Koj paub ntau npaum li cas txog kev tsim kho tshuab?

Kev tsim kho tshuab yog ib ceg ntawm engineering uas siv ntau lub hauv paus ntsiab lus thiab cov tswv yim los tsim, txheeb xyuas thiab ua kom zoo dua cov tshuab thiab cov khoom siv. Kev tsim kho tshuab suav nrog kev nkag siab txog lub hom phiaj ntawm cov khoom siv lossis cov txheej txheem, xaiv cov khoom tsim nyog, suav nrog ntau yam, xws li kev ntxhov siab thiab cov kab mob thiab kev quab yuam, thiab ua kom ntseeg tau thiab ua haujlwm tau zoo.

Mechanical tsim muaj xws li tshuab tsim, qauv tsim, tsim mechanism thiab tsim khoom. Cov khoom tsim muaj kev txhawj xeeb nrog kev tsim cov khoom siv lub cev xws li cov khoom siv, cov khoom siv thiab lwm yam khoom siv. Lub tshuab tsim, ntawm qhov tod tes, tsom rau kev tsim cov tshuab xws li cav, turbines thiab cov cuab yeej tsim khoom. Mechanism tsim muaj kev txhawj xeeb nrog kev tsim cov txheej txheem uas hloov cov khoom nkag mus rau qhov xav tau. Kev tsim qauv yog cov kauj ruam kawg. Nws suav nrog kev tsom xam thiab tsim cov qauv xws li txuas hniav, cov tsev, thiab cov thav ntawv rau lawv lub zog, ruaj khov, kev nyab xeeb, thiab kav ntev.

Cov txheej txheem tsim tshwj xeeb zoo li cas?

Cov txheej txheem tsim qauv feem ntau suav nrog ntau cov kauj ruam, xws li kev txheeb xyuas qhov teeb meem kev tshawb fawb thiab kev tsom xam, kev tsim lub tswv yim thiab cov ncauj lus kom ntxaws tsim thiab prototyping, nrog rau kev sim thiab kev nthuav dav. Nyob rau hauv cov theem no engineers siv ntau cov tswv yim thiab cov cuab yeej xws li computer-aided design (CAD) software, finite element analysis (FEA) thiab simulation los xyuas thiab txhim kho tus tsim.

Yam dab tsi uas cov neeg tsim qauv yuav tsum xav txog?

Kev tsim kho tshuab feem ntau suav nrog cov khoom xws li kev tsim khoom, ergonomics, kev ua haujlwm tau zoo thiab kev ruaj ntseg. Cov kws tsim qauv sim tsim cov qauv uas tsis yog tsuas yog siv tau thiab ua tau zoo txawm li cas los xij, lawv kuj yuav tsum xav txog cov neeg siv khoom xav tau, kev cuam tshuam ib puag ncig thiab kev txwv nyiaj txiag.

Nws yog ib qho tseem ceeb uas yuav tsum nco ntsoov tias thaj chaw ntawm kev tsim kho tshuab ib qho kev nthuav dav thiab txuas ntxiv mus nrog cov ntaub ntawv tshiab, thev naus laus zis thiab cov txheej txheem tsim los tas li. Yog li, cov neeg tsim khoom siv tshuab yuav tsum txuas ntxiv kho lawv cov kev txawj ntse thiab kev paub kom nyob twj ywm hauv qhov ua ntej ntawm kev txhim kho thev naus laus zis.

Cov hauv qab no yog cov ntsiab lus kev paub txog kev tsim kho tshuab sau thiab teeb tsa los ntawm Anebon pab pawg engineering los qhia rau cov npoj yaig.

1. Qhov ua rau tsis ua hauj lwm hauv cov khoom siv tshuab yog: kev puas tsuaj dav dav lossis ntau dhau qhov seem deformation nto puas tsuaj rauprecision tig Cheebtsam(corrosion hnav, txhuam kev qaug zog thiab hnav) Ua tsis tiav vim muaj kev cuam tshuam ntawm kev ua haujlwm ib txwm muaj.

2. Cov khoom tsim tsim yuav tsum muaj peev xwm ua tau raws li: cov kev cai kom tsis txhob ua tsis tau raws li lub sijhawm teev tseg (lub zog los yog nruj, lub sijhawm) thiab cov kev xav tau ntawm cov txheej txheem, kev lag luam, kev xav tau zoo, thiab cov kev xav tau rau kev ntseeg siab.

3. Cov qauv tsim ib feem muaj xws li cov qauv muaj zog, cov qauv nruj ntawm lub neej, cov qauv kev vibration stability thiab kev ntseeg siab.

4. Txoj kev tsim ib feem: theoretical design, empirical design, model test design.

5. Feem ntau siv rau cov khoom siv tshuab yog cov khoom siv rau cov khoom siv kho tshuab xws li cov khoom siv ceramic, cov khoom siv polymer thiab cov khoom sib xyaw.

6. Lub zog ntawm lubmachined qhov chawyog muab faib ua static stress strength as well as variable stress strength.

7. Qhov kev ntxhov siab piv r = -1 yog asymmetrical cyclic stress. tus piv r = 0 qhia tau hais tias elongated cyclic stress.

8. Nws ntseeg tau tias theem BC yog hu ua strain fatigue (low cycle fatigue); CD yog theem kawg ntawm lub neej qaug zog. kab ntu tom qab D point sawv cev rau theem infinity life-failure ntawm tus qauv. D yog qhov txwv mus tas li rau kev qaug zog.

9. Cov tswv yim los txhim kho lub zog ntawm qhov chaw thaum qaug zog Txo qhov cuam tshuam ntawm kev ntxhov siab concentration raucnc milled qhov chawkom muaj peev xwm loj tshaj plaws (load txo qhov zawj qhib qhov zawj) Xaiv cov khoom siv nrog lub zog qaug zog thiab tseem qhia txog cov txheej txheem rau kev kho cua sov thiab cov txheej txheem ntxiv dag zog uas ua rau kom muaj zog ntawm cov ntaub ntawv qaug zog.

10. Kev sib txhuam zawv zawg: Kev sib txhuam qhuav ntawm thaj tsam kev sib txhuam, kev sib txhuam dej, thiab kev sib txhuam sib xyaw.

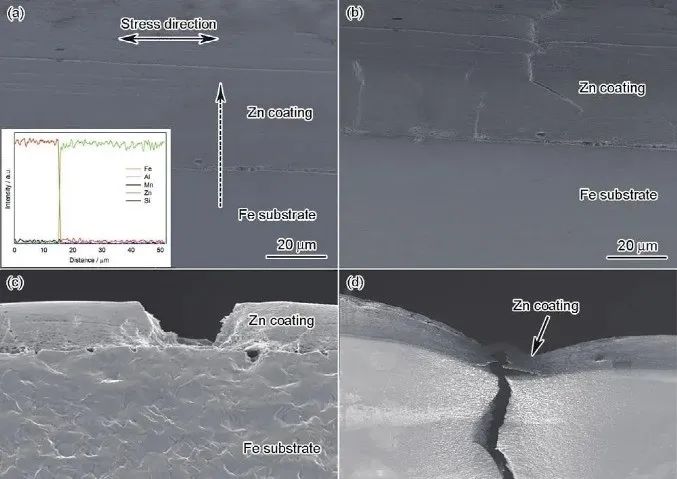

11. Cov txheej txheem hnav rau cov khoom muaj xws li cov khoom siv khiav hauv theem thiab cov theem hnav ruaj khov thiab theem hnyav hnyav. Kev siv zog yuav tsum tau ua kom txo qis lub sijhawm rau kev khiav-hauv, txuas ntxiv lub sijhawm ntawm kev ruaj khov thiab ncua sij hawm qhov tshwm sim ntawm kev hnav uas hnyav heev.

12. Kev faib tawm ntawm kev hnav yog Abrasive hnav, nplaum hnav thiab qaug zog corrosion hnav, erosion hnav thiab fretting hnav.

13. Lubricants muaj peev xwm muab faib ua plaub yam uas yog kua, roj semi-khoom, khoom thiab kua roj greases yog muab faib ua peb pawg: calcium-based greases nano-based greases lithium-based grease, aluminium-based grease, thiab aluminium-based greases.

14. Tus txheej txheem txuas xov hniav tsim yog ib qho kev sib npaug ntawm daim duab peb sab uas muaj cov khoom zoo ntawm tus kheej thiab kev sib kis ntawm cov xov sib sib zog nqus kis tau zoo dua rau lwm cov xov. Trapezoidal threads yog cov khoom siv dav siv ntau tshaj plaws.

15. Feem ntau ntawm kev sib txuas cov xov muaj peev xwm ua rau nws tus kheej, yog li ntawd ib leeg xov xov yog feem ntau siv. Kev sib kis xov xav tau kev ua haujlwm siab rau kev sib kis thiab yog li ntawd cov xov triple, los yog ob txoj xov xov feem ntau yog siv.

16. Bolt kev twb kev txuas ntawm ib txwm hom (los ntawm lub qhov los yog hinged qhov uas yog qhib rau ntawm qhov chaw uas txuas) kev sib txuas, stud kev twb kev txuas ntsia hlau txuas, teem ntsia hlau txuas.

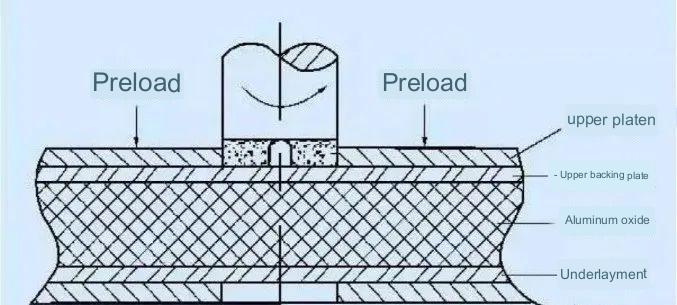

17. Yog vim li cas rau threaded kev twb kev txuas pre-tightening yog los txhim kho lub zog thiab durability ntawm kev twb kev txuas. Nws kuj tseem pab kom tsis txhob muaj qhov khoob thiab zawv zawg ntawm cov khoom tom qab thauj khoom. Qhov teeb meem tseem ceeb ntawm kev sib txuas threaded loosening yog los tiv thaiv kev sib hloov ntawm cov ntsia hlau thaum thauj khoom. (Kev sib txhuam los tiv thaiv kev xoob, kev tiv thaiv kev tiv thaiv kom tsis txhob xoob, dissolving cov ntsia hlau-pair kev sib raug zoo)

18. Cov txheej txheem los ua kom lub zog ntawm cov xov sib txuas txo qhov amplitude ntawm cov kev ntxhov siab uas cuam tshuam rau lub zog ntawm kev qaug zog ntawm lub ntsia liaj qhov rooj (txo qis qhov nruj ntawm lub ntsia liaj qhov rooj nrog rau kev ua kom nruj rau cov khoom sib txuas) thiab txhim kho qhov tsis sib xws ntawm kev thauj khoom ntawm cov ntsia hlau. cov hniav ntawm threads, txo cov nyhuv los ntawm kev ntxhov siab concentration thiab siv cov txheej txheem tsim tau zoo.

19. Ntsiab kev sib txuas hom Ntsiab kev sib txuas hom: tiaj tus (ob tog muaj chaw ua hauj lwm) semicircular key connector wedge key connector tangential key connection.

20. Kev siv txoj hlua khi tuaj yeem muab faib ua ob hom: meshing hom thiab kev sib txhuam hom.

21. Thawj qhov kev ntxhov siab tshaj plaws ntawm txoj siv yog nyob rau hauv qhov chaw uas qhov kawg ntawm txoj siv tawv pib txav mus los ntawm lub rubey me me. Qhov nro hloov 4 zaug thaum lub sijhawm kawm ntawm txoj siv.

22. Tensioning ntawm V-siv kis tau tus mob: tsis tu ncua tensioning ntaus ntawv, tsis siv neeg tensioning ntaus ntawv, tensioning ntaus ntawv siv tensioning pulley.

23. Cov saw txuas suav nrog hauv cov saw hlau feem ntau sib npaug (cov nyiaj ntawm cov hniav hauv lub sprocket yog ib tus lej coj txawv txawv) thiab cov saw txuas txuas ntxiv yog siv thaum tus lej ntawm cov saw txuas yog tus lej khib.

24. Yog vim li cas rau tensioning ntawm cov saw tsav yog kom ntseeg tau tias meshing tsis faulty thiab tsis txhob saws kev co yog hais tias lub sag ntawm lub xoob kawg uas yog loj heev thiab kuj yuav ua rau kom lub meshing nrug ntawm cov saw raws li sprocket.

25. Qhov ua rau tsis ua hauj lwm ntawm cov iav yog cov hniav tawg, hnav ntawm cov hniav nto (qhib iav) lub pitting ntawm cov hniav (kaw iav) Cov hniav nto nplaum thiab deformation ntawm cov yas (ridges yog pom ntawm cov tsav tsheb cov kab tshwm nyob rau hauv. lub kauj tsheb).

26. Cov iav uas muaj qhov nyuaj ntawm ntau dua 350HBS thiab 38HRS yog lub npe hu ua tawv ntsej muag lossis, yog tias lawv tsis yog, cov iav muag muag muag.

27. Txhim kho qhov raug precision thiab txo qhov loj ntawm lub iav kom txo qhov ceev ntawm nws mus yuav txo tau lub dynamic load. Yuav kom txo qhov load dynamically, lub cuab yeej yuav raug kho rau saum nws. cov hniav ntawm cov iav yog tsim rau hauv lub nruas los txhim kho qhov zoo ntawm cov iav hniav. mus thauj khoom faib.

28. Qhov ntau dua cov hlau lead lub kaum sab xis ntawm txoj kab uas hla coefficient yog, qhov ua tau zoo dua, thiab qhov tsis muaj kev ruaj ntseg ntawm tus kheej lub peev xwm yog qhov tsawg dua.

29. Tsiv cov cab cab. Tom qab hloov chaw koj yuav pom tias lub suab voj voog ntawm qhov zoo li lub suab lub voj voog sib tshooj, txawm li cas los xij nws pom tseeb tias cov kab kab kab kab kab cab tau hloov pauv, thiab nws tsis ua raws li nws lub suab voj voog.

30. Qhov ua rau tsis ua hauj lwm nyob rau hauv lub cab tsav yog pitting corrosion thiab cov hniav hauv paus hniav puas, cov hniav nto glueing thiab dhau hnav. Kev ua tsis tiav feem ntau yog tshwm sim los ntawm tus kab mob cab.

31. Fais fab tuag los ntawm kaw worm tsav meshing hnav tsis hnav Poob bearings thiab poob ntawm cov roj splashes raws li cov khoom nkag mus rau hauv cov roj tank do cov roj.

32. Cov cab cab yuav tsum xam qhov sib npaug ntawm cov cua sov raws li qhov yuav tsum tau ua kom ntseeg tau tias cov nqi calorific ib chav tsev ntawm lub sij hawm sib npaug rau cov cua kub dissipated tib lub sij hawm.

Kev daws: Ntxiv cov dab dej kub kom ua rau thaj tsam kom muaj cua sov. muab tso rau hauv cov kiv cua nyob ze ntawm lub ncej kom nce cua ntws, thiab tom qab ntawd nruab cov cua kub hauv lub thawv kis. Lawv tuaj yeem txuas nrog lub raj xa dej txias.

33. Qhov yuav tsum tau ua ua ntej rau kev tsim ntawm hydrodynamic lubrication yog tias ob qhov chaw uas swb yuav tsum tsim ib qho kev sib txawv. Ob qhov chaw uas sib cais los ntawm cov roj zaj duab xis yuav tsum muaj cov txheeb ze txaus ntawm zawv zawg, thiab nws txoj kev txav yuav tsum ua kom cov roj lubricating ntws los ntawm lub qhov ncauj uas loj rau hauv lub qhov ncauj me me. yog yuav tsum tau rau cov roj kom muaj ib tug tej yam viscosity thiab muab cov roj yuav tsum tau kom txaus.

34. Cov qauv uas yog lub hauv paus ntawm dov bearings yog lub nplhaib sab nraud, sab hauv Hydrodynamic lub cev, tawb.

35. Peb tapered menyuam bearings tsib pob bearings nrog thrust sib sib zog nqus groove pob bearings 7 bearings nrog angular contacts cylindrical roller bearings 01, 02, 01 thiab 02 thiab 03 feem. D = 10mm, 12mm 15mm, 17mm yog hais txog 20mm d = 20mm thiab 12 yog sib npaug rau 60mm.

36. Lub neej ntawm qhov kev ntsuam xyuas yooj yim: 10 feem pua ntawm cov bearings nyob rau hauv ib assortment ntawm bearings raug kev puas tsuaj pitting, whereas 90% ntawm bearings tsis cuam tshuam los ntawm pitting puas. Cov sij hawm ua hauj lwm ntau npaum li cas yog lub neej ntev uas cov kabmob.

37. Qhov yooj yim dynamic ntsuam xyuas: tus nqi uas cov kabmob muaj peev xwm txhawb nqa thaum lub hauv paus ntsuas ntawm lub tshuab yog 106 revolutions.

38. Txoj kev txiav txim siab txog kev teeb tsa cov kabmob: ob lub Fulcrums raug kho rau ib qho kev taw qhia txhua. Ib qho taw tes yog tsau bidirectionally, thaum lwm qhov fulcrum xaus ua luam dej hauv ob qho kev qhia, thaum lwm qhov kawg ua luam dej rau kev txhawb nqa.

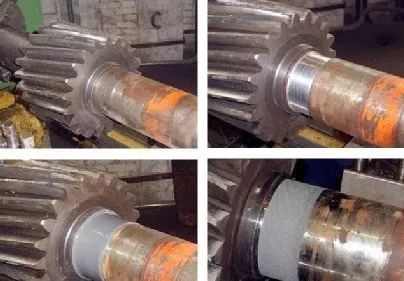

39. Bearings raug cais raws li tus nqi ntawm cov ncej load (bending moment and torque) mandrel (bending moment) thiab Transmission shaft (torque).

Anebon ua raws li lub tswv yim tseem ceeb ntawm "Zoo yog qhov tseem ceeb ntawm kev lag luam thiab cov xwm txheej yuav yog qhov tseem ceeb ntawm nws" Rau cov luv nqi loj ntawm Kev Cai precision 5 Axis Tshuab dhoscnc machined qhov chaw, Anebon ntseeg siab tias peb yuav muab cov khoom lag luam zoo thiab cov kev pabcuam ntawm tus nqi pheej yig thiab kev pabcuam zoo tom qab muag rau cov neeg siv khoom. Tsis tas li ntawd, Anebon yuav muaj peev xwm tsim kom muaj kev sib raug zoo mus ntev nrog koj.

Tuam Tshoj Professional Tuam Tshoj CNC Part thiab Hlau Machining Parts, Anebon nyob ntawm cov khoom zoo tshaj plaws, tsim zoo meej, tshwj xeeb rau cov neeg siv khoom thiab tus nqi pheej yig kom tau txais kev ntseeg siab ntawm ntau tus neeg muas zaub los ntawm ob qho tib si txawv teb chaws thiab hauv Asmeskas. Feem ntau ntawm cov khoom raug xa mus rau kev lag luam txawv teb chaws.

Post lub sij hawm: Aug-02-2023