Kev kho deg yog tsim ib txheej txheej nrog ib lossis ntau qhov tshwj xeeb ntawm cov khoom siv los ntawm kev siv lub cev lossis tshuaj. Kev kho deg tuaj yeem txhim kho cov khoom zoo li, kev ntxhib los mos, kev ua haujlwm, thiab lwm yam ntawm kev ua haujlwm.

1. Anodizing

Nws yog tsuas yog anodic oxidation ntawm txhuas, uas siv lub hauv paus ntsiab lus ntawm electrochemistry los tsim ib txheej ntawm Al2O3 (txhuas oxide) zaj duab xis rau saum npoo ntawm txhuas thiab txhuas alloys. Cov oxide zaj duab xis txheej no muaj cov khoom tshwj xeeb xws li kev tiv thaiv, kho kom zoo nkauj, rwb thaiv tsev thiab hnav tsis kam.Anodized kub CNC tig ib feem

Txheej txheem khiav:

Monochrome, gradient xim: polishing / sandblasting / kos duab → degreasing → anodizing → neutralizing → dyeing → sealing → ziab

Ob-xim:

① Polishing / sandblasting / hlau kos duab → degreasing → npog → anodizing 1 → anodizing 2 → sealing → ziab

② Polishing / sandblasting / hlau kos duab → degreasing → anodizing 1 → laser engraving → anodizing 2 → sealing → ziab

Technical nta:

1. Ua kom muaj zog

2. Paub txhua yam xim tshwj tsis yog dawb

3. Ua tiav nickel-dawb sealing thiab ua tau raws li qhov yuav tsum tau muaj ntawm Tebchaws Europe, Tebchaws Asmeskas thiab lwm lub tebchaws kom tsis muaj nickel.

Kev nyuaj siab thiab cov ntsiab lus tseem ceeb rau kev txhim kho: qib yield ntawm anodizing muaj feem xyuam rau tus nqi ntawm cov khoom kawg. Tus yuam sij rau kev txhim kho oxidation yield yog qhov tsim nyog tus nqi ntawm oxidant, tsim nyog qhov kub thiab txias tam sim no, uas yuav tsum tau cov txheej txheem tivthaiv manufacturers txuas ntxiv mus tshawb hauv cov txheej txheem ntau lawm, nrhiav kev ua kom tiav. (Peb pom zoo kom koj ua tib zoo saib rau "Mechanical Engineer" pej xeem account, thiab paub txog kev paub txog cov khoom qhuav thiab cov ntaub ntawv kev lag luam kom sai li sai tau)

Cov khoom pom zoo: E + G arc kov, ua los ntawm cov khoom siv anodized, ib puag ncig tus phooj ywg thiab ruaj khov.CNC machining stainless hlau.

2. Electrophoresis

Siv nyob rau hauv stainless hlau, aluminium alloy, thiab lwm yam., nws tuaj yeem ua rau cov khoom qhia ntau yam xim, tswj cov xim hlau, thiab tib lub sij hawm txhim kho qhov kev ua tau zoo, nrog kev ua haujlwm zoo los tiv thaiv corrosion.

Txheej txheem khiav: pretreatment → electrophoresis → ziab

qhov zoo:

1. Cov xim nplua nuj;

2. Tsis muaj hlau zoo nkauj, tuaj yeem koom tes nrog sandblasting, polishing, hlau kos duab, thiab lwm yam;

3. Kev ua haujlwm nyob rau hauv ib puag ncig ua kua tuaj yeem paub txog kev kho saum npoo ntawm cov qauv nyuaj;

4. Cov thev naus laus zis yog qhov paub tab thiab tuaj yeem tsim tawm ntau.

Disadvantages: Lub peev xwm los npog qhov tsis xws luag yog dav dav, thiab electrophoresis ntawm tuag castings yuav tsum tau pretreatment ntau dua.

3. Micro-arc oxidation

Cov txheej txheem ntawm kev siv hluav taws xob siab hauv cov tshuaj electrolyte (feem ntau yog cov tshuaj tsis muaj zog alkaline) los tsim cov txheej txheem ceramic nto, uas yog qhov tshwm sim ntawm kev sib koom ua ke ntawm lub cev tawm thiab electrochemical oxidation.

Txheej txheem khiav: pretreatment → dej kub ntxuav → MAO → ziab

qhov zoo:

1. Ceramic kev ntxhib los mos, dull tsos, tsis muaj high-gloss khoom, ilv tes zoo, anti-ntiv tes;

2. Ntau yam ntawm substrates: Al, Ti, Zn, Zr, Mg, Nb, thiab lawv cov alloys, thiab lwm yam;

3. Lub pretreatment yog yooj yim; cov khoom muaj zoo heev corrosion thiab huab cua tsis kam thiab zoo tshav kub dissipation kev ua tau zoo.

Disadvantages: Tam sim no, xim yog txwv; tsuas yog dub thiab grey yog cov paub tab, thiab cov xim ci yog tam sim no nyuaj rau ua tiav; tus nqi yog feem ntau cuam tshuam los ntawm kev siv hluav taws xob siab, thiab nws yog ib qho ntawm cov nqi siab tshaj plaws hauv kev kho deg.

4. PVD nqus plating

Lub npe tag nrho yog lub cev vapor deposition, cov txheej txheem tsim khoom siv feem ntau siv cov txheej txheem lub cev los tso cov yeeb yaj kiab nyias.CNC machining qhov chaw

Cov txheej txheem ntws: ua ntej PVD tu → nqus tsev rau hauv lub cub tawg → lub hom phiaj ntxuav thiab ion tu → txheej → txheej tiav, txias tawm ntawm lub cub tawg → tom qab ua tiav (polishing, AFP) (Peb xav kom koj them sai sai rau "Mechanical Engineer" official account, thawj zaug los tuav cov khoom qhuav paub, kev lag luam cov ntaub ntawv)

Cov yam ntxwv tshwj xeeb: PVD (Lub Cev Vapor Deposition, Lub Cev Vapor Deposition) tuaj yeem pleev xim rau cov hlau uas muaj zog plating thiab hnav tsis kam cermet hniav txheej.

5. Electroplating

Nws yog cov cuab yeej siv hluav taws xob los txuas cov txheej txheem ntawm cov yeeb yaj kiab hlau rau saum npoo ntawm cov hlau los tiv thaiv corrosion, txhim kho hnav tsis kam, hluav taws xob conductivity, reflectivity, thiab txhim khu kev zoo nkauj.

Txheej txheem khiav: pretreatment → cyanide-dawb alkali tooj liab → cyanide-free cupronickel tin → chrome plating

Qhov zoo:

1. Cov txheej txheej muaj lub ntsej muag zoo nkauj thiab zoo nkauj zoo nkauj;

2. Cov khoom siv hauv paus yog SUS, Al, Zn, Mg, thiab lwm yam; tus nqi qis dua PVD.

Qhov tsis zoo: kev tiv thaiv ib puag ncig tsis zoo thiab muaj kev pheej hmoo siab ntawm kev ua qias tuaj ib puag ncig.

6. hmoov txheej

Cov hmoov txheej yog txau rau saum npoo ntawm qhov chaw ua haujlwm los ntawm cov khoom siv tshuaj txau (electrostatic spraying tshuab). Nyob rau hauv qhov hluav taws xob zoo li qub, cov hmoov yuav sib npaug ntawm qhov chaw ntawm lub workpiece los tsim cov hmoov txheej. Nws kho kom haum thiab dhau los ua txheej txheej kawg nrog ntau yam teebmeem (txhim kho qhov sib txawv rau cov hmoov txheej).

Cov txheej txheem thev naus laus zis: sab sauv → electrostatic plua plav tshem tawm → txau → qis kub theem → ci

Qhov zoo:

1. Cov xim nplua nuj, siab gloss thiab matte yeem;

2. Tus nqi qis, tsim nyog rau lub tsev cov khoom siv rooj tog thiab cov plhaub ntawm cov dab dej kub, thiab lwm yam .;

3. Kev siv siab, 100% kev siv, kev tiv thaiv ib puag ncig;

4. Muaj peev xwm npog qhov tsis xws luag; 5. Nws tuaj yeem ua raws li cov nyhuv ntoo.

Disadvantages: Tam sim no siv hauv cov khoom siv hluav taws xob tsawg dua.

7. Hlau hlau kos duab

Nws yog txoj kev kho saum npoo uas tsim cov kab ntawm qhov chaw ua haujlwm los ntawm kev sib tsoo cov khoom, uas muaj cov nyhuv zoo nkauj. Cov kab sib txawv, tom qab kos duab, tuaj yeem muab faib ua cov kab ncaj nraim, cov qauv random, cov qauv corrugated, thiab cov qauv swirl.

Cov yam ntxwv tshwj xeeb: Kev kho hlau kos duab tuaj yeem muab cov hlau saum npoo uas tsis yog daim iav zoo li cov hlau nplaum, thiab cov hlau kos duab kho kuj tuaj yeem tshem tawm qhov tsis xws luag ntawm cov hlau nto.

Cov khoom pom zoo: LAMP kov, Zwei L kho, siv kev sib tsoo zoo heev los qhia qhov saj.

8. Sandblasting

Nws yog cov txheej txheem uas compressed cua yog siv los ua lub zog los tsim cov kab hluav taws xob nrawm nrawm los txau cov khoom siv tshuaj tsuag rau ntawm qhov chaw ua haujlwm kom raug kho ntawm kev kub ceev kom cov tsos los yog cov duab ntawm sab nrauv ntawm lub workpiece. Qhov chaw hloov pauv, thiab qee qhov kev huv huv thiab qhov sib txawv roughness tau txais.

Technical nta:

1. Kom ua tiav qhov sib txawv ntawm qhov sib txawv lossis matt.

2. Nws tuaj yeem ntxuav cov burrs me me ntawm qhov chaw ua haujlwm thiab ua kom lub ntsej muag ntawm lub workpiece smoother, tshem tawm cov kev puas tsuaj ntawm burrs thiab txhim kho qib ntawm cov khoom ua haujlwm.

3. Tshem tawm cov av uas seem tshuav nyob rau hauv pretreatment, txhim kho lub smoothness ntawm lub workpiece, ua rau lub workpiece qhia ib tug uniform thiab zoo hlau xim xim, thiab ua kom lub workpiece zoo nkauj thiab zoo nkauj. (Peb pom zoo kom koj ua tib zoo saib rau "Mechanical Engineer" pej xeem tus account thiab paub txog kev paub txog cov khoom qhuav thiab cov ntaub ntawv kev lag luam kom sai li sai tau)

Khoom pom zoo: E + G classic choj kov, sandblasted nto, high-end cua.

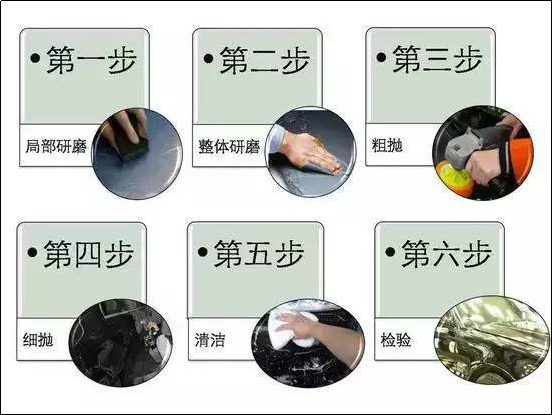

9. Polishing

Ua kom tiav lub workpiece nto siv cov cuab yeej hloov tau yooj yim polishing, cua abrasive particle, thiab lwm yam xov xwm polishing. Rau cov txheej txheem polishing sib txawv, xws li polishing ntxhib (cov txheej txheem polishing), nruab nrab polishing (txheej txheem txheej), thiab polishing zoo (cov txheej txheem glazing), xaiv cov polishing uas tsim nyog tuaj yeem ua tiav qhov zoo tshaj plaws polishing nyhuv thiab txhim kho polishing efficiency.

Technical nta: Txhim kho lub workpiece qhov seem lossis geometric duab raug, tau ib tug du nto los yog daim iav gloss, thiab tshem tawm gloss.

Khoom pom zoo: E + G ntev kov, polished nto, yooj yim thiab elegant

10. Etching

Feem ntau hu ua etching, tseem hu ua photochemical etching, nws muaj feem xyuam rau kev tshem tawm cov yeeb yaj kiab tiv thaiv hauv cheeb tsam yuav tsum tau etched tom qab raug rau phaj ua thiab kev loj hlob thiab kev sib cuag nrog cov tshuaj tov thaum lub sij hawm etching kom tiav cov nyhuv ntawm dissolution thiab corrosion. , tsim concave-convex lossis hollow molding nyhuv.

Txheej txheem khiav:

Txoj kev raug: Lub phiaj xwm npaj qhov loj ntawm cov khoom raws li cov duab kos duab - kev npaj cov khoom - cov khoom tu - ziab → zaj duab xis los yog txheej → ziab → raug → kev loj hlob → ziab - etching → stripping → OK

Cov txheej txheem luam ntawv: txiav cov khoom → ntxuav phaj (stainless hlau thiab lwm yam khoom siv hlau) → tshuaj ntsuam luam ntawv → etching → stripping → OK

Qhov zoo:

1. Nws tuaj yeem nqa tawm micro-kev ua haujlwm ntawm cov hlau nto;

2. Muab cov teebmeem tshwj xeeb rau cov hlau nto;

Disadvantages: Feem ntau corrosive kua (acids, alkalis, thiab lwm yam) siv nyob rau hauv etching ua phem rau ib puag ncig.

Anebon Hlau Khoom Limited tuaj yeem muab CNC Machining, Tuag Casting, Sheet Hlau Fabrication kev pabcuam, thov koj xav tiv tauj peb.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Post lub sij hawm: Apr-08-2022