HV, HB, na HRC bụ ntụle nke ike siri ike ejiri na nyocha ihe. Ka anyị gbarie ha:

1)HV ike ike (Vickers ike ike): Isi ike HV bụ ihe nrịbama nke ihe na-eguzogide ntinye. A na-ekpebi ya site n'itinye ibu ama ama n'elu ihe ahụ site na iji ihe ntinye diamond ma na-atụle nha nke ntinye aka na-esi na ya pụta. A na-egosipụta ike HV na nkeji nke Vickers hardness (HV) ma na-ejikarị eme ihe maka ihe ndị dị mkpa, mkpuchi na obere akụkụ.

2)HB ike siri ike (Brinell ike ike): Isi ike HB bụ ihe ọzọ e ji egosi nguzogide ihe onwunwe na ntinye. Ọ na-agụnye itinye ibu amaara ama na ihe ahụ site na iji mgbanaka bọọlụ nchara siri ike ma tụọ dayameta nke ntinye n'ime ya. A na-egosipụta ike siri ike HB na nkeji nke Brinell hardness (HB) ma na-ejikarị eme ihe maka ihe ndị buru ibu na nke buru ibu, gụnyere ọla na alloys.

3) ike ike HRC (Rockwell ike ike): Isi ike HRC bụ ihe nledo nke ihe na-eguzogide ntinye ma ọ bụ ntinye. Ọ na-eji akpịrịkpa dị iche iche (A, B, C, wdg) dabere na usoro nnwale a kapịrị ọnụ na ụdị indenter ejiri (cone diamond ma ọ bụ bọọlụ siri ike). A na-ejikarị ọnụ ọgụgụ HRC eme ihe maka ịlele ike nke ihe ọla. A na-anọchi anya uru ike siri ike dị ka ọnụọgụ na nha HRC, dị ka HRC 50.

Tebụlụ ntụnyere ike HV-HB-HRC a na-ejikarị:

| Tebụlụ ntụnyere ike ike igwe a na-ahụkarị (ntụgharị ike dị ka) | ||||

| Nkewa isi ike | Ike ọdụdọ N/mm2 | |||

| Rockwell | Vickers | Brinell | ||

| HRC | HRA | HV | HB | |

| 17 | - | 211 | 211 | 710 |

| 17.5 | - | 214 | 214 | 715 |

| 18 | - | 216 | 216 | 725 |

| 18.5 | - | 218 | 218 | 730 |

| 19 | - | 221 | 220 | 735 |

| 19.5 | - | 223 | 222 | 745 |

| 20 | - | 226 | 225 | 750 |

| 20.5 | - | 229 | 227 | 760 |

| 21 | - | 231 | 229 | 765 |

| 21.5 | - | 234 | 232 | 775 |

| 22 | - | 237 | 234 | 785 |

| 22.5 | - | 240 | 237 | 790 |

| 23 | - | 243 | 240 | 800 |

| 23.5 | - | 246 | 242 | 810 |

| 24 | - | 249 | 245 | 820 |

| 24.5 | - | 252 | 248 | 830 |

| 25 | - | 255 | 251 | 835 |

| 25.5 | - | 258 | 254 | 850 |

| 26 | - | 261 | 257 | 860 |

| 26.5 | - | 264 | 260 | 870 |

| 27 | - | 268 | 263 | 880 |

| 27.5 | - | 271 | 266 | 890 |

| 28 | - | 274 | 269 | 900 |

| 28.5 | - | 278 | 273 | 910 |

| 29 | - | 281 | 276 | 920 |

| 29.5 | - | 285 | 280 | 935 |

| 30 | - | 289 | 283 | 950 |

| 30.5 | - | 292 | 287 | 960 |

| 31 | - | 296 | 291 | 970 |

| 31.5 | - | 300 | 294 | 980 |

| 32 | - | 304 | 298 | 995 |

| 32.5 | - | 308 | 302 | 1010 |

| 33 | - | 312 | 306 | 1020 |

| 33.5 | - | 316 | 310 | 1035 |

| 34 | - | 320 | 314 | 1050 |

| 34.5 | - | 324 | 318 | 1065 |

| 35 | - | 329 | 323 | 1080 |

| 35.5 | - | 333 | 327 | 1095 |

| 36 | - | 338 | 332 | 1110 |

| 36.5 | - | 342 | 336 | 1125 |

| 37 | - | 347 | 341 | 1140 |

| 37.5 | - | 352 | 345 | 1160 |

| 38 | - | 357 | 350 | 1175 |

| 38.5 | - | 362 | 355 | 1190 |

| 39 | 70 | 367 | 360 | 1210 |

| 39.5 | 70.3 | 372 | 365 | 1225 |

| 40 | 70.8 | 382 | 375 | 1260 |

| 40.5 | 70.5 | 377 | 370 | 1245 |

| 41 | 71.1 | 388 | 380 | 1280 |

| 41.5 | 71.3 | 393 | 385 | 1300 |

| 42 | 71.6 | 399 | 391 | 1320 |

| 42.5 | 71.8 | 405 | 396 | 1340 |

| 43 | 72.1 | 411 | 401 | 1360 |

| 43.5 | 72.4 | 417 | 407 | 1385 |

| 44 | 72.6 | 423 | 413 | 1405 |

| 44.5 | 72.9 | 429 | 418 | 1430 |

| 45 | 73.2 | 436 | 424 | 1450 |

| 45.5 | 73.4 | 443 | 430 | 1475 |

| 46 | 73.7 | 449 | 436 | 1500 |

| 46.5 | 73.9 | 456 | 442 | 1525 |

| 47 | 74.2 | 463 | 449 | 1550 |

| 47.5 | 74.5 | 470 | 455 | 1575 |

| 48 | 74.7 | 478 | 461 | 1605 |

| 48.5 | 75 | 485 | 468 | 1630 |

| 49 | 75.3 | 493 | 474 | 1660 |

| 49.5 | 75.5 | 501 | 481 | 1690 |

| 50 | 75.8 | 509 | 488 | 1720 |

| 50.5 | 76.1 | 517 | 494 | 1750 |

| 51 | 76.3 | 525 | 501 | 1780 |

| 51.5 | 76.6 | 534 | - | 1815 |

| 52 | 76.9 | 543 | - | 1850 |

| 52.5 | 77.1 | 551 | - | 1885 |

| 53 | 77.4 | 561 | - | 1920 |

| 53.5 | 77.7 | 570 | - | 1955 |

| 54 | 77.9 | 579 | - | 1995 |

| 54.5 | 78.2 | 589 | - | 2035 |

| 55 | 78.5 | 599 | - | 2075 |

| 55.5 | 78.7 | 609 | - | 2115 |

| 56 | 79 | 620 | - | 2160 |

| 56.5 | 79.3 | 631 | - | 2205 |

| 57 | 79.5 | 642 | - | 2250 |

| 57.5 | 79.8 | 653 | - | 2295 |

| 58 | 80.1 | 664 | - | 2345 |

| 58.5 | 80.3 | 676 | - | 2395 |

| 59 | 80.6 | 688 | - | 2450 |

| 59.5 | 80.9 | 700 | - | 2500 |

| 60 | 81.2 | 713 | - | 2555 |

| 60.5 | 81.4 | 726 | - | - |

| 61 | 81.7 | 739 | - | - |

| 61.5 | 82 | 752 | - | - |

| 62 | 82.2 | 766 | - | - |

| 62.5 | 82.5 | 780 | - | - |

| 63 | 82.8 | 795 | - | - |

| 63.5 | 83.1 | 810 | - | - |

| 64 | 83.3 | 825 | - | - |

| 64.5 | 83.6 | 840 | - | - |

| 65 | 83.9 | 856 | - | - |

| 65.5 | 84.1 | 872 | - | - |

| 66 | 84.4 | 889 | - | - |

| 66.5 | 84.7 | 906 | - | - |

| 67 | 85 | 923 | - | - |

| 67.5 | 85.2 | 941 | - | - |

| 68 | 85.5 | 959 | - | - |

| 68.5 | 85.8 | 978 | - | - |

| 69 | 86.1 | 997 | - | - |

| 69.5 | 86.3 | 1017 | - | - |

| 70 | 86.6 | 1037 | - | - |

Ndụmọdụ ntụgharị maka mgbanwe HRC/HB

Isi ike dị elu karịa 20HRC, 1HRC≈10HB,

Isi ike dị ala karịa 20HRC, 1HRC≈11.5HB.

Nkwupụta: Maka ịkpụ nhazi, enwere ike ịtụgharị ya n'otu n'otu 1HRC≈10HB (ike nke ihe eji arụ ọrụ nwere oke mgbanwe)

Isi ike nke ihe igwe

Isi ike na-ezo aka n'ikike nke ihe nwere ike iguzogide nrụrụ mpaghara, ọkachasị nrụrụ plastik, ntinye ma ọ bụ ncha. Ọ bụ ndeksi iji tụọ ịdị nro na ike nke ihe ahụ.

Dị ka ụzọ ule dị iche iche si dị, a na-ekewa ike ike n'ime ụdị atọ.

①Ikpochapu ike. A na-ejikarị ya atụnyere ịdị nro na ike nke mineral dị iche iche. Usoro bụ ịhọrọ mkpanaka nke nwere otu njedebe siri ike na njedebe nke ọzọ dị nro, nyefee ihe a ga-anwale n'akụkụ mkpanaka ahụ, ma chọpụta ike nke ihe a ga-anwale dịka ọnọdụ nke ncha. N'ikwu okwu nke ọma, ihe ndị siri ike na-eme ogologo ncha na ihe dị nro na-eme mkpụmkpụ.

②Isi ike nbanye. A na-ejikarị eme ihe maka ígwè, usoro a bụ iji ụfọdụ ibu iji pịa kpọmkwem indenenter n'ime ihe a ga-anwale, ma tụnyere nro na ike nke ihe a ga-anwale site na nha nke nrụrụ plastik mpaghara n'elu. ihe. N'ihi ọdịiche nke indenenter, ibu na ogologo oge ibu, enwere ọtụtụ ụdị ike ike indentation, ọkachasị gụnyere Brinell hardness, Rockwell hardness, Vickers hardness na microhardness.

③Isi ike nlọghachi. A na-ejikarị ya eme ihe maka ígwè, usoro a bụ ime ka obere hama pụrụ iche daa n'enweghị ihe ọ bụla site n'ịdị elu ga-emetụta ihe nlele nke ihe a ga-anwale, ma jiri ọnụọgụ ike echekwara (ma wepụta ya) na nlele n'oge oge. mmetụta (site na nlọghachi nke obere hama) tụọ elu elu) iji chọpụta ike nke ihe.

Ihe siri ike Brinell na-ahụkarị, hardness Rockwell na ike siri ike nke ihe igwe bụ nke ike indentation. Uru siri ike na-egosi ikike nke elu ihe ahụ iji gbochie nrụrụ plastik nke ihe ọzọ na-agbanye n'ime ya; C) iji tụọ ike siri ike, na uru siri ike na-anọchite anya oke ọrụ nrụrụ nke ígwè.

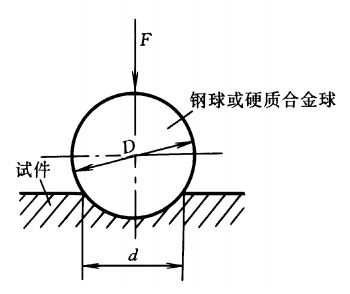

Brinell Hardness

Jiri bọọlụ nchara agbanyụọ ma ọ bụ bọọlụ alloy siri ike nke nwere dayameta D dị ka onye ntinye, pịa ya n'elu mpempe ule ya na ike nnwale kwekọrọ F, na mgbe oge ejidere akọwapụtara, wepụ ike nnwale ahụ iji nweta indentation na. dayameta nke d. Kewaa ike nnwale ahụ site n'akụkụ elu nke indentation, uru ga-esi na ya pụta bụ uru Brinell hardness, na HBS ma ọ bụ HBW nọchiri anya akara ahụ.

Ọdịiche dị n'etiti HBS na HBW bụ ihe dị iche na indenenter. HBS pụtara na indenenter bụ bọọlụ nchara siri ike, nke a na-eji tụọ ihe nwere uru siri ike Brinell dị n'okpuru 450, dị ka igwe dị nro, igwe nkedo isi awọ na ọla ndị na-abụghị igwe. HBW pụtara na indenter bụ carbide cemented, nke a na-eji tụọ ihe nwere uru siri ike brinell n'okpuru 650.

Maka otu ngọngọ ule ahụ, mgbe ọnọdụ ule ndị ọzọ bụ otu kpọmkwem, nsonaazụ nke ule abụọ ahụ dị iche, na uru HBW na-adịkarị karịa uru HBS, ọ dịghịkwa iwu ọnụọgụ ọnụọgụ ga-agbaso.

Mgbe afọ 2003 gachara, obodo m anabatala ụkpụrụ mba ụwa, kagbuo ihe nrịbama igwe, yana isi bọọlụ carbide niile ejirila ya. Ya mere, a kwụsịrị HBS, a na-ejikwa HBW nọchite anya akara ike Brinell. N'ọtụtụ ọnọdụ, a na-egosipụta ike Brinell naanị na HB, na-ezo aka na HBW. Otú ọ dị, a ka na-ahụ HBS site n'oge ruo n'oge na akwụkwọ edemede.

Usoro nrịba siri ike nke Brinell dabara adaba maka ígwè nkedo, alloys na-abụghị nke ígwè, nchara dị iche iche annealed na quenched na tempered, na adabaghị maka nlele sample ma ọ bụ.cnc ntụgharị akụkụnke siri ike, pere mpe, dị gịrịgịrị, ma ọ bụ nke na-adịghị ekwe ka nnukwu nbanye n'elu.

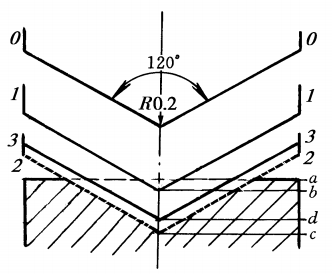

Rockwell Hardness

Jiri cone diamond nwere akụkụ cone nke 120° ma ọ bụ Ø1.588mm na Ø3.176mm bọọlụ nchara menyụọ dị ka ihe ntinye na ibu iji kwado ya. Ibu mbụ bụ 10kgf na ngụkọta ibu bụ 60, 100 ma ọ bụ 150kgf (ya bụ, ibu mbụ gbakwunyere ibu bụ isi). A na-egosipụta ike siri ike site na ọdịiche dị n'etiti ihe omimi nke ntinye mgbe a na-ewepụ isi ihe na ntinye aka mgbe a na-ejigide ibu isi na ntinye ntinye n'okpuru ibu mbụ mgbe a na-etinye ihe niile.

Nnwale hardness Rockwell na-eji ike ule atọ na indenters atọ. Enwere ngwakọta 9 n'ime ha, kwekọrọ na akpịrịkpa 9 nke hardness Rockwell. Ngwa nke ndị ọchịchị 9 ndị a na-ekpuchi ihe fọrọ nke nta ka ọ bụrụ ihe niile eji eji ígwè eme ihe. Enwere HRA atọ a na-ejikarị, HRB na HRC, n'ime nke HRC ka a na-ejikarị eme ihe.

Tebụlụ nkọwapụta ule hardness Rockwell nke a na-ejikarị:

| Isi ike | | | Isi ike | |

| | | | | Carbide, mmanụ aṅụ, |

| | | | | Annealed, nchara nkịtị, aluminum alloy |

| | | | | ígwè siri ike, agbanyụ na ọkụ, miri emi |

Oke nke ojiji nke HRC ọnụ ọgụgụ bụ 20 ~ 70HRC. Mgbe uru hardness bụ ihe na-erughị 20HRC, n'ihi na conicalaluminum cnc machining akụkụnke indenter na-enwe ike nke ukwuu, uche na-ebelata, na HRB ọnụ ọgụgụ kwesịrị iji kama; mgbe ike nke ihe nlele ahụ karịrị 67HRC, nrụgide dị n'ọnụ ọnụ nke onye na-eme ihe dị ukwuu, na diamond na-adị mfe imebi. A ga-eme ka ndụ onye na-eme ihe dị mkpụmkpụ dị mkpụmkpụ, yabụ, a ga-eji ọnụ ọgụgụ HRA mee ihe n'ozuzu ya.

Nnwale ike ike Rockwell dị mfe, ngwa ngwa na obere ntinye, ma nwee ike nwalee elu ngwaahịa emechara yana ihe arụ ọrụ siri ike ma dị gịrịgịrị. N'ihi obere indentation, n'ihi na ihe ndị na-erughị eru Ọdịdị na ike siri ike, ike ike uru na-agbanwe nke ukwuu, na izi ezi adịghị elu dị ka Brinell ike. A na-eji hardness Rockwell iji chọpụta ike nke igwe, ọla ndị na-abụghị nke igwe, alloys siri ike, wdg.

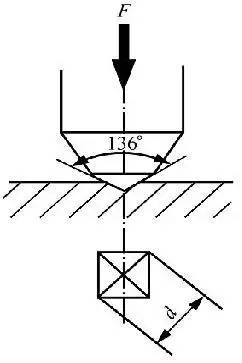

Vickers ike ike Vickers isi ike

Ụkpụrụ nke nha ike ike Vickers yiri nke Brinell hardness. Jiri pyramid square diamond nwere akụkụ agụnyere 136 Celsius ka ịpịnye n'elu ihe ahụ na ike nnwale a kapịrị ọnụ, wee wepụ ike nnwale ahụ ka ị nwesịrị oge a kapịrị ọnụ. A na-egosipụta ike siri ike site na nkezi nrụgide na mpaghara elu otu nke ntinye pyramid square. Uru, akara akara bụ HV.

Ogologo nha ike siri ike nke Vickers buru ibu, ọ nwekwara ike tụọ ihe siri ike sitere na 10 ruo 1000HV. Ntinye ya dị ntakịrị, a na-ejikarị ya atụta ihe ndị dị gịrịgịrị na elu ndị siri ike dị ka carburizing na nitriding.

Ike ike Leeb ike

Jiri ahụ mmetụta nwere ụfọdụ isi bọọlụ tungsten carbide iji metụta elu nke mpempe ule n'okpuru omume nke ụfọdụ ike, wee maliteghachi. N'ihi ike dị iche iche nke ihe, nkwụghachi ọsọ ọsọ mgbe mmetụta dị iche iche. A na-etinye magnet na-adịgide adịgide na ngwaọrụ mmetụta. Mgbe ahụ mmetụta ahụ na-agbago elu na ala, eriri igwe dị n'akụkụ ya ga-eme ka mgbama electromagnetic dabara na ọsọ, wee gbanwee ya ka ọ bụrụ uru siri ike Leeb site na sekit eletrọnịkị. Akara akara a ka HL.

The Leeb hardness tester adịghị mkpa a worktable, na ekweghị ekwe ihe mmetụta dị ka obere ka a pen, nke nwere ike na-arụ ọrụ ozugbo site n'aka, na ike na-adị mfe achọpụta ma ọ bụ a nnukwu, arọ workpiece ma ọ bụ a workpiece na mgbagwoju geometric akụkụ.

Uru ọzọ nke siri ike Leeb bụ na ọ nwere ntakịrị mmebi n'elu ngwaahịa ahụ, na mgbe ụfọdụ enwere ike iji ya mee ihe dị ka ule na-adịghị emebi emebi; ọ bụ ihe pụrụ iche na ule siri ike n'akụkụ niile, oghere dị warara na pụrụ icheakụkụ aluminom.

Anebon na-agbaso n'ụkpụrụ "Eziokwu, onye na-arụsi ọrụ ike, onye na-azụ ahịa, ihe ọhụrụ" iji nweta ngwọta ọhụrụ mgbe niile. Anebon na-ele anya, ihe ịga nke ọma dị ka ihe ịga nke ọma nke onwe ya. Ka Anebon wuo aka n'ọdịniihu na-aga nke ọma maka akụkụ brass machined na Complex titanium cnc part / stamping ngwa. Anebon ugbu a nwere ngwa ahịa zuru oke yana ọnụahịa ire ere bụ uru anyị. Nnọọ ịjụ ajụjụ maka ngwaahịa Anebon.

Trending Ngwaahịa China CNC Machiging Part na nkenke akụkụ, n'ezie kwesịrị ihe ọ bụla n'ime ihe ndị a ga-amasị gị, biko mee ka anyị mara. Anebon ga-enwe obi ụtọ ịnye gị nhota mgbe ị natachara nkọwapụta nke mmadụ. Anebon nwere ndị injinia R&D ọkachamara n'onwe anyị iji gboo ihe ọ bụla achọrọ. Anebon na-atụ anya ịnata ajụjụ gị n'oge adịghị anya ma nwee olile anya na ị ga-enwe ohere iso gị rụkọọ ọrụ n'ọdịnihu. Nnọọ ileba anya na nzukọ Anebon.

Oge nzipu: Mee-18-2023