Cov Kev Xav Tau Rau Kev Siv Hluav Taws Xob tau muab tso ua ke los ntawm pab pawg Anebon suav nrog cov npe hauv qab no:

1. Cov kev cai dav dav

2. Kev kho cua sov yuav tsum tau ua

3. Kev kam rau siab

4. Ntu Lub kaum sab xis

5. Kev sib dhos yuav tsum tau ua

6. Casting yuav tsum tau

7. Txheej txheej yuav tsum tau ua

8. Cov kav dej yuav tsum tau ua

9. Solder kho yuav tsum

10. Forging yuav tsum tau

11. Yuav tsum tau txiav workpiece

▌ General Technical Requirements

1. Qhov chaw tshem tawm cov tawv nqaij oxide.

2. Nyob rau saum npoo ntawm cov khoom ua tiav, yuav tsum tsis muaj khawb, bruises thiab lwm yam tsis xws luag uas ua rau qhov chaw ntawm qhov chaw puas.

3. Tshem tawm burrs.

▌ Cov Kev Cai Kho Mob Kub Kub

1. Tom qab tempering kho, HRC50 ~ 55.

2. Qhov chaw rau high-frequency quenching, 350 ~ 370 ℃ tempering, HRC40 ~ 45.

3. Carburizing qhov tob 0.3mm.

4. Kub kub kev kho mob laus.

▌ Yam Yuav Tsum Tau Ua

1. Cov qauv tsis muaj cim yuav tsum ua raws li qhov yuav tsum tau ua ntawm GB1184-80.

2. Qhov tso cai sib txawv ntawm qhov tsis pom qhov ntev yog ± 0.5mm.

3. Qhov chaw kam rau ua casting yog symmetrical rau qhov loj me me configuration ntawm qhov dawb paug casting.

▌ Cov kaum thiab cov npoo ntawm qhov chaw

1. Lub kaum lub vojvoog R5 tsis tau teev tseg.

2. Lub chamfer tsis txhaj tshuaj yog 2 × 45 °.

3. Lub kaum ntse ntse / ntse kaum / ntse npoo yog blunted.

▌ Cov Kev Cai Sib Koom Tes

1. Ua ntej sib dhos, txhua lub foob yuav tsum muab tso rau hauv cov roj.

2. Roj cua sov tau tso cai rau qhov kub them ntawm dov bearings thaum sib dhos, nrog cov roj kub tsis tshaj 100 ℃.

3. Ua raws li cov iav sib dhos, cov ntsiab lus sib cuag thiab rov qab ntawm cov hniav yuav tsum ua raws li cov qauv teev tseg hauv GB10095 thiab GB11365.

4. Nyob rau hauv lub rooj sib txoos ntawm hydraulic system, kev siv cov sealing muab tub lim los yog sealant tau tso cai, yog tias nws khaws cia tawm ntawm qhov system.

5. Txhua tusmachining qhov chawthiab cov khoom nkag mus rau hauv lub rooj sib txoos (nrog rau cov yuav khoom lossis cov khoom tawm) yuav tsum muaj ntawv pov thawj los ntawm lub chaw soj ntsuam.

6. Ua ntej sib dhos, cov khoom yuav tsum tau ua kom huv si kom tsis txhob muaj cov burrs, flash, oxide, xeb, chips, roj, tshuaj pleev xim, thiab hmoov av.

7. Ua ntej sib dhos, nws yog ib qho tseem ceeb uas yuav tsum tau saib xyuas lub ntsiab haum qhov ntev ntawm cov khoom thiab cov khoom, tshwj xeeb tshaj yog qhov cuam tshuam haum qhov ntev thiab qhov muaj feem cuam tshuam.

8. Thoob plaws hauv kev sib dhos, cov khoom yuav tsum tsis txhob kov, kov, khawb, lossis tso cai rau xeb.

9. Thaum tuav cov screws, bolts, thiab ceev, nws yog ib qho tseem ceeb kom tsis txhob ntaus lawv los yog siv cov spanners thiab wrenches tsis raug. Cov ntsia hlau ntsia hlau, txiv ntseej, ntsia hlau, thiab ntsia liaj qhov rooj taub hau yuav tsum tsis txhob puas tsuaj tom qab zawm.

10. Cov fasteners uas yuav tsum tau nruj torque yuav tsum tau ruaj ntseg siv lub torque ciaj ntswj thiab nruj raws li lub torque teev.

11. Thaum fastening tib seem nrog ntau cov ntsia hlau (bolts), lawv yuav tsum tau nruj nreem nyob rau hauv ib tug ntoo khaub lig, symmetrical, step-by-step, thiab uniformity.

12. Lub rooj sib txoos ntawm lub khob hliav qab yuav tsum muaj xim rau lub qhov, kom ntseeg tau tias qhov kev sib cuag tsis pub tsawg tshaj 60% ntawm qhov sib txuam ntev, sib npaug sib npaug.

13. Ob sab ntawm lub tiaj tus yuam sij thiab qhov tseem ceeb ntawm tus ncej yuav tsum muaj kev sib cuag tsis sib xws.

14. Qhov tsawg kawg nkaus ntawm 2/3 ntawm cov hniav yuav tsum nyob rau hauv kev sib cuag thaum lub sij hawm sib dhos spline, nrog rau tus nqi sib cuag tsis pub tsawg tshaj 50% ntawm qhov ntev thiab qhov siab ntawm cov hniav tseem ceeb.

15. Thaum sib dhos ntawm lub tiaj tus yuam sij (los yog spline) rau zawv zawg qhov sib tw, cov ntu ntu yuav tsum txav mus los ywj pheej, tsis muaj qhov tsis sib xws.

16. Cov nplaum nplaum yuav tsum tau muab tshem tawm tom qab kev sib txuas.

17. Lub qhov semi-circular ntawm lub nplhaib sab nrauv, qhib lub rooj zaum, thiab cov kabmob npog yuav tsum tsis txhob daig.

18. Lub nplhaib sab nraud yuav tsum muaj kev sib cuag zoo nrog lub voj voog ib nrab ntawm lub rooj zaum qhib thiab cov kabmob npog, thiab nthuav tawm kev sib cuag nrog lub rooj zaum bearing nyob rau hauv qhov kev teev tseg thaum lub sijhawm tshuaj xyuas xim.

19. Tom qab kev sib dhos, lub nplhaib sab nraud ntawm cov kabmob yuav tsum muaj kev sib cuag nrog lub ntsej muag kawg ntawm qhov kawg ntawm qhov kev coj tus kabmob npog.

20. Tom qab lub installation ntawm dov bearings, phau ntawv kev sib hloov yuav tsum hloov tau thiab ruaj khov.

21. Kev sib xyaw ua ke ntawm cov kabmob sab saud thiab qis qis yuav tsum nruj nruj thiab raug kuaj xyuas nrog lub siab 0.05mm.

22. Thaum kho lub plhaub bearing nrog ib tug positioning pin, nws yuav tsum tau drilled thiab muab faib mus rau hauv kev sib raug zoo nrog rau cov bearing qhov. Tus pin yuav tsum tsis loosen tom qab installation.

23. Lub cev ntawm cov kabmob kheej kheej thiab lub rooj zaum bearing yuav tsum nyob rau hauv ib qho kev sib cuag, nrog rau kev sib cuag tsis pub tsawg tshaj 70% thaum kuaj nrog cov xim.

24. Lub alloy bearing hauv ob sab phlu yuav tsum tsis txhob siv thaum nws tig daj, thiab lub nucleation tshwm sim tsis pub nyob rau hauv lub teev kev sib cuag lub kaum sab xis, nrog rau lub nucleation cheeb tsam sab nraum lub contactor txwv tsis pub ntau tshaj 10% ntawm tag nrho cov tsis- tiv tauj cheeb tsam.

25. Kev siv lub ntsej muag kawg ntawm lub iav (worm iav) thiab lub xub pwg nyom (los yog lub ntsej muag kawg ntawm lub tes tsho) yuav tsum haum yam tsis tso cai rau 0.05mm feeler hla, kom ntseeg tau tias perpendicularity nrog lub iav siv kawg lub ntsej muag thiab axis.

26. Qhov sib xyaw ua ke ntawm lub iav lub thawv thiab lub hau yuav tsum muaj kev sib cuag zoo.

27. Ua ntej sib dhos, nws yog ib qho tseem ceeb uas yuav tsum tau ua tib zoo xyuas thiab tshem tawm cov kaum ntse ntse, burrs, thiab cov khoom txawv teb chaws uas tseem tshuav los ntawm cov khoom ua haujlwm, kom ntseeg tau tias lub foob tseem tsis tau khawb thaum lub sijhawm thauj khoom.

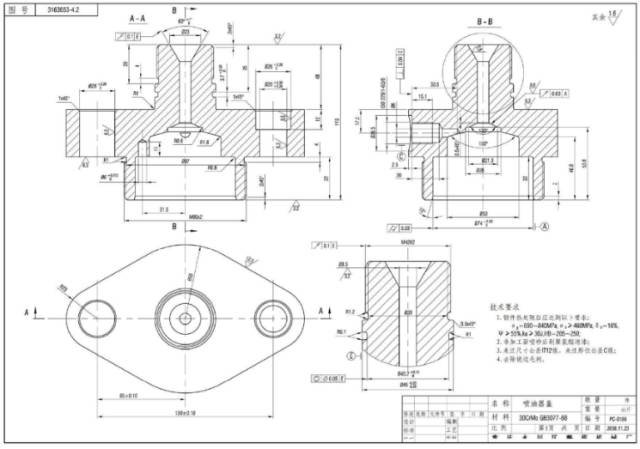

▌ Casting Requirements

1. Casting nto yuav tsum tsis txhob muaj cov rwb thaiv tsev tsawg, tawg, contractions, los yog imperfections xws li inadequacies nyob rau hauv casting (xws li, tsis txaus cov khoom, mechanical puas, thiab lwm yam).

2. Castings yuav tsum tau ua kom huv si kom tshem tawm txhua qhov protrusions, cov npoo ntse, thiab qhia txog cov txheej txheem ua tsis tiav, thiab lub rooj vag pouring yuav tsum tau muab ntxuav kom huv nrog cov txheej txheem casting.

3. Qhov uas tsis yog-machined nto ntawm lub casting yuav tsum kom meej meej pom cov casting hom thiab cim, ua tau raws li cov kos duab specifications nyob rau hauv cov nqe lus ntawm txoj hauj lwm thiab font.

4. Lub roughness ntawm qhov tsis-machined nto ntawm lub casting, nyob rau hauv cov ntaub ntawv ntawm xuab zeb casting R, yuav tsum tsis txhob ntau tshaj 50μm.

5. Castings yuav tsum tau tshem ntawm sprue, projections, thiab lwm yam sprue nyob rau hauv uas tsis yog-machined nto yuav tsum tau ua theem thiab polished kom tau raws li cov qauv zoo.

6. Lub casting yuav tsum tsis pub molding xuab zeb, core xuab zeb, thiab core seem.

7. Lub inclined qhov chaw thiab qhov ntev kam rau ua cheeb tsam ntawm lub casting yuav tsum tau symmetrically teem raws lub inclined dav hlau.

8. Txhua yam xuab zeb molding, core sand, core remnants, as well as any soft or adhesive sand on the casting, will be smoothed out and cleansed.

9. Hom txoj cai thiab tsis ncaj ncees lawm thiab tej convex casting deviations yuav tsum tau rectified los xyuas kom meej ib tug du kev hloov thiab lav lub zoo zoo.

10. Lub creases ntawm qhov tsis-machined nto ntawm lub casting yuav tsum tsis txhob ntau tshaj qhov tob ntawm 2 hli, nrog rau qhov tsawg kawg nkaus qhov sib nrug ntawm 100 hli.

11. Lub tshuab tsis siv lub tshuab cov khoom castings yuav tsum tau txhaj tshuaj peening lossis kev kho cov menyuam kom ua tau raws li kev cai huv ntawm Sa2 1/2.

12. Castings yuav tsum tau hardened nrog dej.

13. Lub casting nto yuav tsum du, thiab txhua lub rooj vag, protrusions, nplaum xuab zeb, thiab lwm yam, yuav tsum tau muab tshem tawm.

14. Castings yuav tsum tsis muaj rwb thaiv tsev tsawg, tawg, voids, los yog lwm yam casting flaws uas yuav cuam tshuam rau kev siv.

▌ Painting Requirements

1. Ua ntej pleev xim rau cov hlau, nws yog ib qho tseem ceeb uas yuav tsum tau tshem tawm cov kab xeb, oxide, grime, plua plav, av, ntsev, thiab lwm yam kab mob ntawm qhov chaw.

2. Txhawm rau npaj cov hlau rau kev tshem tawm xeb, siv cov kuab tshuaj ntuj, cov dej qab zib caustic, emulsifying cov neeg ua haujlwm, chav dej, lossis lwm yam tsim nyog los tshem tawm cov roj thiab cov av ntawm qhov chaw.

3. Tom qab txhaj tshuaj tiv thaiv kab mob los yog kev tshem tawm xeb, lub sij hawm ntawm kev npaj qhov chaw thiab siv cov primer yuav tsum tsis pub tshaj 6 teev.

4. Ua ntej kev sib txuas, siv 30 mus rau 40μm tuab txheej ntawm cov xim tiv thaiv corrosion rau qhov chaw ntawm riveted qhov chaw nyob rau hauv kev sib cuag nrog ib leeg. Seal lub ntug ntawm lub puab tsaig sib koom nrog cov xim, muab tub lim, los yog nplaum. Yog hais tias lub primer puas thaum lub sij hawm machining los yog welding, rov muab lub tsho tshiab.

▌ Piping Requirements

1. Tshem tawm cov flash, burrs, lossis bevels ntawm cov yeeb nkab kawg ua ntej sib dhos. Siv cov cua compressed los yog ib txoj hauv kev tsim nyog los tshem cov impurities thiab cov xeb seem ntawm phab ntsa hauv cov kav dej.

2. Ua ntej sib dhos, xyuas kom meej tias tag nrho cov kav hlau steel, nrog rau cov khoom ua ntej, raug kho nrog degreasing, pickling, neutralization, ntxuav, thiab tiv thaiv corrosion.

3. Thaum lub sij hawm sib dhos, ceev nrooj fasten threaded kev sib txuas xws li cov yeeb nkab clamps, kev txhawb nqa, flanges, thiab cov pob qij txha kom tsis txhob xoob.

4. Ua ib qho kev ntsuas siab ntawm cov welded seem ntawm cov kav dej prefabricated.

5. Thaum tsiv los yog hloov cov kav dej, muab cov yeeb nkab sib cais taw tes nrog cov nplaum nplaum los yog lub hau yas kom tsis txhob muaj cov khib nyiab nkag mus, thiab xyuas kom meej tias nws tau sau npe raws li.

▌ Yuav tsum tau kho qhov vuam vuam

1. Ua ntej welding, nws yog ib qho tseem ceeb kom tshem tawm cov imperfections thiab xyuas kom meej tias qhov zawj saum npoo yog txawm thiab tsis muaj cov npoo ntse.

2. Raws li qhov tsis zoo ntawm cov hlau cam khwb cia, qhov chaw vuam tuaj yeem kho tau los ntawm kev khawb, puas, carbon arc gouging, roj txiav, lossis cov txheej txheem siv tshuab.

3. Ntxuav tag nrho cov cheeb tsam ib puag ncig hauv ib lub vojvoog 20 hli ntawm qhov vuam zawj, xyuas kom tshem tawm cov xuab zeb, roj, dej, xeb, thiab lwm yam kab mob.

4. Thoob plaws hauv cov txheej txheem vuam, qhov preheating cheeb tsam ntawm cov hlau casting yuav tsum tswj qhov kub tsis qis dua 350 ° C.

5. Yog tias muaj xwm txheej, sim ua vuam nyob rau hauv txoj hauj lwm kab rov tav.

6. Thaum ua kev kho vuam, txwv tsis pub dhau kev txav ntawm cov electrode.

7. Ua raws li txhua qhov kev sib txuas, kom ntseeg tau tias qhov sib tshooj yog tsawg kawg yog 1/3 ntawm qhov dav hla. Lub weld yuav tsum muaj zog, tsis muaj qhov kub hnyiab, tawg, thiab pom qhov tsis sib xws. Cov tsos ntawm cov welds yuav tsum tau zoo siab, tsis muaj undercutting, tshaj slag, porosity, tawg, spatter, los yog lwm yam faults. Cov hlaws welding yuav tsum zoo ib yam.

▌ Forging Requirements

1. Lub qhov ncauj dej thiab riser ntawm lub ingot yuav tsum tau txiav kom txaus kom tsis txhob shrinkage voids thiab tseem ceeb deviations thaum lub sij hawm forging.

2. Cov forgings yuav tsum tau ua raws li cov xovxwm uas muaj peev xwm txaus los xyuas kom meej tag nrho cov kev sib koom ua ke.

3. Lub xub ntiag ntawm qhov pom kev tawg, creases, lossis lwm yam kev pom tsis zoo uas cuam tshuam kev ua haujlwm tsis raug tso cai hauv forgings. Cov kev tsis haum hauv zos tuaj yeem kho tau, tab sis qhov tob ntawm kev kho yuav tsum tsis pub tshaj 75% ntawm cov nyiaj ua haujlwm machining. Qhov tsis xws luag ntawm qhov chaw tsis siv neeg yuav tsum tau muab tshem tawm thiab hloov pauv seamlessly.

4. Forgings yog txwv tsis pub los ntawm kev nthuav tawm blemishes xws li cov pob dawb, nyob rau hauv fissures, thiab residual shrinkage voids.

▌ Yuav tsum tau txiav workpiece

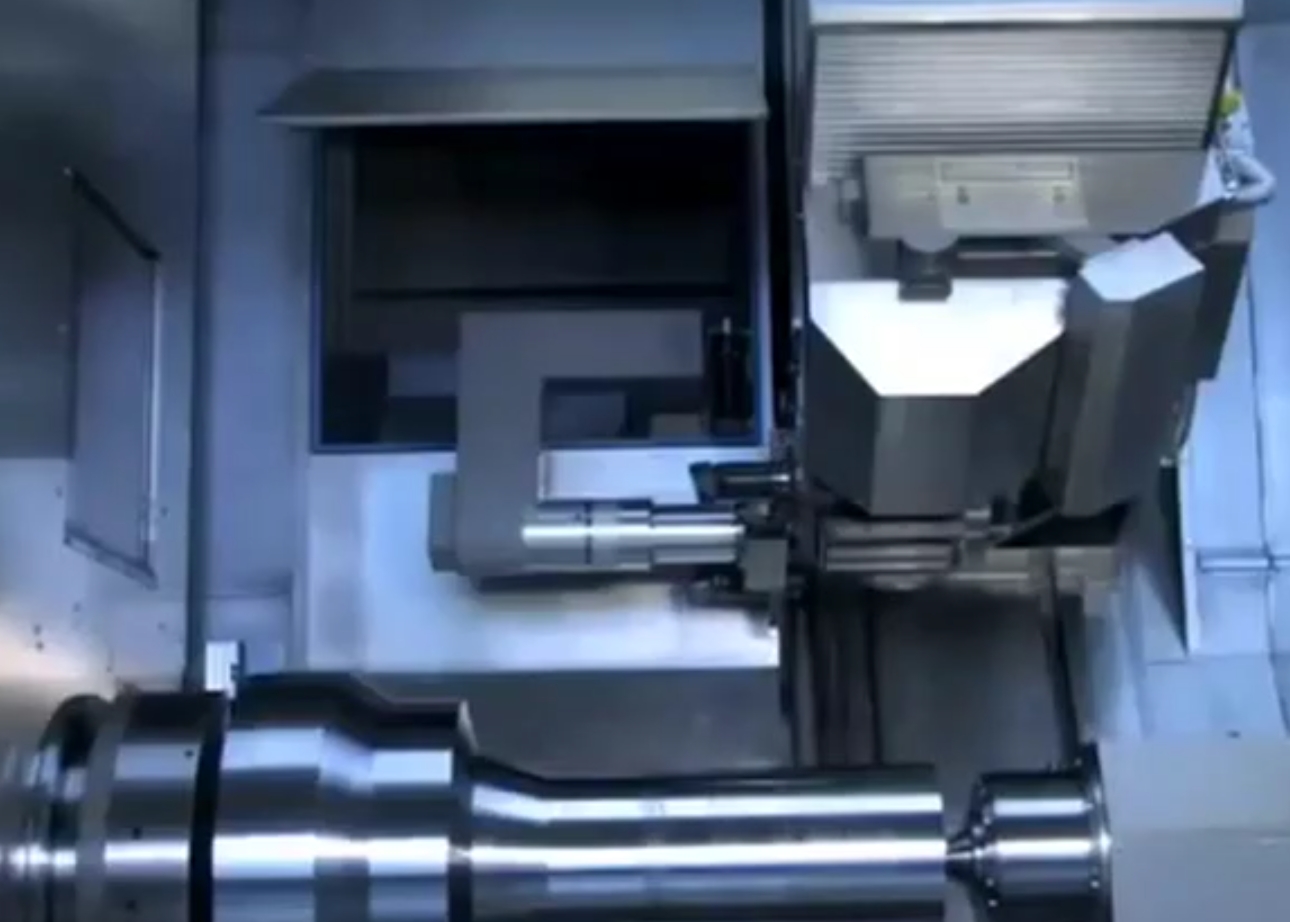

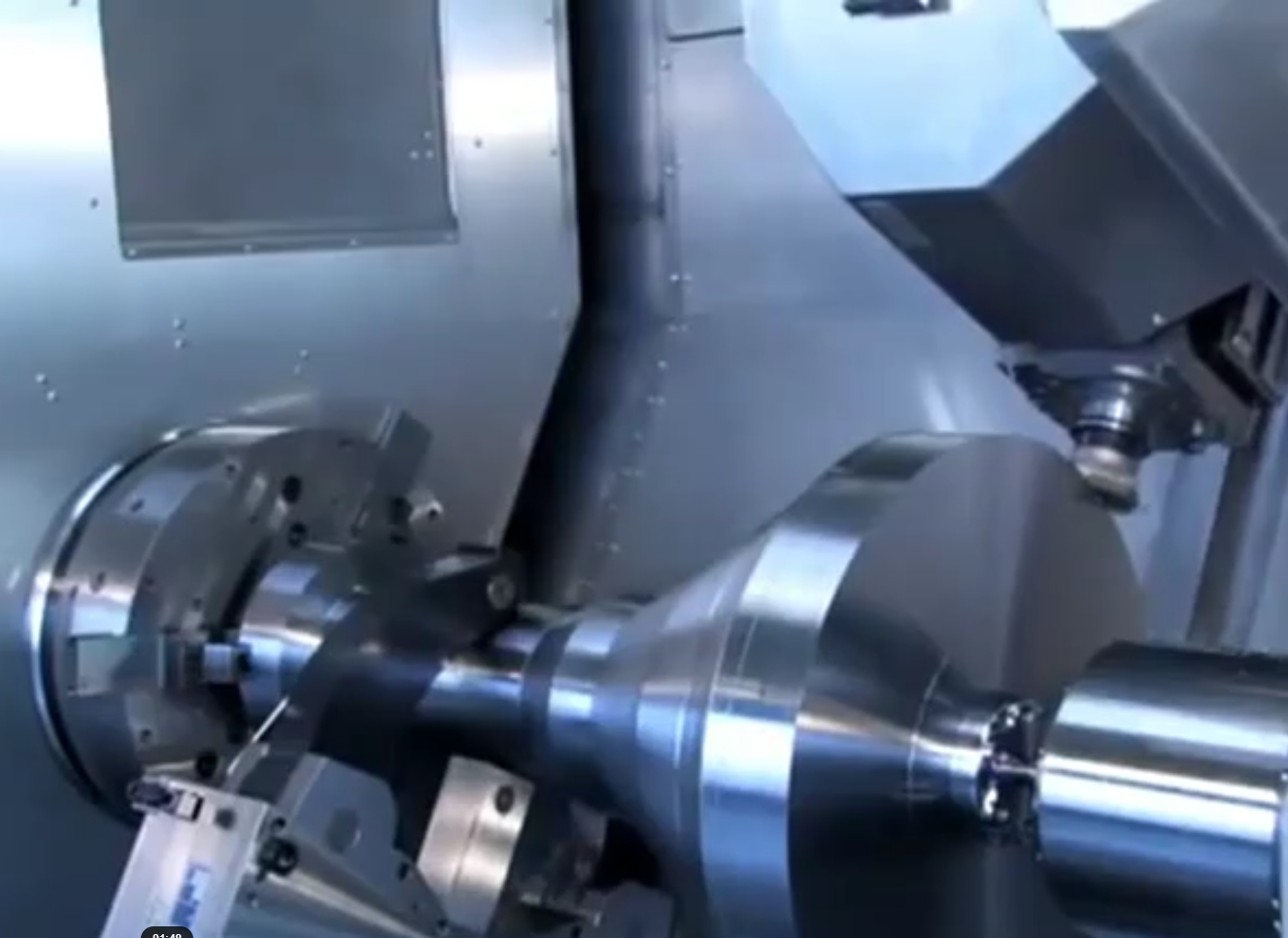

1. Precision tig Cheebtsamyuav tsum tau soj ntsuam xyuas thiab kev pom zoo hauv kev ua raws li cov txheej txheem tsim khoom, kom ntseeg tau tias kev nce qib mus rau theem tom ntej tsuas yog thaum muaj kev lees paub los ntawm kev tshuaj xyuas ua ntej.

2. Cov khoom tiav tiav yuav tsum tsis txhob muaj qhov tsis sib xws hauv daim ntawv ntawm protrusions.

3. Cov khoom tiav yuav tsum tsis txhob muab tso ncaj qha rau hauv pem teb, thiab yuav tsum muaj kev txhawb nqa thiab kev tiv thaiv kev tiv thaiv. Xyuas kom tsis muaj xeb, xeb, thiab muaj kev cuam tshuam rau kev ua haujlwm, kev ua haujlwm ntev, lossis cov tsos, suav nrog cov dents, khawb, lossis lwm yam tsis zoo, yog qhov tseem ceeb rau cov khoom tiav.

4. Qhov saum npoo tom qab dov tiav txheej txheem yuav tsum tsis txhob tshwm sim ntawm qhov tshwm sim tom qab dov.

5. Cov khoom siv tom qab kev kho cua sov zaum kawg yuav tsum tsis txhob tso tawm oxidation nto. Tsis tas li ntawd, cov mating thiab hniav nto tom qab ua tiav yuav tsum nyob twj ywm tsis muaj kev cuam tshuam.

6. Qhov saum npoo ntawm cov xov txheej txheem yuav tsum tsis txhob tso tawm ib qho kev tsis zoo xws li qhov tsaus nti, qhov tawm, qhov tsis sib xws, los yog cov protrusions.

Txhawm rau tsim kom muaj txiaj ntsig ntau rau cov neeg yuav khoom yog Anebon lub tswv yim kev lag luam; tus neeg yuav khoom loj hlob yog Anebon lub zog ua haujlwm. Rau Cov Khoom Kub Tshiab Cov Khoom Siv Txhuas Txhuascnc machining qhov chawthiabtooj dag milling qhov chawthiab kev cai stamping qhov chaw, koj puas tseem tab tom nrhiav rau cov khoom lag luam zoo uas yog nyob rau hauv ua ke nrog koj lub koom haum zoo heev thaum nthuav koj cov khoom lag luam? Xav txog Anebon cov khoom lag luam zoo. Koj qhov kev xaiv yuav ua pov thawj tias ntse!

Cov Khoom Kub Tshiab Tuam Tshoj iav thiab Acrylic iav, Anebon cia siab rau cov ntaub ntawv zoo, tsim zoo meej, kev pabcuam zoo rau cov neeg siv khoom thiab cov nqi sib tw kom yeej kev ntseeg siab ntawm ntau tus neeg muas zaub hauv tsev thiab txawv teb chaws. 95% cov khoom raug xa tawm mus rau kev lag luam txawv teb chaws.

Yog tias koj xav paub ntau ntxiv lossis xav tau kev nug, thov hu rauinfo@anebon.com.

Post lub sij hawm: Jan-30-2024