Rau cov cav, cov khoom sib txuas xws li crankshafts, camshafts, thiab lub tog raj kheej liner siv chucks hauv txhua txoj kev ua. Thaum lub sij hawm ua, lub chucks center, clamp thiab tsav lub workpiece. Raws li lub peev xwm ntawm lub chuck los tuav lub workpiece thiab tswj qhov chaw, nws muab faib ua nruj chuck thiab ntab chuck. Kab lus no feem ntau tham txog ob lub chucks 'cov ntsiab cai xaiv thiab cov ntsiab lus tu txhua hnub.5 aixs CNC machining qhov chaw

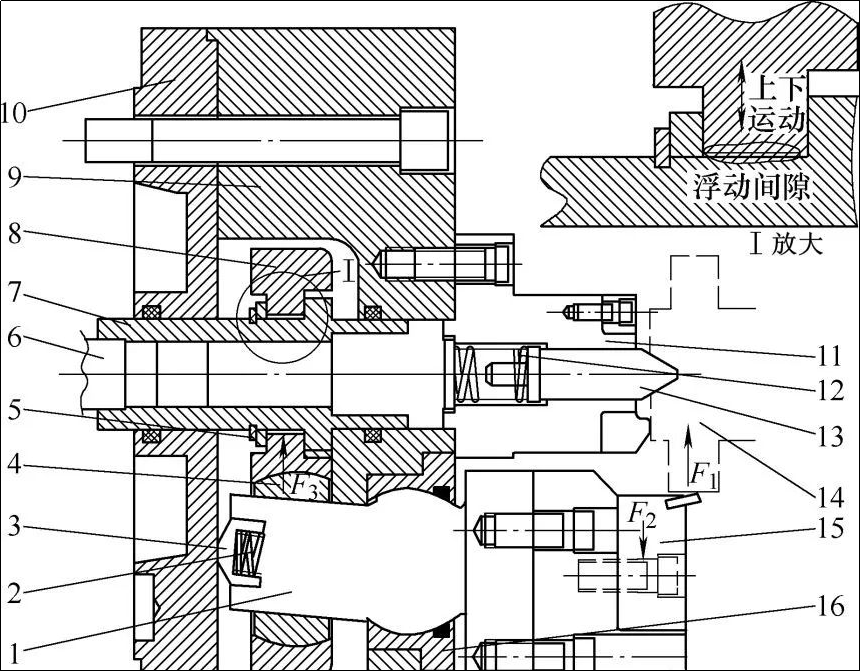

Rigid chucks thiab ntab chucks sib txawv heev hauv cov qauv thiab kev hloov kho. Noj cov chucks ntawm Japanese hom ua piv txwv, Daim duab 1 qhia txog kev ua haujlwm ntawm cov chuck ntab: lub workpiece yog nyob rau hauv qhov kev txiav txim ntawm qhov chaw txhawb nqa thaiv thiab sab saum toj. Axial thiab radial positioning thiab clamping yog nqa tawm. Tom qab ntawd, lub chuck lub tog raj kheej tsav lub chuck center khi pas nrig, qhov sib txawv hloov phaj, lub puab tsaig caj npab txhawb phaj, kheej kheej sib koom tes, thiab lub puab tsaig caj npab los ntawm txoj hlua khi, thaum kawg paub txog lub puab tsaig chuck kom clamp lub workpiece.

Thaum muaj qhov sib txawv tseem ceeb ntawm lub coaxially ntawm qhov nruab nrab ntawm peb lub puab tsaig ntawm lub chuck thiab qhov chaw ntawm lub workpiece, lub puab tsaig ntawm lub chuck uas tiv tauj lub workpiece ua ntej yuav raug rau lub zog F2, uas yog kis mus rau lub puab tsaig. caj npab txhawb nqa phaj los ntawm lub puab tsaig caj npab thiab lub puab kheej kheej. F3 ua rau ntawm caj npab txhawb nqa phaj. Rau cov floating chuck, muaj qhov sib txawv ntawm nruab nrab rub pas nrig ntawm chuck thiab claw caj npab txhawb phaj. Nyob rau hauv qhov kev txiav txim ntawm lub zog F3, lub claw caj npab txhawb nqa phaj siv qhov khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob txav mus rau qhov kev taw qhia ntawm lub zog kom txog thaum peb lub puab tsaig clamp lub workpiece nkaus.

Daim duab 1 Floating chuck qauv

1. Claw caj npab

2. Rectangular caij nplooj ntoos hlav

3. Spherical sab saum toj npog

4. Kev sib koom ua ke

5. Clearance hloov phaj

6. Lub tog raj kheej rub pas nrig

7. Chuck center rub pas nrig

8. Claw caj npab txhawb phaj

9. Chuck lub cev 10. Chuck lub kawg cover

10. Qhov chaw txhawb nqa thaiv

12. Workpiece yuav tsum tau ua

13. Chuck Jaws 16. Pob txhawb nqa

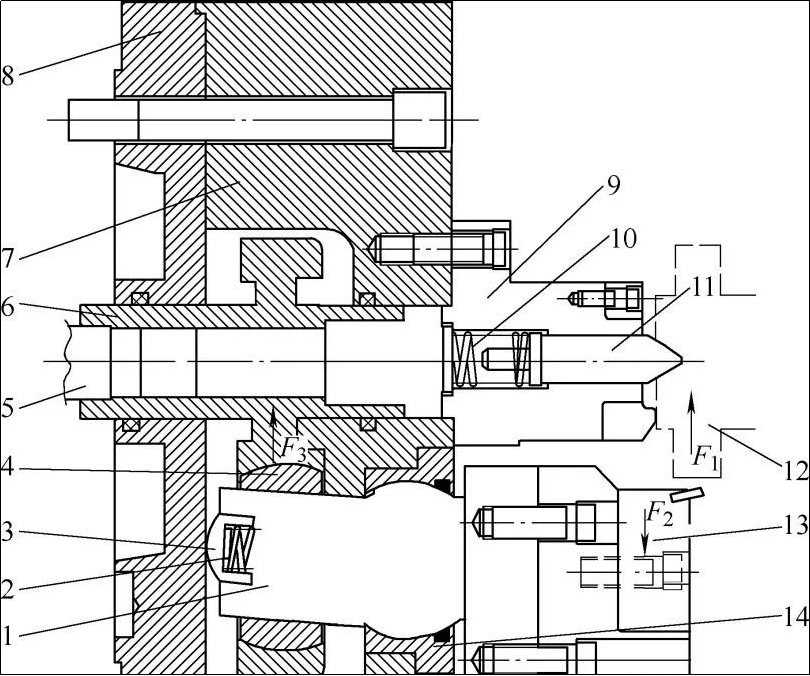

Daim duab 2 qhia txog cov txheej txheem kev ua ntawm lub chuck nruj

Nyob rau hauv qhov kev txiav txim ntawm qhov chaw txhawb nqa thaiv thiab sab saum toj, lub workpiece yog positioned thiab clamped axially thiab radially, thiab tom qab ntawd lub chuck roj lub tog raj kheej tsav lub hauv paus rub pas nrig, spherical sib koom tes thiab lub puab tsaig ntawm chuck los ntawm rub pas nrig. Lub caj npab txav, thiab thaum kawg, lub puab tsaig chuck clamp lub workpiece. Txij li thaum lub nruab nrab rub pas nrig ntawm chuck yog rigidly txuas nrog lub puab kheej kheej thiab lub puab tsaig caj npab, tom qab lub chuck puab tsaig (peb lub puab tsaig) yog clamped, ib tug clamping center yuav tsim. Lub chaw clamping tsim los ntawm sab saum toj tsis sib tshooj, thiab lub workpiece yuav pom tseeb clamping deformation tom qab chuck yog clamped. Ua ntej siv chuck, nws yuav tsum tau kho qhov sib tshooj ntawm qhov nruab nrab ntawm lub chuck thiab qhov nruab nrab ntawm qhov chaw kom paub tseeb tias chuck yuav tsis tshwm sim virtual tom qab clamping. Clamped mob.

Daim duab 2 Rigid chuck qauv

1. Claw caj npab

2. 10. Rectangular caij nplooj ntoos hlav

3. Spherical sab saum toj npog

4. Kev sib koom ua ke

5. Lub tog raj kheej khi pas nrig

6. Chuck center khi pas nrig

7. Chuck lub cev

8. Chuck lub rear-kawg npog

9. Qhov chaw txhawb nqa thaiv

10. Saum

11. Workpiece yuav tsum tau ua

12. Chuck lub puab tsaig

13. Spherical txhawb nqa

Los ntawm kev tsom xam ntawm cov txheej txheem ntawm chuck nyob rau hauv daim duab 1 thiab daim duab 2, lub floating chuck thiab cov chuck nruj muaj qhov sib txawv hauv qab no.

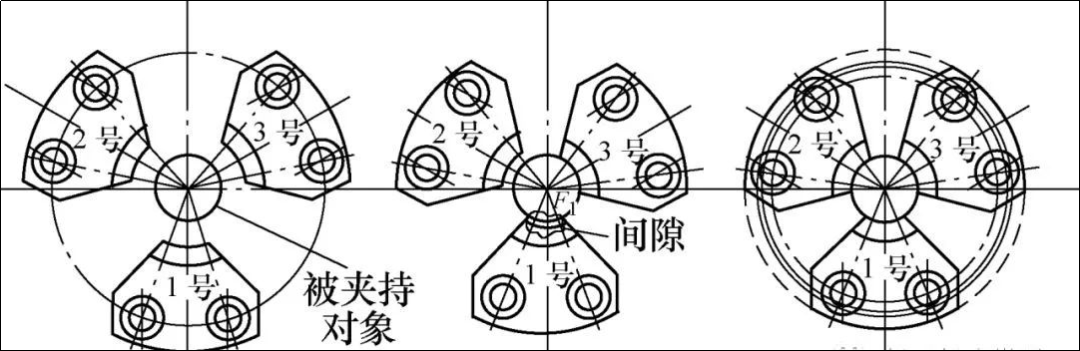

Floating chuck: Raws li pom nyob rau hauv daim duab 3, nyob rau hauv tus txheej txheem ntawm clamping lub workpiece, vim qhov sib txawv heights ntawm lub workpiece dawb paug nto los yog lub loj roundness kam rau ua ntawm lub dawb paug, lub No. 3 lub puab tsaig yuav tuaj rau hauv kev sib cuag nrog lub workpiece nto thiab Lub puab tsaig 1 thiab No. 2 yuav tshwm sim. Yog hais tias lub workpiece tseem tsis tau kov, nyob rau lub sij hawm no, lub floating mechanism ntawm lub floating chuck ua hauj lwm, siv cov nto ntawm lub workpiece raws li kev txhawb nqa rau ntab lub puab tsaig 3. Tsuav tus nqi ntab txaus txaus, lub puab tsaig No. Lub workpiece muaj me ntsis cuam tshuam rau qhov chaw ntawm lub workpiece.

Daim duab 3 Clamping txheej txheem ntawm floating chuck puab tsaig

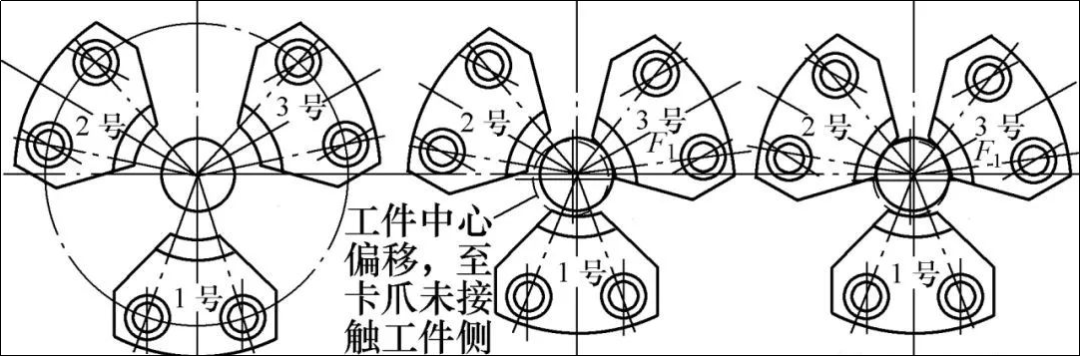

Rigid chuck: Raws li pom nyob rau hauv daim duab 4, thaum lub sij hawm lub clamping txheej txheem, yog hais tias lub concentricity ntawm lub chuck thiab lub workpiece yog tsis kho kom zoo, lub No. nyob rau hauv kev sib cuag nrog lub workpiece. , ces lub chuck clamping quab yuam F1 yuav ua rau ntawm lub workpiece. Yog hais tias lub zog loj txaus, lub workpiece yuav raug offset los ntawm qhov chaw predetermined, yuam lub workpiece txav mus rau qhov chaw ntawm chuck; thaum lub clamping quab yuam ntawm lub chuck me me, qee qhov yuav tshwm sim. Thaum lub puab tsaig tsis tuaj yeem ncav cuag lub workpiece, kev vibration tshwm sim thaum lub tshuab ua haujlwm.cnc milling connector

Daim duab 4 Clamping txheej txheem ntawm txhav chuck puab tsaig

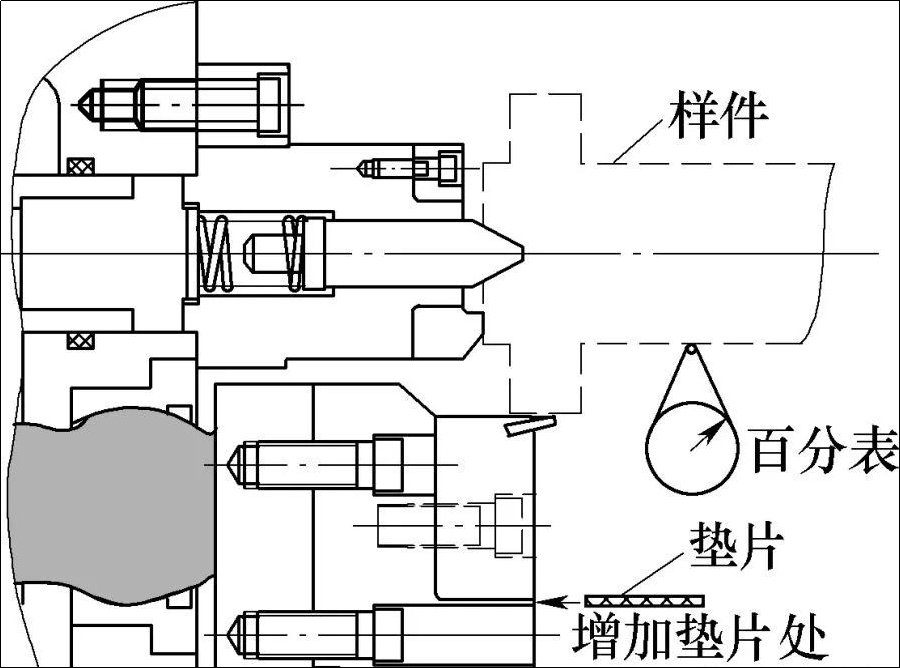

Kev hloov kho ua ntej siv chuck: Lub chuck nruj yuav tsim qhov chaw clamping ntawm chuck nws tus kheej tom qab clamping. Thaum siv lub chuck nruj, nws yuav tsum tau kho qhov chaw clamping ntawm lub chuck kom sib haum nrog lub clamping thiab qhov chaw ntawm qhov chaw ua haujlwm, raws li qhia hauv daim duab 5 qhia.cnc machining aluminium qhov chaw

Daim duab 5 Kev hloov kho ntawm qhov nro chuck center

Raws li kev soj ntsuam ntawm cov qauv saum toj no, nws raug pom zoo kom ua raws li cov hauv qab no hauv kev hloov kho thiab kev saib xyuas ntawm chuck: Lub lubrication thiab roj ntawm cov khoom txav hauv lub chuck yog hloov tsis tu ncua. Qhov txav ntawm qhov txav hauv qhov chuck yog qhov yooj yim zawv zawg kev sib txhuam. Nws yog ib qho tsim nyog yuav tau ntxiv thiab tsis tu ncua hloov cov qib teev ntawm lubricating roj / roj raws li kev saib xyuas ntawm chuck. Thaum ntxiv roj, nws yog ib qho tsim nyog los nyem tawm tag nrho cov roj siv nyob rau lub sijhawm dhau los, thiab tom qab ntawd thaiv cov roj tawm qhov chaw nres nkoj tom qab clamping lub chuck kom tiv thaiv cov kab noj hniav ntawm chuck los ntawm kev tuav rov qab.

Kev tshuaj xyuas tsis tu ncua thiab kev hloov kho ntawm qhov chaw clamping ntawm lub chuck nruj thiab qhov nruab nrab ntawm lub workpiece: Lub chuck nruj yuav tsum tau ntsuas ib ntus seb qhov nruab nrab ntawm chuck thiab qhov nruab nrab ntawm lub workpiece spindle zoo ib yam. Ntsuas qhov khiav ntawm lub disc. Yog tias nws tshaj qhov yuav tsum tau muaj, ntxiv spacers kom tsim nyog ntawm ib lossis ob lub puab tsaig sib raug rau qhov siab, thiab rov ua cov kauj ruam saum toj no kom txog rau thaum cov kev xav tau.

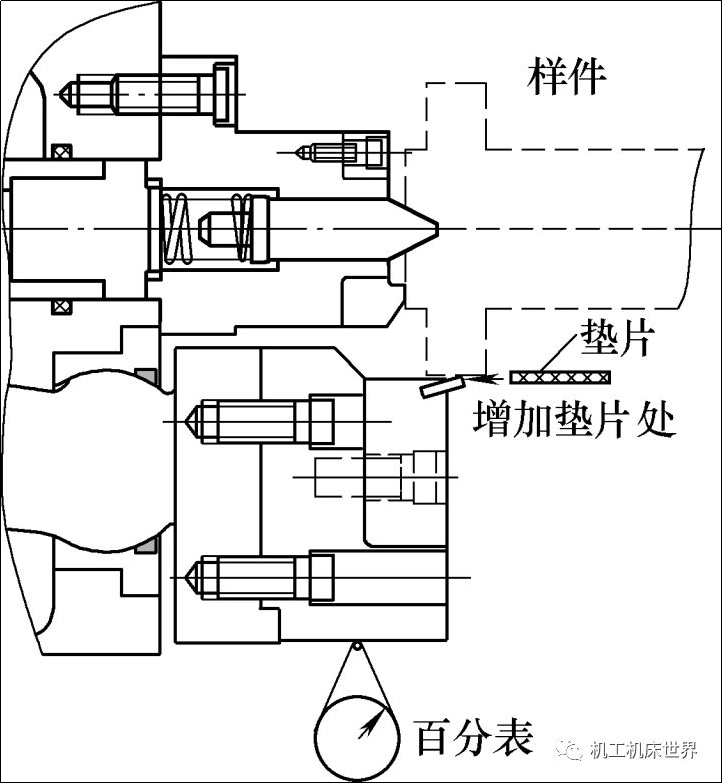

Kev tshuaj xyuas ib ntus ntawm cov nyiaj ntab ntawm cov ntab chuck (saib daim duab 6). Hauv kev saib xyuas chuck txhua hnub, nws yog ib qho tsim nyog yuav tsum ntsuas qhov ntab ntab thiab ntab qhov tseeb ntawm lub chuck ntab, thiab muab kev taw qhia rau kev saib xyuas sab hauv ntawm chuck nyob rau theem tom ntej. Txoj kev ntsuas ntawm ntab precision: tom qab chuck clamps tus qauv, muab chuck los ntsuas. Tig lub claw mus rau ib qho yooj yim ntsuas txoj hauj lwm, ntsuas lub dial taw qhia (yuav tsum tau muab lub magnetic meter puag rau lub txav ncej), thiab kos lub ntsuas taw tes raws li xoom point txoj hauj lwm. Tom qab ntawd tswj lub servo axis kom txav lub dial taw qhia, qhib lub chuck, tso lub gasket nrog lub thickness ntawm Amm ntawm lub puab tsaig yuav tsum tau ntsuas thiab cov qauv, clamp tus qauv ntawm lub chuck, txav lub dial taw tes mus rau xoom point txoj hauj lwm, thiab paub meej tias seb cov ntaub ntawv nias los ntawm lub dial qhia yog hais txog Amm. Yog tias nws yog, nws txhais tau hais tias qhov tseeb ntab yog qhov zoo. Yog tias cov ntaub ntawv sib txawv heev, nws txhais tau hais tias muaj teeb meem nrog lub floating mechanism ntawm chuck. Kev ntsuas ntawm lwm lub puab tsaig yog tib yam li saum toj no.

Daim duab 6 Kev tshuaj xyuas ntawm qhov ntab ntab ntawm cov ntab chuck

Kev hloov pauv tsis tu ncua xws li cov ntsaws ruaj ruaj, gaskets, thiab springs hauv chuck: rectangular springs, chuck body, chuck rear end cover, rectangular springs, and seals and springs in spherical support yuav tsum tau ua raws li kev siv ntau zaus thiab saum toj no. xeem tau. Hloov tsis tu ncua. Txwv tsis pub, qaug zog yuav ua rau nws puas tsuaj, uas ua rau ib tug floating npaum li cas thiab rigid chuck runout.

Los ntawm kev soj ntsuam saum toj no ntawm cov ntsiab lus tseem ceeb ntawm chuck qauv hloov kho thiab kev saib xyuas, xyuam xim rau cov hauv paus ntsiab lus hauv qab no hauv kev xaiv chucks: yog tias lub chuck clamping ib feem ntawm cov txheej txheem ua tiav yog qhov khoob khoob, qhov floating chuck yog nyiam, thiab cov chuck nruj. yog siv nyob rau hauv lub workpiece. Lub chuck clamping nto ntawm lub tshuab yog qhov chaw tom qab roughing, semi-tiav / tiav. Tom qab ua raws li cov cai yooj yim saum toj no, kev xaiv meej raws li kev ua haujlwm sib txawv yog qhov tsim nyog.

Kev xaiv ntawm rigid chuck:

①Machining tej yam kev mob xav tau ib tug loj npaum li cas ntawm txiav thiab ib tug loj txiav quab yuam. Tom qab clamped los ntawm lub workpiece yuav tsum tau ua tiav thiab kev txhawb nqa los ntawm lub hauv paus ncej, ib tug muscular workpiece rigidity, thiab ib tug loj workpiece rotational tsav tsheb yuav tsum.

②Thaum tsis muaj ib lub sijhawm nruab nrab, xws li sab saum toj, xav tau kev tsim ntawm chuck centering.

Floating chuck xaiv:

① Cov kev xav tau siab rau qhov nruab nrab ntawm lub workpiece spindle. Tom qab lub chuck yog clamped, nws ntab yuav tsis cuam tshuam qhov chaw nruab nrab ntawm lub workpiece spindle.

② Cov nyiaj txiav tsis loj, thiab nws tsuas yog tsim nyog los tsav lub workpiece spindle kom tig thiab ua kom cov rigidity ntawm lub workpiece.

Cov lus saum toj no piav qhia txog qhov sib txawv ntawm cov qauv thiab kev saib xyuas thiab xaiv cov kev xav tau ntawm cov ntab thiab cov chucks nruj, uas yuav pab tau rau kev siv thiab tu. Koj xav tau kev nkag siab tob dua thiab siv tau yooj yim; koj yuav tsum tau sau cov kev paub dhau los hauv kev siv ntawm qhov chaw thiab kev saib xyuas.

Anebon Hlau Khoom Limited tuaj yeem muab CNC Machining, Tuag Casting, Sheet Hlau Fabrication kev pabcuam, thov koj xav tiv tauj peb.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Lub sij hawm xa tuaj: Mar-31-2022