Koj paub dab tsi txog cov txheej txheem kho saum npoo ntawm cov ntaub ntawv hauv CNC machining?

Rau CNC machining, kev kho saum npoo yog cov txheej txheem ua haujlwm los txhim kho cov tsos zoo li kev ua haujlwm thiab kev ua haujlwm ntev ntawm cov khoom siv machined. Cov txheej txheem feem ntau siv los kho qhov chaw siv hauv CNC machining suav nrog deburring. Cov txheej txheem no suav nrog kev tshem tawm cov npoo ntse, burrs, lossis cov khoom siv ntau dhau ntawm qhov chaw ntawm cov khoom siv tshuab. Deburring txhim kho kev zoo nkauj thiab kev nyab xeeb ntawm cov khoom kawg.

Polishing:Polishing tuaj yeem siv los ua kom du ntawm qhov chaw ntawm cov khoom uas ua rau lub ntsej muag ci ntsa iab. Nws txhim kho cov tsos ntawm cov khoom thiab txo kev sib txhuam ntawm qhov chaw.

Sib tsoo: Nws yog siv los tshem tawm cov imperfections ntawm qhov chaw los yog ua kom muaj kev tolerances meej. Qhov no suav nrog kev siv lub log grinder kom tshem tawm cov khoom ntawm ib qho haujlwm.

Anodizing:Nws yog cov txheej txheem electrochemical uas tsim cov txheej txheem tiv thaiv oxide zoo li cov khoom siv hlau zoo li txhuas. Nws txhim khu kev tiv thaiv corrosion nrog rau kev zoo nkauj, hardness thiab.

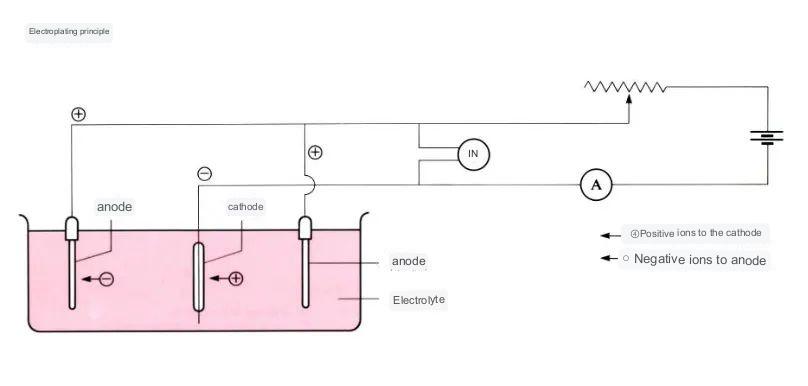

ElectroplatingNws suav nrog kev tso cov txheej nyias ntawm cov hlau nplaum rau saum cov khoom siv. Nws txhim kho kev tiv thaiv corrosion nrog rau cov conductivity thiab zoo li.

Txheej:Deg txheej yog txheej txheem ntawm kev siv cov txheej txheem los tiv thaiv corrosion los yog pleev xim rau saum npoo ntawm cov khoom. Nws tuaj yeem muab kev tiv thaiv corrosion thiab hnav tsis kam. Nws kuj tuaj yeem txhim kho kev zoo nkauj.

Kev kho cua sov:Qhov no suav nrog kev nthuav tawm cov khoom siv rau qhov kub thiab txias tswj kom hloov kho lawv cov cuab yeej cuab tam. Cov txheej txheem no txhim kho cov khoom siv tau ntev, hardness thiab tiv taus hnav thiab deformation.

Cov kev kho mob rau qhov chaw no tuaj yeem txhim kho tag nrho qhov zoo, kev ua tau zoo thiab kev ua haujlwm ntev ntawm CNC machined Cheebtsam. Hom kev kho mob uas koj xaiv los siv yog nyob ntawm cov khoom siv, nws daim ntawv thov npaj, thiab cov txiaj ntsig xav tau.

Kev kho deg yog txheej txheem los tsim cov khoom siv hauv qab uas muaj tshuaj lom neeg, lub cev, thiab cov yam ntxwv uas txawv ntawm cov khoom siv hauv paus.

Lub hom phiaj ntawm kev kho deg yog kom txaus siab rau kev hnav, corrosion thiab lwm yam kev xav tau ntawm cov khoom muag. Cov txheej txheem feem ntau siv los kho qhov chaw muaj xws li cov neeg kho tshuab zom, tshuaj lom neeg kev kho cua sov thiab txau rau ntawm qhov chaw. Kev kho deg yog cov txheej txheem ntawm kev ntxuav qhov chaw, cheb nws, deburr nws thiab degrease rau sab nrauv ntawm daim. Niaj hnub no, peb yuav tham txog cov txheej txheem ntawm kev kho deg.

Cov txiaj ntsig dab tsi tuaj yeem kho qhov chaw tuaj yeem ua rau machining qhov chaw?

Cov txheej txheem kho qhov chaw saum npoo tuaj yeem nqa tau ntau qhov zoo raumachined qhov chaw, muaj xws li: Txhim Kho Kev Zoo Nkauj: Kev kho deg xws li sprucing li, anodizing, plating thiab tiav tuaj yeem txhawb qhov pom kev ntxim nyiam ntawm cov khoom siv machined. Nws tuaj yeem muab qhov du, ci los yog kho kom haum, txhim kho tag nrho cov khoom zoo.

Txhim kho xeb tsis kam: Ntau qhov chaw kho mob, xws li anodizing, plating, thiab tiav, tsim cov txheej tiv thaiv ntawm cov khoom siv. Cov txheej no ua rau muaj kev cuam tshuam, tiv thaiv ib feem los ntawm kev sib cuag nrog qhov chaw corrosive, yog li txhim kho nws cov corrosion kuj.

Boosted hnav tsis kam: Cov kev kho deg xws li kev kho kom sov lossis kev ua tiav tuaj yeem ua rau muaj kev hnav tsis kam ntawm cov khoom siv machined. Cov txheej txheem no tuaj yeem txhim kho qhov firmness, toughness thiab kuj sturdiness ntawm cov ntaub ntawv, ua rau lawv muaj zog tiv thaiv kom txhob rub, puas thiab hnav. Boost lubrication thiab txo qhov rub tawm: Qee qhov chaw kho mob, xws li polishing lossis txheej nrog cov ntaub ntawv tsis tshua muaj kev sib txhuam, tuaj yeem txo kev sib txhuam ntawm cov khoom txav. Qhov no ua rau cov txheej txheem smoother, txo qis hnav, thiab tseem txhim kho tag nrho kev ua haujlwm ntawm cov khoom siv machined.

Cov tshuaj tiv thaiv zoo dua: Los ntawm kev kho saum npoo, cov tshuaj tiv thaiv ntawm cov khoom siv machined tuaj yeem txhawb nqa. Qhov no yog qhov tshwj xeeb tshaj yog thaum cov khoom sib txuas nrog cov tshuaj tsis zoo lossis cov khoom sib txuas uas tuaj yeem rhuav tshem cov khoom. Tighter Tolerances as well as Higher Precision: Deg kev kho mob xws li kev sib tsoo lossis polishing pab ua kom nruj dua qhov kev tiv thaiv thiab tseem ua kom qhov tseeb ntau dua hauv cov khoom siv. Qhov no yog qhov tseem ceeb rau cov ntawv thov uas xav tau siab precision thiab kuj nruj kam rau ua.

Txhim kho Adhesion thiab Bonding: Kev npaj nto tuaj yeem tsim thaj chaw tsim nyog rau cov nplaum, xim lossis lwm yam kev sib txuas. Qhov no tso cai rau kom muaj zog dua thiab muaj txiaj ntsig ntau dua nyob rau ntawm cov khoom sib txawv, txhim kho kev ncaj ncees ntawm cov khoom. Zuag qhia tag nrho, cov txheej txheem kho saum npoo ua si lub luag haujlwm tseem ceeb hauv kev ua kom zoo dua qub, kev ua neej ntev thiab saib ntawmmachined yam, ua rau lawv tsim nyog rau lawv qhov kev thov thiab txhim kho lawv cov khoom zoo tag nrho.

Cov txheej txheem kev kho saum npoo feem ntau yog:

Nqus electroplating, electroplating txheej txheem, anodizing, electrolytic polishing, ncoo printing txheej txheem, galvanizing txheej txheem, hmoov txheej, dej hloov printing, tshuaj ntsuam luam ntawv, electrophoresis, thiab lwm yam.

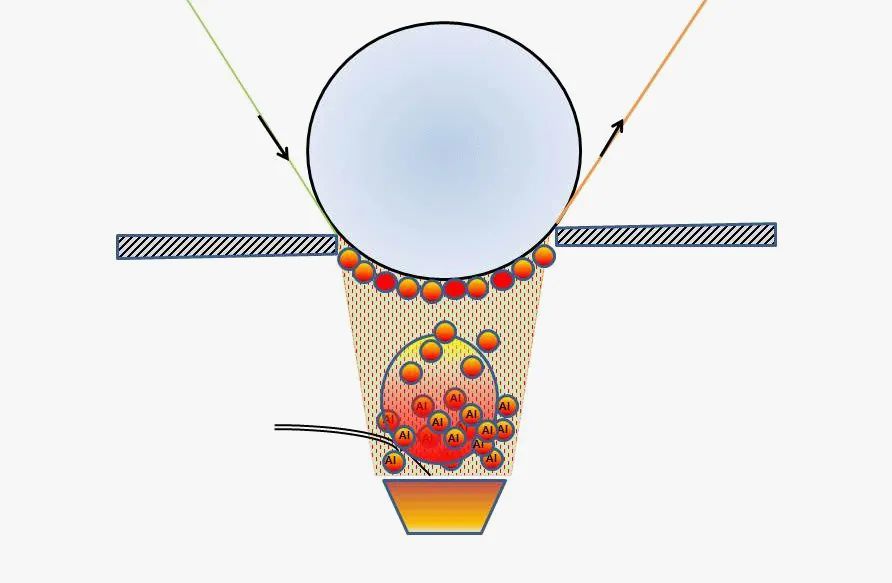

01. Nqus plating

—— Nqus Metalizing ——

Lub tshuab nqus tsev plating tuaj yeem piav qhia raws li cov txheej txheem ntawm lub cev. Hauv cov ntsiab lus, cov roj argon yog txhaj rau hauv lub xeev ntawm lub tshuab nqus tsev, cov roj atoms ntaus cov khoom ntawm kev xaiv, thiab cov khoom uas yog tsom mus rau hauv cov molecules, uas yog absorbed los ntawm cov khoom siv hluav taws xob los tsim cov txheej txheem zoo li qub thiab du. .

Cov ntaub ntawv siv tau:

1. Ntau yam ntaub ntawv tuaj yeem coated, nrog rau cov hlau tawv thiab mos yas, ceramics, cov ntaub ntawv sib xyaw thiab iav. Txoj kev siv feem ntau ntawm electroplating yog aluminium, uas yog ua raws li tooj liab thiab nyiaj.

2. Cov ntaub ntawv ntuj tsis tsim nyog rau vapor plating vim qhov tseeb tias cov dej noo hauv cov ntaub ntawv ntuj tuaj yeem hloov pauv qhov chaw nqus tsev.

Tus nqi ntawm cov txheej txheem yog tus nqi ntawm vapor plating cov khoom yuav tsum tau muab txau, thauj khoom thiab rov qab mus rau cov tshuaj tsuag, uas txhais tau hais tias tus nqi ntawm kev ua haujlwm yog kim, txawm li cas los xij nws muaj feem xyuam rau qhov loj thiab qhov nyuaj ntawm workpiece.

Kev cuam tshuam ib puag ncig: Lub tshuab nqus tsev electroplating ua rau muaj kev cuam tshuam ib puag ncig tsawg, uas zoo ib yam li cov txheej txheem ntawm ib puag ncig ib puag ncig.

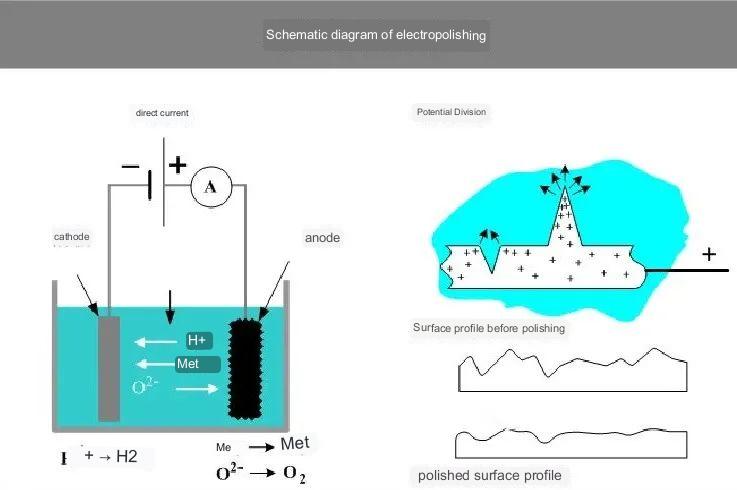

02. Electropolishing

—— Electropolishing ——

Electropolishing yog hais txog cov txheej txheem electrochemical uas cov atoms nyob rau hauvcnc tig qhov chawuas yog immersed nyob rau hauv ib tug electrolyte yog hloov mus rau hauv ions thiab ces tshem tawm los ntawm lub nto los ntawm cov ndlwg ntawm tus nqi hluav taws xob, uas ua rau kom tshem tawm cov nplua burrs thiab txhim khu lub brightness ntawm lub nto.

Cov ntaub ntawv siv tau:

1. Feem ntau ntawm cov hlau yog electrolytically polished nrog rau polishing ntawm qhov chaw uas stainless hlau undergoes yog feem ntau siv (tshwj xeeb tshaj yog nrog austenitic stainless qib).

2. Cov ntaub ntawv sib txawv tsis tuaj yeem ua electropolished ib txhij lossis txawm nyob hauv tib qho hnyav rau electrolysis.

Tus nqi ntawm cov txheej txheem: tag nrho cov txheej txheem electrolytic polishing yog yuav luag tag nrho automated, txhais tau tias tus nqi ntawm kev ua haujlwm yog tsawg heev. Kev cuam tshuam rau ib puag ncig: Electrolytic polishing ntiav cov tshuaj cuam tshuam tsawg. Tag nrho cov txheej txheem tsuas yog ib qho me me ntawm cov dej xwb, thiab siv tau yooj yim heev. Tsis tas li ntawd, nws tuaj yeem txhim kho cov khoom ntawm cov hlau tsis muaj steel nrog rau ncua kev corrosion ntawm stainless hlau.

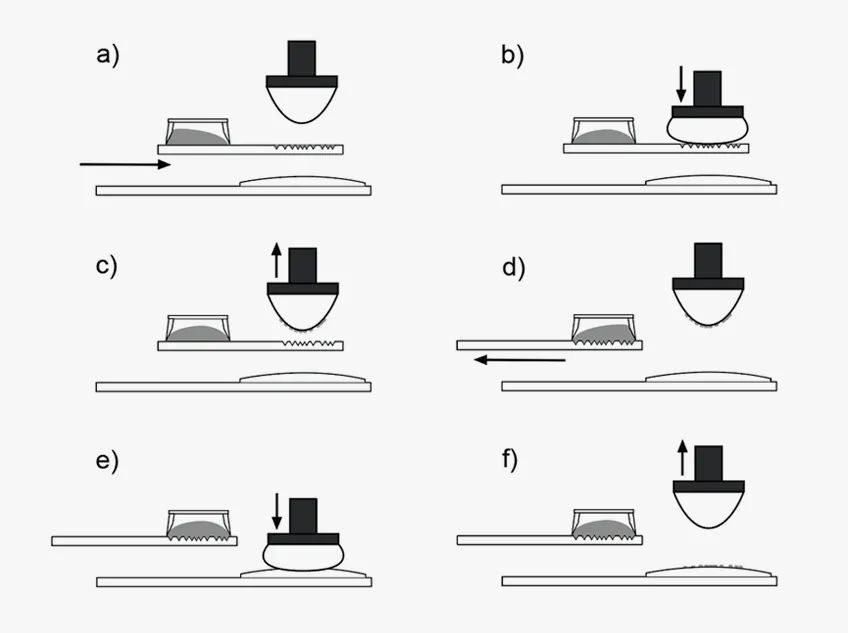

03. Cov txheej txheem luam ntawv Pad

— Pad Printing —

Kev muaj peev xwm luam tawm cov duab, ntawv nyeem thiab cov duab kos rau ntawm qhov chaw ntawm cov khoom tsis sib xws tau dhau los ua ib qho tseem ceeb ntawm kev luam ntawv tshwj xeeb.

Cov ntaub ntawv siv tau:

Pad luam ntawv yog ib qho kev xaiv siv tau ntawm yuav luag txhua yam khoom, tsis yog cov ntaub ntawv uas muaj nkig ntau dua li cov ntaub qhwv silicone zoo li PTFE.

Tus nqi txheej txheem Tsawg tus nqi pwm thiab tus nqi ua haujlwm tsawg.

Kev cuam tshuam ib puag ncig: Raws li cov txheej txheem no tau txwv rau cov inks uas yog soluble (uas muaj cov kab mob tsis zoo) thiab muaj kev cuam tshuam rau ib puag ncig.

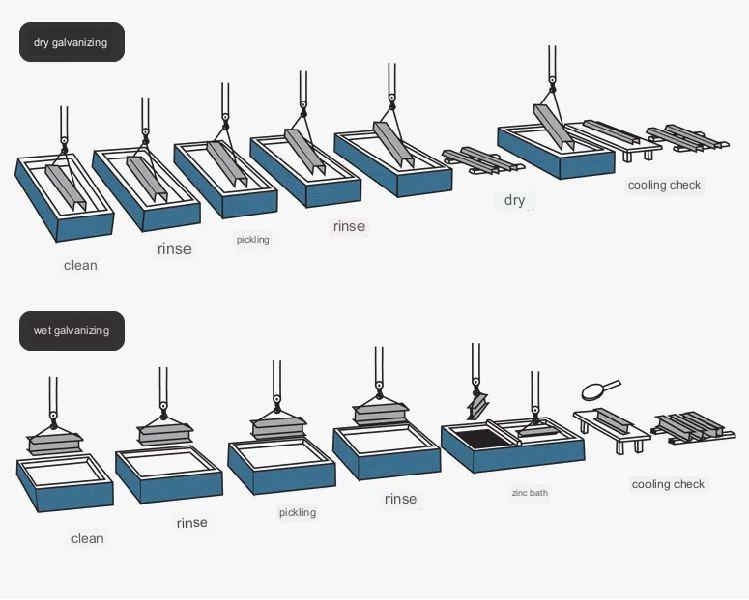

04. Galvanizing txheej txheem

—— Galvanizing--

Ib qho cuab yeej siv rau kev kho qhov chaw uas coated ib txheej zinc rau saum cov alloys ua los ntawm cov hlau rau kev zoo nkauj thiab cov txiaj ntsig los tiv thaiv xeb. Cov zinc txheej rau saum npoo ua raws li cov txheej txheem tiv thaiv electrochemical uas tiv thaiv cov hlau corrosion. Ob txoj kev siv feem ntau yog kub-dip galvanizing thiab galvanized.

Cov ntaub ntawv siv tau:

Vim tias galvanizing cia siab rau metallurgical bonding txheej txheem no yog tsim rau kev kho mob ntawm qhov chaw ntawm hlau thiab hlau.

Tus nqi ntawm cov txheej txheem: Tsis muaj pwm tus nqi, lub voj voog luv luv lossis nruab nrab tus nqi ua haujlwm, txij li qhov zoo ntawm qhov chaw ntawm lub workpiece yog txiav txim siab loj los ntawm kev kho deg ua los ntawm tes ua ntej galvanizing.

Kev cuam tshuam ib puag ncig: Raws li cov txheej txheem ntawm galvanizing tuaj yeem ua rau lub neej ntev ntawm cov hlau qhov nruab nrab ntawm 40 thiab 100 xyoo thiab tseem tiv thaiv corrosion thiab xeb uas tuaj yeem tshwm sim ntawm nws, cov txheej txheem tuaj yeem cuam tshuam rau kev tiv thaiv ib puag ncig. Tsis tas li ntawd, cov khoom ua haujlwm uas tau galvanized tuaj yeem raug coj rov qab mus rau lub tank zinc thaum nws lub sijhawm siv tas sijhawm thiab kev siv cov zinc txuas ntxiv hauv cov kua dej tsis ua rau lub cev lossis tshuaj pov tseg.

05. Electroplating txheej txheem

—— Electroplating ——

Cov txheej txheem ntawm kev txuas ib txheej nyias ntawm cov yeeb yaj kiab hlau rau saum npoo ntawm cov khoom siv los ntawm electrolysis, txhawm rau kom tsis txhob hlau oxidation, txhim khu kev hnav tsis kam ntawm lub teeb pom kev tiv thaiv corrosion, thiab txhim kho cov tsos. Cov txheej txheej ntawm ntau npib kuj tuaj yeem ua electroplated. .

Cov ntaub ntawv siv tau:

1. Ntau cov hlau yog electroplated. Txawm li cas los xij, ntau yam hlau tuaj nrog ntau theem ntawm purity thiab plating efficiency. Qhov nrov tshaj plaws ntawm cov no yog cov hauv qab no: tin thiab chromium, nyiaj, npib tsib xee, thiab rhodium.

2. Cov khoom siv nrov tshaj plaws los ua electroplating yog ABS. ABS.

3. Nickel hlau yuav tsum tsis txhob siv rau cov khoom siv electroplate uas tuaj rau ntawm daim tawv nqaij vim nws yog khaus thiab ua rau cov tawv nqaij.

Tus nqi ntawm cov txheej txheem: Tsis muaj cov nqi pwm, txawm li cas los xij cov khoom siv yuav tsum tau ua kom ruaj ntseg cov nqi sij hawm raws li qhov kub thiab txias thiab hom hlau los yog tus nqi zog (nruab nrab-siab) yog qhov tseem ceeb ntawm cov khoom plating tshwj xeeb, xws li cov hniav nyiaj hniav kub thiab silverware, uas yuav tsum tau muaj kev txawj ntse. Nws yog tswj hwm los ntawm cov neeg ua haujlwm txawj ntse heev vim qhov kev xav tau siab ntawm cov tsos thiab lub neej ntev.

Kev cuam tshuam ib puag ncig ntawm electroplating: Muaj ntau cov tshuaj lom neeg ua haujlwm nyob rau hauv cov txheej txheem electroplating uas yog vim li cas kev sib txawv thiab kev rho tawm yog qhov tseem ceeb los txo qhov cuam tshuam ib puag ncig.

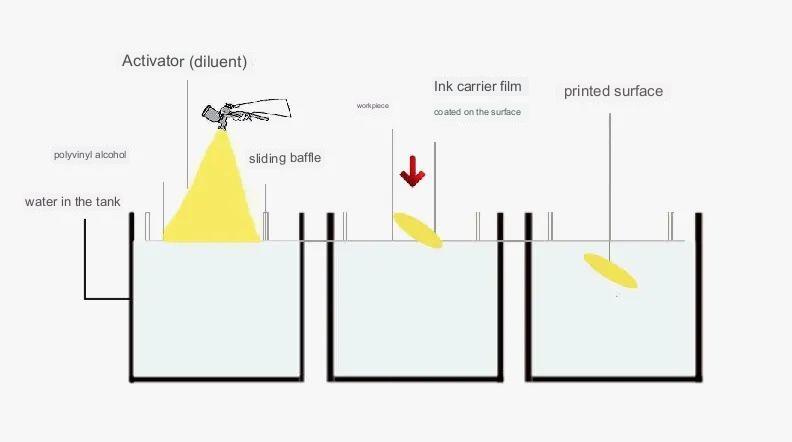

06. Dej hloov luam ntawv

—— Hydro Transfer Printing ——

Nws yog ib qho txheej txheem los luam cov xim xim rau hauv daim ntawv hloov chaw ntawm cov khoom peb-seem siv cov dej siab. Raws li tib neeg xav tau kev ntim khoom thiab kho kom zoo nkauj ntawm qhov chaw, kev siv cov ntawv luam tawm ntawm kev thov tau txais ntau thiab ntau dua.

Cov ntaub ntawv siv tau:

Txhua yam ntawm cov ntaub ntawv nyuaj yog haum rau dej hloov luam ntawv thiab cov ntaub ntawv uas haum rau kev txau yuav tsum haum rau luam ntawv nrog dej. Qhov nrov tshaj plaws yog kev txhaj tshuaj molded qhov chaw thiab cov khoom siv hlau.

Tus nqi ntawm cov txheej txheem: Tsis muaj pwm ntsig txog tus nqi, txawm li cas los xij, ntau yam khoom yuav tsum tau hloov mus rau hauv dej tib lub sijhawm los ntawm kev siv cov khoom siv. tus nqi tag nrho tsis ntau tshaj li lub sijhawm ntawm ib lub voj voog.

Kev cuam tshuam ib puag ncig: Hauv kev sib piv rau cov tshuaj tsuag rau cov khoom siv dej hloov luam ntawv ntau dua siv cov xim luam ntawv uas txo qhov muaj feem cuam tshuam thiab pov tseg.

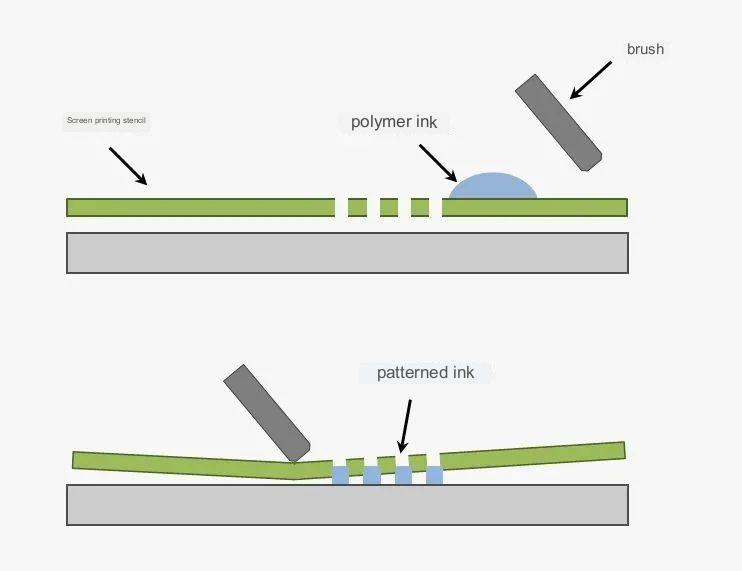

07. Screen luam ntawv

—— Screen Printing —

Los ntawm extrusion ntawm scraper, tus number case yog pauv mus rau saum npoo ntawm nws lub mesh thiab ua rau tib daim duab uas tau luam tawm thawj zaug. Cov tshuab luam ntawv tshuaj ntsuam yog cov neeg siv yooj yim, thiab yooj yim luam tawm thiab ua daim hlau, nrog tus nqi qis thiab ua tau zoo heev.

Cov ntaub ntawv luam tawm uas feem ntau siv suav nrog cov xim roj pleev xim rau daim ntawv tshaj tawm, daim npav lag luam, cov ntawv tshaj tawm khi npog, cov khoom siv kos npe, nrog rau cov dyed thiab luam ntawv textiles.

Cov ntaub ntawv siv tau:

Yuav luag txhua yam khoom siv tuaj yeem luam tawm, suav nrog hlau, yas, ntawv ceramics, iav thiab lwm yam.

Tus nqi ntawm cov txheej txheem pwm tus nqi yog tsawg, tab sis nws tseem yog nyob ntawm tus nqi ntawm cov xim siv, vim txhua xim yuav tsum tau tsim ntawm nws tus kheej. Cov nqi rau kev ua haujlwm yog siab heev, tshwj xeeb tshaj yog nyob rau hauv cov ntaub ntawv ntawm ntau xim luam ntawv.

Kev cuam tshuam ib puag ncig: Kev tshuaj ntsuam luam ntawv nrog lub teeb xim xim tsis muaj qhov cuam tshuam rau ib puag ncig, txawm li cas los xij cov inks uas ua los ntawm PVC thiab formaldehyde yog cov tshuaj lom neeg sib xyaw, thiab yuav tsum tau rov ua dua thiab muab pov tseg thaum lub sijhawm tsim nyog kom tsis txhob muaj dej paug. .

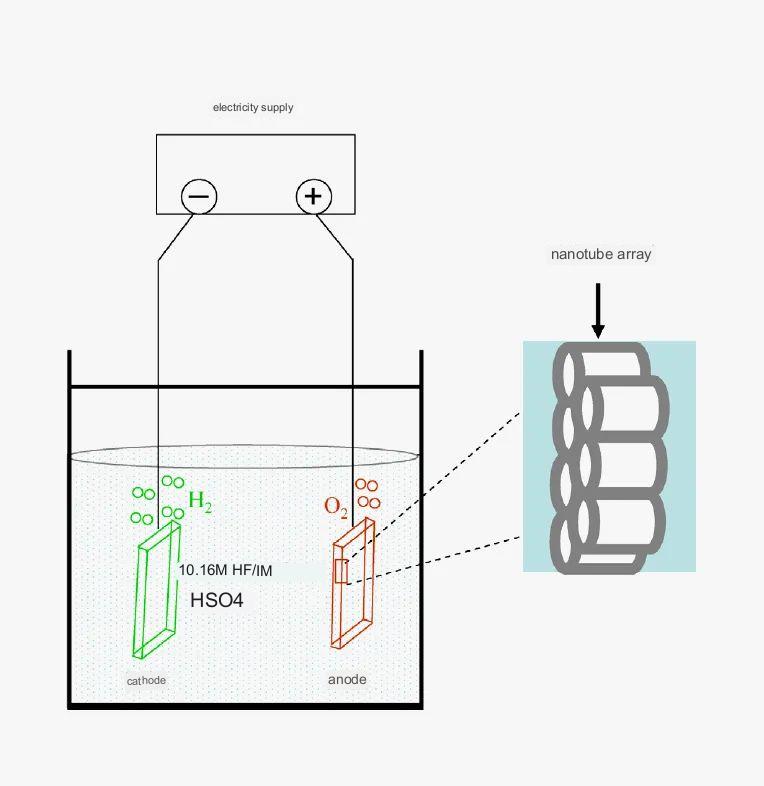

08. Anodizing

---- Anodic Oxidation--

Cov txheej txheem anodic oxidation rau txhuas feem ntau yog ua raws li lub tswv yim electrochemical los tsim cov txheej txheem nyias nyias uas muaj Al2O3 (aluminium oxide) zaj duab xis ntawm txhuas thiab txhuas alloy. Cov oxide muaj cov khoom sib txawv xws li kev tiv thaiv corrosion, kho kom zoo nkauj, rwb thaiv tsev thiab tiv thaiv hnav.

Cov ntaub ntawv siv tau:

Aluminium, aluminium alloy, thiab lwm yam khoom siv txhuas

Tus nqi ntawm cov txheej txheem: Hauv cov txheej txheem ntawm kev tsim cov khoom siv hluav taws xob thiab dej yog qhov tseem ceeb, tshwj xeeb tshaj yog thaum cov txheej txheem oxidation. Kev siv hluav taws xob los ntawm cov tshuab nws tus kheej yuav tsum tau ua kom txias tas li nrog dej ntws. Lub zog noj ib tonne feem ntau yog txog 1000 degrees.

Kev cuam tshuam ib puag ncig: Anodizing tsis yog qhov tshwj xeeb ntawm kev siv hluav taws xob. Txawm li cas los xij, nyob rau hauv tus txheej txheem ntawm kev tsim electrolysis ntawm txhuas cov tshuaj tiv thaiv anode generates gasses uas muaj teeb meem tsis zoo rau cov huab cua ozone txheej.

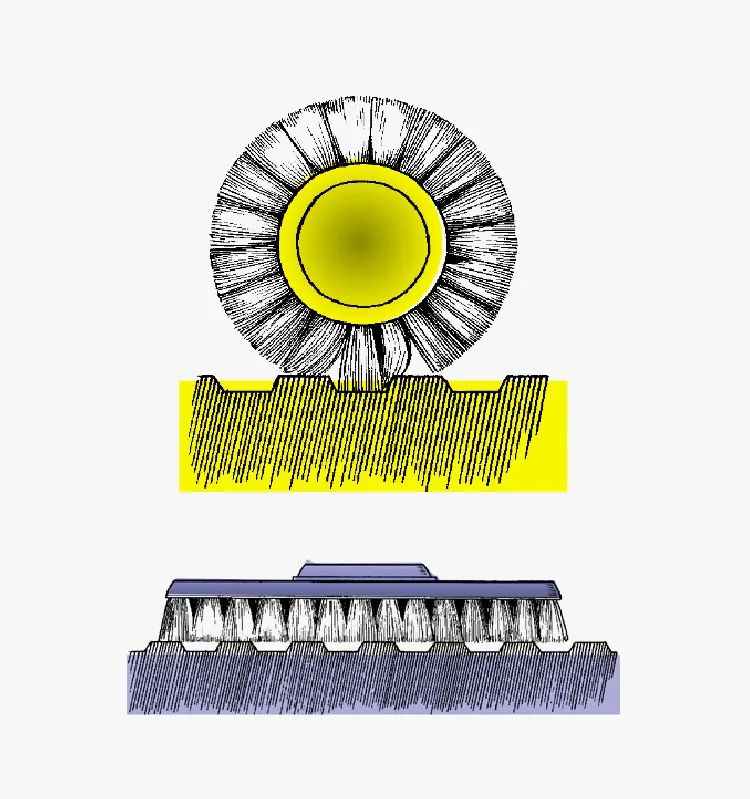

09. Hlau hlau kos duab

—— Hlau Hlau ——

Nws yog txoj hauv kev kho saum npoo uas tsim cov kab ntawm qhov chaw ntawm qhov chaw ua haujlwm los ntawm kev sib tsoo cov khoom kom muaj kev cuam tshuam zoo nkauj. Raws li ntau yam qauv tom qab kab kos duab, nws tuaj yeem muab faib ua: ncaj kab kos duab, kab kos duab tsis zoo, corrugated, zoo li swirling.

Cov ntaub ntawv ntsig txog: Yuav luag txhua cov ntaub ntawv hlau tuaj yeem siv cov txheej txheem hlau txuas.

Cov txheej txheem kev siv nyiaj: Cov txheej txheem ua kom yooj yim, cov cuab yeej siv ncaj qha, cov khoom siv tsawg heev, tus nqi raug txo qis, thiab tseem muaj txiaj ntsig nyiaj txiag siab.

Kev cuam tshuam ib puag ncig: cov khoom siv hlau ntshiab, tsis muaj xim lossis lwm yam khoom siv tshuaj lom neeg ntawm qhov chaw, 600 degrees kub tsis yaj, tsis tsim cov pa phem, ua tau raws li kev ruaj ntseg hluav taws thiab kev tiv thaiv ib puag ncig.

10. Hauv-pwm kho kom zoo nkauj

—— Hauv Pwm Kho Kom Zoo Nkauj-IMD ——

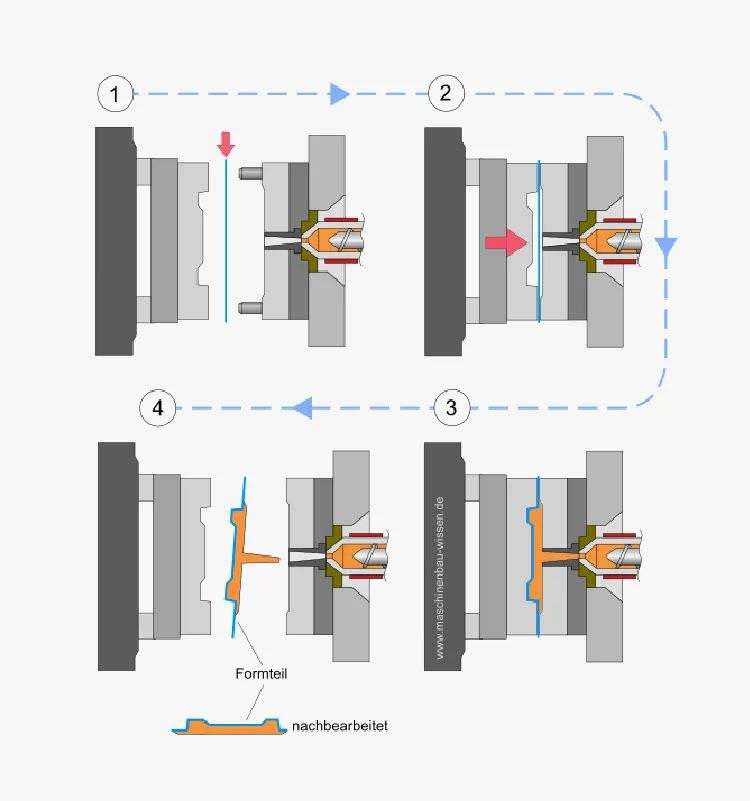

Nws yog cov txheej txheem molding uas muab cov qauv luam tawm diaphragm txoj cai rau hauv cov pwm hlau thiab pwm, infuses cov resin rau molding txoj cai rau hauv cov pwm hlau thiab pwm zoo li koom nrog cov diaphragm, thiab ua rau cov qauv luam tawm diaphragm zoo li resin incorporated nrog rau solidified txoj cai rau hauv cov khoom tiav.

Cov khoom tsim nyog: thaj chaw yas

Cov nqi kho kom zoo: tsuas yog yuav tsum qhib cov khoom sib sau ntawm pwm thiab pwm, uas tuaj yeem txo cov nuj nqis thiab cov tib neeg-teev, cov khoom siv siab tsis siv neeg, kev tsim cov txheej txheem yooj yim, ib zaug txhaj tshuaj molding mus kom ze, nrog rau kev molding thiab kho kom zoo nkauj. tib lub sijhawm.

Kev cuam tshuam ib puag ncig: Cov cuab yeej siv niaj hnub no yog ib puag ncig zoo nrog rau ib puag ncig tus phooj ywg, tiv thaiv kev sib kis los ntawm cov pa pleev xim zoo li electroplating.

Qhov zoo ntawm Anebon yog cov nqi qis dua, pab pawg neeg tau txais txiaj ntsig, QC tshwj xeeb, cov chaw tsim khoom ruaj khov, cov kev pabcuam zoo tshaj plaws rau cnc machining aluminium qhov chaw ua kev pabcuam thiab cnc machining tig qhov kev pabcuam. Anebon tau teeb tsa lub hom phiaj ntawm Kev Txhim Kho Kev Txhim Kho Kev Lag Luam, kev tswj hwm kev tsim kho tshiab, cov neeg tseem ceeb innovation thiab kev tsim kho tshiab, muab kev ua si tag nrho rau qhov zoo ntawm tag nrho, thiab niaj hnub ua kev txhim kho kom txhawb nqa zoo.

Anebon Cov Khoom Tshiab Tuam Tshoj Xauv-Qhov Tshuab Ua Tshuab thiab Aluminium Qhov rai Xauv Qhov Tshuab Ua Tshuab, Anebon muaj cov khoom tiav cov kab ntau lawm, sib dhos kab, kev tswj xyuas zoo, thiab qhov tseem ceeb tshaj plaws, tam sim no Anebon muaj ntau yam patents thev naus laus zis thiab kev paub txog kev tsim khoom & pab pawg muag khoom, kev pab cuam muag khoom. pab neeg. Nrog rau txhua tus neeg zoo, peb tau mus tsim "lub koob npe nrov thoob ntiaj teb hom nylon monofilaments", thiab nthuav peb cov khoom muag mus rau txhua lub ces kaum ntawm lub ntiaj teb. Peb tau txav mus los thiab sim peb qhov zoo tshaj plaws los pab cov neeg siv khoom ntawm Anebon.

Post lub sij hawm: Lub Xya hli ntuj-29-2023