Dab tsi yog CNC cuab yeej?

Kev sib xyaw ua ke ntawm cov cuab yeej ua haujlwm siab heev thiab cov cuab yeej ua haujlwm siab CNC tuaj yeem muab kev ua si tag nrho rau nws qhov kev ua tau zoo thiab ua tiav cov txiaj ntsig zoo nyiaj txiag. Nrog rau txoj kev loj hlob sai ntawm cov cuab yeej cuab tam, ntau yam tshiab cov cuab yeej cuab tam tau zoo heev txhim kho lawv lub cev, mechanical zog thiab txiav kev ua tau zoo, thiab lawv daim ntawv thov ntau yam kuj tseem nthuav.

Cov txheej txheem muaj pes tsawg leeg ntawm CNC cov cuab yeej?

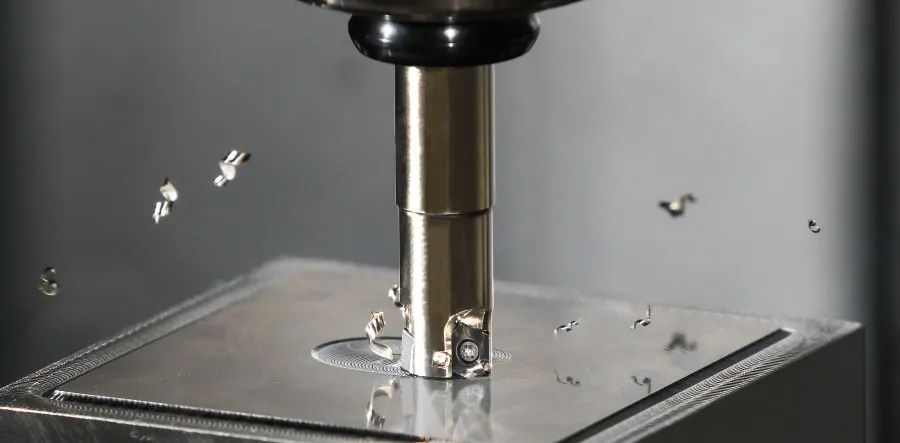

CNC (Computer Numerical Control) cov cuab yeej yog cov cuab yeej siv tshuab uas ua haujlwm los ntawm cov programmed commands encoded rau hauv nruab nrab cia, xws li lub computer. Cov cuab yeej siv lub khoos phis tawj tswj hwm los ua cov haujlwm precision machining, xws li txiav, drilling, milling, thiab shaping. Cov cuab yeej siv hauv kev tsim khoom, tshwj xeeb hauv kev lag luam xws li aerospace, automotive, kho mob, thiab hlau ua haujlwm.

CNC cov cuab yeej suav nrog ntau yam ntawm cov tshuab, xws liCNC millingcov tshuab, CNCtxheej txheem tshuab dhos, CNC routers, CNC plasma cutters, thiab CNC laser cutters. Cov cuab yeej no ua haujlwm los ntawm kev txav cov cuab yeej txiav lossis cov khoom ua haujlwm hauv peb lossis ntau dua axes siv lub computer tswj cov lej.

CNC cov cuab yeej paub txog lawv qhov tseeb, qhov tseeb, thiab rov ua dua, uas ua rau lawv zoo tagnrho rau kev tsim cov khoom siv thiab cov khoom siv nrog nruj tolerances. Lawv kuj muaj peev xwm tsim cov khoom lag luam zoo ntawm tus nqi nrawm dua li cov tshuab phau ntawv ib txwm siv, uas pab txhawb kev tsim khoom thiab kev ua haujlwm hauv kev tsim khoom.

Dab tsi yog cov yam ntxwv ntawm cov cuab yeej CNC yuav tsum muaj?

1. Hardness: CNC cuab yeej cov ntaub ntawv yuav tsum nyuaj txaus los tiv thaiv hnav thiab tsim kua muag thaum lub sij hawm machining txheej txheem.

2. Toughness: CNC cuab yeej cov ntaub ntawv yuav tsum nruj txaus los tiv thaiv tej yam thiab poob siab loads.

3. Thaum tshav kub kub tsis kam: CNC cuab yeej cov ntaub ntawv yuav tsum muaj peev xwm tiv taus siab kub generated thaum lub sij hawm machining txheej txheem tsis poob lawv lub zog los yog durability.

4. Hnav tsis kam: cov khoom siv CNC yuav tsum tiv taus cov hnav tsis zoo los ntawm kev sib cuag nrog cov khoom ua haujlwm.

5. Chemical stability: CNC cuab yeej cov ntaub ntawv yuav tsum tau chemically ruaj kom tsis txhob muaj corrosion thiab lwm yam ntaub ntawv ntawm cov tshuaj puas.

6. Machinability: CNC cuab yeej cov ntaub ntawv yuav tsum tau yooj yim rau tshuab thiab puab rau hauv daim ntawv xav tau.

7. Tus nqi-zoo: CNC cov cuab yeej cov ntaub ntawv yuav tsum pheej yig thiab raug nqi, xav txog lawv cov kev ua tau zoo thiab kev ua haujlwm ntev.

Hom, yam ntxwv, yam ntxwv thiab kev siv ntawm cov khoom siv txiav

Txhua hom khoom muaj nws cov khoom tshwj xeeb, yam ntxwv, thiab kev siv. Nov yog qee yam khoom siv cuab yeej txiav, nrog rau lawv cov khoom thiab kev siv:

1. High-Speed Steel (HSS):

HSS yog cov khoom siv feem ntau siv los txiav, ua los ntawm cov hlau, tungsten, molybdenum, thiab lwm yam. Nws yog lub npe hu rau nws cov hardness siab, hnav tsis kam, thiab toughness, ua rau nws haum rau machining ntau yam ntaub ntawv, xws li steels, aluminium alloys, thiab plastics.

2. Carbide:

Carbide yog cov khoom sib xyaw ua ke los ntawm kev sib xyaw ntawm tungsten carbide hais thiab cov khoom siv hlau, xws li cobalt. Nws yog lub npe hu rau nws qhov tshwj xeeb hardness, hnav tsis kam, thiab kub tsis kam, ua rau nws zoo tagnrho rau machining cov ntaub ntawv tawv, xws li stainless hlau, cam khwb cia hlau, thiab high-temperature alloys.

3. Ceramic:

Ceramic txiav cov cuab yeej yog tsim los ntawm ntau yam khoom siv ceramic, xws li txhuas oxide, silicon nitride, thiab zirconia. Lawv paub txog lawv cov hardness siab, hnav tsis kam, thiab tshuaj stability, ua rau lawv haum rau machining nyuaj thiab abrasive cov ntaub ntawv, xws li ceramics, composites, thiab superalloys.

4. Cubic Boron Nitride (CBN):

CBN yog cov khoom siv hluavtaws ua los ntawm cubic boron nitride crystals. Nws paub txog nws qhov tshwj xeeb hardness, hnav tsis kam, thiab kub tsis kam, ua rau nws haum rau machining hardened steels thiab lwm yam ntaub ntawv uas nyuaj rau tshuab siv lwm yam cuab yeej cuab tam.

5. Pob zeb diamond:

Pob zeb diamond txiav cov cuab yeej yog tsim los ntawm ntuj lossis hluavtaws pob zeb diamond. Lawv paub txog lawv qhov tshwj xeeb hardness, hnav tsis kam, thiab kub tsis kam, ua rau lawv haum rau machining non-ferrous hlau, composites, thiab lwm yam ntaub ntawv nyuaj thiab abrasive.

Kuj tseem muaj cov cuab yeej tshwj xeeb hu ua cov cuab yeej coated.

Feem ntau, cov ntaub ntawv saum toj no yog siv los ua cov txheej, thiab lawv tau siv dav hauv CNC tshuab cuab yeej.

Cov cuab yeej coated yog cov cuab yeej nrog cov txheej nyias nyias ntawm cov khoom siv rau nws qhov chaw los txhim kho nws cov kev ua tau zoo thiab txuas ntxiv nws txoj sia. Cov khoom siv txheej yog xaiv raws li lub cuab yeej siv, thiab cov ntaub ntawv txheej txheej muaj xws li titanium nitride (TiN), titanium carboni (TiCN), thiab pob zeb diamond zoo li carbon (DLC).

Cov txheej txheem tuaj yeem txhim kho cov cuab yeej ua haujlwm hauv ntau txoj hauv kev, xws li txo kev sib txhuam thiab hnav, ua kom tawv thiab tawv, thiab txhim kho kev tiv thaiv corrosion thiab tshuaj lom neeg puas tsuaj. Piv txwv li, TiN-coated laum ntsis tuaj yeem kav ntev txog peb zaug ntev dua li qhov tsis muaj coated, thiab TiCN-coated kawg zeb tuaj yeem txiav los ntawm cov ntaub ntawv nyuaj nrog tsawg hnav.

Cov cuab yeej coated feem ntau yog siv hauv kev lag luam xws li kev tsim khoom, aerospace, tsheb, thiab kev tsim khoom siv kho mob. Lawv tuaj yeem siv rau kev txiav, drilling, milling, sib tsoo, thiab lwm yam kev ua haujlwm.

Kev xaiv cov txheej txheem ntawm cov khoom siv CNC

Kev xaiv cov khoom siv CNC yog ib qho tseem ceeb rau kev txiav txim siab thaum tsim thiab tsim precisiontig qhov chaw. Kev xaiv ntawm cov khoom siv yog ua raws li ntau yam, nrog rau cov khoom siv ua tshuab, kev ua haujlwm machining, thiab qhov xav tau tiav.

Nov yog qee qhov kev xaiv ntawm CNC cuab yeej cov ntaub ntawv:

1. Hardness:Cov cuab yeej siv yuav tsum yog qhov nyuaj txaus los tiv thaiv lub zog thiab qhov kub thiab txias tsim thaum lub sijhawm ua haujlwm. Hardness feem ntau yog ntsuas ntawm Rockwell C nplai lossis Vickers nplai.

2. Toughness:Cov khoom siv kuj tseem yuav tawv txaus los tiv thaiv tawg thiab chipping. Toughness feem ntau yog ntsuas los ntawm kev cuam tshuam lub zog lossis tawg toughness.

3. Hnav tsis kam:Cov cuab yeej siv yuav tsum muaj qhov hnav tsis zoo los tswj nws txoj kev txiav thiab zam cov cuab yeej tsis ua haujlwm. Kev hnav tsis kam ntawm cov khoom siv feem ntau ntsuas los ntawm qhov ntim ntawm cov khoom uas raug tshem tawm ntawm lub cuab yeej thaum lub sij hawm ib qho nyiaj ntawm machining.

4. Thermal conductivity: Cov khoom siv yuav tsum muaj cov thermal conductivity zoo kom dissipate tshav kub generated thaum machining. Qhov no yuav pab kom tsis txhob muaj cov cuab yeej tsis ua haujlwm thiab tswj kom muaj qhov tseeb qhov tseeb.

5. Tshuaj stability:Cov khoom siv yuav tsum muaj tshuaj lom neeg ruaj khov kom tsis txhob muaj tshuaj lom neeg nrog cov khoom siv ua haujlwm.

6. Nqi:Tus nqi ntawm cov cuab yeej siv kuj yog ib qho tseem ceeb rau kev txiav txim siab, tshwj xeeb tshaj yog rau cov khoom ntim ntau lawm.

Cov khoom siv dav siv rau CNC cuab yeej muaj xws li carbide, high-speed steel, ceramic, thiab pob zeb diamond. Kev xaiv cov khoom siv yog nyob ntawm qhov kev ua haujlwm tshwj xeeb thiab qhov xav tau ua tiav, nrog rau cov khoom siv thiab cov khoom siv.

1) Cov cuab yeej txiav cov khoom sib xws nrog cov khoom siv tshuab ntawm cov khoom siv machined

Sib piv cov cuab yeej txiav cov cuab yeej rau cov khoom siv tshuab ntawm cov khoom siv tshuab yog qhov tseem ceeb hauv CNC machining. Cov khoom siv ntawm cov khoom siv machined suav nrog nws cov hardness, toughness, thiab ductility, thiab lwm yam. Xaiv cov khoom siv txiav uas sib tw lossis ua tiav cov khoom siv ntawm cov khoom siv tshuab tuaj yeem txhim kho kev ua haujlwm thiab kev ua haujlwm zoo, txo cov cuab yeej hnav, thiab txhim kho qhov zoo ntawm cov khoom tiav.

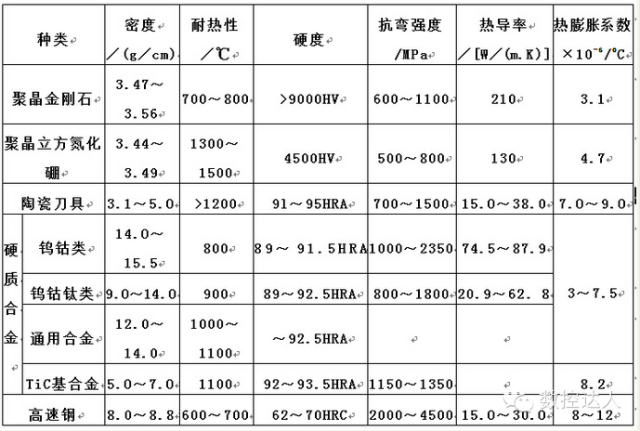

① Qhov kev txiav txim ntawm cov cuab yeej hardness yog: pob zeb diamond cuab tam> cubic boron nitride cuab tam> ceramic cuab tam> tungsten carbide> high-speed steel.

② Qhov kev txiav txim ntawm dabtsi yog khoov lub zog ntawm cov khoom siv yog: high-speed steel> cemented carbide> ceramic cov cuab yeej> pob zeb diamond thiab cubic boron nitride cov cuab yeej.

③ Qhov kev txiav txim siab ntawm cov khoom siv yog: high-speed steel> cemented carbide> cubic boron nitride, pob zeb diamond thiab cov cuab yeej ceramic.

Piv txwv li, yog tias cov khoom siv tau ua los ntawm cov khoom siv tawv thiab nkig xws li cov hlau tawv tawv lossis cov hlau cam, cov cuab yeej txiav ua los ntawm cov khoom siv tawv thiab hnav-resistant xws li carbide lossis ceramic tej zaum yuav yog qhov kev xaiv zoo tshaj. Cov ntaub ntawv no tuaj yeem tiv taus lub zog txiav siab thiab qhov kub thiab txias tsim thaum lub sijhawm machining thiab tswj lawv cov ntse txiav rau lub sijhawm ntev.

Ntawm qhov tod tes, yog tias cov khoom siv tau ua los ntawm cov khoom siv softer thiab ntau dua zoo li txhuas lossis tooj liab, cov cuab yeej txiav ua los ntawm cov khoom siv tawv zoo li cov hlau kub ceev yuav tsim nyog dua. High-speed steel tuaj yeem nqus tau qhov poob siab thiab kev co thaum lub sijhawm ua haujlwm, txo qhov kev pheej hmoo ntawm cov cuab yeej tawg thiab txhim kho lub neej ntawm cov cuab yeej.

2) Kev sib txuam ntawm cov cuab yeej txiav cov khoom siv rau lub cev ntawm cov khoom siv machined

Sib piv cov cuab yeej txiav cov khoom rau lub cev lub cev ntawm cov khoom siv machined kuj yog ib qho tseem ceeb rau kev txiav txim siab hauv CNC machining. Lub cev lub cev ntawm cov khoom siv machined suav nrog nws cov thermal conductivity, coefficient ntawm thermal expansion, thiab qhov yuav tsum tau ua kom tiav, thiab lwm yam. Xaiv cov khoom siv txiav uas sib tw lossis ua tiav cov khoom siv lub cev ntawm cov khoom siv tuaj yeem txhim kho kev ua haujlwm, txo cov cuab yeej hnav, thiab txhim kho qhov zoo ntawm qhov ua tiav.

① Kub-resistant kub ntawm ntau yam khoom siv: 700-8000C rau cov cuab yeej pob zeb diamond, 13000-15000C rau PCBN cov cuab yeej, 1100-12000C rau cov cuab yeej ceramic, 900-11000C rau TiC(N)-raws li cemented carbide, thiab 900C-110C -based ultrafine nplej Cemented carbide yog 800 ~ 9000C, HSS yog 600 ~ 7000C.

② Qhov kev txiav txim ntawm thermal conductivity ntawm ntau yam khoom siv: PCD> PCBN> WC-raws li cemented carbide> TiC (N)-raws li cemented carbide> HSS> Si3N4-based ceramics> A1203-raws li ceramics.

③ Qhov kev txiav txim ntawm thermal expansion coefficient ntawm ntau yam khoom siv yog: HSS> WC-based cemented carbide> TiC(N)> A1203-based ceramics> PCBN> Si3N4-based ceramics> PCD.

④ Qhov kev txiav txim ntawm thermal shock tsis kam ntawm ntau yam khoom siv yog: HSS> WC-raws li cemented carbide> Si3N4-based ceramics> PCBN> PCD> TiC (N)-raws li cemented carbide> A1203-raws li ceramics.

Piv txwv li, yog hais tias lub machined khoom muaj ib tug high thermal conductivity, xws li tooj liab los yog txhuas, ib tug txiav cuab tam nrog ib tug high thermal conductivity thiab tsawg coefficient ntawm thermal expansion tej zaum yuav yog qhov zoo tshaj plaws kev xaiv. Qhov no tso cai rau lub cuab yeej kom dissipate tshav kub zoo thaum lub sij hawm machining thiab txo qhov kev pheej hmoo ntawm thermal puas rau ob lub cuab yeej thiab cov khoom machined.

Ib yam li ntawd, yog tias cov khoom siv machined muaj qhov yuav tsum tau ua kom tiav, lub cuab yeej txiav nrog kev hnav tsis kam thiab qis coefficient ntawm kev sib txhuam yuav yog qhov kev xaiv zoo tshaj plaws. Qhov no tuaj yeem pab ua kom tiav qhov xav tau ntawm qhov chaw tiav yam tsis muaj cov cuab yeej siv ntau dhau los yog kev puas tsuaj rau cov khoom siv machined.

3) Sib piv cov khoom siv txiav rau cov khoom siv tshuaj ntawm cov khoom siv machined

Sib piv cov cuab yeej txiav cov cuab yeej rau cov khoom siv tshuaj ntawm cov khoom siv machined kuj yog ib qho tseem ceeb hauv CNC machining. Cov khoom siv tshuaj lom neeg ntawm cov khoom siv machined suav nrog nws cov reactivity, corrosion resistance, thiab tshuaj muaj pes tsawg leeg, thiab lwm yam. Xaiv cov khoom siv txiav uas sib tw lossis ua tiav cov khoom siv tshuaj ntawm cov khoom siv tuaj yeem txhim kho kev ua haujlwm, txo cov cuab yeej hnav, thiab txhim kho qhov zoo ntawm cov khoom tiav.

Piv txwv li, yog tias cov khoom siv tau ua los ntawm cov khoom siv tsis zoo lossis cov khoom corrosive zoo li titanium lossis stainless hlau, cov cuab yeej txiav ua los ntawm cov khoom siv corrosion-resistant xws li pob zeb diamond lossis PCD (polycrystalline pob zeb diamond) yuav yog qhov kev xaiv zoo tshaj. Cov ntaub ntawv no tuaj yeem tiv taus qhov corrosive lossis reactive ib puag ncig thiab tswj lawv cov ntse txiav rau lub sijhawm ntev.

Ib yam li ntawd, yog tias cov khoom siv tshuab muaj cov tshuaj sib xyaw ua ke, cov cuab yeej txiav ua los ntawm cov khoom siv tshuaj lom neeg ruaj khov thiab inert, xws li pob zeb diamond lossis cubic boron nitride (CBN), yuav yog qhov kev xaiv zoo tshaj. Cov ntaub ntawv no tuaj yeem zam cov tshuaj lom neeg nrog rau cov khoom siv ua haujlwm thiab tswj xyuas lawv cov kev ua haujlwm hauv lub sijhawm.

① Kev tiv thaiv kub ntawm ntau yam khoom siv (nrog hlau) yog: PCBN>ceramic> hard alloy> HSS.

② oxidation kuj kub ntawm ntau yam khoom siv yog raws li nram no: ceramic> PCBN> tungsten carbide> pob zeb diamond> HSS.

③ Lub zog diffusion ntawm cov khoom siv (rau hlau) yog: pob zeb diamond> Si3N4-based ceramics> PCBN> A1203-raws li ceramics. Diffusion siv (rau titanium) yog: A1203-raws li ceramics> PCBN> SiC> Si3N4> pob zeb diamond.

4) Tsim nyog xaiv CNC tej cuab yeej cuab tam

Kev xaiv ntawm CNC txiav cov cuab yeej yog nyob ntawm ntau yam xws li cov khoom siv ua haujlwm, kev ua haujlwm machining, thiab cov cuab yeej geometry. Txawm li cas los xij, qee cov lus qhia dav dav rau xaiv cov cuab yeej cuab tam rau CNC machining suav nrog:

1. Cov khoom siv ntawm cov khoom ua haujlwm: Xav txog cov khoom siv kho tshuab, lub cev, thiab tshuaj lom neeg ntawm cov khoom siv ua haujlwm thaum xaiv cov khoom siv txiav. Sib piv cov cuab yeej txiav cov khoom siv rau cov khoom siv ua haujlwm kom ua tau zoo thiab ua haujlwm zoo.

2. Kev ua haujlwm machining: Xav txog hom kev ua haujlwm machining, xws li tig, milling, drilling, lossis sib tsoo. Kev ua haujlwm sib txawv machining xav tau cov cuab yeej sib txawv geometry thiab cov ntaub ntawv.

3. Cov cuab yeej geometry: Xav txog cov cuab yeej txiav geometry thaum xaiv cov khoom siv. Xaiv cov khoom uas muaj peev xwm tswj tau qhov ntse txiav ntug thiab tiv taus cov txiav quab yuam tsim thaum lub sijhawm ua haujlwm machining.

4. Cov cuab yeej hnav: Xav txog cov cuab yeej hnav tus nqi thaum xaiv cov khoom siv txiav. Xaiv cov khoom siv uas tuaj yeem tiv taus lub zog txiav thiab tswj nws cov ntse txiav kom ntev li ntev tau los txo cov cuab yeej hloov pauv thiab txhim kho kev ua haujlwm zoo.

5. Nqi: Xav txog tus nqi ntawm cov khoom siv txiav thaum xaiv cov cuab yeej. Xaiv cov khoom siv uas muab qhov zoo tshaj plaws sib npaug ntawm kev txiav thiab nqi.

Qee cov khoom siv txiav cov cuab yeej siv hauvCNC machiningmuaj xws li high-speed steel, carbide, ceramic, pob zeb diamond, thiab CBN. Txhua yam khoom muaj nws qhov zoo thiab qhov tsis zoo, thiab kev xaiv cov khoom siv yuav tsum ua raws li kev nkag siab zoo ntawm kev ua haujlwm machining thiab cov khoom siv ua haujlwm.

Anebon txoj kev mus nyob mus ib txhis yog tus cwj pwm ntawm "xav txog kev ua lag luam, hais txog kev cai, hais txog kev tshawb fawb" thiab txoj kev xav ntawm "zoo qhov yooj yim, ntseeg thawj thiab tswj cov qib siab" rau kub muag Hoobkas OEM Service High Precision CNC Machining qhov chaw rau automation industrial, Anebon quote rau koj nug. Yog xav paub ntxiv, thov hu rau peb, Anebon yuav teb koj ASAP!

Kub muag Hoobkas Tuam Tshoj 5 axis cnc machining qhov chaw, CNC tig qhov chaw thiab milling tooj liab qhov chaw. Txais tos tuaj xyuas peb lub tuam txhab, Hoobkas thiab peb chav ua yeeb yam uas nthuav tawm ntau yam khoom siv plaub hau uas yuav ua tau raws li koj qhov kev cia siab. Lub caij no, nws yooj yim mus xyuas Anebon lub vev xaib, thiab Anebon cov neeg ua haujlwm muag yuav sim lawv qhov zoo tshaj plaws los xa koj cov kev pabcuam zoo tshaj plaws. Thov hu rau Anebon yog tias koj xav paub ntau ntxiv. Lub hom phiaj ntawm Anebon yog los pab cov neeg siv khoom paub lawv lub hom phiaj. Anebon tau siv zog ua kom tiav qhov kev yeej-yeej qhov xwm txheej no.

Post lub sij hawm: Mar-08-2023