Raws li ib tug tswv cuab ntawm kev lag luam, koj puas to taub qhov txawv ntawm qhov sib txawv ntawm kev kho deg rau ntau yam khoom?

Muaj ntau yam txheej txheem kho saum npoo ib txwm, suav nrog tab sis tsis txwv rau:

Txheej:Siv ib txheej nyias ntawm cov khoom (xws li xim, enamel, lossis hlau) los tiv thaiv qhov chaw, txhim kho kev zoo nkauj, tiv thaiv corrosion, lossis txhim kho cov haujlwm tshwj xeeb.

Plating:Electroplating yuav tsum tso ib txheej nyias ntawm cov hlau mus rau saum npoo ntawm lub substrate los txhim kho corrosion kuj, conductivity, los yog zoo li.

Kev kho cua sov:Siv cov txheej txheem tswj cua sov thiab cua txias los hloov cov microstructure thiab cov khoom ntawm cov hlau, xws li kev txhim kho hardness, lub zog, los yog ductility.

Nto tu thiab npaj:Tshem tawm cov impurities, cov kab mob, lossis oxidation txheej los ntawm qhov chaw kom ntseeg tau tias muaj adhesion thiab kev sib txuas ntawm cov coatings lossis lwm yam kev kho saum npoo.

Kev hloov kho saum npoo:Cov txuj ci zoo li ion implantation, nto alloying, los yog laser kho yog siv los hloov cov muaj pes tsawg leeg los yog cov qauv ntawm cov nto los txhim kho cov khoom xws li hardness, hnav tsis kam, los yog tshuaj inertness.

Nto Texturing:Tsim cov qauv tshwj xeeb, grooves, lossis textures ntawm qhov chaw los txhim kho tuav, txo kev sib txhuam, lossis txhim kho qhov zoo nkauj.

Txhais:

Kev kho deg yog txheej txheem ntawm kev tsim cov txheej txheem ntawm cov khoom nto ntawm lub hauv paus nrog cov khoom sib txawv, lub cev, thiab tshuaj lom neeg.

Lub hom phiaj:

Kev kho deg feem ntau yog ua los txhim kho kev ua haujlwm ntawm cov khoom, xws li corrosion kuj, durability, lossis kho kom zoo nkauj. Kev kho deg yog ua los ntawm kev sib tsoo tshuab, kev kho cua sov ntawm qhov chaw, tshuaj txau, thiab kev kho tshuaj. Kev kho deg muaj xws li ntxuav, cheb, deburring, degreasing, thiab descaling nto ntawm lub workpiece.

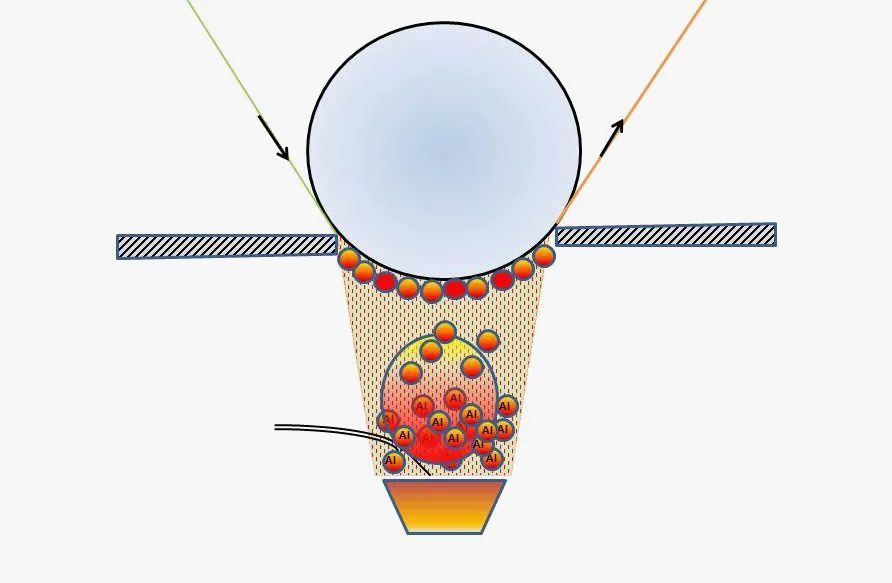

01. Nqus plating

—— Nqus Metalizing ——

Nqus plating tshwm sim los ntawm cov txheej txheem ntawm lub cev. Hauv lub tshuab nqus tsev, argon txhaj tshuaj thiab tom qab ntawd ntaus lub hom phiaj. Lub hom phiaj yog muab cais ua cov molecules uas yog adsorbent los ntawm cov khoom siv hluav taws xob, tsim kom muaj ib qho kev sib xws, du txheej txheej hlau.

Cov ntaub ntawv siv tau:

1. Lub tshuab nqus tsev plating yog ua tau rau ntau yam khoom xws li hlau, sib xyaw, ceramics, iav, thiab cov yas mos thiab tawv. Aluminium yog feem ntau siv electroplating nto kho, ua raws li tooj liab thiab nyiaj.

2. Cov ntaub ntawv ntuj tsis tuaj yeem ua lub tshuab nqus tsev vim tias lawv cov dej noo yuav cuam tshuam rau lub tshuab nqus tsev.

Tus nqi ntawm cov txheej txheem:

Cov nqi ua haujlwm yog siab heev hauv lub tshuab nqus tsev vim tias cov khoom ua haujlwm yuav tsum tau txau thiab tom qab ntawd thauj khoom, tshem tawm, thiab rov ua dua. Nws kuj yog nyob ntawm seb lub workpiece yog qhov nyuaj thiab loj npaum li cas.

Environmental cuam tshuam:

Nqus Electroplating zoo ib yam li txau raws li nws qhov kev cuam tshuam ib puag ncig.

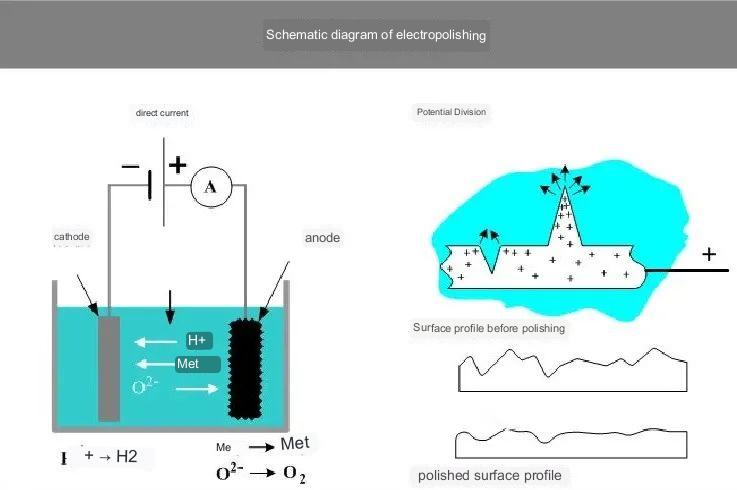

02. Electropolishing

—— Electropolishing ——

Electropolishing yog txheej txheem electrochemical uas cov atoms ntawm lub workpiece raus hauv ib qho electrolyte tau hloov mus rau hauv ions thiab tshem tawm ntawm qhov chaw vim yog qhov hluav taws xob tam sim no, yog li ua tiav cov txiaj ntsig ntawm kev tshem tawm cov burrs zoo thiab ua kom qhov ci ntawm qhov chaw ua haujlwm.

Cov ntaub ntawv siv tau:

1. Feem ntau cov hlau tuaj yeem ua electrolytically polished, cov uas feem ntau siv polishing ntawm stainless hlau (tshwj xeeb tshaj yog rau austenitic nuclear qib stainless hlau).

2. Cov khoom sib txawv tsis tuaj yeem electropolished tib lub sijhawm, lossis txawm tias muab tso rau hauv tib lub tshuab electrolytic hnyav.

Tus nqi txheej txheem:

Tag nrho cov txheej txheem ntawm electrolytic polishing yog ua tiav tiav, yog li tus nqi ua haujlwm tsawg heev. Kev cuam tshuam ib puag ncig: Electrolytic polishing siv cov tshuaj tsis zoo. Tag nrho cov txheej txheem yuav tsum muaj cov dej me me thiab yooj yim rau kev khiav lag luam. Tsis tas li ntawd, nws tuaj yeem ua kom ntev lub zog ntawm stainless hlau thiab ncua kev xeb ntawm stainless hlau.

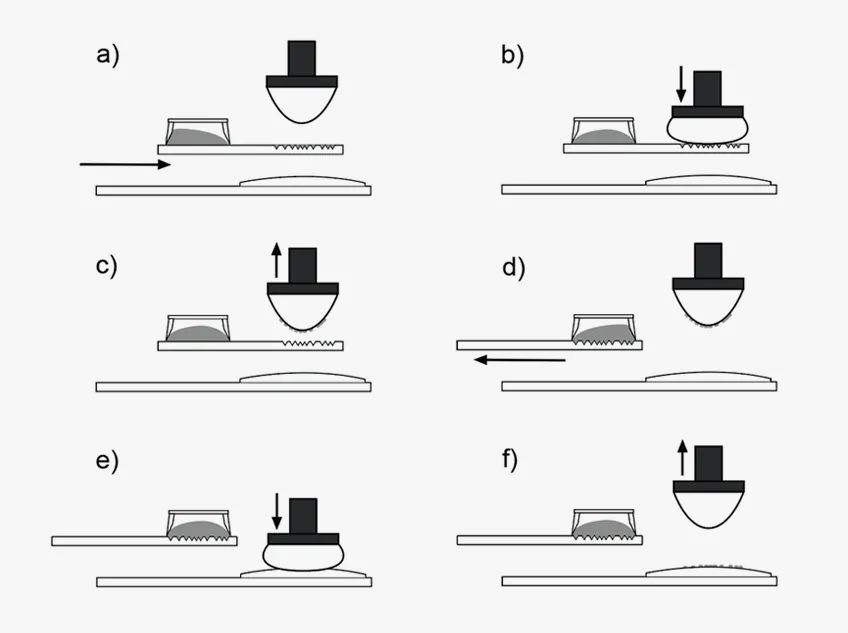

03. Cov txheej txheem luam ntawv Pad

— Pad Printing —

Muaj peev xwm luam tawm cov ntawv, duab thiab cov duab ntawm qhov chaw ntawm cov khoom tsis zoo li tam sim no dhau los ua qhov tseem ceeb tshwj xeeb luam ntawv.

Cov ntaub ntawv siv tau:

Pad luam ntawv tuaj yeem siv rau yuav luag txhua yam ntaub ntawv, tshwj tsis yog cov ntaub ntawv softer dua silicone pads, xws li PTFE.

Tus nqi txheej txheem:

tus nqi pwm qis thiab tus nqi ua haujlwm tsawg.

Kev cuam tshuam ib puag ncig: Txij li cov txheej txheem no tsuas yog siv rau cov kuab tshuaj soluble (uas muaj cov tshuaj phem), nws muaj kev cuam tshuam rau ib puag ncig.

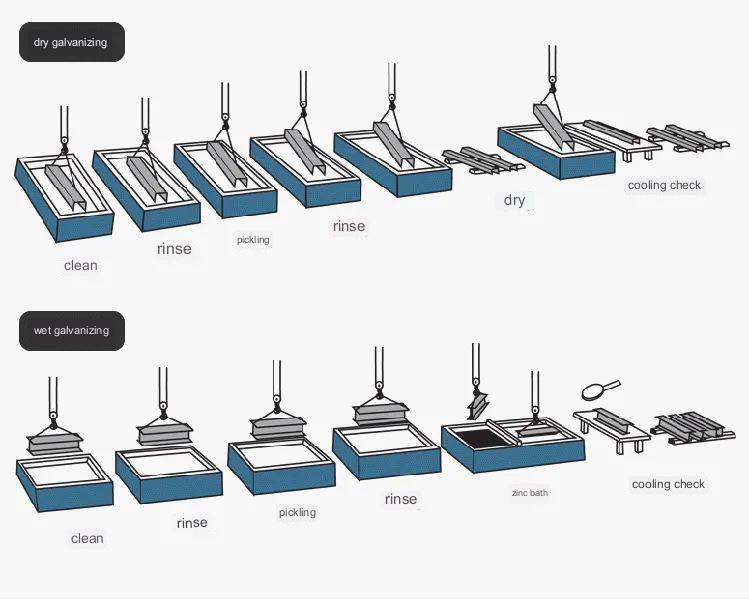

04. Galvanizing txheej txheem

--- Galvanizing ---

Kev kho deg uas siv cov txheej nyias ntawm zinc rau saum npoo ntawm cov ntaub ntawv hlau alloy. Qhov no yog ua kom zoo nkauj, thiab tseem muaj cov khoom tiv thaiv xeb. Cov zinc txheej rau saum npoo ua raws li cov txheej txheem tiv thaiv electrochemical los tiv thaiv hlau corrosion. Kub-dip galvanizing yog txoj kev tseem ceeb siv.

Cov ntaub ntawv siv tau:

Galvanizing yog kev kho deg rau cov hlau thiab hlau nkaus xwb.

Tus nqi txheej txheem:

Tsis muaj nqi pwm. Lub voj voog luv / nruab nrab nqi zog. Qhov saum npoo zoo ntawm daim yog feem ntau nyob ntawm qhov kev npaj ua ntej galvanizing.

Cov txheej txheem galvanizing muaj qhov cuam tshuam zoo rau ib puag ncig. Nws nce lub neej expectancy ntawmcnc milled qhov chawlos ntawm 40 mus rau 100 xyoo, thiab nws tiv thaiv xeb thiab corrosion. Cov khoom galvanized tseem tuaj yeem xa rov qab mus rau nws lub tank galvanizing thaum nws tau mus txog qhov kawg ntawm nws lub neej muaj txiaj ntsig. Qhov no yuav tsis muaj tshuaj lom neeg lossis lub cev pov tseg.

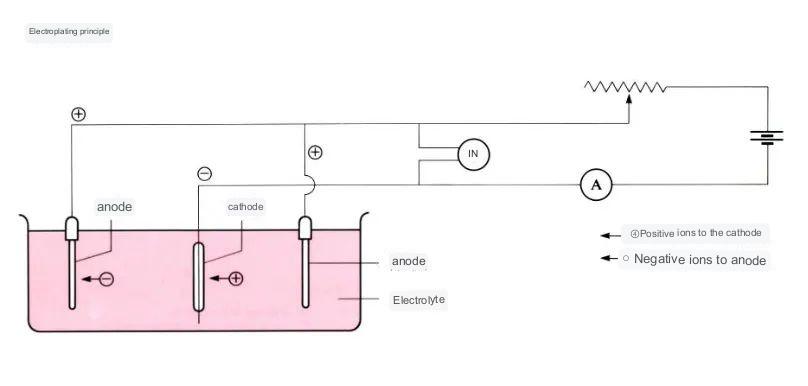

05. Cov txheej txheem electroplating

--- Electroplating ---

Electroplating yog txheej txheem ntawm kev siv cov txheej nyias ntawm cov hlau rau cov khoom siv electrolysis. Qhov no pab txhim kho corrosion kuj, hnav tsis kam, conductivity thiab zoo nkauj. Ntau cov npib muaj lawv cov txheej txheej electroplated. .

Cov ntaub ntawv siv tau:

1. Electroplating yog ua tau rau feem ntau cov hlau, tab sis lub purity thiab efficiency ntawm plating nws txawv. Cov no suav nrog tin thiab nickel.

2. ABS yog cov yas siv ntau tshaj plaws rau electroplating.

3. Nickel yog tshuaj lom thiab ua rau tawv nqaij. Nws tsis tuaj yeem siv rau hauv cov khoom siv electroplated.

Tus nqi txheej txheem:

Tsis muaj tus nqi pwm, tab sis cov khoom siv yuav tsum tau kho los kho qhov chaw. Tus nqi sij hawm yog nyob ntawm hom hlau thiab qhov kub thiab txias. Tus nqi zog (nruab nrab siab) nyob ntawm cov plating tshwj xeeb. Silverware thiab hniav nyiaj hniav kub plating xav tau cov neeg ua haujlwm txawj heev vim nws qhov kev xav tau siab ntawm cov tsos thiab kav ntev.

Environmental cuam tshuam:

Electroplating siv ntau cov tshuaj lom neeg, uas yuav tsum tau muaj kev rho tawm thiab kev hloov pauv kom txo qis ib puag ncig.

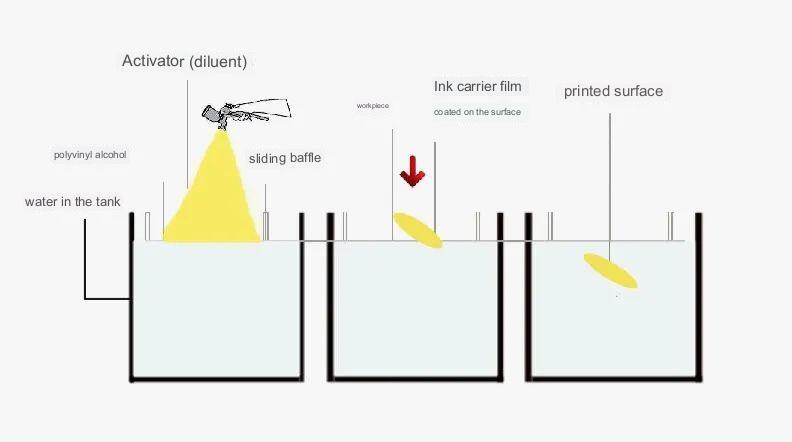

06. Dej Txau Luam Ntawv

--- Hydro Transfer Printing ---

Dej siab yog siv los hloov cov qauv ntawm cov xim mus rau qhov chaw peb-dimensional khoom. Dej hloov luam ntawv tau dhau los ua neeg nyiam dua li cov neeg muaj kev cia siab ntau dua rau kev ntim khoom thiab kho kom zoo nkauj.

Cov ntaub ntawv siv tau:

Kev hloov luam dej tuaj yeem ua tau ntawm txhua yam ntaub ntawv nyuaj. Cov ntaub ntawv tsim nyog rau kev txau kuj tsim nyog rau hom luam ntawv no. Txhaj tshuaj molded thiabcnc hlau tig qhov chawyog cov feem ntau.

Tus nqi ntawm cov txheej txheem: Thaum tsis muaj pwm, ntau yam khoom yuav tsum tau muab dej-hloov ib txhij siv fixtures. Lub sij hawm xav tau ntawm ib lub voj voog feem ntau tsis tshaj 10 feeb.

Dej hloov luam ntawv yog ib puag ncig zoo dua li cov khoom txau vim tias nws siv cov xim luam ntawv kom ntau dua, yog li txo cov khib nyiab pov tseg.

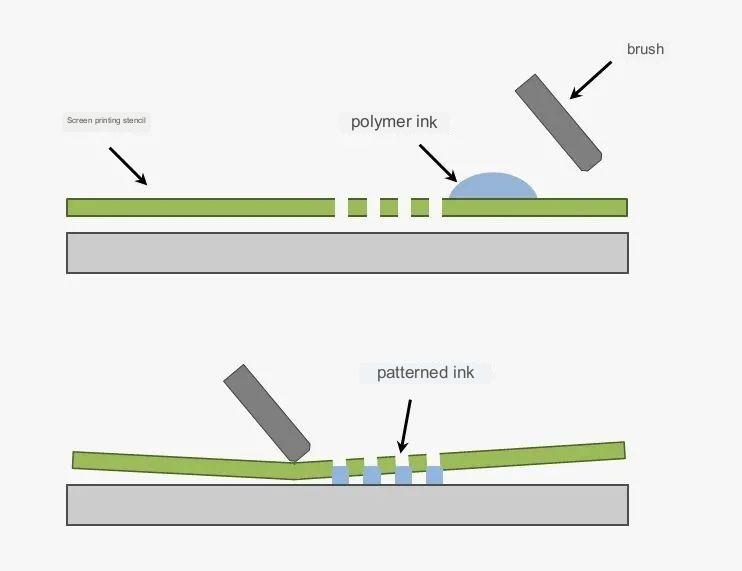

07. Screen Printing

—-Screen Printing —--

Tus number case yog kis los ntawm cov mesh ntawm cov duab nraaj mus rau lub substrate los ntawm extrusion. Qhov no ua rau cov duab kos zoo ib yam li qhov qub. Cov khoom siv tshuaj ntsuam luam ntawv yooj yim siv, yooj yim los ua daim hlau thiab luam ntawv, thiab tus nqi qis.

Cov ntaub ntawv luam tawm uas feem ntau siv suav nrog cov xim roj pleev xim thiab cov ntawv tshaj tawm, daim npav ua lag luam thiab cov npog npog.

Cov ntaub ntawv siv tau:

Kev tshuaj ntsuam luam ntawv tuaj yeem ua tiav ntawm yuav luag txhua yam khoom siv, suav nrog ceramics, iav, ceramics thiab hlau.

Tus nqi txheej txheem:

Pwm tus nqi qis tab sis tseem nyob ntawm tus lej xim vim tias txhua lub phaj xim yuav tsum tau ua nyias. Cov nqi zog ua haujlwm siab thaum luam ntawv ntau xim.

Environmental cuam tshuam:

Screen luam ntawv inks nrog lub teeb xim muaj feem cuam tshuam rau ib puag ncig. Txawm li cas los xij, cov inks uas muaj formaldehyde thiab PVC yog cov tshuaj tsis zoo thiab yuav tsum tau rov siv dua lossis pov tseg kom raws sijhawm kom tsis txhob muaj dej paug.

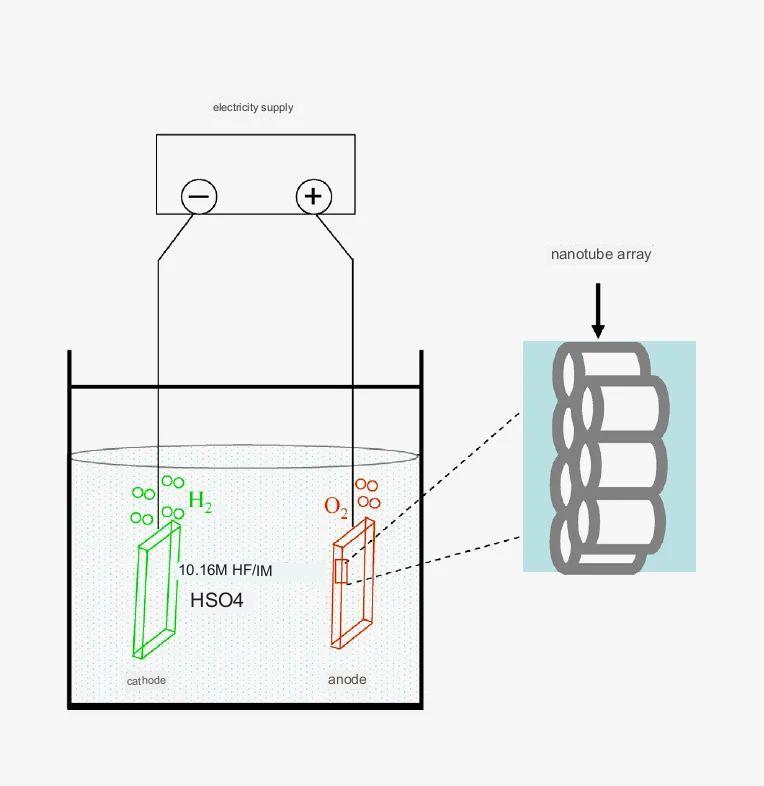

08. Anodizing

---- Anodic Oxidation--

Lub anodic oxidation ntawm txhuas yog tsuas yog raws li lub hauv paus ntsiab lus ntawm electrochemical los tsim ib txheej ntawm Al2O3 (aluminium oxide) zaj duab xis rau saum npoo ntawm txhuas thiab txhuas alloy. Cov txheej ntawm oxide zaj duab xis no muaj cov yam ntxwv tshwj xeeb xws li kev tiv thaiv, kho kom zoo nkauj, rwb thaiv tsev, thiab hnav tsis kam.

Cov ntaub ntawv siv tau:

Aluminium, aluminium alloy thiab lwm yamcnc machining aluminium qhov chaw

Tus nqi txheej txheem: Hauv cov txheej txheem tsim khoom, kev siv dej thiab hluav taws xob yog qhov loj heev, tshwj xeeb tshaj yog nyob rau hauv cov txheej txheem oxidation. Kev siv cua sov ntawm lub tshuab nws tus kheej yuav tsum tau ua kom txias tsis tu ncua los ntawm cov dej ntws, thiab lub zog noj ib tuj feem ntau nyob ib ncig ntawm 1000 degrees.

Environmental cuam tshuam:

Anodizing tsis yog qhov zoo tshaj plaws nyob rau hauv cov nqe lus ntawm lub zog efficiency, thaum nyob rau hauv zus tau tej cov txhuas electrolysis, cov nyhuv anode kuj tsim gases uas muaj kev puas tsuaj tshwm sim nyob rau hauv atmospheric ozone txheej.

09. Hlau hlau kos duab

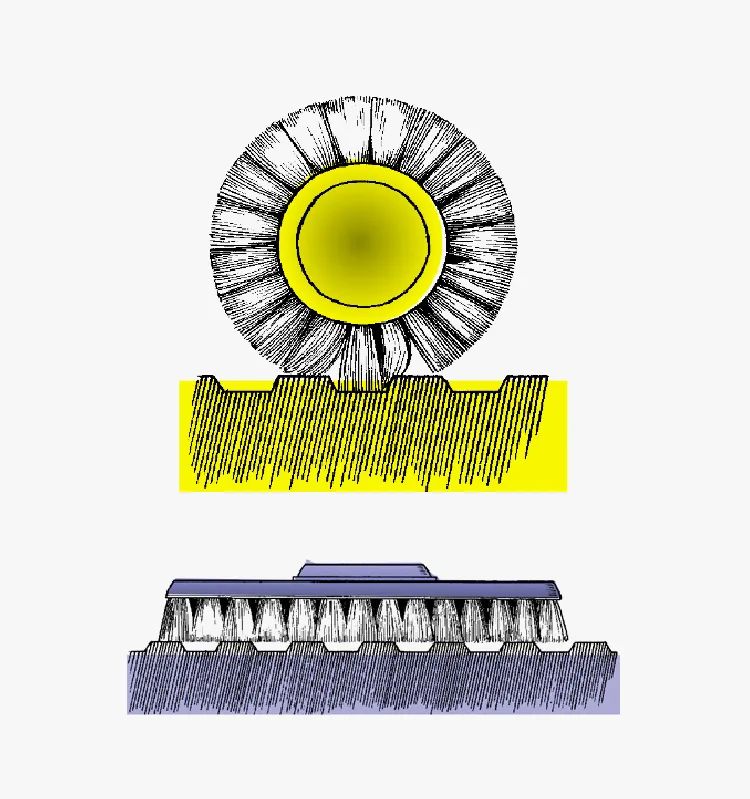

—— Hlau Hlau ——

Nws yog txoj kev kho saum npoo uas tsim cov kab ntawm qhov chaw ua haujlwm los ntawm kev sib tsoo cov khoom kom ua tiav cov txiaj ntsig zoo nkauj. Raws li qhov sib txawv textures tom qab xaim kos duab, nws tuaj yeem muab faib ua: ncaj hlau kos duab, chaotic hlau kos duab, corrugated, thiab swirling.

Cov ntaub ntawv siv tau:

Yuav luag txhua cov ntaub ntawv hlau tuaj yeem siv cov txheej txheem hlau hlau kos duab.

10. Hauv-pwm Kho kom zoo nkauj

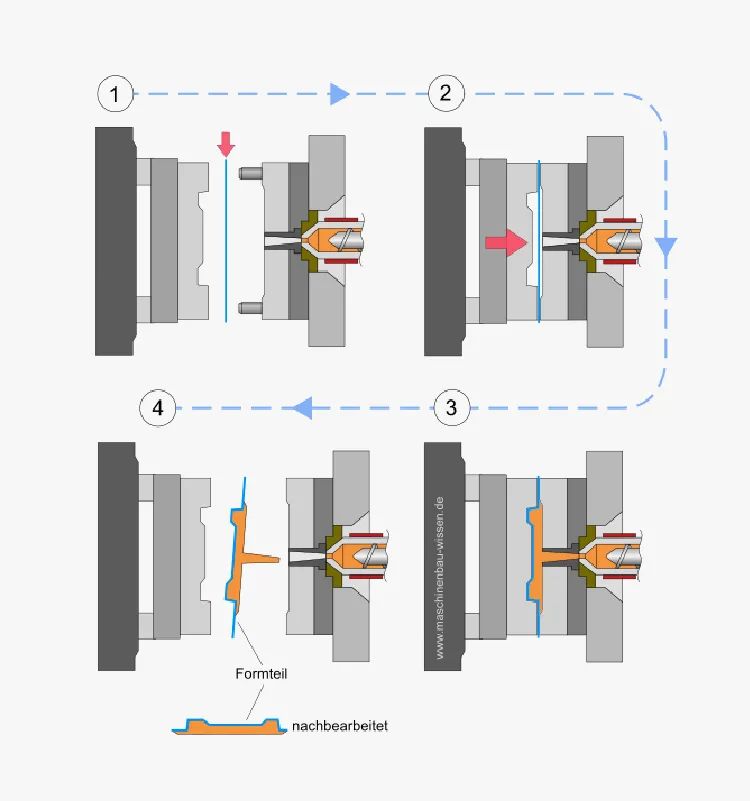

—- Hauv-Pwm Kho Kom Zoo Nkauj-IMD —-

Txoj kev molding no suav nrog kev ntxig cov qauv-luam hlau diaphragm rau hauv cov pwm hlau, txhaj cov cob rau hauv pwm, koom nrog cov diaphragm ua ke, thiab sib xyaw cov khoom siv thiab cov qauv luam tawm hlau diaphragm los tsim cov khoom kawg.

Cov khoom siv:

Pyas nto

Tus nqi txheej txheem:

Tsuas yog yuav tsum qhib ib txheej pwm. Qhov no tuaj yeem txo cov nqi thiab cov sij hawm ua haujlwm, Kev Tsim Kho Siab Tsis Siv Neeg, Kev Tsim Kho Yooj Yim, Txoj Kev Txhaj Tshuaj Ib zaug, thiab ua tiav ob qho tib si molding thiab decorating tib yam.

Environmental cuam tshuam:

Cov thev naus laus zis yog ib puag ncig tus phooj ywg thiab ntsuab, thiab zam cov pa phem uas ib txwm siv electroplating thiab pleev xim ua rau.

Tus nqi txheej txheem:

Cov txheej txheem txheej txheem yog yooj yim, cov cuab yeej siv tau yooj yim, cov khoom siv tsawg heev, tus nqi qis, thiab cov txiaj ntsig kev lag luam yog siab.

Environmental cuam tshuam:

Cov khoom siv hlau ntshiab, tsis muaj xim lossis tshuaj lom neeg ntawm qhov chaw, 600 degrees kub tsis hlawv, tsis tsim cov pa phem, ua tau raws li kev tiv thaiv hluav taws thiab kev tiv thaiv ib puag ncig.

Ua kom txhim kho, txhawm rau xyuas kom meej tias cov khoom lag luam yog raws li cov qauv kev lag luam thiab cov neeg siv khoom. Anebon muaj kev tswj xyuas zoo nyob rau hauv qhov chaw kom ntseeg tau tias zoo 2022 kub muag Yam khoom rau ABS Yas Drilling CNC Machining Turning Part Service, ntseeg Anebon thiab koj yuav tau txais ntau yam txiaj ntsig. Thov siv sij hawm los cuag peb rau cov ntaub ntawv ntxiv, Anebon lav koj peb cov kev saib xyuas tag nrho txhua hnub.

Nws pib spare qhov chaw zoo milling qhov chaw, steel tig qhov chaw tsim los ntawm Tuam Tshoj Anebon. Cov khoom lag luam los ntawm Anebon tau txais kev lees paub ntau ntxiv los ntawm cov neeg siv khoom txawv teb chaws thiab tau tsim kev sib raug zoo mus ntev thiab muaj txiaj ntsig zoo nrog Anebon. Anebon yuav muab kev pabcuam zoo tshaj plaws rau txhua tus neeg siv khoom. Peb zoo siab tos txais cov phooj ywg tshiab los koom nrog Anebon thiab tsim kev sib koom ua ke.

Post lub sij hawm: Lub Xya hli ntuj-18-2023