Koj puas nkag siab txog daim ntawv thov ntawm geometric kam rau ua hauv CNC machining?

Qhov tshwj xeeb ntawm geometric tolerances yog ib qho tseem ceeb ntawm CNC machining, vim nws ua kom muaj tseeb ntawm cov khoom. Geometric kam rau ua yog cov variations uas yuav ua tau nyob rau hauv qhov loj, zoo, orientation thiab qhov chaw ntawm ib tug feature ntawm ib daim. Cov kev hloov pauv no tseem ceeb heev rau kev ua haujlwm ntawm qhov chaw.

Geometric kam rau ua yog siv hauv CNC machining rau ntau yam kev siv.

Dimensional tswj:

Geometric tolerences tso cai rau kev tswj xyuas qhov loj thiab qhov loj me ntawm cov yam ntxwv ua haujlwm. Nws ua kom ntseeg tau tias txhua qhov chaw tau zoo sib xws thiab ua tau raws li lawv qhov kev xav tau.

Daim Ntawv Tswj:

Geometric Tolerances xyuas kom meej tias cov duab xav tau thiab contour tiav rau cov yam ntxwv ua haujlwm. Nws yog ib qho tseem ceeb rau cov khoom uas yuav tsum tau sib sau ua ke, los yog muaj cov kev cai tshwj xeeb mating.

Orientation Control:

Geometric tolerences yog siv rau kev tswj ntawm lub kaum sab xis ntawm cov nta xws li qhov, qhov thiab qhov chaw. Nws yog ib qho tseem ceeb tshwj xeeb tshaj yog rau cov khoom uas xav tau kev sib raug zoo los yog yuav tsum haum rau lwm qhov chaw.

Geometric Tolerances:

Geometric tolerences yog qhov sib txawv uas tuaj yeem ua rau hauv txoj haujlwm ntawm cov yam ntxwv ntawm ib yam khoom. Nws ua kom ntseeg tau tias cov yam ntxwv tseem ceeb ntawm ib feem tau muab tso rau hauv kev sib raug zoo rau ib leeg, ua kom muaj kev ua haujlwm zoo thiab sib dhos.

Tswj profile:

Geometric Tolerances yog siv los tswj tag nrho cov duab thiab profile rau cov yam ntxwv nyuaj xws li curves, contours thiab nto. Qhov no ua kom paub tseeb tias cov khoom siv ua tau raws li qhov yuav tsum tau ua ntawm qhov profile.

Control ntawm Concentricity & Symmetry:

Geometric tolerances ua lub luag haujlwm tseem ceeb hauv kev ua tiav qhov sib npaug & sib luag rau cov yam ntxwv ua haujlwm. Nws yog ib qho tseem ceeb tshwj xeeb tshaj yog thaum aligning rotating Cheebtsam xws li shafts, gears thiab bearings.

Kev tswj kev khiav hauj lwm:

Geometric tolerances qhia qhov kev tso cai hloov pauv hauv qhov ncaj thiab voj voog ntawm kev sib hloovcnc tig part. Nws yog tsim los xyuas kom meej kev ua haujlwm du thiab txo kev vibrations thiab yuam kev.

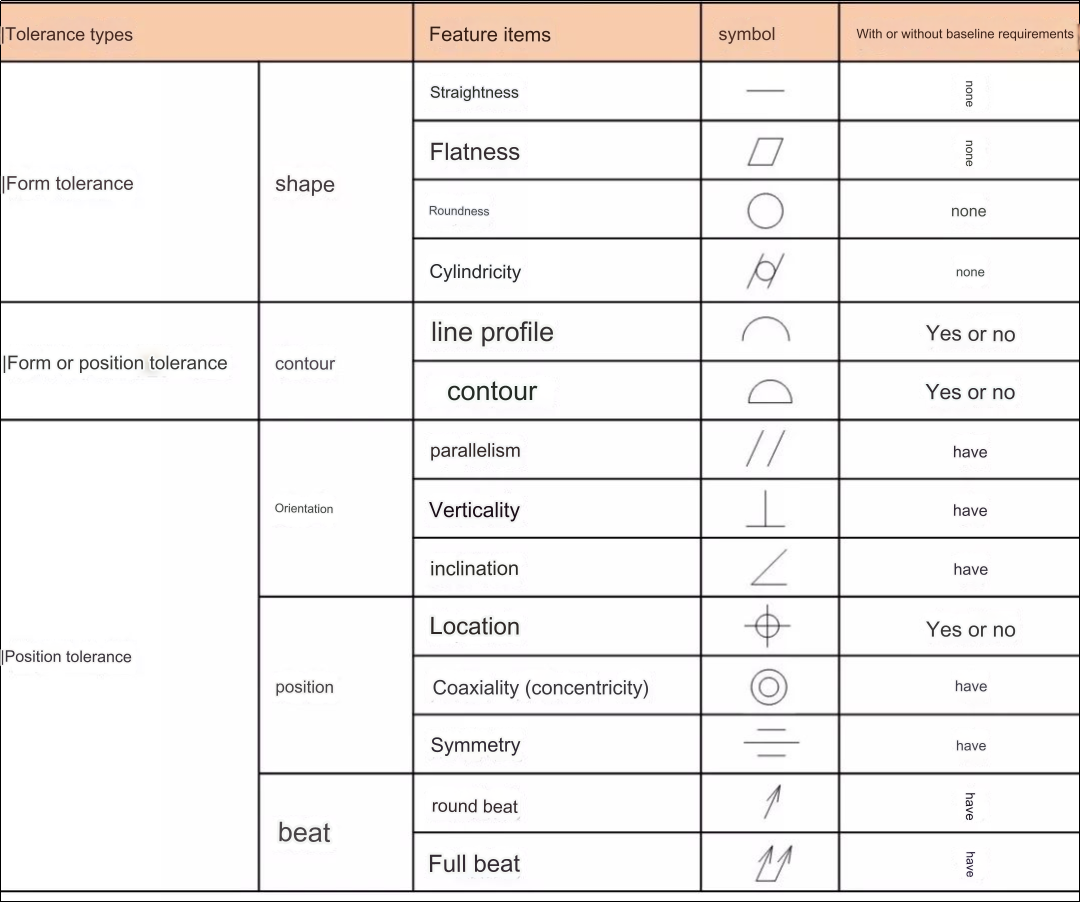

Yog tias peb tsis nkag siab txog geometric tolerances ntawm cov duab kos hauv kev tsim khoom, tom qab ntawd kev soj ntsuam kev ua haujlwm yuav raug kaw thiab cov txiaj ntsig ntawm kev ua haujlwm tseem yuav loj heev. Cov lus no muaj 14-khoom thoob ntiaj teb tus qauv geometric kam rau ua cim.

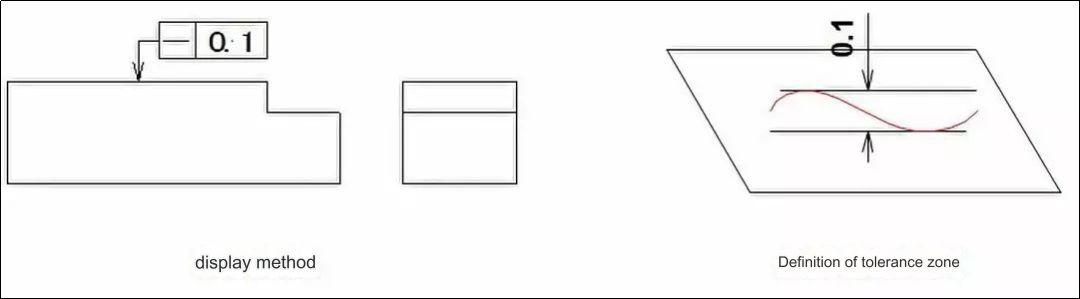

1. Kev ncaj

Straightness yog lub peev xwm ntawm ib feem los tuav ib qho zoo tagnrho straightline. Straightness kam rau ua yog txhais raws li qhov siab tshaj plaws sib txawv ntawm ib txoj kab ncaj nraim los ntawm txoj kab zoo tagnrho.

Piv txwv 1:Qhov kev kam rau siab nyob rau hauv ib lub dav hlau yuav tsum nyob nruab nrab ntawm ob qho tib si ncaj nraim nrog qhov deb 0.1 hli.

Piv txwv 2:Yog tias koj ntxiv cov cim Ph rau tus nqi kam rau ua ces nws yuav tsum nyob rau hauv thaj tsam ntawm ib lub cylindrical nto uas muaj txoj kab uas hla 0.08mm.

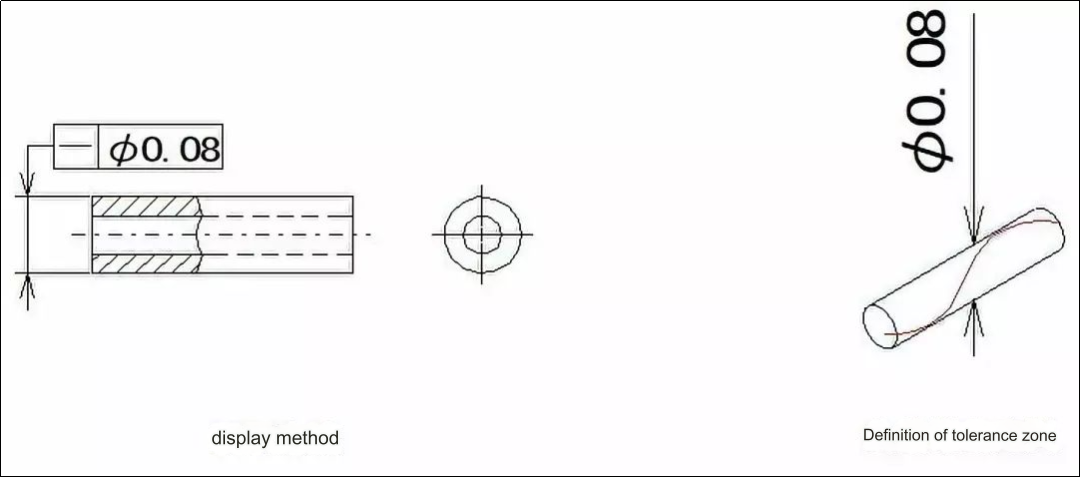

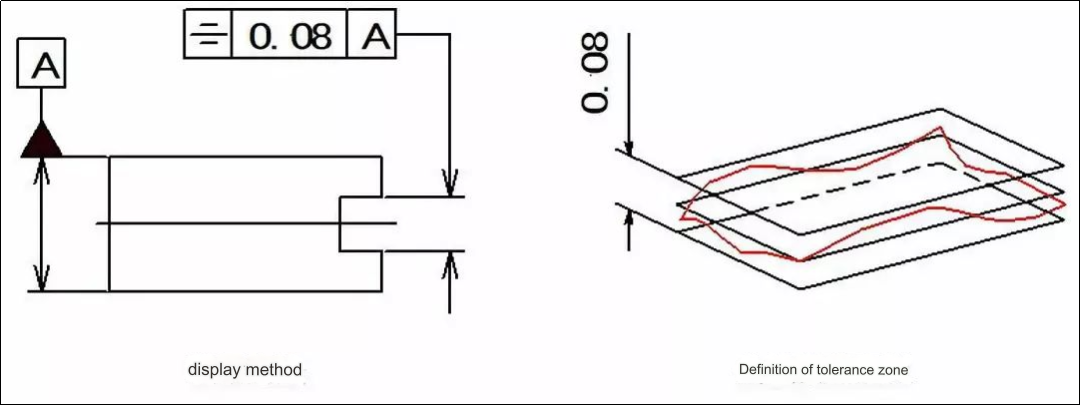

2. Flatness

Flatness (tseem hu ua flatness) yog qhov xwm txheej uas ib feem tswj tau lub dav hlau zoo tagnrho. Flatness kam rau ua yog ib qho kev ntsuas ntawm qhov sib txawv ntawm qhov siab tshaj plaws uas tuaj yeem ua rau ntawm qhov chaw zoo tagnrho thiab qhov chaw tiag tiag.

Piv txwv li, thaj tsam kam rau ua yog txhais tau tias yog qhov chaw nruab nrab ntawm cov dav hlau sib luag uas yog 0.08mm sib nrug.

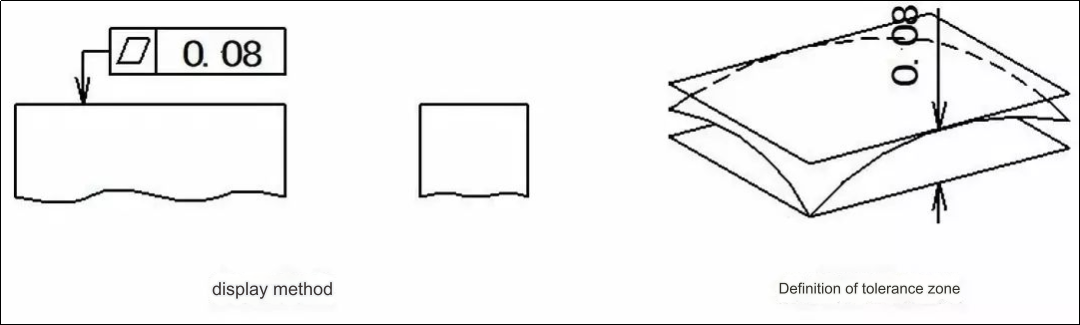

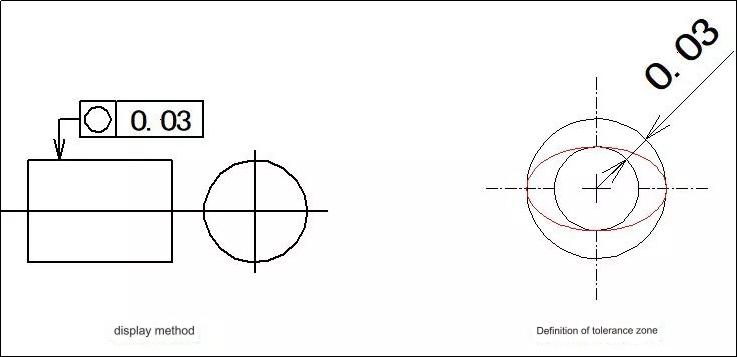

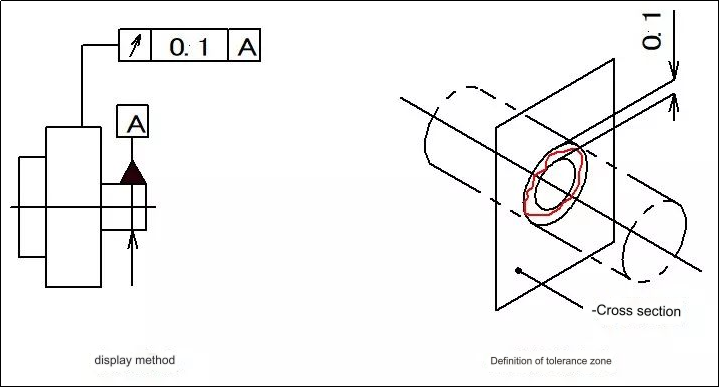

3. Roundness

Lub roundness ntawm ib feem yog qhov kev ncua deb ntawm qhov chaw thiab cov duab tiag tiag. Lub roundness kam rau ua yog txhais raws li qhov siab tshaj plaws sib txawv ntawm qhov tseeb lub voj voog los ntawm qhov zoo tshaj plaws voj voog nyob rau tib seem.

Piv txwv:Tolerance tsam yuav tsum nyob rau ntawm tib seem. Qhov sib txawv ntawm lub vojvoog yog txhais raws li qhov kev ncua deb ntawm ob lub nplhaib concentric nrog kev ua siab ntev ntawm 0.03mm.

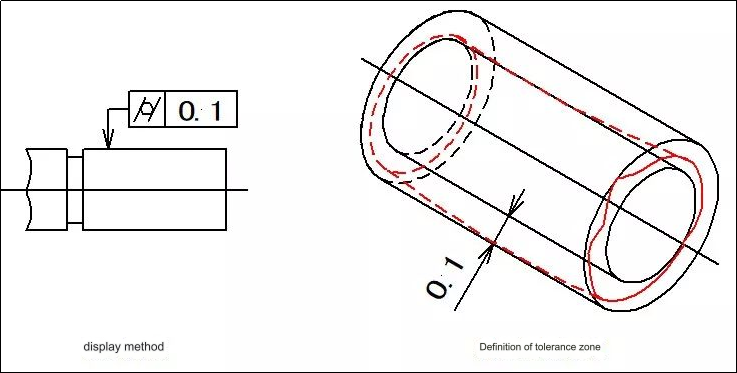

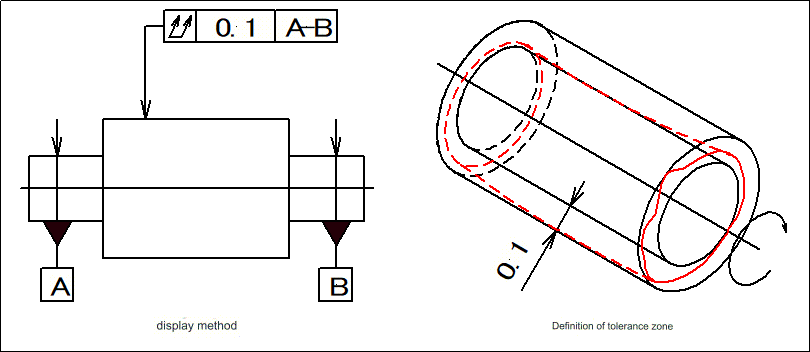

4. Lub tog raj kheej

Lo lus 'Cylindricity' txhais tau hais tias cov ntsiab lus ntawm lub cylindrical nto ntawm ib feem yog txhua qhov sib npaug ntawm nws qhov axis. Qhov siab tshaj plaws kev hloov pauv ntawm qhov tseeb cylindrical nto thiab qhov zoo tshaj plaws cylindrical yog hu ua cylinderricity kam rau ua.

Piv txwv:Tolerance zone yog txhais raws li thaj tsam ntawm coaxial cylindrical qhov chaw uas muaj qhov sib txawv ntawm lub vojvoog ntawm 0.1 hli.

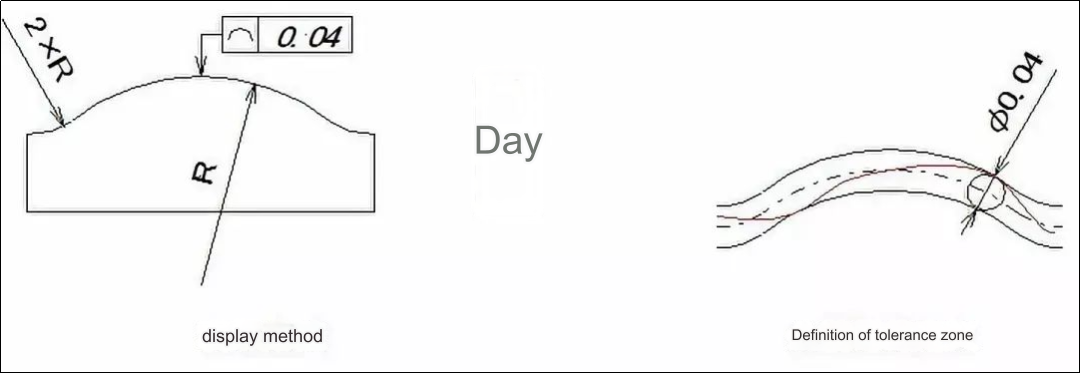

5. Kab contour

Kab profile yog qhov xwm txheej uas txhua qhov nkhaus, tsis hais nws cov duab zoo li cas, tuav cov duab zoo tagnrho hauv ib lub dav hlau ntawm ib feem. Tolerance rau kab profile yog qhov kev hloov pauv uas tuaj yeem ua rau hauv contour ntawm cov kab nkhaus uas tsis yog voj voog.

Piv txwv li, thaj tsam kam rau ua yog txhais tau tias yog qhov chaw nruab nrab ntawm ob lub hnab ntawv uas muaj cov voj voog ntawm txoj kab uas hla 0.04mm. Lub voj voog 'centres yog nyob ntawm kab uas muaj cov duab geometrically.

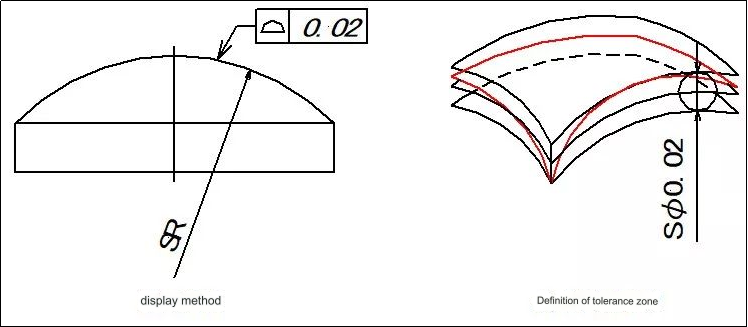

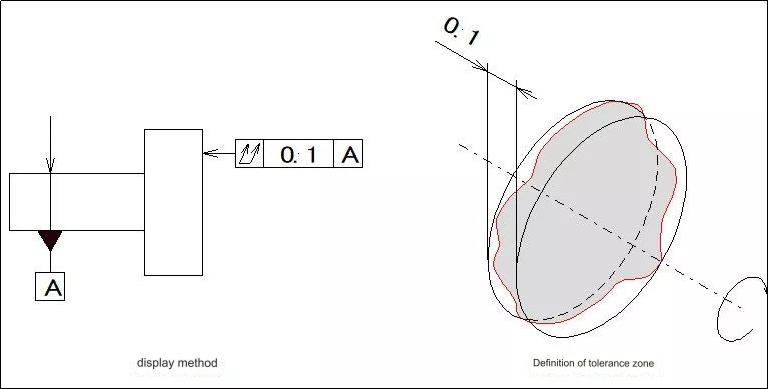

6. Nto contour

Surface contour yog qhov xwm txheej uas qhov kev txiav txim siab zoo li lub ntsej muag ntawm ib qho khoom siv tuav nws daim ntawv zoo tagnrho. Surface contour kam rau ua yog qhov sib txawv ntawm cov kab contour thiab zoo tagnrho contour nto ntawm ib qho chaw uas tsis yog ib puag ncig.

Piv txwv li:Qhov kev kam rau siab nyob nruab nrab ntawm ob lub hnab ntawv kab uas ntim cov pob series nrog 0.02mm txoj kab uas hla. Qhov nruab nrab ntawm txhua lub pob yuav tsum nyob rau saum npoo ntawm cov duab geometrically.

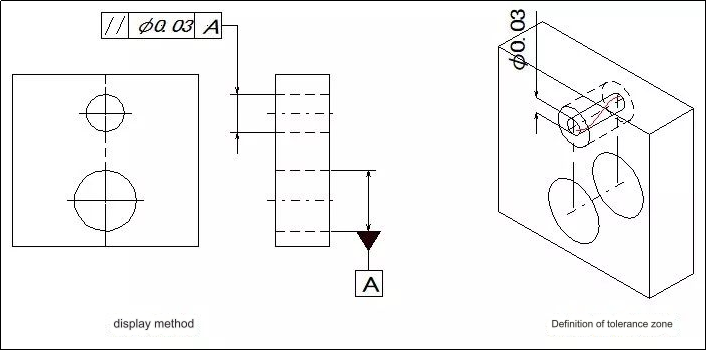

7. Parallelism

Lub degree ntawm parallelism yog ib lo lus siv los piav txog qhov tseeb tias cov ntsiab lus ntawm ib feem yog equidistant deb ntawm datum. Parallelism kam rau ua yog txhais tau tias yog qhov kev hloov pauv siab tshaj plaws uas tuaj yeem ua los ntawm cov kev taw qhia uas ntsuas qhov tseeb yog qhov tseeb thiab cov kev taw qhia zoo tagnrho, sib npaug rau cov datum.

Piv txwv:Yog tias koj ntxiv cov cim Ph ua ntej tus nqi kam rau siab ces qhov kev kam rau siab yuav nyob rau hauv lub tog raj kheej nto nrog rau txoj kab uas hla ntawm Ph0.03mm.

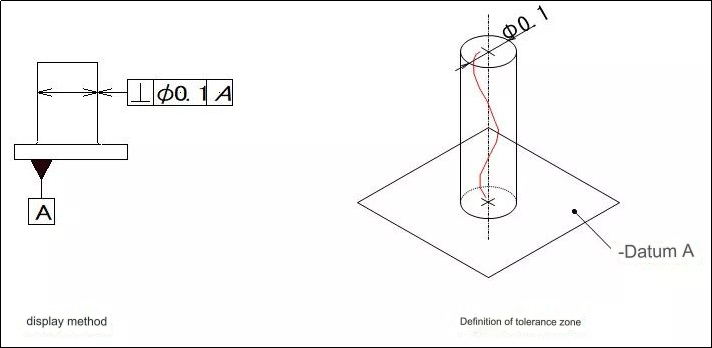

Qhov degree ntawm orthogonality, tseem hu ua perpendicularity ntawm ob lub ntsiab lus qhia tias lub caij ntsuas ntawm qhov tuav qhov tseeb 90deg txheeb ze rau datum. Verticality kam rau ua yog qhov kev hloov pauv siab tshaj plaws ntawm cov kev taw qhia uas qhov ntsuas tau ntsuas thiab qhov perpendicularly rau datum.

Piv txwv 1:Lub cheeb tsam kam rau siab yuav yog perpendicular nrog lub cylindrical nto thiab ib tug datum ntawm 0.1 hli yog hais tias tus cim Ph tshwm ua ntej nws.

Piv txwv 2:Tolerance tsam yuav tsum nyob nruab nrab ntawm ob lub dav hlau sib luag, 0.08mm sib nrug, thiab perpendicular cov kab datum.

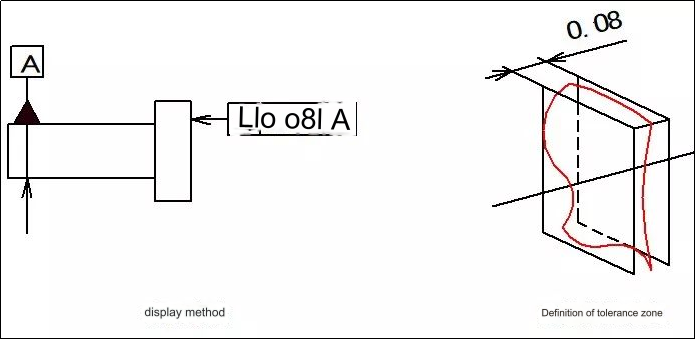

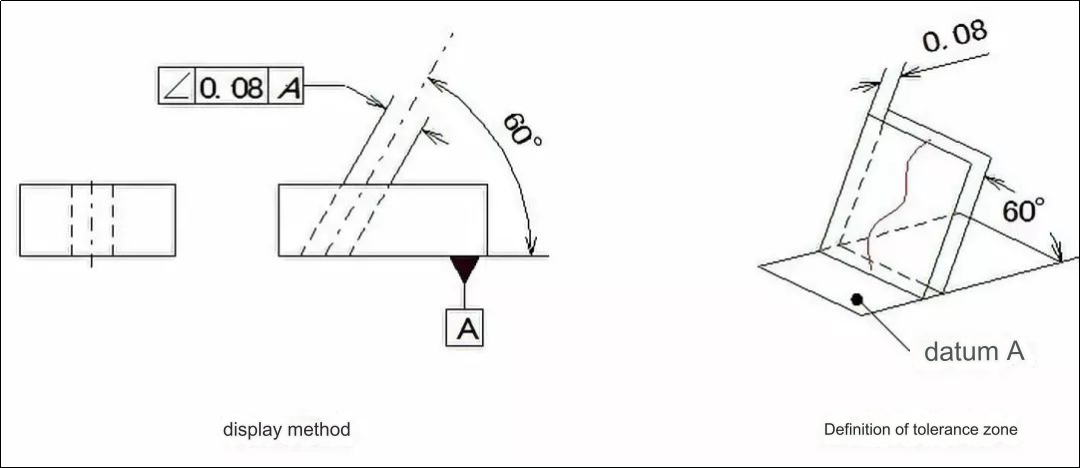

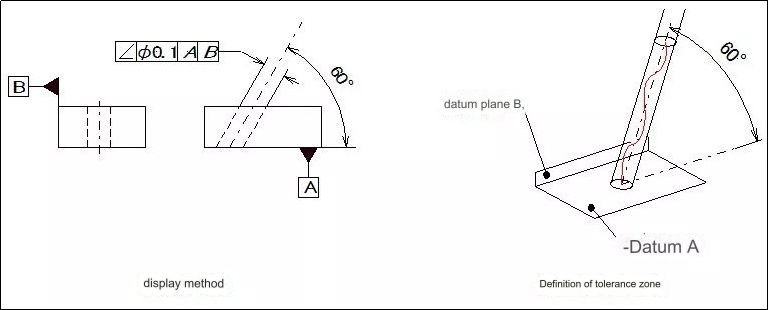

9. Kev xav

Inclination yog qhov xwm txheej uas ob lub ntsiab lus yuav tsum muaj lub kaum ntse ntse hauv lawv qhov kev txheeb ze. Txoj kab nqes siab kam rau ua yog tus nqi ntawm qhov sib txawv uas tuaj yeem tso cai ntawm qhov taw qhia ntawm qhov ntsuas qhov ntsuas thiab qhov kev taw qhia zoo tagnrho, ntawm txhua lub kaum sab xis txheeb ze rau datum.

Piv txwv 1:Tolerance tsam ntawm lub dav hlau ntsuas yog thaj chaw nruab nrab ntawm ob lub dav hlau thaum uas tig mus uas muaj kev kam rau siab ntawm 0.08mm, thiab lub kaum sab xis ntawm 60deg rau lub dav hlau datum.

Piv txwv 2:Yog tias koj ntxiv cov cim Ph rau tus nqi kam rau ua ces thaj tsam ntawm kev kam rau siab yuav tsum nyob hauv ib lub tog raj kheej nrog txoj kab uas hla 0.1 hli. Lub cheeb tsam kam rau ua yuav tsum yog thaum uas tig mus rau dav hlau A perpendicularly rau datum B thiab ntawm lub kaum sab xis ntawm 60deg los ntawm datum A.

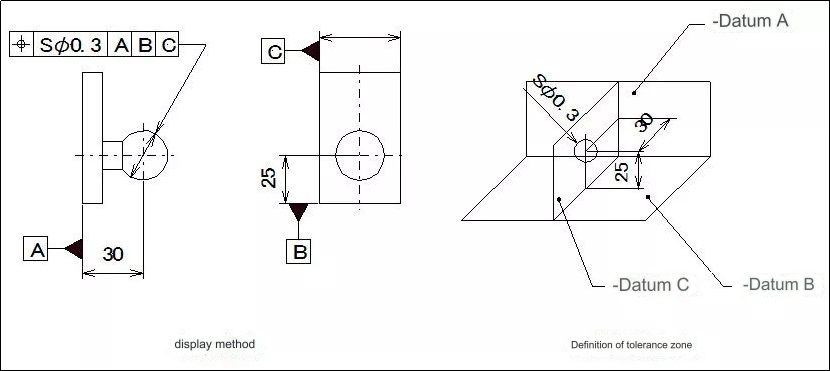

10. Qhov chaw

Txoj hauj lwm yog qhov tseeb ntawm cov ntsiab lus, qhov chaw, kab thiab lwm yam ntsiab lus txheeb ze rau lawv txoj haujlwm zoo tagnrho. Txoj hauj lwm kam rau ua yog txhais tau tias yog qhov kev hloov pauv siab tshaj plaws uas tuaj yeem tso cai rau hauv txoj hauj lwm tiag tiag txheeb ze rau txoj hauj lwm zoo.

Raws li ib qho piv txwv, thaum SPh cim tau ntxiv rau thaj tsam kam rau ua, qhov kam rau ua yog sab hauv lub pob uas muaj txoj kab uas hla 0.3mm. Qhov nruab nrab ntawm qhov kam rau ua ntawm lub pob yog qhov loj me hauv txoj kev xav, txheeb ze rau cov ntaub ntawv ntawm A, B thiab C.

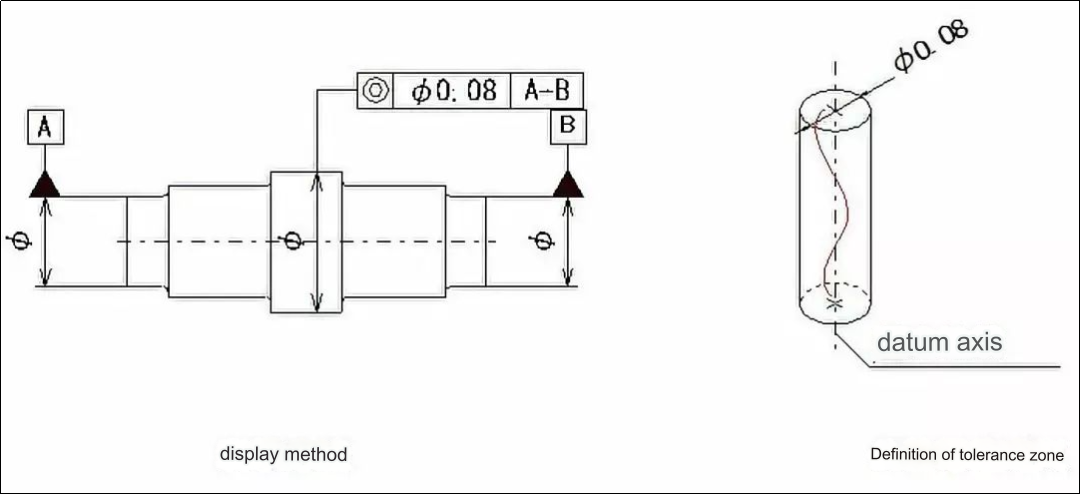

11. Coaxiality (concentricity).

Coaxiality yog lo lus siv los piav txog qhov tseeb tias qhov ntsuas axis ntawm qhov nyob twj ywm nyob rau hauv tib txoj kab ncaj nraim rau qhov siv axis. Kev kam rau siab rau coaxiality yog qhov kev hloov pauv uas tuaj yeem ua rau ntawm qhov tseeb axis thiab qhov siv axis.

Piv txwv li:Lub cheeb tsam kam rau ua, thaum cim nrog tus nqi kam rau ua, yog qhov chaw nruab nrab ntawm ob lub tog raj kheej ntawm txoj kab uas hla 0.08mm. Lub voj voog kam rau ua cheeb tsam lub axis coincides nrog datum.

12. Symmetry

Lub symmetry kam rau ua yog qhov siab tshaj qhov sib txawv ntawm lub dav hlau symmetry (los yog kab hauv nruab nrab, axis) los ntawm lub dav hlau zoo tagnrho. Lub symmetry kam rau ua yog txhais raws li qhov siab tshaj plaws sib txawv ntawm qhov tseeb feature lub symmetry center dav hlau, los yog nruab nrab kab (axis), los ntawm lub zoo tagnrho dav hlau.

Piv txwv:Tolerance zone yog qhov chaw nruab nrab ntawm ob kab sib txuas lossis dav hlau uas yog 0.08mm los ntawm ib leeg thiab sib xyaw ua ke nrog lub dav hlau datum lossis centerline.

13. Vaj Huam Sib Luag

Lub sij hawm ncig lub voj voog yog hais txog qhov tseeb tias qhov chaw ntawm lub kiv puag ncig ntawm cov khoom tseem ruaj khov nyob rau hauv kev sib raug zoo nrog lub dav hlau datum nyob rau hauv ib qho kev ntsuas dav hlau txwv. Qhov siab tshaj plaws kam rau ua rau lub voj voog khiav yog tso cai nyob rau hauv ib qho kev ntsuas kev txwv, thaum lub caij yuav tsum tau ntsuas ua tiav tag nrho cov kev sib hloov nyob ib ncig ntawm lub axis siv yam tsis muaj axial txav.

Piv txwv 1:Tolerance zone yog txhais raws li thaj tsam ntawm concentric lub voj voog nrog qhov sib txawv ntawm lub vojvoog ntawm 0.1mm thiab lawv cov chaw nyob ntawm tib lub dav hlau datum.

14. Full Beat

Tag nrho cov runout yog tag nrho cov runout nyob rau saum npoo ntawm qhov ntsuas thaum nws tig tsis tu ncua nyob ib ncig ntawm lub reference axis. Tag nrho runout kam rau ua yog siab tshaj runout thaum ntsuas lub caij thaum nws tig tsis tu ncua nyob ib ncig ntawm lub datum axis.

Piv txwv 1:Tolerance cheeb tsam txhais tau tias yog thaj tsam ntawm ob qhov chaw cylindrical uas muaj qhov sib txawv ntawm lub vojvoog ntawm 0.1mm, thiab yog coaxial rau datum.

Piv txwv 2:Tolerance zone yog txhais tias yog thaj tsam ntawm cov dav hlau sib luag uas muaj qhov sib txawv ntawm lub vojvoog ntawm 0.1mm, perpendicular nrog cov datum.

Dab tsi cuam tshuam rau digital kam rau ua rau CNC machined qhov chaw?

Qhov tseeb:

Digital kam rau ua kom paub tseeb tias qhov ntev ntawm cov khoom siv machined yog nyob rau hauv cov kev txwv. Nws tso cai rau cov khoom tsim tawm uas haum ua ke kom raug thiab ua haujlwm raws li qhov xav tau.

Kev sib raug zoo:

Digital kam rau ua tso cai rau qhov sib xws ntawm ntau qhov chaw los ntawm kev tswj qhov loj thiab cov duab sib txawv. Qhov no yog qhov tseem ceeb tshwj xeeb tshaj yog rau cov khoom uas yuav tsum tau hloov pauv, lossis siv rau hauv cov txheej txheem xws li kev sib dhos uas xav tau kev sib koom ua ke.

Haum thiab sib dhos

Digital kam rau ua yog siv los xyuas kom meej tias cov khoom tuaj yeem sib dhos kom raug thiab seamlessly. Nws tiv thaiv cov teeb meem xws li cuam tshuam, kev tshem tawm ntau dhau, misalignment thiab khi ntawm qhov chaw.

Kev ua tau zoo:

Digital kam rau ua yog qhov tseeb thiab tso cai rau cov khoom tsim tawm uas ua tau raws li cov qauv kev ua haujlwm. Digital kam rau ua yog qhov tseem ceeb hauv kev lag luam xws li aerospace thiab automotive qhov twg nruj tolerances tseem ceeb. Nws xyuas kom meej tias cov khoom ua haujlwm tau zoo thiab ua tau raws li cov qauv zoo.

Tus nqi optimization

Digital kam rau ua yog qhov tseem ceeb hauv kev nrhiav qhov sib npaug ntawm qhov tseeb, tus nqi thiab kev ua haujlwm. Los ntawm kev txiav txim siab ua tib zoo, cov tuam ntxhab tuaj yeem zam dhau qhov tseeb, uas tuaj yeem nce tus nqi thaum tswj kev ua haujlwm thiab kev ua haujlwm.

Kev Tswj Xyuas Zoo:

Digital kam rau ua tso cai rau kev tswj xyuas kom zoo los ntawm kev muab cov lus qhia meej meej thaum ntsuas thiab tshuaj xyuasmachined yam. Nws tso cai rau kev tshawb pom ntxov ntawm kev sib txawv ntawm kev kam rau siab. Qhov no ua kom zoo ib yam thiab kho raws sijhawm.

Tsim Flexibility

Designers muaj qhov yooj yim dua thaum nws los txog rau kev tsimmachined qhov chawnrog digital kam rau ua. Cov neeg tsim qauv tuaj yeem txheeb xyuas qhov ua siab ntev los txiav txim siab qhov kev txwv thiab kev hloov pauv, thaum tseem ua kom ntseeg tau tias kev ua haujlwm thiab kev ua haujlwm yuav tsum tau ua.

Anebon tuaj yeem yooj yim muab cov kev daws teeb meem zoo tshaj plaws, tus nqi sib tw thiab lub tuam txhab cov neeg siv khoom zoo tshaj plaws. Anebon lub hom phiaj yog "Koj tuaj ntawm no nrog kev nyuaj thiab peb muab koj luag nyav kom tshem tawm" rau Cov Neeg Muag Khoom Zoo Muag Khoom Precision Part CNC Machining Hard Chrome Plating Iav, Ua raws li cov qauv kev lag luam me ntawm kev sib nrig sib zoo, tam sim no Anebon tau yeej lub koob npe nrov ntawm peb. buyers vim peb cov tuam txhab zoo tshaj plaws, cov khoom zoo thiab cov nqi sib tw. Anebon zoo siab tos txais cov neeg yuav khoom los ntawm koj lub tsev thiab txawv teb chaws los koom tes nrog peb kom tau txais txiaj ntsig zoo.

Zoo Lag Luam Muag Khoom Tuam Tshoj machined stainless hlau, precision 5 axis machining ib feem thiabcnc uakev pabcuam. Anebon lub hom phiaj tseem ceeb yog muab peb cov neeg siv khoom thoob ntiaj teb nrog cov khoom zoo, tus nqi sib tw, txaus siab xa thiab cov kev pabcuam zoo. Cov neeg siv khoom txaus siab yog peb lub hom phiaj tseem ceeb. Peb zoo siab tos txais koj tuaj xyuas peb lub showroom thiab chaw ua haujlwm. Anebon tau tos ntsoov los tsim kev lag luam kev sib raug zoo nrog koj.

Yog xav paub ntxiv, thov hu rauinfo@anebon.com

Post lub sij hawm: Nov-17-2023