——

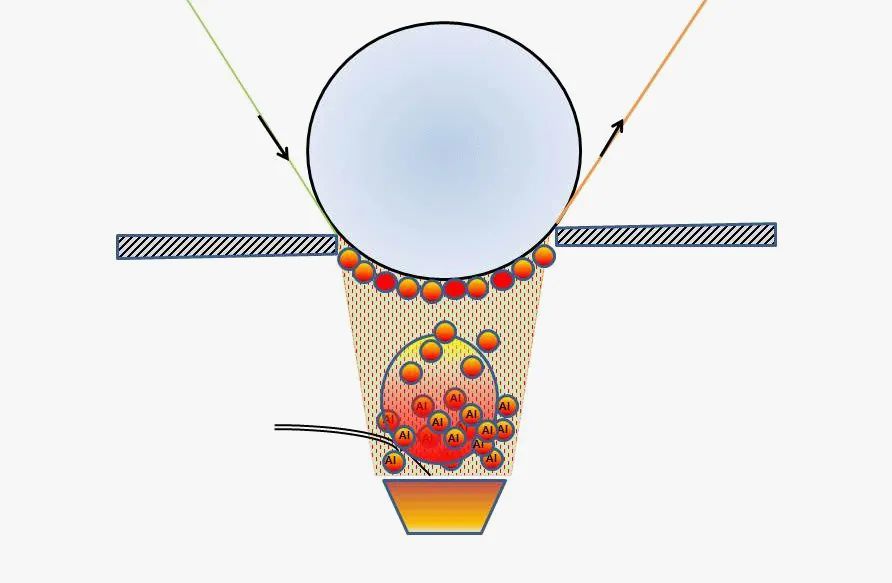

Enwere ike ịkọwa ịkwanye oghere dị ka usoro ntinye nke anụ ahụ. N'ezie, argon gas na-agbanye n'ime ọnọdụ nke agụụ, atom gas kụrụ ihe a chọrọ, na ihe a na-ezubere iche na-ekewa n'ime ụmụ irighiri ihe, nke na-etinye uche na ya site na ihe ndị na-eduzi ihe na-eme ka oyi akwa metal dị larịị na-eṅomi. .

Ngwa ndị ọdabara:

1. Enwere ike kpuchie ihe dị iche iche, gụnyere ọla siri ike na plastik dị nro, ceramics, ihe ngwakọta na iko. Ụzọ a na-ejikarị eme ihe nke electroplating bụ aluminum, nke na-esote ọla kọpa na ọlaọcha.

2. Ihe ndị e kere eke adịghị mma maka ịkwanye vepo n'ihi na mmiri dị n'ime ihe ndị sitere n'okike nwere ike gbanwee gburugburu oghere.

Ọnụ nke usoro a bụ ọnụ ahịa vapor plating ihe ahụ ka a ga-ebutu ya, buru ya wee laghachi na ịgba, nke pụtara na ụgwọ ọrụ dị oke ọnụ, Otú ọ dị, ọ dabere na nha na mgbagwoju anya nke workpiece.

Mmetụta gburugburu ebe obibi: Vacuum electroplating na-akpata ntakịrị mmetụta gburugburu ebe obibi, nke yiri mmetụta nke usoro na gburugburu ebe obibi.

02. Electropolishing

—— Electropolishing ——

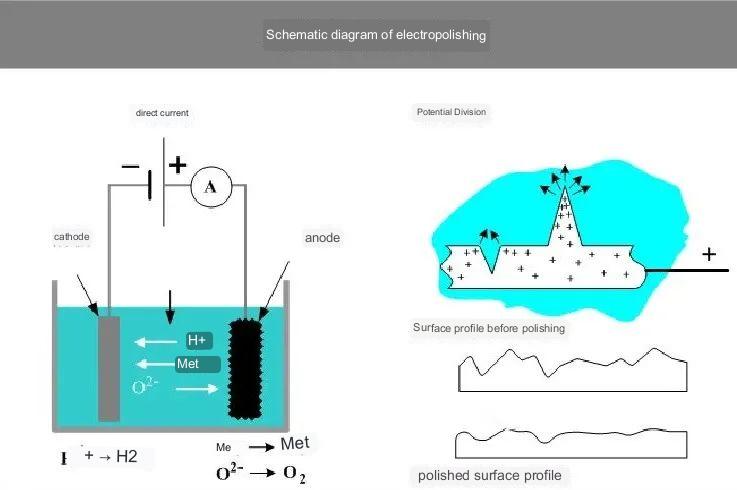

Electropolishing na-ezo aka na usoro eletrọnịkị nke atom ndị dị na yacnc ntụgharị akụkụnke a na-emikpu n'ime electrolyte na-agbanwe ghọọ ions wee wepụ ya n'elu site na ntinye nke ọkụ eletrik, nke na-eme ka ikpochapụ ihe ndị dị mma ma na-eme ka ìhè dị elu.

Ngwa ndị ọdabara:

1. Ọtụtụ n'ime ọla bụ electrolytically polished gụnyere polishing nke elu nke igwe anaghị agba nchara na-na-na-emekarị tinye n'ọrụ (karịsịa na austenitic igwe anaghị agba nchara).

2. Ihe dị iche iche enweghị ike ịmegharị ọkụ n'otu oge ma ọ bụ ọbụna n'ime otu ihe mgbaze maka electrolysis.

Ọnụ nke usoro a: Usoro polishing dum electrolytic fọrọ nke nta ka ọ bụrụ akpaaka kpamkpam, nke pụtara na ọnụ ahịa ọrụ dị oke ala. Mmetụta na gburugburu ebe obibi: Electrolytic polishing na-eji kemịkalụ mmetụta dị ala. Usoro a dum chọrọ naanị ntakịrị mmiri, ọ dịkwa mfe iji. Ọzọkwa, ọ nwere ike ịkwalite njirimara nke igwe anaghị agba nchara yana igbu oge nchara nke igwe anaghị agba nchara.

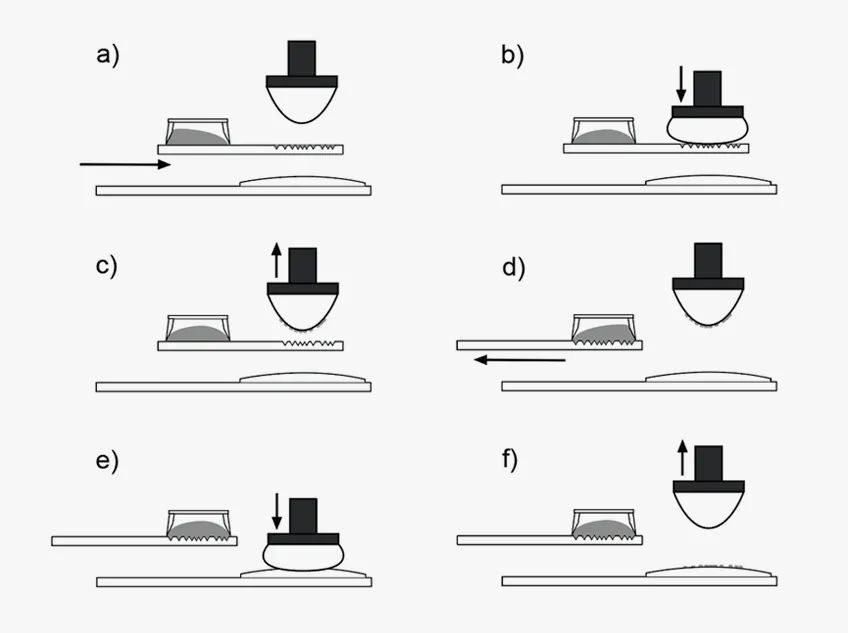

03. Pad usoro obibi akwụkwọ

——Pad Printing——

Ikike ibipụta onyonyo, ederede na eserese n'elu ihe ndị a na-emebeghị ka ọ bụrụ akụkụ dị mkpa nke mbipụta pụrụ iche.

Ngwa ndị ọdabara:

Mpempe akwụkwọ mpempe akwụkwọ bụ nhọrọ dị mma n'ihe fọrọ nke nta ka ọ bụrụ ihe ọ bụla, ma e wezụga ihe ndị na-esiwanye ike dị ka paịlị silicone dị ka PTFE.

Usoro na-eri ọnụ ala dị ala na ọnụ ahịa ọrụ dị ala.

Mmetụta gburugburu ebe obibi: Ebe usoro a na-ejedebe na ink na-agbaze (nke ejiri kemịkal na-emerụ ahụ metọọ) ma nwee mmetụta dị ukwuu na gburugburu ebe obibi.

04. Usoro galvanizing

—— Galvanizing ——

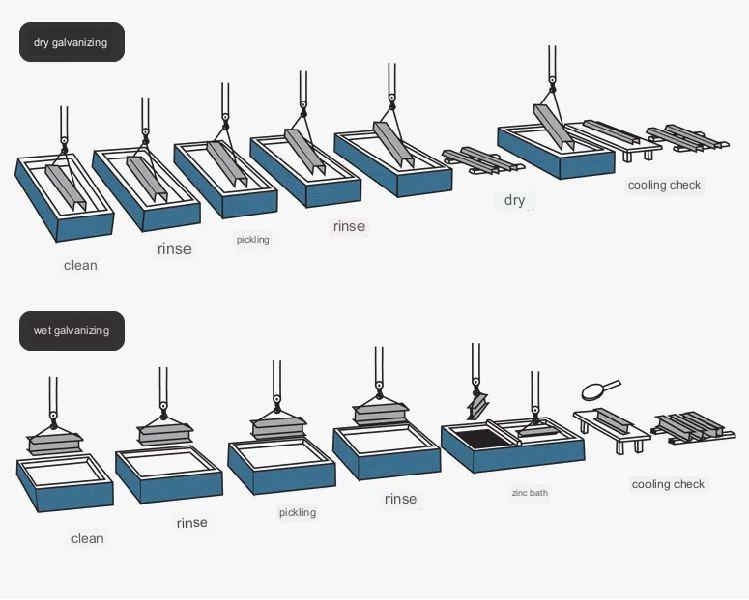

Teknụzụ maka ọgwụgwọ elu nke na-ekpuchi akwa zinc n'elu alloys ejiri ígwè mee maka ịchọ mma na uru mgbochi nchara. Ihe mkpuchi zinc dị n'elu na-arụ ọrụ dị ka ihe nchebe electrochemical nke na-egbochi mmebi ígwè. Ụzọ abụọ a na-ejikarị eme ihe bụ ikpo ọkụ na-ekpo ọkụ na Galvanized.

Ngwa ndị ọdabara:

N'ihi na galvanizing na-adabere na nkedo metallurgical usoro a dabara adaba maka ọgwụgwọ nke elu na ígwè na ígwè.

Ọnụ nke usoro: Ọ dịghị ebu na-eri, obere okirikiri ma ọ bụ ọkara ọrụ na-eri, ebe ọ bụ na àgwà nke elu na workpiece na-n'ụzọ dị ukwuu kpebisiri ike site elu ọgwụgwọ rụrụ site n'aka tupu galvanizing.

Mmetụta gburugburu ebe obibi: Dị ka usoro nke galvanizing nwere ike ime ka ndụ nke akụkụ ígwè dịkwuo n'etiti 40 na 100 afọ ma na-egbochikwa corrosion na nchara nke nwere ike ime na ya, usoro ahụ nwere ike inwe mmetụta na nchebe nke gburugburu. Ọzọkwa, workpiece nke e galvanized nwere ike laghachi azụ na zinc tank ozugbo oge eji ya agwụ na iji zinc na-aga n'ihu n'ụdị mmiri mmiri anaghị ebute ihe mkpofu anụ ahụ ma ọ bụ kemịkal.

05. Electroplating usoro

—— Electrolating ——

The usoro nke attaching a mkpa oyi akwa dara dara film n'elu nke components site electrolysis, iji kwụsị metal ọxịdashọn, welie eyi iguzogide conductivity nke ìhè echiche corrosion iguzogide, na melite ọdịdị. Enwere ike ịmegharị akwa oyi akwa nke ọtụtụ mkpụrụ ego. .

Ngwa ndị ọdabara:

1. Ọtụtụ ọla bụ electroplated. Otú ọ dị, ọla dị iche iche na-abịa na ọkwa dị iche iche nke ịdị ọcha na ịrụ ọrụ nke ọma. Ihe kacha ewu ewu n'ime ndị a bụ: tin na chromium, ọlaọcha, nickel, na rhodium.

2. Ihe kachasị ewu ewu na-eduzi electroplating bụ ABS. ABS.

3. E kwesịghị iji metal nickel mee ihe na-emekọ ihe na akpụkpọ ahụ n'ihi na ọ na-agbakasị ahụ ma na-emerụ ahụ.

Ọnụ nke usoro: Ọ dịghị akwụ ụgwọ ebu, Otú ọ dị fixtures a chọrọ iji chekwa akụkụ oge na-akwụ ụgwọ na-adabere na okpomọkụ na ụdị nke metal ma ọ bụ ọrụ na-eri (ọkara-elu) na-adabere na kpọmkwem ụdị plating components, dị ka ọla na. ọlaọcha, nke chọrọ ọkwa dị elu nke ọkachamara. Ndị ọrụ nwere nkà na-achịkwa ya n'ihi nnukwu ihe a na-achọsi ike na ọdịdị na ogologo ndụ.

Mmetụta gburugburu ebe obibi nke electroplating: A na-arụ ọrụ dị ukwuu nke kemịkal na-egbu egbu na usoro electroplating nke mere ntụgharị ọkachamara na mmịpụta ji dị mkpa iji belata mmetụta gburugburu ebe obibi.

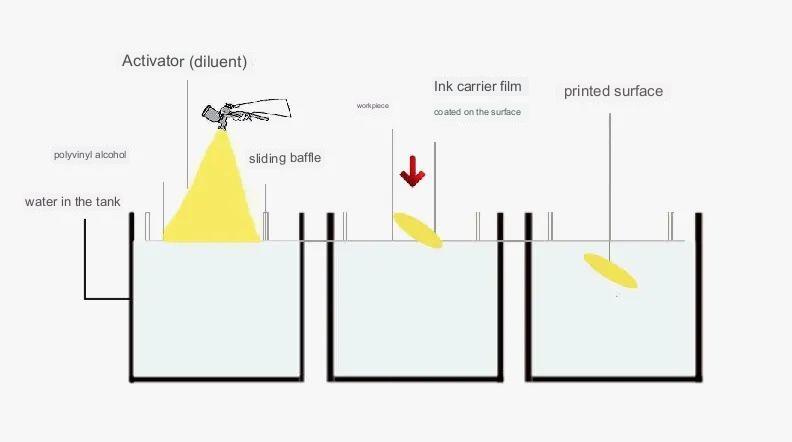

06. Mbipụta mbufe mmiri

—— Mbipụta Mbufe mmiri ——

Ọ bụ usoro iji bipụta ụkpụrụ agba n'elu akwụkwọ mbufe elu nke ngwaahịa nwere akụkụ atọ site na iji mmiri nrụgide. Dị ka ihe ndị mmadụ na-achọ maka nkwakọ ngwaahịa na ịchọ mma nke elu, ojiji a na-ebipụta na-achọ na-abawanye ụba.

Ngwa ndị ọdabara:

Ụdị ihe niile siri ike na-adabara maka mbipụta na-ebufe mmiri na ihe ndị kwesịrị ekwesị maka ịgbasa ga-adị mma maka ibipụta na mmiri. Ihe kachasị ewu ewu bụ akụkụ ndị a na-akpụ akpụ akpụ nakwa dị ka ígwè.

Ọnụ nke usoro a: Enweghị ụgwọ ọ bụla metụtara ebu, agbanyeghị, a ga-ebufe ọtụtụ ngwaahịa na mmiri n'otu oge site na iji ihe ndozi. Ọnụ ego a na-eri abụghị karịa oge oge kwa okirikiri.

Mmetụta gburugburu ebe obibi: N'iji ya tụnyere ịgbasa na ngwaahịa na-ebi akwụkwọ mbufe mmiri na-emetụta kpamkpam agba obibi nke na-ebelata ohere nke ntapu na mkpofu.

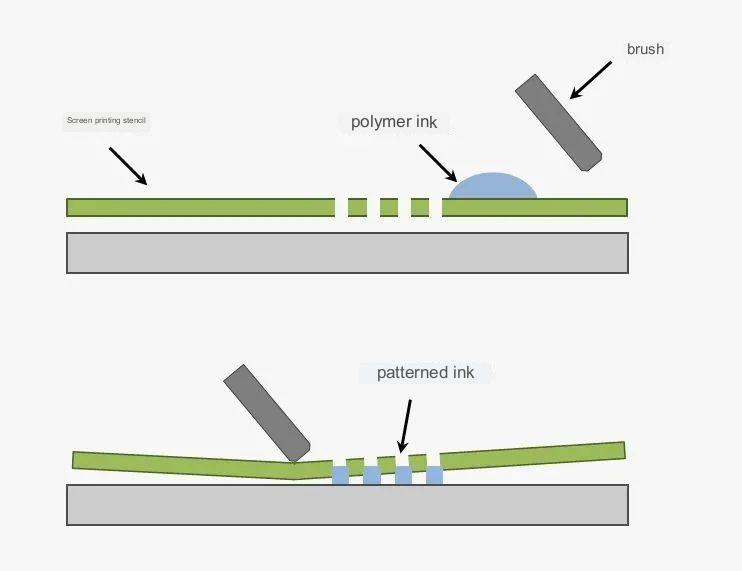

07. Mbipụta ihuenyo

—— Mbipụta ihuenyo ——

Site na extrusion nke scraper, a na-ebufe ink n'elu site na ntupu ya wee mepụta otu ihe oyiyi ahụ nke ebipụtara na mbụ. Ndị na-ebi akwụkwọ ihuenyo dị mfe iji enyi na enyi, ma dị mfe ibipụta na ịme efere, yana ọnụ ala dị ala yana ezigbo mgbanwe.

Ihe ndị a na-ebikarị na-agụnye akwụkwọ mmado eserese agba agba, kaadị azụmahịa, akwụkwọ mmado e ji ekpuchi ihe, akara ngwa ahịa, yana akwa ejiri esiji na nke ebipụtara.

Ngwa ndị ọdabara:

Ihe fọrọ nke nta ka ọ bụrụ ihe ọ bụla nwere ike ibipụta ihuenyo, gụnyere ígwè, plastik, ceramik akwụkwọ, iko na ihe ndị ọzọ.

Ọnụ ego nke usoro ihe eji eme ihe dị ntakịrị, ma ọ ka na-adabere na agba agba, ebe ọ bụ na agba ọ bụla ga-emepụta n'onwe ya. Ọnụ ego a na-akwụ maka ịrụ ọrụ dị oke oke, ọkachasị n'ihe gbasara mbipụta ọtụtụ agba.

Mmetụta gburugburu ebe obibi: Mbipụta ihuenyo na ink na-acha ọkụ adịghị enwe mmetụta na-adịghị mma na gburugburu ebe obibi, n'agbanyeghị inks ndị mejupụtara PVC na formaldehyde bụ ogige kemịkalụ na-egbu egbu, ma na-achọgharị ma tụfuo ya n'oge kwesịrị ekwesị iji kwụsị mmetọ mmiri. .

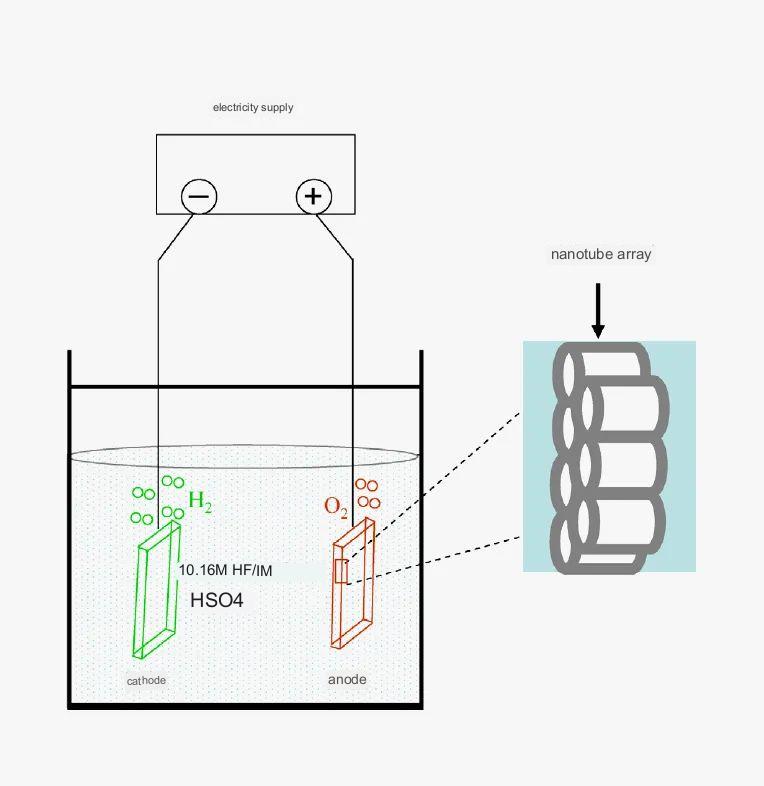

08. Anodizing

——Anodic Oxidation ——

Usoro oxidation nke anodic maka aluminom na-adabere na echiche electrochemical iji mepụta ihe nkiri dị nro nke mejupụtara ihe nkiri Al2O3 (aluminom oxide) na aluminom yana aluminom alloy. Oxide nwere ihe dị iche iche dị ka nchebe pụọ na corrosion, ịchọ mma, mkpuchi na iguzogide iyi.

Ngwa ndị ọdabara:

Aluminium, aluminom alloy na ngwaahịa aluminom ndị ọzọ

Ọnụ ego usoro: Na usoro mmepụta ihe oriri nke ọkụ eletrik na mmiri dị oke mkpa, karịsịa n'oge usoro oxidation. Oriri ike nke igwe n'onwe ya chọrọ ka ejiri mmiri pọpụ mee ka ọ dị jụụ mgbe niile. Oriri ike kwa tonne na-adịkarị ihe dịka 1000 degrees.

Mmetụta gburugburu: Anodizing abụghị ihe pụrụ iche n'ihe gbasara arụmọrụ ike. Otú ọ dị, n'ime usoro mmepụta electrolysis nke aluminom, mmeghachi omume anode na-emepụta gas nke nwere mmetụta ọjọọ na-emerụ ahụ na oyi akwa ozone nke ikuku.

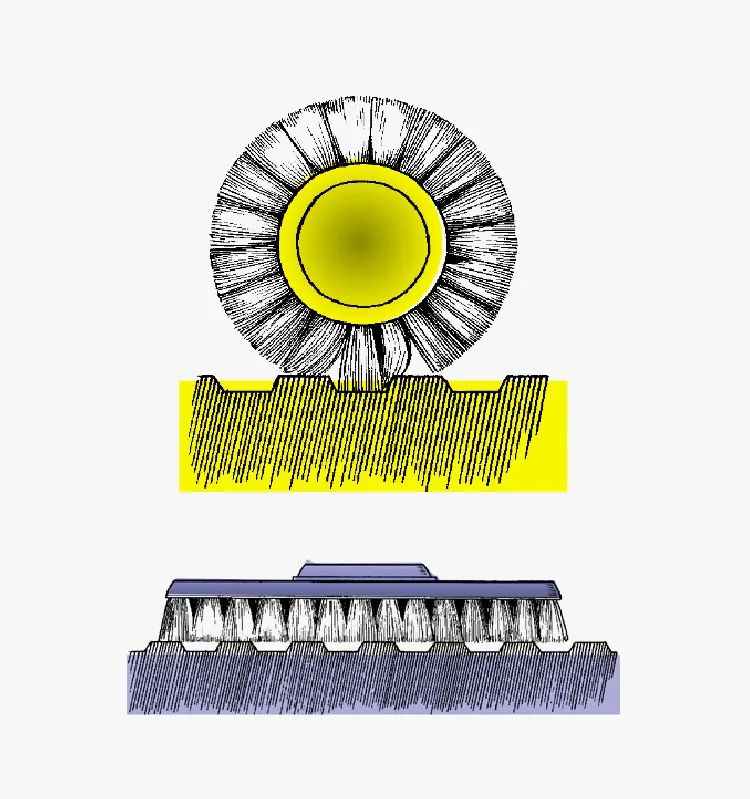

09. Ihe osise waya igwe

—— Metal wired ——

Ọ bụ usoro ọgwụgwọ n'elu nke na-emepụta ahịrị n'elu elu ọrụ site na-egweri ihe ahụ iji nweta mmetụta mara mma. Dị ka usoro dị iche iche si dị mgbe ihe atụ USB gasịrị, enwere ike kewaa ya n'ime: eserese USB kwụ ọtọ, eserese eriri na-adịghị mma, corrugated, yana swirling.

Ihe ndị dị mkpa: Ihe fọrọ nke nta ka ọ bụrụ ihe igwe niile nwere ike iji usoro ịse eriri igwe.

Ọnụ ego nke usoro: Usoro usoro ahụ dị mfe, ngwaọrụ ndị ahụ kwụ ọtọ, oriri ihe eji eme ihe dị ntakịrị, ọnụ ahịa na-ebelata nke ọma, yana uru ego dị elu.

Mmetụta gburugburu ebe obibi: ngwaahịa metal dị ọcha, enweghị agba ma ọ bụ ụdị kemịkal ọ bụla dị n'elu, ogo 600 dị elu anaghị agbaze, anaghị emepụta gas na-egbu egbu, na-ezute nchekwa ọkụ yana ihe nchebe gburugburu ebe obibi chọrọ.

10. Na-ebu mma

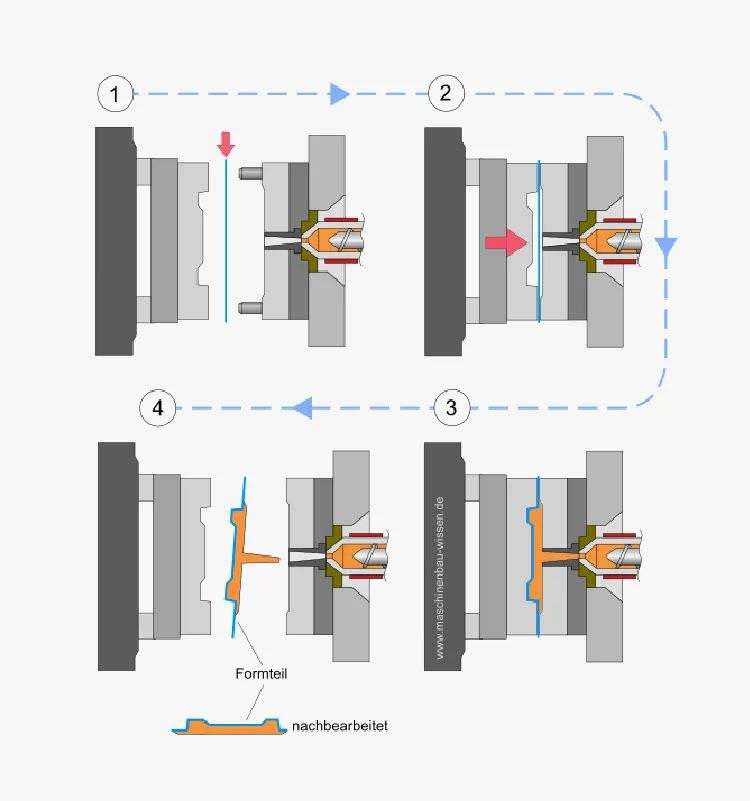

—— In-Mold Decoration-IMD ——

Ọ bụ usoro ịkpụzi nke na-etinye diaphragm nke e biri ebi nke ọma n'ime nchara nchara na mildew, na-etinye resin maka ịkpụzi ya ozugbo n'ime ihe eji akpụ akpụ n'ime igwe ahụ yana mildew yana jikọtara diaphragm ahụ, ma na-eme diaphragm nke ebipụtara ụkpụrụ yana resin webatara yana gbasie ike na ngwaahịa emechara.

Ngwaahịa kwesịrị ekwesị: ebe elu plastik

Nnụcha na-eri: dị nnọọ chọrọ imeghe a collection of ebu na mildews, nke nwere ike ibelata mmefu na kwa awa mmadụ, elu akpaaka mmepụta, mfe mmepụta usoro, otu oge injection ịkpụzi obibia, yana nweta ịkpụzi na ịchọ mma na otu oge.

Mmetụta gburugburu ebe obibi: Nkà na ụzụ ọgbara ọhụrụ a bụ enyi na gburugburu ebe obibi yana mmekọrịta gburugburu ebe obibi, na-egbochi mmetọ nke eserese omenala na-ebute yana electroplating.

Uru nke Anebon bụ obere ụgwọ, otu ndị na-enweta ego siri ike, QC pụrụ iche, ụlọ ọrụ siri ike, ọrụ dị mma maka cnc machining aluminom na-arụ ọrụ na cnc machining na-atụgharị akụkụ na-arụ ọrụ. Anebon setịpụrụ ihe mgbaru ọsọ na usoro ihe ọhụrụ na-aga n'ihu, njikwa njikwa, mmepụta ihe ọhụrụ na mmepụta ihe nke ngalaba, na-enye egwuregwu zuru oke maka uru niile, na-emeziwanyewanye mgbe niile iji kwado ọmarịcha.

Anebon New Product China Lock-Hole Processing Machine na Aluminom Window Lock Hole Processing Machine, Anebon nwere zuru ezu ihe mmepụta ahịrị, agbakọta ahịrị , àgwà akara usoro, na ndị kasị mkpa, ugbu a Anebon nwere ọtụtụ patents technology na ahụmahụ teknuzu&production otu, ahụmahụ ahịa ọrụ. otu. Site na uru mmadụ niile, anyị na-aga imepụta "ụdị nylon monofilaments a ma ama na mba ụwa", ma gbasaa ngwa ahịa anyị n'akụkụ ọ bụla nke ụwa. Anyị na-aga n'ihu ma na-agbalị ike anyị niile iji jeere ndị ahịa nke Anebon ozi.

Oge nzipu: Jul-29-2023