quenching kab nrib pleb yog ib qho quenching tsis xws luag hauv CNC machining, thiab muaj ntau yam rau lawv. Vim tias kev kho cua sov tsis zoo pib los ntawm cov khoom tsim, Anebon ntseeg tias kev ua haujlwm ntawm kev tiv thaiv cov kab nrib pleb yuav tsum pib los ntawm cov khoom tsim. Nws yog ib qho tsim nyog yuav tsum xaiv cov ntaub ntawv kom raug, tsim nyog ua cov qauv tsim, muab tso rau kev kho cua sov kom tsim nyog, npaj cov txheej txheem kom raug, thiab xaiv cov cua sov kom tsim nyog, tuav lub sij hawm, cua sov nruab nrab, txias nruab nrab, txias txoj kev thiab kev ua haujlwm hom, thiab lwm yam.

1. Khoom siv

1.1Cov pa roj carbon monoxide yog ib qho tseem ceeb cuam tshuam rau kev nyiam ntawm quenching thiab cracking. Cov ntsiab lus carbon nce, MS point txo, thiab quenching crack tendency nce. Yog li ntawd, nyob rau hauv cov xwm txheej ntawm kev txaus siab rau cov khoom siv xws li hardness thiab lub zog, cov ntsiab lus qis carbon yuav tsum raug xaiv kom deb li deb tau los xyuas kom meej tias nws tsis yooj yim rau quench thiab tawg.

1.2Kev cuam tshuam ntawm cov ntsiab lus alloying ntawm quenching cracking nyiam yog feem ntau cuam tshuam rau ntawm hardenability, MS point, grain loj loj hlob nyiam thiab decarburization. Alloying ntsiab cuam tshuam rau quenching cracking nyiam los ntawm kev cuam tshuam ntawm hardenability. Feem ntau hais lus, hardenability nce thiab hardenability nce, tab sis tib lub sij hawm thaum lub hardenability nce, nws muaj peev xwm siv ib tug quenching nruab nrab uas tsis muaj zog cua txias peev xwm txo quenching deformation los tiv thaiv deformation thiab tawg ntawm complex qhov chaw. Yog li ntawd, rau qhov chaw nrog cov duab nyuaj, txhawm rau kom tsis txhob quenching cov kab nrib pleb, nws yog ib qho kev daws teeb meem zoo dua los xaiv cov hlau nrog zoo hardenability thiab siv qhov nruab nrab quenching nrog tsis muaj zog cua txias.

Alloying cov ntsiab lus muaj kev cuam tshuam zoo rau MS point. Feem ntau hais lus, qhov qis dua MS, qhov ntau dua qhov kev sib tw tawg. Thaum MS taw tes siab, lub martensite tsim los ntawm theem hloov pauv tuaj yeem ua rau nws tus kheej tam sim ntawd, yog li tshem tawm ib feem ntawm theem hloov pauv. Kev ntxhov siab tuaj yeem zam kev tawg tawg. Yog li ntawd, thaum txiav txim siab cov ntsiab lus carbon, ib qho me me ntawm cov ntsiab lus alloying yuav tsum raug xaiv, lossis cov qib steel uas muaj cov ntsiab lus me me ntawm MS point.

1.3Thaum xaiv cov khoom steel, overheating rhiab heev yuav tsum tau xav txog. Hlau uas yog rhiab heev rau overheating yog feem ntau ua rau cov kab nrib pleb, yog li yuav tsum tau them nyiaj mloog rau xaiv cov khoom.

2. Cov qauv tsim ntawm qhov chaw

2.1Qhov seem loj yog uniform. Cov khoom uas muaj kev hloov pauv ntawm qhov loj me me yuav muaj cov kab nrib pleb vim muaj kev ntxhov siab sab hauv thaum kho cua sov. Yog li ntawd, qhov kev hloov tam sim ntawm seem loj yuav tsum zam kom deb li deb tau thaum tsim. Phab ntsa thickness yuav tsum yog uniform. Yog tias tsim nyog, qhov tuaj yeem raug drilled hauv cov phab ntsa tuab uas tsis cuam tshuam ncaj qha rau daim ntawv thov. Qhov yuav tsum tau ua los ntawm qhov ntau npaum li qhov ua tau. Raucnc machining aluminium qhov chawnrog cov thickness sib txawv, cais tsim tuaj yeem nqa tawm, thiab tom qab ntawd sib sau ua ke tom qab kev kho cua sov.

2.2Hloov lub kaum sab xis. Thaum cov khoom muaj cov ces kaum, cov ces kaum ntse, zawj thiab kab rov tav qhov, cov khoom no ua rau muaj kev ntxhov siab, uas yuav ua rau quenching thiab tawg ntawm qhov chaw. Vim li no, cov khoom yuav tsum tau tsim nyob rau hauv cov duab uas tsis ua rau muaj kev ntxhov siab ntau li ntau tau, thiab cov ces kaum ntse thiab cov kauj ruam tau ua tiav rau hauv cov ces kaum sib npaug.

2.3Qhov sib txawv ntawm qhov txias txias vim qhov zoo ntawm qhov zoo. Qhov ceev ntawm qhov txias txias txawv nrog cov duab ntawm cov khoom thaum cov khoom quenched. Txawm nyob rau hauv txawvcnc ntuntawm ib feem, qhov txias txias yuav txawv vim muaj ntau yam. Yog li ntawd, sim ua kom tsis txhob muaj qhov sib txawv ntawm qhov txias txias kom tsis txhob quenching tawg.

3. Cov txheej txheem kev kho cua sov

3.1Hauv zos quenching lossis deg hardening yuav tsum tau siv ntau li ntau tau.

3.2Tsim nyog kho lub zos hardness ntawm quenched qhov chaw raws li kev pab cuam tej yam kev mob ntawm qhov chaw. Thaum lub zos quenching hardness yuav tsum tsawg, sim tsis txhob yuam tag nrho hardness kom zoo ib yam.

3.3Ua tib zoo mloog rau cov nyhuv loj ntawm cov hlau.

3.4Tsis txhob tempering nyob rau hauv thawj hom tempering brittle cheeb tsam.

4. Tsim nyog npaj cov txheej txheem thiab cov txheej txheem tsis

Thaum cov khoom siv, cov qauv thiab kev ua haujlwm ntawm lubhlau qhov chawtau txiav txim siab, cov kws kho cua sov yuav tsum ua cov txheej txheem kev tshuaj xyuas los txiav txim siab txog cov txheej txheem tsim nyog, uas yog, txhawm rau txhim kho txoj haujlwm ntawm kev npaj cov cua sov kom raug, ua kom txias thiab ua haujlwm kub thiab txiav txim siab qhov ntsuas cua sov.

Quenching tawg

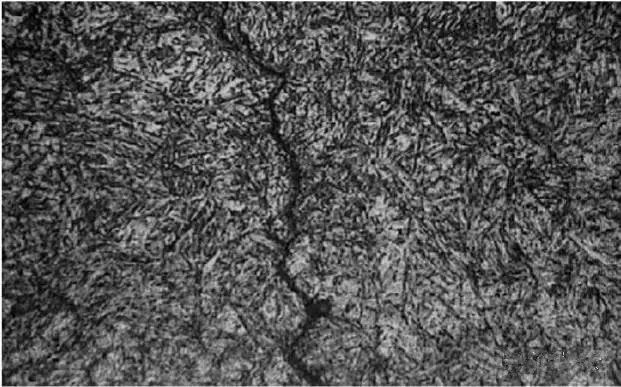

4.1Hauv qab 500X, nws yog jagged, qhov tawg thaum pib yog dav, thiab qhov tawg ntawm qhov kawg yog me me rau tsis muaj.

4.2 Microscopic tsom xam: txawv txav metallurgical inclusions, cov kab nrib pleb nthuav dav hauv cov duab jagged; pom tom qab corrosion nrog 4% nitric acid cawv, tsis muaj qhov tshwm sim decarburization, thiab cov tsos mob microscopic tau pom hauv daim duab hauv qab no:

1 # qauv

Tsis muaj qhov txawv txav ntawm cov khoom siv metallurgical thiab decarburization tau pom nyob rau ntawm cov khoom tawg, thiab cov kab nrib pleb txuas ntxiv rau hauv cov duab zigzag, uas muaj cov yam ntxwv ntawm quenching cov kab nrib pleb.

2 # qauv

Analysis xaus:

4.1.1 Cov qauv ntawm cov qauv ua tau raws li qhov yuav tsum tau ua ntawm tus qauv thiab sib haum rau qhov sib xyaw ntawm cov khoom siv hluav taws xob qub.

4.1.2 Raws li kev soj ntsuam microscopic, tsis muaj qhov txawv txav ntawm cov khoom siv hlau tau pom ntawm qhov tawg ntawm cov qauv, thiab tsis muaj qhov tshwm sim decarburization. Cov kab nrib pleb txuas ntxiv nyob rau hauv cov duab zigzag, uas muaj cov yam ntxwv ntawm quenching tawg.

forging tawg

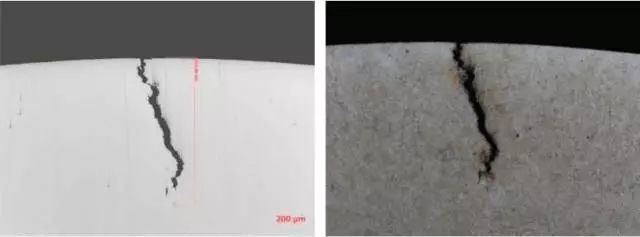

1. Cov kab nrib pleb tshwm sim los ntawm cov khoom siv vim li cas, cov npoo yog oxides.

2. Micro kev soj ntsuam

Lub ci dawb txheej ntawm qhov chaw yuav tsum yog txheej thib ob quenching, thiab cov xim dub tsaus nyob rau hauv cov txheej txheem thib ob yog txheej txheej kub kub.

Analysis xaus:

Cov kab nrib pleb nrog decarburization yuav tsum tau txheeb xyuas seb lawv puas yog cov khoom siv raw khoom tawg. Feem ntau, cov kab nrib pleb nrog decarburization qhov tob ntau dua lossis sib npaug ntawm qhov tob decarburization yog cov khoom siv raw, thiab cov kab nrib pleb nrog decarburization qhov tob tsawg dua qhov decarburization qhov tob yog forging tawg.

Nrog Anebon cov thev naus laus zis zoo ib yam li peb lub siab ntawm kev tsim kho tshiab, kev sib koom tes, cov txiaj ntsig thiab kev txhim kho, peb yuav tsim kom muaj kev vam meej yav tom ntej ua ke nrog koj cov lag luam zoo rau OEM Chaw Tsim Tshuaj Custom High Precision txhuas qhov chaw, tig hlau qhov chaw, cnc milling steel qhov chaw, Thiab tseem muaj ntau tus phooj ywg nyob txawv teb chaws tuaj pom, lossis tso siab rau peb mus yuav lwm yam khoom rau lawv. Koj yuav zoo siab txais tos tuaj rau Tuam Tshoj, rau Anebon lub nroog thiab rau Anebon lub chaw tsim khoom!

Tuam Tshoj Lag luam wholesale Tuam Tshoj machined Cheebtsam, cnc khoom, steel tig qhov chaw thiab stamping tooj liab. Anebon muaj cov cuab yeej siv ntau lawm, thiab nrhiav kev tshiab hauv cov khoom. Tib lub sijhawm, kev pabcuam zoo tau txhim kho lub koob npe zoo. Anebon ntseeg tias ntev npaum li koj nkag siab txog peb cov khoom, koj yuav tsum txaus siab los ua tus koom tes nrog peb. tos ntsoov rau koj qhov kev nug.

Post lub sij hawm: Feb-20-2023