HV, HB, thiab HRC yog tag nrho cov kev ntsuas ntawm hardness siv nyob rau hauv cov ntaub ntawv ntsuam xyuas. Cia peb rhuav tshem lawv:

1) HV Hardness (Vickers Hardness): HV hardness yog ib qho kev ntsuas ntawm cov khoom tiv thaiv rau indentation. Nws yog txiav txim los ntawm kev siv ib tug paub load rau saum npoo ntawm cov khoom siv lub pob zeb diamond indenter thiab ntsuas qhov loj ntawm qhov tshwm sim indentation. HV hardness yog qhia nyob rau hauv units ntawm Vickers hardness (HV) thiab feem ntau yog siv rau nyias cov ntaub ntawv, txheej, thiab me me qhov chaw.

2) HB Hardness (Brinell Hardness): HB hardness yog lwm qhov kev ntsuas ntawm cov khoom tiv thaiv rau indentation. Nws suav nrog kev siv lub peev xwm paub rau cov khoom siv uas siv lub pob steel pob indenter thiab ntsuas lub cheeb ntawm qhov tshwm sim indentation. HB hardness yog qhia nyob rau hauv units ntawm Brinell hardness (HB) thiab feem ntau yog siv rau loj thiab bulkier cov ntaub ntawv, nrog rau cov hlau thiab alloys.

3) HRC Hardness (Rockwell Hardness): HRC hardness yog ib qho kev ntsuas ntawm cov khoom tiv thaiv rau indentation lossis nkag. Nws siv cov nplais sib txawv (A, B, C, thiab lwm yam) raws li txoj kev ntsuas tshwj xeeb thiab hom indenter siv (pob zeb diamond cone lossis pob zeb tawv tawv). HRC nplai feem ntau yog siv los ntsuas qhov hardness ntawm cov khoom siv hlau. Tus nqi hardness yog sawv cev raws li tus lej ntawm HRC nplai, xws li HRC 50.

Feem ntau siv HV-HB-HRC hardness sib piv lub rooj:

| Common ferrous hlau hardness sib piv rooj (kwv yees lub zog hloov dua siab tshiab) | ||||

| Kev faib tawm hardness | Tensile zog N / hli2 | |||

| Rockwell | Vickers | Brinell | ||

| HRC | HRA | HV | HB | |

| 17 | — | 211 | 211 | 7 10 |

| 17.5 Nws | — | 214 | 214 | 715 ib |

| 18 | — | 216 | 216 | 725 ib |

| 18.5 Nws | — | 218 | 218 | 730 ua |

| 19 | — | 221 | 220 | 735 ib |

| 19.5 Nws | — | 223 | 222 | 745 ib |

| 20 | — | 226 | 225 | 750 |

| 20.5 ib | — | 229 | 227 | 760 ib |

| 21 | — | 231 | 229 | 765 ib |

| 21.5 ib | — | 234 | 232 | 775 ib |

| 22 | — | 237 | 234 | 785 ib |

| 22.5 ib | — | 240 | 237 | 790 ua |

| 23 | — | 243 | 240 | 800 |

| 23.5 Nws | — | 246 | 242 | 810 |

| 24 | — | 249 | 245 | 820 |

| 24.5 ib | — | 252 | 248 | 8 30 |

| 25 | — | 255 | 251 | 835 ib |

| 25.5 ib | — | 258 | 254 | 850 |

| 26 | — | 261 | 257 | 860 ua |

| 26.5 ib | — | 264 | 260 | 870 ib |

| 27 | — | 268 | 263 | 880 ua |

| 27.5 ib | — | 271 | 266 | 890 ua |

| 28 | — | 274 | 269 | 900 |

| 28.5 Nws | — | 278 | 273 | 9 10 |

| 29 | — | 281 | 276 | 9 20 |

| 29.5 Nws | — | 285 | 280 | 935 ua |

| 30 | — | 289 | 283 | 950 ua |

| 30.5 ib | — | 292 ib | 287 | 960 ua |

| 31 | — | 296 ib | 291 ib | 970 ua |

| 31.5 ib | — | 300 | 294 ib | 980 ua |

| 32 | — | 304 | 298 | 995 ib |

| 32.5 ib | — | 308 | 302 | 1010 |

| 33 | — | 312 | 306 | 1020 |

| 33.5 ib | — | 316 | 310 | 1035 ib |

| 34 | — | 320 | 314 | 1050 |

| 34.5 ib | — | 324 | 318 | 1065 ib |

| 35 | — | 329 | 323 | 1080 |

| 35.5 ib | — | 333 | 327 | 1095 ib |

| 36 | — | 338 | 332 | 1110 |

| 36.5 ib | — | 342 ib | 336 | 1125 |

| 37 | — | 347 ib | 341 | 1140 |

| 37.5 ib | — | 352 ib | 345 | 1160 |

| 38 | — | 357 ib | 350 | 1175 ib |

| 38.5 ib | — | 362 ib | 355 | 1190 ib |

| 39 | 70 | 367 ib | 360 | 1210 |

| 39.5 ib | 70.3 ib | 372 ib | 365 | 1225 |

| 40 | 70.8 ua | 382 ib | 375 | 1260 |

| 40.5 ib | 70.5 ua | 377 ib | 370 | 1245 ib |

| 41 | 71.1 ib | 388 | 380 | 1280 |

| 41.5 ib | 71.3 ib | ib 393 | 385 | 1300 |

| 42 | 71.6 ib | 399 ib | 391 ib | 1320 |

| 42.5 ib | 71.8 ib | 405 | ib 396 | 1340 ib |

| 43 | 72.1 ib | 411 | 401 | 1360 |

| 43.5 ib | 72.4 ib | 417 | 407 | 1385 ib |

| 44 | 72.6 ib | 423 | 413 | 1405 ib |

| 44.5 ib | 72.9 ua | 429 ib | 418 | 1430 ib |

| 45 | 73.2 ib | 436 ib | 424 ib | 1450 |

| 45.5 ib | 73.4 ib | 443 ib | 430 | 1475 ib |

| 46 | 73.7 ua | 449 ib | 436 ib | 1500 |

| 46.5 ib | 73.9 ua | 456 ib | 442 ib | 1525 |

| 47 | 74.2 ib | 463 ib | 449 ib | 1550 |

| 47.5 ib | 74.5 ib | 470 ib | 455 | 1575 ib |

| 48 | 74.7 ib | 478 ib | 461 ib | 1605 ib |

| 48.5 ib | 75 | 485 ib | 468 ib | 1630 |

| 49 | 75.3 ib | 493 ib | 474 ib | 1660 |

| 49.5 ib | 75.5 ib | 501 | 481 ib | 1690 |

| 50 | 75.8 ua | 509 ib | 488 ib | 1720 |

| 50.5 ib | 76.1 ib | 517 ib | 494 ib | 1750 |

| 51 | 76.3 ib | 525 | 501 | 1780 |

| 51.5 ib | 76.6 ib | 534 ib | — | 1815 |

| 52 | 76.9 ua | 543 ib | — | 1850 |

| 52.5 ib | 77.1 ib | 551 ib | — | Xyoo 1885 |

| 53 | 77.4 ib | 561 ib | — | Xyoo 1920 |

| 53.5 ib | 77.7 ib | 570 ib | — | Xyoo 1955 |

| 54 | 77.9 ua | 579 ib | — | Xyoo 1995 |

| 54.5 ib | 78.2 ib | 589 ib | — | 2035 ib |

| 55 | 78.5 ib | 599 ib | — | 2075 ib |

| 55.5 ib | 78.7 ib | 609 ib | — | 2115 ib |

| 56 | 79 | 620 | — | 2160 |

| 56.5 ib | 79.3 ib | 631 ib | — | 2205 |

| 57 | 79.5 ib | 642 ib | — | 2250 |

| 57.5 ib | 79.8 ua | 653 ib | — | 2295 ib |

| 58 | 80.1 ib | 664 ib | — | 2345 ib |

| 58.5 ib | 80.3 ib | 676 ib | — | 2395 ib |

| 59 | 80.6 ib | 688 ua | — | 2450 |

| 59.5 ib | 80.9 ua | 700 | — | 2500 |

| 60 | 81.2 ib | 713 ib | — | 2555 ib |

| 60.5 ib | 81.4 ib | 726 ib | — | — |

| 61 | 81.7 ib | 739 ib | — | — |

| 61.5 ib | 82 | 752 ib | — | — |

| 62 | 82.2 ib | 766 ib | — | — |

| 62.5 ib | 82.5 ib | 780 ua | — | — |

| 63 | 82.8 ib | 795 ib | — | — |

| 63.5 ib | 83.1 ib | 810 | — | — |

| 64 | 83.3 ib | 825 ib | — | — |

| 64.5 ib | 83.6 ib | 840 ib | — | — |

| 65 | 83.9 ua | 856 ib | — | — |

| 65.5 ib | 84.1 ib | 872 ib | — | — |

| 66 | 84.4 ib | 889 ua | — | — |

| 66.5 ib | 84.7 ib | 906 ib | — | — |

| 67 | 85 | 923 ib | — | — |

| 67.5 ib | 85.2 ib | 941 ib | — | — |

| 68 | 85.5 ua | 959 ua | — | — |

| 68.5 ib | 85.8 ua | 978 ua | — | — |

| 69 | 86.1 ib | 997 ib | — | — |

| 69.5 ib | 86.3 ib | 1017 | — | — |

| 70 | 86.6 ib | 1037 ib | — | — |

HRC/HB Cov Lus Qhia Txog Kev Hloov Siab

Lub hardness siab tshaj 20HRC, 1HRC≈10HB,

Lub hardness qis dua 20HRC, 1HRC≈11.5HB.

Lus Cim: Rau kev txiav, nws tuaj yeem hloov pauv tsis tu ncua 1HRC≈10HB (qhov hardness ntawm cov khoom siv ua haujlwm muaj qhov sib txawv)

Hardness ntawm cov khoom siv hlau

Hardness yog hais txog lub peev xwm ntawm cov khoom siv los tiv thaiv lub zos deformation, tshwj xeeb tshaj yog cov yas deformation, indentation lossis khawb. Nws yog qhov ntsuas los ntsuas qhov softness thiab hardness ntawm cov khoom.

Raws li kev sim sib txawv, hardness muab faib ua peb hom.

①Kos hardness. Nws yog tsuas yog siv los sib piv cov softness thiab hardness ntawm txawv minerals. Txoj kev yog xaiv tus pas nrig nrog ib kawg nyuaj thiab lwm qhov kawg mos, hla cov khoom yuav tsum tau kuaj raws tus pas nrig, thiab txiav txim siab qhov hardness ntawm cov khoom yuav tsum tau kuaj raws li txoj hauj lwm ntawm khawb. Hais lus zoo, cov khoom tawv ua rau khawb ntev thiab cov khoom muag muag ua rau luv luv.

②Indentation hardness. Feem ntau yog siv rau cov ntaub ntawv hlau, txoj kev yog siv ib qho kev thauj khoom los nias lub cim indenter rau hauv cov khoom yuav tsum tau kuaj, thiab sib piv cov softness thiab hardness ntawm cov khoom yuav tsum tau kuaj los ntawm qhov luaj li cas ntawm lub zos yas deformation nyob rau saum npoo ntawm cov khoom. cov khoom. Vim qhov sib txawv ntawm indenter, load thiab load ntev, muaj ntau hom indentation hardness, feem ntau suav nrog Brinell hardness, Rockwell hardness, Vickers hardness thiab microhardness.

③Rebound hardness. Feem ntau yog siv rau cov ntaub ntawv hlau, txoj kev yog ua rau lub me me tshwj xeeb rauj poob dawb los ntawm qhov siab los cuam tshuam cov qauv ntawm cov khoom siv los kuaj, thiab siv cov khoom siv zog khaws cia (thiab tom qab ntawd tso tawm) hauv cov qauv thaum lub sijhawm cuam tshuam (los ntawm kev rov qab los ntawm lub me me rauj) dhia qhov siab ntsuas) los txiav txim qhov hardness ntawm cov khoom.

Feem ntau Brinell hardness, Rockwell hardness thiab Vickers hardness ntawm cov ntaub ntawv hlau yog rau indentation hardness. Tus nqi hardness qhia txog lub peev xwm ntawm cov khoom nto los tiv thaiv cov yas deformation los ntawm lwm yam khoom raug nias rau hauv; C) los ntsuas qhov hardness, thiab tus nqi hardness sawv cev rau qhov loj ntawm elastic deformation muaj nuj nqi ntawm cov hlau.

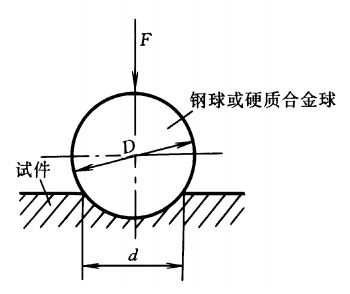

Brinell Hardness

Siv lub pob quenched steel los yog lub pob nyuaj alloy nrog ib txoj kab uas hla ntawm D raws li lub indenter, nias nws mus rau hauv qhov chaw ntawm lub xeem daim ntawv nrog rau cov kev xeem quab yuam F, thiab tom qab ib tug teev tuav lub sij hawm, tshem tawm lub xeem quab yuam kom tau ib tug indentation nrog. ib diam d. Faib qhov kev xeem quab yuam los ntawm thaj tsam ntawm qhov indentation, thiab qhov tshwm sim tus nqi yog Brinell hardness tus nqi, thiab lub cim yog sawv cev los ntawm HBS lossis HBW.

Qhov sib txawv ntawm HBS thiab HBW yog qhov txawv ntawm qhov indenter. HBS txhais tau hais tias lub indenter yog ib lub pob steel hardened, uas yog siv los ntsuas cov ntaub ntawv nrog ib tug Brinell hardness nqi qis dua 450, xws li me me hlau, grey cam khwb cia hlau thiab non-ferrous hlau. HBW txhais tau hais tias lub indenter yog cemented carbide, uas yog siv los ntsuas cov ntaub ntawv nrog Brinell hardness nqi qis dua 650.

Rau tib qhov kev sim thaiv, thaum lwm qhov kev sim ntsuas zoo ib yam, cov txiaj ntsig ntawm ob qhov kev xeem sib txawv, thiab tus nqi HBW feem ntau ntau dua li HBS tus nqi, thiab tsis muaj ntau txoj cai los ua raws.

Tom qab xyoo 2003, kuv lub teb chaws tau sib npaug tau txais cov qauv thoob ntiaj teb, tshem tawm cov hlau pob indenters, thiab txhua lub taub hau siv carbide pob. Yog li, HBS raug txiav tawm, thiab HBW yog siv los sawv cev rau Brinell hardness cim. Feem ntau, Brinell hardness tsuas yog qhia hauv HB, xa mus rau HBW. Txawm li cas los xij, HBS tseem pom qee lub sijhawm hauv cov ntaub ntawv sau.

Brinell hardness ntsuas txoj kev yog tsim rau cam khwb cia hlau, non-ferrous alloys, ntau yam annealed thiab quenched thiab tempered steels, thiab tsis haum rau kev kuaj cov qauv los yogcnc tig qhov chawuas nyuaj dhau, me me dhau, nyias dhau, lossis tsis tso cai rau qhov loj me ntawm qhov chaw.

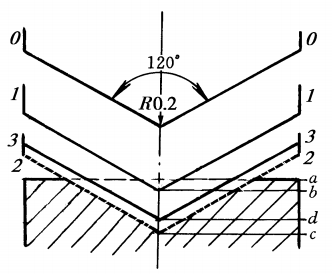

Rockwell Hardness

Siv lub pob zeb diamond lub khob hliav qab lub khob hliav qab ntawm 120 ° los yog Ø1.588mm thiab Ø3.176mm quenched steel npas li lub indenter thiab lub load los koom tes nrog nws. Thawj qhov load yog 10kgf thiab tag nrho cov load yog 60, 100 los yog 150kgf (uas yog, thawj load ntxiv rau lub ntsiab load). Lub hardness yog qhia los ntawm qhov sib txawv ntawm qhov tob indentation thaum lub ntsiab load raug tshem tawm thiab lub indentation qhov tob thaum lub ntsiab load yog khaws cia thiab lub indentation qhov tob nyob rau hauv thawj load tom qab tag nrho cov load yog thov.

Rockwell hardness test siv peb lub zog thiab peb indenters. Muaj 9 qhov sib xyaw ua ke ntawm lawv, sib xws rau 9 teev ntawm Rockwell hardness. Daim ntawv thov ntawm 9 tus kav no npog yuav luag txhua yam khoom siv hlau. Muaj peb feem ntau siv HRA, HRB thiab HRC, uas HRC yog siv dav tshaj plaws.

Feem ntau siv Rockwell hardness test specification cov lus:

| Hardness | | | Hardness | |

| | | | | Carbide hmoov, |

| | | | | Annealed, normalized steel, aluminium alloy |

| | | | | hardened steel, quenched thiab tempered steel, sib sib zog nqus |

Qhov ntau ntawm kev siv HRC nplai yog 20 ~ 70HRC. Thaum tus nqi hardness tsawg dua 20HRC, vim lub conicalaluminium cnc machining qhov chawntawm lub indenter yog nias ntau dhau, qhov rhiab heev txo, thiab HRB nplai yuav tsum tau siv los hloov; Thaum lub hardness ntawm tus qauv yog ntau tshaj 67HRC, lub siab ntawm lub taub ntawm lub indenter yog heev loj, thiab lub pob zeb diamond yog yooj yim puas. Lub neej ntawm lub indenter yuav luv heev, yog li HRA nplai yuav tsum tau siv feem ntau hloov.

Rockwell hardness test yog qhov yooj yim, ceev, thiab me me indentation, thiab tuaj yeem kuaj cov khoom tiav thiab cov khoom ua haujlwm nyuaj thiab nyias. Vim qhov me me indentation, rau cov ntaub ntawv nrog cov qauv tsis sib xws thiab hardness, hardness tus nqi fluctuates heev, thiab qhov tseeb yog tsis siab li Brinell hardness. Rockwell hardness yog siv los txiav txim siab hardness ntawm steel, non-ferrous hlau, nyuaj alloys, thiab lwm yam.

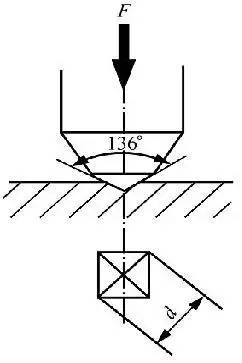

Vickers Hardness Vickers Hardness

Lub hauv paus ntsiab lus ntawm Vickers hardness ntsuas yog zoo ib yam li Brinell hardness. Siv lub pob zeb diamond square pyramid indenter nrog lub kaum sab xis ntawm 136 ° los nias rau hauv qhov chaw ntawm cov khoom siv nrog lub zog ntsuas F, thiab tshem tawm qhov kev sim quab yuam tom qab tswj lub sijhawm. Lub hardness yog qhia los ntawm qhov nruab nrab siab nyob rau hauv lub cheeb tsam cheeb tsam ntawm lub square pyramid indentation. Tus nqi, lub cim cim yog HV.

Vickers hardness ntsuas ntau yam yog loj, thiab nws muaj peev xwm ntsuas cov ntaub ntawv nrog ib tug hardness ntawm 10 mus rau 1000HV. Lub indentation yog me me, thiab nws feem ntau yog siv los ntsuas cov ntaub ntawv nyias nyias thiab cov txheej txheej tawv tawv xws li carburizing thiab nitriding.

Leeb Hardness Leeb Hardness

Siv lub cev cuam tshuam nrog qee qhov loj ntawm tungsten carbide pob lub taub hau kom cuam tshuam rau saum npoo ntawm daim ntawv xeem nyob rau hauv qhov kev txiav txim ntawm ib qho kev quab yuam, thiab tom qab ntawd rov qab. Vim qhov sib txawv hardness ntawm cov ntaub ntawv, lub rebound ceev tom qab kev cuam tshuam kuj txawv. Ib qho hlau nplaum ruaj khov yog ntsia rau ntawm cov khoom cuam tshuam. Thaum qhov cuam tshuam lub cev txav mus los, nws cov peripheral coil yuav ua rau lub teeb liab electromagnetic proportional rau qhov nrawm, thiab tom qab ntawd hloov nws mus rau Leeb hardness nqi los ntawm hluav taws xob Circuit Court. Lub cim cim yog HL.

Lub Leeb hardness tester tsis xav tau lub rooj ua haujlwm, thiab nws qhov hardness sensor yog me me li tus cwj mem, uas tuaj yeem ua haujlwm ncaj qha los ntawm tes, thiab tuaj yeem tshawb pom tau yooj yim txawm tias nws yog ib qho loj, hnyav workpiece lossis workpiece nrog complex geometric qhov ntev.

Lwm qhov zoo ntawm Leeb hardness yog tias nws muaj kev puas tsuaj me me rau ntawm qhov chaw ntawm cov khoom, thiab qee zaum nws tuaj yeem siv los ua qhov kev sim tsis muaj kev puas tsuaj; nws yog qhov tshwj xeeb hauv kev sim hardness nyob rau hauv tag nrho cov lus qhia, nqaim qhov chaw thiab tshwj xeebaluminium qhov chaw.

Anebon ua raws li txoj cai "Honest, industious, enterprising, innovative" kom tau txais cov kev daws teeb meem tshiab tsis tu ncua. Anebon suav nrog kev cia siab, kev vam meej raws li nws tus kheej txoj kev vam meej. Cia Anebon tsim kev vam meej yav tom ntej hauv tes rau tooj dag machined qhov chaw thiab Complex titanium cnc qhov chaw / stamping accessories. Anebon tam sim no muaj cov khoom muag khoom muag nrog rau tus nqi muag yog peb qhov zoo dua. Txais tos nug txog Anebon cov khoom.

Trending Khoom Tuam Tshoj CNC Maching Part thiab Precision Part, tiag tiag yuav tsum ib yam ntawm cov khoom no yuav txaus siab rau koj, thov qhia rau peb paub. Anebon yuav txaus siab muab cov lus hais rau koj thaum tau txais cov ncauj lus kom ntxaws specifications. Anebon muaj peb tus kheej tshwj xeeb R & D enginners kom tau raws li ib qho ntawm cov requriement. Anebon tos ntsoov yuav tau txais koj cov lus nug sai sai thiab vam tias yuav muaj sijhawm los ua haujlwm ua ke nrog koj yav tom ntej. Zoo siab txais tos mus saib lub koom haum Anebon.

Post lub sij hawm: May-18-2023