Ib txoj xov txiav

Feem ntau, nws yog hais txog machining xov ntawm lub workpiece nrog ib tug sib sau los yog sib tsoo cov cuab yeej, feem ntau xws li tig, milling, tapping thiab threading sib tsoo, sib tsoo, cua daj cua dub txiav, thiab lwm yam. Thaum tig, milling, thiab sib tsoo cov xov, kis tau tus mob saw ntawm lub tshuab cuab yeej xyuas kom meej tias lub cuab tam tig, milling cutter, los yog sib tsoo log txav ib tug txhuas kom raug thiab tusyees raws axial kev taw qhia ntawm lub workpiece txhua. kev sib hloov. Thaum tapping lossis threading, lub cuab yeej (kais lossis tuag) tig txheeb ze rau qhov chaw ua haujlwm, thiab thawj cov xov groove coj lub cuab yeej (lossis workpiece) txav axially.

Ob txoj hlua tig

Carding cov cuab yeej siv tau los tig los yog xov xov ntawm lub tshuab dhos (saib xov ua cov cuab yeej). Tig xov nrog txoj kev tig lub cuab yeej yog ib txoj hauv kev rau ib daim thiab cov khoom me me ntawm cov xov workpiece vim nws cov qauv yooj yim; tig xov nrog xov combing cuab yeej muaj ntau lawm efficiency, tab sis nws cov qauv yog complex, yog li nws tsuas yog haum rau xa luv xov workpiece nrog zoo hniav nyob rau hauv nruab nrab thiab loj batch ntau lawm. Lub suab raug ntawm txoj hlua trapezoidal nrog lub tshuab dhos dav dav tuaj yeem ncav cuag 8-9 qib (jb2886-81, tib yam hauv qab no); cov khoom tsim tau los yog qhov tseeb tuaj yeem txhim kho tau zoo thaum siv cov xov xov ntawm lub tshuab dhos tshwj xeeb.

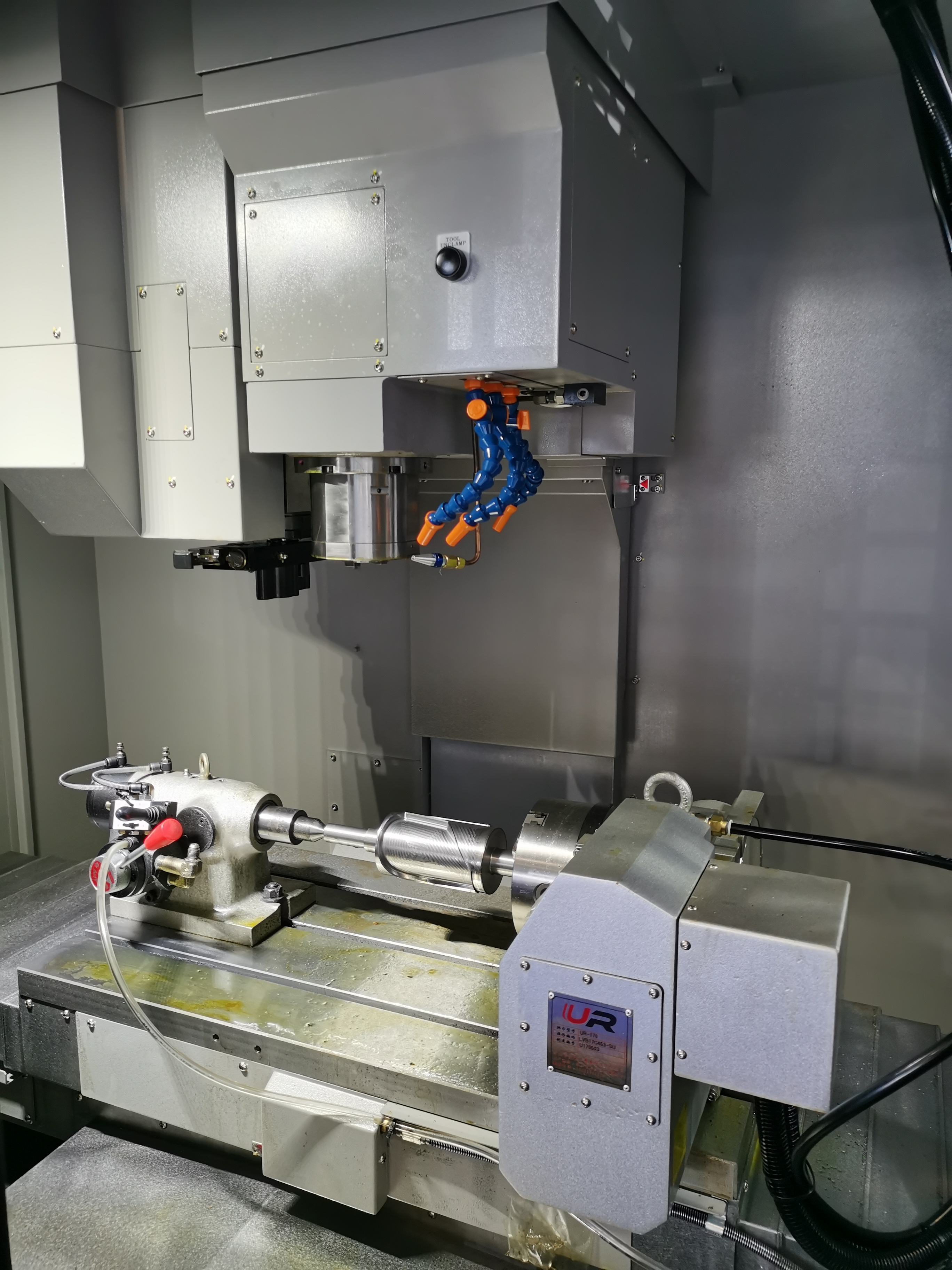

Peb xov milling

Lub disc milling cutter los yog zuag milling cutter yog siv rau milling ntawm lub xov milling tshuab. Lub disc milling cutter yog siv feem ntau rau milling trapezoid lwm threads ntawm cov ntsia hlau rods, worms, thiab lwm yam workpieces. Ib qho combo milling cutter zeb sab hauv thiab sab nraud cov xov thiab taper xov. Vim tias nws txoj haujlwm ua haujlwm ntev dua cov xov ntev yuav tsum tau ua tiav los ntawm ntau lub ntug milling cutter, lub workpiece tuaj yeem ua tiav los ntawm kev tig 1.25-1.5 revolutions, nrog cov khoom lag luam siab. Qhov tseeb ntawm cov xov milling tuaj yeem ncav cuag 8-9 qib, thiab qhov roughness yog r5-0.63 μ M. Txoj kev no yog tsim rau huab hwm coj ntau lawm ntawm cov xov xov workpieces lossis ntxhib machining ua ntej sib tsoo.

Plaubxov sib tsoo

Nws yog tsuas yog siv los ua cov txheej txheem precision ntawm lub hardened workpiece ntawm xov grinder. Raws li qhov sib txawv ntawm qhov sib txawv ntawm qhov sib tsoo log, nws tuaj yeem muab faib ua ob hom: ib kab sib tsoo lub log thiab ntau txoj kab sib tsoo. Lub suab raug ntawm ib kab sib tsoo log yog 5-6 qib, thiab qhov chaw roughness yog r1.25-0.08 μ m, yog li nws yooj yim los ua kom tiav cov kev sib tsoo. Txoj kev no yog tsim rau kev sib tsoo precision screws, xov gauges, worms, me me batch ntawm xov workpieces, thiab precision hobTwotwo hom kev sib tsoo meth muaj: longitudinal sib tsoo thiab txiav-hauv kev sib tsoo. Qhov dav ntawm kev sib tsoo lub log nrog txoj kev sib tsoo longitudinal yog tsawg dua qhov ntev ntawm cov xov rau hauv av, thiab cov xov tuaj yeem ua hauv av mus rau qhov kawg loj tom qab lub log sib tsoo txav mus ntev ib zaug lossis ob peb zaug. Qhov dav ntawm kev sib tsoo lub log ntawm txoj kev txiav-hauv kev sib tsoo yog qhov loj dua qhov ntev ntawm cov xov rau hauv av. Kev sib tsoo lub log txiav rau hauv qhov chaw ntawm lub workpiece radially, thiab lub workpiece tuaj yeem ua hauv av tom qab tig txog 1.25 revolutions. Cov khoom tsim tau ntau dua, tab sis qhov tseeb yog me ntsis qis dua, thiab kev hnav khaub ncaws ntawm kev sib tsoo log yog qhov nyuaj dua. Txoj kev txiav-hauv kev sib tsoo yog tsim rau shoveling ntau cov kais dej thiab sib tsoo ib co fastening threads. Kev ua hlau yog tsim nyog ntawm kev mloog!

Tsib xov sib tsoo

Cov txiv ntoo-hom lossis ntsia hlau-hom xov-lapping cuab yeej yog ua los ntawm cov ntaub ntawv mos xws li cam khwb cia hlau. Qhov chaw ntawm cov xov ua tiav ntawm lub workpiece nrog pitch yuam kev yog hauv av los ntawm kev sib hloov rau pem hauv ntej thiab rov qab los txhim kho lub suab raug. Lub hardened internal thread feem ntau yog tshem tawm los ntawm kev sib tsoo los txhim kho qhov tseeb.

Rau tapping thiab threading

Tapping yog siv lub zog tshwj xeeb los txhuam tus kais dej rau hauv lub qhov-drilled hauv qab qhov ntawm lub workpiece los ua cov xov sab hauv.

Threading yog txiav cov xov sab nraud ntawm lub bar (los yog raj) workpiece nrog ib tug tuag. Lub machining raug ntawm tapping los yog threading nyob ntawm qhov tseeb ntawm tus kais los yog tuag. Txawm hais tias muaj ntau txoj hauv kev los ua cov xov sab hauv thiab sab nraud, cov xov me me hauv cov xov tsuas tuaj yeem ua tiav los ntawm cov kais dej. Tapping thiab threading tuaj yeem ua los ntawm tes lossis los ntawm tshuab dhos, tshuab drilling, tshuab tapping, thiab tshuab threading.

Xyaxov dov

Cov txheej txheem ntawm kev sib sau thiab dov tuag los tsim cov yas deformation ntawm lub workpiece kom tau txais xov dov yog feem ntau nqa tawm ntawm cov xov dov tshuab lossis lub tshuab dhos tsis siv neeg txuas nrog lub tshuab qhib thiab kaw cov xov dov lub taub hau, uas yog tsim rau ntau lawm. ntawm sab nraud xov qauv ntawm tus qauv fasteners thiab lwm yam threaded pob qij txha. Feem ntau, sab nraud ntawm cov xov dov tsis ntau tshaj 25 hli, qhov ntev tsis tshaj 100 hli, thiab cov xov raug tuaj yeem ncav cuag qib 2 (gb197-63). Txoj kab uas hla ntawm qhov khoob siv yog kwv yees sib npaug ntawm lub suab kab ntawm cov xov yuav tsum tau ua. Feem ntau, cov xov sab hauv tsis tuaj yeem ua tiav los ntawm dov. Txawm li cas los xij, rau cov khoom ua haujlwm mos, qhov txias extrusion sab hauv xov tuaj yeem siv yam tsis muaj qhov txuas extrusion kais (qhov siab tshaj plaws txoj kab uas hla tuaj yeem ncav cuag li 30mm), thiab txoj haujlwm ua haujlwm zoo ib yam li tapping. Lub torque yuav tsum tau rau txias extrusion ntawm cov xov sab hauv yog hais txog 1 lub sij hawm loj tshaj qhov ntawd rau tapping, thiab lub machining raug thiab nto zoo yog me ntsis siab tshaj qhov tapping.

Qhov zoo ntawm xov dov yog raws li nram no:

① Qhov saum npoo roughness tsawg dua li tig, milling, thiab sib tsoo;

② Qhov saum npoo ntawm cov xov tom qab dov tuaj yeem txhim kho lub zog thiab hardness vim kev ua haujlwm txias txias;

③ cov khoom siv yog siab;

④ cov khoom tsim tau yog ob npaug piv nrog cov txheej txheem txiav, thiab nws yooj yim kom paub automation;

⑤ lub neej kev pab cuam ntawm lub dov tuag yog ntev heev. Txawm li cas los xij, qhov nyuaj ntawm cov khoom siv ua haujlwm tsis yog ntau tshaj hrc40, qhov tseeb ntawm qhov loj me me yuav tsum siab, thiab qhov tseeb thiab hardness ntawm dov tuag kuj siab, yog li nws nyuaj rau tsim cov tuag. Nws tsis haum rau cov xov nrog ib qho asymmetric dov profile.

Raws li qhov sib txawv dov tuag, xov dov tuaj yeem muab faib ua ob hom: xov dov thiab xov dov.

Ob lub xov dov daim hlau nrog xov profiles yog staggered los ntawm 1/2 suab, lub phaj zoo li qub yog tsau, thiab cov phaj txav txav mus rau hauv ib txoj kab ncaj nraim mus rau lub phaj zoo li qub. Yog tias koj xav kawm UG programming hauv pab pawg 565120797, nws tuaj yeem pab koj thaum lub tshuab ua haujlwm tau muab tso rau hauv ob daim hlau, txav lub phaj rau pem hauv ntej kom rub thiab nias lub workpiece, ua rau nws cov yas deformation rau hauv xov.

Muaj peb hom dov: radial, tangential, thiab dov taub hau dov.

① Radial xov dov:ob (los yog peb) xov-zoo li tus xov dov lub log yog ntsia rau ntawm kev sib txuas ua ke shafts, lub workpiece yog muab tso rau ntawm kev txhawb nqa ntawm ob lub log, thiab ob lub log tig ntawm tib lub ceev nyob rau hauv tib txoj kev, ib tug ntawm uas kuj ua radial. pub mov. Lub rolling log tsav lub workpiece tig, thiab qhov saum npoo yog extruded radially los ua ib tug xov. Ib txoj kev dov zoo sib xws kuj tuaj yeem siv rau qee cov ntsia hlau uas tsis muaj qhov yuav tsum tau ua.

② tangential xov dov:tseem hu ua planetary xov dov. Cov cuab yeej dov muaj xws li ib qho kev sib hloov hauv nruab nrab xov dov lub log thiab peb qhov ruaj khov arc-zoo li tus xov daim hlau. Lub workpiece tuaj yeem noj tsis tu ncua thaum dov, yog li cov khoom tsim tau siab dua li cov xov rubbing thiab radial dov.

③ Xov dov ntawm xov dov taub hau:Nws yog nqa tawm ntawm lub tshuab dhos tsis siv neeg thiab feem ntau yog siv los ua cov xov luv luv ntawm lub workpiece. Muaj 3-4 rolling rollers faib uniformly nyob ib ncig ntawm lub workpiece. Thaum dov, lub workpiece tig, thiab lub taub hau dov axially dov lub workpiece tawm ntawm cov xov.

| CNC Machining Cheebtsam | Amazing CNC Machining | Cnc Online Service |

| Machining Aluminium Parts | Machining Aircraft Parts | Kev cai hlau tsim |

| CNC ua | Brass Machined Parts | Brass CNC tig qhov chaw |

www.anebon.com

Anebon Hlau Khoom Limited tuaj yeem muab CNC machining, tuag casting, sheet hlau machining kev pabcuam, thov koj xav tiv tauj peb.

Tel: +86-769-89802722 Email: info@anebon.com Website : www.anebon.com

Post lub sij hawm: Oct-04-2019