Koj paub ntau npaum li cas txog tag nrho cov txheej txheem ntawm kev sib dhos tshuab?

Mechanical assembly yog cov txheej txheem ntawm kev sib sau ua ke ntau yam los tsim cov khoom siv tshuab ua haujlwm lossis cov khoom lag luam. Qhov no suav nrog kev nyeem ntawv thiab nkag siab txog kev kos duab kos duab, xaiv thiab siv cov cuab yeej tsim nyog thiab cov cuab yeej siv kom haum thiab sib dhos, txuas cov khoom siv nrog ntau yam txuj ci (xws li bolting, adhesives, los yog vuam), thiab ua cov kev ntsuam xyuas kom zoo los xyuas kom muaj kev ua haujlwm zoo. Cov txheej txheem sib dhos tuaj yeem ua raws li qhov xav tau thiab qhov nyuaj ntawm txhua yam khoom.

Kev npaj ua homework

(1)Cov ntaub ntawv ua haujlwm: suav nrog cov kos duab sib dhos dav dav (GA), cov khoom sib dhos kos duab (CA), qhov kos duab kos duab (PD), cov ntaub ntawv BOM thiab lwm yam. Qhov ua tiav, zoo huv si, thiab kev ncaj ncees ntawm tag nrho cov txheej txheem cov ntaub ntawv cov ntaub ntawv thiab cov duab kos yuav tsum tau khaws cia kom txog thaum kawg ntawm kev tsim kho. qhov project.

(2)Chaw ua haujlwm: Qhov chaw uas cov khoom raug muab tso thiab cov khoom sib dhos yuav tsum tau teev tseg. Nws yog ib qho tseem ceeb los npaj qhov chaw uas koj yuav sib sau ua ke thiab tso koj lub tshuab. Txhua qhov chaw ua haujlwm yuav tsum ua kom zoo, tsim qauv thiab txiav txim kom txog thaum qhov project tiav.

(3)Cov ntaub ntawv sib dhos. Cov ntaub ntawv sib dhos yuav tsum tau npaj ua ntej ua haujlwm. Qhov kev txiav txim ntawm kev ua haujlwm tuaj yeem hloov pauv yog tias tsis muaj qee yam khoom siv tsis raug txiav txim siab. Tom qab ntawv yuav tsum ua kom tiav daim ntawv thov kom tiav thiab xa mus rau lub chaw yuav khoom.

(4)Ua ntej sib dhos, Nws yog ib qho tseem ceeb kom nkag siab txog cov qauv, kev sib dhos txheej txheem thiab cov cuab yeej siv cuab yeej cuab tam.

Basic specification

(1) Lub tshuab sib dhos yuav tsum tau ua raws li kev ua raws li kev sib dhos, cov txheej txheem yuav tsum tau ua thiab cov lus qhia los ntawm pab pawg tsim. Nws yog txwv tsis pub hloov cov ntsiab lus ntawm kev ua hauj lwm yam tsis tau kev tso cai, los yog hloov qhov chaw nyob rau hauv ib qho kev txawv txav.

(2) Cov khoom sib dhos yuav tsum yog cov khoom uas dhau los ntawm kev tshuaj xyuas thiab kev pom zoo los ntawm lub tuam txhab kev lees paub zoo. Tshaj tawm tej yam tsis tsim nyog tau pom thaum lub rooj sib txoos.

(3) Qhov chaw sib dhos yuav tsum tsis txhob muaj plua plav thiab lwm yam kuab paug. Cov khoom yuav tsum tau khaws cia rau hauv qhov chaw tsis muaj plua plav, qhuav thiab tiv thaiv nrog cov ntaub qhwv.

(4) Cov khoom yuav tsum tau sib sau ua ke yam tsis raug tsoo, txiav lossis puas rau saum npoo. Txawm li cas los xij, lawv tuaj yeem khoov, twisted lossis deformed hauv txoj kev tseem ceeb. Lub mating nto yuav tsum tsis txhob puas.

(5) Thaum sib dhos cov khoom uas yog cov khoom txawb, nws raug nquahu kom ntxiv lubricating roj (roj) ntawm qhov chaw sib cuag.

(6) Qhov loj me ntawm qhov sib txuam yuav tsum yog qhov tseeb.

(7) Cov khoom thiab cov cuab yeej yuav tsum tau muab tso rau hauv ib txoj kev tshwj xeeb thaum sib dhos. Cov khoom thiab cov cuab yeej yuav tsum tsis txhob muab tso ncaj qha rau ntawm lossis rau saum lub tshuab. Nyob rau hauv cov xwm txheej uas yuav tsum tau tiv thaiv lev los yog ntaub pua plag, lawv yuav tsum tau muab tso rau hauv qhov chaw ntawm qhov chaw.

Nyob rau hauv txoj cai, nws yog txwv tsis pub kauj ruam ntawm lub tshuab thaum sib dhos. Nyob rau hauv qhov xwm txheej uas yuav tsum tau taug kev ntawm lub tshuab, cov ntaub pua plag lossis mats yuav tsum muab tso rau saum. Kev nce qib ntawm cov khoom tseem ceeb lossis cov khoom tsis yog hlau tsis muaj zog yog txwv nruj heev.

Koom txoj kev

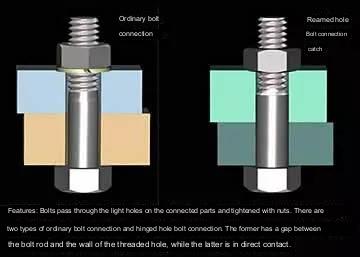

(1) Bolt txuas

A. Siv ib lub tshuab ntxhua khaub ncaws nkaus xwb thaum tuav cov bolts. Cov ntsia hlau taub hau yuav tsum tau muab tso rau hauv lub tshuab qhov chaw tom qab cov ntsia hlau countersunk tau nruj.

B. Nyob rau hauv dav dav threaded kev twb kev txuas xav tau los tiv thaiv xoob washers. Txoj kev rau zawm ntau symmetrical bolts yog kom nruj lawv maj mam thiab nyob rau hauv ib tug symmetrical yam. Strip connectors kuj tseem nruj me ntsis thiab symmetrically los ntawm nruab nrab sab nraud.

C. Thaum cov screws tsis tas yuav tsum tau disassembled thaum lub sij hawm fastening los yog txij nkawm ntawm cov khoom txav, lawv yuav tsum tau coated nyob rau hauv xov kua nplaum ua ntej sib dhos.

D. Ib tug torque ciaj ntswj yog siv los zawm fasteners uas tau teev torque yuav tsum tau. Bolts tsis muaj lub zog tshwj xeeb yuav tsum tau nruj raws li "Cov Ntawv Ntxiv" cov cai.

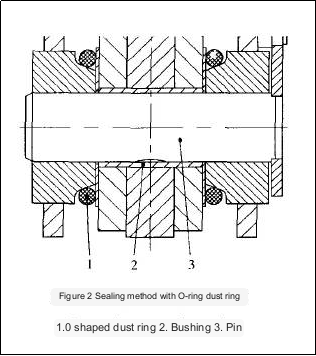

(2) Pin kev twb kev txuas

A. Feem ntau, lub ntsej muag kawg ntawm tus pin yuav tsum siab dua me ntsis ntawm qhov chawmilling cov khoom. Qhov loj kawg ntawm cov ntsia hlau-tail tapered tus pin yuav tsum tau muab tso rau hauv lub qhov tom qab nws tau muab tso rau hauv ib feem.

B. Lub cotter pin lub tails yuav tsum yog 60deg mus rau 90deg sib nrug tom qab nws tau raug thauj mus rau hauv qhov tsim nyog.

(3) Kev sib txuas tseem ceeb

A. Yuav tsum tsis txhob muaj qhov sib txawv ntawm cov mating nto ntawm lub tiaj tus thiab cov yuam sij ruaj khov.

B. Thaum qhov txav ntawm qhov tseem ceeb lossis spline txav mus rau hauv axial kev taw qhia tom qab sib dhos, yuav tsum tsis muaj qhov tsis sib xws.

C. Cov hlua khi thiab cov hlua khi yuav tsum tau sib sau ua ke kom lawv qhov chaw sib cuag tsis poob qis dua 70% ntawm tag nrho cov chaw ua haujlwm. Cov khoom tsis sib cuag yuav tsum tsis txhob muab ua ke, thiab yuav tsum tsis pub tshaj 10% -15% qhov ntev.

(4) Riveting

A. Cov ntaub ntawv thiab cov lus qhia tshwj xeeb rau riveting yuav tsum ua raws li cov qauv tsim. Kev ua tiav ntawm qhov ntawm cov rivets yuav tsum ua raws li cov qauv tsim nyog.

B. Qhov saum npoo ntawm rivetedaluminium Cheebtsamyuav tsum tsis txhob puas los yog deformed thaum riveting.

C. Yuav tsum tsis txhob xoob ntawm qhov riveted, tshwj tsis yog tias muaj cov cai tshwj xeeb. Lub taub hau ntawm rivets yuav tsum nyob rau hauv kev sib cuag nrog riveted ib feem thiab du thiab puag ncig.

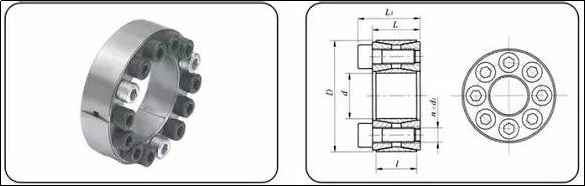

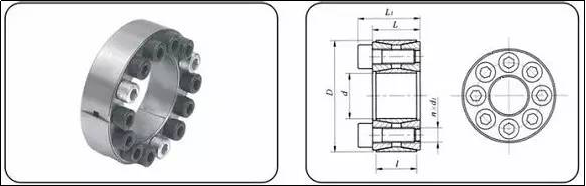

(5) Lub tes tsho nthuav dav txuas

Lub tes tsho nthuav dav sib dhos: Siv cov roj lubricating rau lub tes tsho nthuav dav, muab lub tes tsho nthuav dav rau hauv qhov sib dhos hub qhov, ntxig rau cov ncej installation, kho txoj haujlwm sib dhos, thiab tom qab ntawd kom nruj cov bolts. Qhov kev txiav txim nruj yog bounded los ntawm txoj hlua, thiab sab laug thiab sab xis yog hla thiab symmetrically tightened successively los xyuas kom meej tias tus nqi torque tau mus txog.

(6) Tight kev twb kev txuas

Teem screws nrog conical xaus yuav tsum muaj 90-degree tapered kawg. Lub qhov yuav tsum yog 90 degrees.

Kev teeb tsa ntawm cov ntawv qhia linear

(1) Lub installation nto ntawm txoj kev tsheb ciav hlau yuav tsum tiaj tus thiab tsis muaj av.

(2) Yog hais tias cov kev taw qhia rail muaj ib tug siv ntug, lub tsheb ciav hlau yuav tsum tau ntsia ze ntawm ntug. Yog tias tsis muaj kev siv ntug, ces qhov kev taw qhia zawv zawg yuav tsum phim cov qauv tsim. Txheeb xyuas cov kev taw qhia swb tom qab zawm cov ntsia hlau ntawm cov kev taw qhia rail. Yog tsis yog, nws yuav tsum tau kho.

(3) Yog hais tias tus swb yog tsav los ntawm kev sib kis txoj siv, ces cov siv yuav tsum tau kho thiab tensioned ua ntej txoj siv yuav raug rub nyob rau hauv ib tug oblique kev taw qhia. Txwv tsis pub, lub pulley yuav tsum tau hloov kho kom ntseeg tau tias txoj siv txoj kev tsav tsheb yog sib npaug nrog cov kev taw qhia rail.

Sib dhos ntawm sprocket chains

(1) Lub sprocket yuav tsum tau tsim los koom tes nrog cov ncej.

(2) Cov hniav iav ntawm ob qho tib si tsav thiab tsav sprockets yuav tsum muaj tib lub dav hlau geometric nruab nrab, thiab lawv cov offsets yuav tsum tsis pub tshaj qhov tsim nyog. Nws yuav tsum tsawg dua lossis sib npaug li 2% 0, yog tias tsis tau teev los ntawm tus qauv tsim.

(3) Sab ua hauj lwm ntawm cov saw yuav tsum nruj thaum nws meshes nrog ib tug sprocket.

(4) Cov saw sag ntawm sab uas tsis siv yuav tsum nyob hauv qhov txwv ntawm qhov tsim. Nws yuav tsum tau kho yog tias nws tsis tau teev nyob rau hauv tus tsim.

Iav sib dhos

(1) Thaum lub iav ntug yog 20mm los yog tsawg dua, axial misalignment yuav tsum tsis pub tshaj 1 hli. Yog hais tias lub iav dav yog ntau tshaj 20mm, misalignment tsis tuaj yeem tshaj 5%.

(1) JB180-60 "Bevel Gear kis tau tus mob", JB162 thiab JB162 yuav tsum qhia meej qhov tseeb ntawm kev teeb tsa rau cov cylindrical zog thiab bevel iav.

Raws li cov kev cai, lub meshing nto ntawm iav yuav tsum tau lubricated raws li ib txwm xyaum. Lub gearbox yuav tsum tau sau rau theem kab nrog lubricating roj.

(4) Lub suab nrov ntawm kev sib kis ntawm tag nrho cov load yuav tsum tsis pub tshaj 80dB.

Rack kho thiab kev sib txuas

(1) Racks nyob rau hauv ntau seem ntawm cov racks yuav tsum tau teem rau tib qhov siab, siv tib lub ntsiab lus.

(2) Tag nrho cov racks 'phab ntsa panels yuav tsum tau ua raws li tib lub dav hlau ntsug.

(3) Cov hlau txuas ruaj khov yuav tsum tau muab ntsia nruab nrab ntawm cov ntu tom qab cov racks tau hloov kho rau qhov siab thiab qhov ntev.

Kev sib dhos ntawm pneumatic Cheebtsam

(1) Kev teeb tsa ntawm txhua pawg ntawm cov khoom siv pneumatic yuav tsum tau txuas nrog nruj me ntsis raws li daim duab pneumatic Circuit Court muab los ntawm lub tuam tsev tsim. Lub cev lub cev, cov yeeb nkab txuas, lub tog raj kheej, thiab lwm yam yuav tsum tau txuas kom raug.

(2) Lub qhov hluav taws xob thiab qhov hluav taws xob ntawm tag nrho cov cua nkag siab txo lub valve yog txuas nrog rau hauv cov kev taw qhia ntawm xub, thiab lub khob dej thiab roj khob ntawm lub tshuab lim cua thiab lubricator yuav tsum tau nruab vertically downward.

(3) Ua ntej piping, txiav cov hmoov thiab hmoov av hauv cov yeeb nkab yuav tsum tau tawg tag nrho.

(4) Cov yeeb nkab txuas yog threaded. Yog hais tias cov yeeb nkab xov tsis muaj xov kua nplaum, cov ntaub ntawv raw khoom yuav tsum tau qhwv. Txoj kev winding yog clockwise thaum saib los ntawm pem hauv ntej. Cov ntaub ntawv raw khoom yuav tsum tsis txhob muab sib xyaw rau hauv lub valve. Cov ntaub ntawv raw khoom yuav tsum tsis txhob muab sib xyaw rau hauv lub valve. Thaum winding, ib txoj xov yuav tsum tau tseg.

(5) Cov txheej txheem ntawm lub trachea yuav tsum zoo huv si thiab zoo nkauj, thiab sim tsis txhob hla txoj kev npaj. 90deg luj tshib yuav tsum tau siv ntawm cov ces kaum. Thaum kho lub trachea, tsis txhob muab cov kev ntxhov siab ntxiv rau cov pob qij txha, txwv tsis pub nws yuav ua rau cov pa tawm.

(6) Thaum txuas lub solenoid valve, xyuam xim rau kev ua haujlwm ntawm txhua qhov chaw nres nkoj cua ntawm lub valve: P: tag nrho cov cua nkag; A: cua qhov hluav taws xob 1; B: cua qhov hluav taws xob 2; R (EA): tso zis sib npaug rau A; S (EB): Exhaust corresponding to B.

(7) Thaum lub tog raj kheej sib sau ua ke, lub axis ntawm piston pas nrig thiab cov kev taw qhia ntawm kev thauj khoom yuav tsum zoo ib yam.

(8) Thaum siv cov kab qhia kev coj tus kheej, tom qab qhov kawg ntawm lub tog raj kheej piston pas nrig txuas nrog lub load, yuav tsum tsis txhob muaj kev quab yuam txawv txawv thaum lub sij hawm tag nrho cov hlab ntsha, txwv tsis pub lub tog raj kheej yuav puas.

(9) Thaum siv lub throttle valve, koj yuav tsum tau xyuam xim rau hom lub throttle valve. Feem ntau hais lus, nws yog qhov txawv ntawm qhov loj xub cim rau ntawm lub cev valve. Cov xub loj taw tes rau xov kawg yog siv rau lub tog raj kheej; lub xub loj taw tes rau cov yeeb nkab kawg yog siv rau lub solenoid valve. .

Kev kuaj xyuas ua haujlwm

(1) Txhua zaus kev sib dhos ntawm cov khoom tiav, nws yuav tsum tau kuaj xyuas raws li cov khoom hauv qab no. Yog tias pom muaj teeb meem kev sib dhos, nws yuav tsum tau tshuaj xyuas thiab kho raws sijhawm.

A. Kev ncaj ncees ntawm kev sib dhos ua haujlwm, xyuas cov duab kos, thiab xyuas seb puas muaj cov khoom ploj lawm.

B. Rau qhov tseeb ntawm lub installation txoj hauj lwm ntawm txhua qhov chaw, xyuas cov duab los ua ke los yog cov yuav tsum tau teev nyob rau hauv cov lus qhia saum toj no.

C. Kev ntseeg tau ntawm txhua qhov txuas, seb txhua qhov txuas txuas mus txog qhov torque xav tau rau kev sib dhos, thiab seb cov fasteners tshwj xeeb ua tau raws li qhov yuav tsum tau ua kom tsis txhob xoob.

D. Qhov yooj yim ntawm kev txav ntawm cov khoom txav, xws li seb puas muaj kev sib tsoo lossis stagnation, eccentricity los yog dabtsi yog khoov thaum manually rotating los yog txav conveyor rollers, pulleys, coj rails, thiab lwm yam.

(2) Tom qab kev sib dhos zaum kawg, kev tshuaj xyuas tseem ceeb yog los xyuas cov kev sib txuas ntawm cov khoom sib dhos. Cov ntsiab lus tshuaj xyuas yog ua raws li "plaub yam khoom" teev nyob rau hauv (1) raws li tus qauv ntsuas.

(3) Tom qab kev sib dhos zaum kawg, cov ntaub ntawv hlau, cov khib nyiab, plua plav, thiab lwm yam hauv txhua qhov chaw ntawm lub tshuab yuav tsum tau muab ntxuav kom huv si kom tsis txhob muaj kev cuam tshuam ntawm cov khoom sib kis.

(4) Thaum kuaj lub tshuab, ua tib zoo saib xyuas cov txheej txheem pib. Tom qab lub tshuab pib, tam sim ntawd saib xyuas cov kev ua haujlwm tseem ceeb thiab seb cov khoom txav txav mus li cas.

(5) Cov kev ua haujlwm tseem ceeb suav nrog kev ceev ntawm kev txav, smoothness ntawm kev txav, kev sib hloov ntawm txhua kis ncej, kub, vibration thiab suab nrov, thiab lwm yam.

Anebon yuav ua rau txhua qhov kev ua haujlwm nyuaj los ua qhov zoo tshaj plaws thiab zoo heev, thiab ua kom peb cov kev ntsuas rau sawv los ntawm cov qib siab ntawm intercontinental sab saum toj-qib thiab high-tech tuam txhab rau Tuam Tshoj Kub Supplier rau OEM, Kev cai cnc machining kev pab cuam, Sheet Hlau fabrication kev pab cuam, milling kev pabcuam. Anebon yuav ua koj tus kheej kev yuav khoom kom tau raws li koj tus kheej txaus siab! Anebon lub lag luam teeb tsa ntau lub tuam tsev, suav nrog cov chaw tsim khoom, cov nyiaj tau los, chav tswj xyuas zoo thiab chaw pabcuam, thiab lwm yam.

Factory Supply Tuam Tshojprecision tig qhov chawthiab Aluminium Part, Koj tuaj yeem qhia rau Anebon paub koj lub tswv yim los tsim cov qauv tsim tshwj xeeb rau koj tus kheej cov qauv kom tsis txhob muaj qhov zoo sib xws hauv khw! Peb yuav muab peb cov kev pabcuam zoo tshaj plaws kom txaus siab rau txhua yam koj xav tau! Nco ntsoov hu rau Anebon tam sim ntawd!

Post lub sij hawm: Sep-04-2023