Dab tsi yog eccentric qhov chaw?

Eccentric qhov chaw yog cov khoom siv kho tshuab uas muaj qhov tsis sib xws ntawm qhov nruab nrab ntawm kev sib hloov lossis cov duab tsis sib xws uas ua rau lawv tig mus rau qhov tsis sib xws. Cov khoom no feem ntau yog siv rau hauv cov tshuab thiab cov tshuab tshuab uas yuav tsum muaj kev txav thiab tswj tau.

Ib qho piv txwv ntawm ib qho eccentric yog ib qho eccentric cam, uas yog ib lub voj voog nrog ib qho protrusion ntawm nws qhov chaw uas ua rau nws txav mus rau hauv txoj kev tsis sib xws thaum nws tig. Eccentric qhov chaw tseem tuaj yeem xa mus rau txhua yam khoom siv uas txhob txwm tsim los tig tawm ntawm qhov chaw, xws li flywheel nrog kev faib tsis sib xws ntawm pawg.

Eccentric qhov chaw feem ntau yog siv rau hauv cov ntawv thov xws li cav, twj, thiab conveyor systems uas yuav tsum tau txav thiab tswj tau. Lawv tuaj yeem pab txo qis kev vibration, txhim kho kev ua haujlwm, thiab ua kom lub neej ntev ntawm cov tshuab.

Taw qhia

Nyob rau hauv lub tshuab kis tau tus mob, eccentric qhov chaw xws li eccentric workpieces los yog crankshafts feem ntau yog siv los ua kom tiav cov hauj lwm ntawm kev sib nrig sib hloov ntawm cov lus tsa suab thiab reciprocating motion, yog li eccentric qhov chaw yog dav siv nyob rau hauv mechanical kis tau tus mob. Cov theem ntawm eccentric qhov chaw ua technology (tshwj xeeb tshaj yog loj eccentric workpieces) muaj peev xwm cuam tshuam lub machining technology peev xwm ntawm ib tug enterprise.

Eccentric workpieces ua lub luag haujlwm tseem ceeb hauv kev tsim khoom tiag tiag thiab lub neej. Hauv kev sib kis ntawm cov tshuab, tig cov lus tsa suab mus rau hauv cov lus tsa suab los yog hloov cov kab lus tawm mus rau hauv cov lus tsa suab yog feem ntau ua tiav los ntawm eccentric workpieces lossis crankshafts. Piv txwv li, lub lubricating roj twj tso kua mis nyob rau hauv lub spindle lub thawv yog tsav los ntawm lub eccentric ncej, thiab cov lus tsa suab ntawm lub crankshaft ntawm lub tsheb thiab tsheb laij teb yog tsav los ntawm lub reciprocating linear motion ntawm lub piston.

Cov ntsiab lus tshaj lij / cov npe

1) Eccentric workpiece

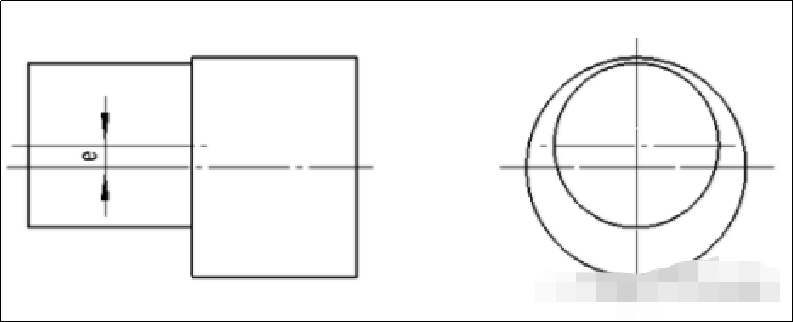

Lub workpiece uas nws axes ntawm lub voj voog sab nrauv thiab lub voj voog sab nrauv lossis lub voj voog sab nraud thiab lub qhov hauv lub qhov yog sib npaug tab sis tsis coincident dhau los ua ib qho kev ua haujlwm eccentric.

2) Eccentric ncej

Lub workpiece uas nws cov axes ntawm lub voj voog sab nrauv thiab lub voj voog sab nraud yog sib npaug thiab tsis yog coincident yog hu ua eccentric ncej.

3) Lub tes tsho eccentric

Lub workpiece uas nws axes ntawm lub voj voog sab nraud thiab lub qhov hauv lub qhov yog sib npaug tab sis tsis coincident yog hu ua lub tes tsho eccentric.

4) Eccentricity

Nyob rau hauv ib qho eccentric workpiece, qhov kev ncua deb ntawm lub axis ntawm lub eccentric ib feem thiab lub axis ntawm cov ntaub ntawv yog hu ua eccentricity.

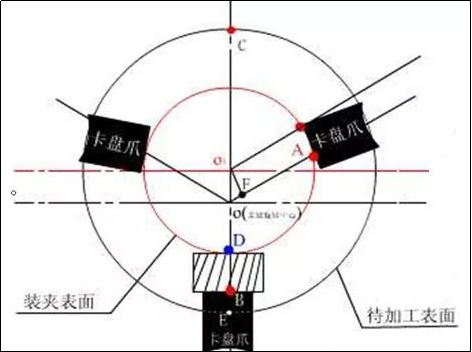

Peb lub puab tsaig lub puab tsaig chuck yog tsim rau eccentric workpieces uas tsis xav tau siab tig precision, me me eccentric nrug, thiab ntev ntev. Thaum tig, lub eccentricity ntawm lub workpiece yog guaranteed los ntawm lub thickness ntawm lub gasket tso rau ntawm lub puab tsaig.

Txawm hais tias cov tsoos ua txoj kev ntawm eccentricCNC machining qhov chawthiab txoj kev txhim kho peb lub puab tsaig tig tuaj yeem ua tiav cov haujlwm ntawm kev ua haujlwm eccentric workpiece qhov chaw, qhov tsis xws ntawm kev ua haujlwm nyuaj, tsis muaj kev ua haujlwm tsawg, kev sib hloov thiab kev ua haujlwm yog qhov nyuaj rau lav. Niaj hnub nimno high-efficiency thiabhigh-precision machiningtswv yim tsis tuaj yeem zam ntawm.

Lub hauv paus ntsiab lus, Txoj Kev thiab Cov Ntsiab Lus rau Kev Ceeb Toom ntawm Eccentricity ntawm Peb lub puab tsaig Chuck

Lub hauv paus ntsiab lus ntawm eccentricity ntawm peb lub puab tsaig chuck: kho qhov chaw sib hloov ntawm lub workpiece nto yuav tsum tau ua tiav kom concentric nrog lub axis ntawm lub tshuab cuab tam spindle. Kho lub geometric centroid ntawm lub clamping ib feem rau qhov kev ncua deb ntawm spindle axis sib npaug zos rau eccentricity.

Gasket thickness xam (thawj, zaum kawg) l Gasket thickness xam mis: x = 1.5e + k qhov twg:

e - workpiece eccentricity, hli;

k — Kho tus nqi (tau tom qab kev xeem khiav, uas yog, k≈1.5△e), mm;

△e - qhov yuam kev ntawm qhov ntsuas eccentricity thiab qhov xav tau eccentricity tom qab kev xeem khiav (ie △e = ee ntsuas), mm;

e ntsuas - ntsuas eccentricity, mm;

Piv txwv 1

Tig lub workpiece nrog lub eccentricity ntawm 3 hli, yog hais tias lub thickness ntawm lub gasket yog tig nrog ib tug sim xaiv, qhov ntsuas eccentricity yog 3.12 hli, thiab qhov tseeb tus nqi ntawm lub thickness ntawm lub gasket yog pom. l Kev daws: Lub thickness ntawm qhov kev sim gasket yog:

X = 1.5e = 1.5 x 3 mm = 4.5 mm

△e = (3-3.12)mm = -0.12mm

K = 1.5△e = 1.5 × (-0.12)mm = -0.18mm

Raws li cov qauv: x = 1.5e + k = (4.5-0.18) mm = 4.32mm

Qhov tseeb tus nqi rau lub gasket thickness yog 4.32mm.

Piv txwv 2

Lub gasket nrog lub thickness ntawm 10 hli yog siv los tig lub eccentric workpiece ntawm lub puab tsaig ntawm lub puab tsaig ntawm peb lub puab tsaig-centering chuck. Tom qab tig, qhov eccentricity ntawm lub workpiece yog ntsuas los ntawm 0.65mm me dua li qhov tsim nyog yuav tsum tau ua. Nrhiav qhov tseeb tus nqi rau lub gasket thickness.

Paub eccentricity yuam kev △e = 0.65mm

Kwv yees gasket thickness: X test = 1.5e = 10mm

K = 1.5△e = 1.5 × 0.65mm = 0.975mm

Raws li cov qauv: x=1.5e+k=(10+0.975)mm=10.975mm

Tus nqi raug rau gasket thickness yog 10.975mm.

Disadvantages ntawm eccentric peb lub puab tsaig tig

Eccentric peb lub puab tsaig tig, tseem hu ua eccentric chucking, yog txoj haujlwm tig qhov chaw ua haujlwm nyob rau hauv chuck uas muaj peb lub puab tsaig uas tsis nyob nruab nrab nrog chuck lub axis. Hloov chaw, ib qho ntawm lub puab tsaig raug teeb tawm ntawm qhov chaw, tsim kom muaj eccentricrotation ntawm lub workpiece.

Thaum eccentric peb lub puab tsaig tig muaj qee qhov zoo, xws li lub peev xwm tig tsis tu ncua thiab txo qhov xav tau rau cov cuab yeej tshwj xeeb, nws kuj muaj qhov tsis zoo, suav nrog:

1. lnaccurate centering: Vim hais tias lub workpiece yog tuav tawm-center, nws yuav ua tau nyuaj toaccurately nruab nrab rau precision machining kev khiav hauj lwm. Qhov no tuaj yeem ua rau cov khoom tsis kam lees lossis muaj qhov tsis sib xws.

2. Txo lub zog tuav: Lub puab tsaig sab nraud muaj lub zog tuav tsawg dua li ob lub puab tsaig, uas tuaj yeem ua rau lub puab tsaig tsis ruaj ntseg. Qhov no tuaj yeem ua rau lub tshuab ua haujlwm hloov lossis plam thaum lub sijhawm ua haujlwm, ua rau tsis raug txiav thiab qhov xwm txheej txaus ntshai.

3. Cov cuab yeej siv ntau ntxiv: Vim tias cov khoom siv tsis yog qhov nruab nrab, cov cuab yeej txiav tej zaum yuav muaj kev hnav tsis sib xws, uas tuaj yeem ua rau lub neej luv dua thiab nce nqi rau kev hloov cuab yeej.

4. Kev txwv ntau yam: Eccentric chucking feem ntau haum rau me me to4.medium-sized qhov chaw, thiabcnc tig partnrog lub cev tsis tu ncua. Nws yuav tsis haum rau qhov loj dua lossis ntau qhov nyuaj, vim tias lub puab tsaig sab nraud yuav tsis muaj kev txhawb nqa txaus.

5. Lub sijhawm teeb tsa ntev dua: Kev teeb tsa lub chuck rau eccentric tig tuaj yeem siv sijhawm ntau dua li kev teeb tsa tus qauv chuck, vim nws yuav tsum tau ceev faj qhov chaw ntawm lub puab tsaig sab nraud kom ua tiav qhov xav tau eccentricity.

Nyob rau hauv CNC tshuab dhos, cov eccentric qhov chaw feem ntau yog tsim los ntawm machining ib feem ntawm alathe siv ib tug tshwj xeeb eccentric chuck los yog ib tug fixture uas tuav ib feem ntawm qhov chaw.

Cov hauv qab no yog cov kauj ruam dav dav los tsim eccentric qhov chaw hauv CNC tshuab dhos:

1. Xaiv qhov tsim nyog eccentric chuck lossis fixture uas haum rau workpiece thiab tso cai rau

xav eccentricity.

2. Teem lub tshuab dhos nrog chuck lossis fixture thiab mount lub workpiece kom ruaj ntseg.

3. Siv lub tshuab dhos lub software los teeb lub offset rau qhov xav tau eccentricity.

4. Kev pab cuam lub tshuab CNC txiav ib feem raws li qhov xav tau tsim, ua kom paub tseeb tias tus account rau qhov offset hauv txoj kev txiav.

5. Khiav ib qho kev sim ntsuas kom paub meej tias qhov raug txiav raug raug thiab qhov eccentricity nyob rau hauv qhov xav tau kev zam.

6. Ua ib qho kev hloov kho uas tsim nyog rau cov kev pab cuam txiav los yog teeb tsa kom ua tiav cov txiaj ntsig xav tau.

7. Txuas ntxiv txiav qhov kom txog rau thaum nws tiav, xyuas kom lub sij hawm xyuas lub eccentricity thiab ua tej yam tsim nyog hloov.

Zuag qhia tag nrho, tsim eccentric qhov chaw hauv CNC tshuab dhos yuav tsum tau ua tib zoo npaj thiab ua tiav los xyuas kom meej tias cov khoom kawg ua tau raws li qhov xav tau tshwj xeeb.

Cov kab lus saum toj no tsuas yog muab los ntawm pab pawg Anebon, kev ua txhaum cai yuav tsum raug tshawb xyuas

Anebonyog lub tuam txhab tsim khoom raws li hauv Shenzhen, Suav teb tshwj xeeb hauv kev muab cov kev pabcuam CNC machining customized. Lub tuam txhab muaj ntau yam kev tsim khoom, suav nrog CNC milling, tig, drilling, thiab sib tsoo, nrog rau kev kho deg thiab kev sib dhos.

Anebon muaj kev paub txog kev ua haujlwm nrog ntau yam ntaub ntawv, suav nrog txhuas, tooj dag, stainless hlau, titanium, thiab yas, thiab tuaj yeem tsim cov khoom nrog cov geometries complex thiab nruj tolerances. Lub tuam txhab siv cov cuab yeej siv siab heev, xws li 3-axis thiab 5-axis CNC tshuab, nrog rau cov khoom siv tshuaj xyuas, kom ntseeg tau cov khoom zoo.

Ntxiv rau cov kev pabcuam CNC machining, Anebon tseem muaj cov kev pabcuam prototyping, tso cai rau cov neeg siv khoom sai sai thiab kho lawv cov qauv ua ntej yuav tsiv mus rau ntau lawm. Lub tuam txhab txaus siab rau nws txoj kev cog lus rau cov neeg siv khoom thiab kev ua haujlwm zoo, thiab ua haujlwm nrog cov neeg siv khoom kom ntseeg tau tias lawv cov kev xav tau tshwj xeeb thiab cov kev xav tau raug ua tiav.

Post lub sij hawm: Feb-27-2023