Kev xav tau ntawm CNC tshuab cuab yeej ntawm cov cuab yeej cuab tam

High hardness thiab hnav tsis kam

Lub hardness ntawm txiav ib feem ntawm lub cuab yeej yuav tsum siab tshaj qhov hardness ntawm lub workpiece khoom. Qhov siab dua qhov hardness ntawm cov khoom siv, qhov zoo dua nws hnav tsis kam. Lub hardness ntawm cov cuab yeej ntawm chav tsev kub yuav tsum siab tshaj HRC62. Lub hardness tuaj yeem siab tshaj qhov qubCNC machining qhov chaw.

Txaus lub zog thiab toughness

Cov cuab yeej dais siab zoo heev hauv cov txheej txheem ntawm kev txiav ntau dhau. Qee zaum, nws ua haujlwm hauv kev cuam tshuam thiab kev vibration. Txhawm rau tiv thaiv lub cuab yeej los ntawm kev tawg thiab tawg, cov khoom siv yuav tsum muaj lub zog txaus thiab toughness. Feem ntau, khoov lub zog yog siv los sawv cev lub zog ntawm cov cuab yeej siv, thiab tus nqi cuam tshuam yog siv los piav qhia qhov toughness ntawm cov khoom siv.

siab dua kub tsis kam

Thaum tshav kub kub tsis kam yog hais txog kev ua haujlwm ntawm cov khoom siv kom muaj zog, hnav tsis kam, lub zog, thiab toughness nyob rau hauv qhov kub thiab txias. Nws yog ib qho kev taw qhia los ntsuas qhov kev ua tau zoo ntawm cov khoom siv. Qhov kev ua tau zoo no tseem hu ua liab hardness ntawm cov khoom siv.

Zoo thermal conductivity

Qhov ntau dua cov thermal conductivity ntawm cov khoom siv, cov cua kub ntau dua yog hloov los ntawm cov cuab yeej, uas yog qhov tsim nyog los txo qhov kub ntawm cov cuab yeej thiab txhim kho nws cov kav ntev.

Kev ua tau zoo

Txhawm rau txhim kho cov cuab yeej ua thiab kev tsim khoom, cov cuab yeej siv yuav tsum muaj cov khoom ua tau zoo, xws li forging, dov, vuam, txiav thiab grindability, cov khoom siv kho cua sov, thiab cov khoom siv yas deformation kub ntawm cov khoom siv. Cemented carbide thiab cov khoom siv ceramic kuj yuav tsum tau ua kom zoo sintering thiab siab-forming zog.

Hom khoom siv

high-speed hlau

High-speed steel yog cov cuab yeej hlau hlau uas muaj W, Cr, Mo, thiab lwm yam hlau alloy. Nws muaj cov thermal stability, lub zog, toughness, thiab ib tug tej yam kev mob ntawm hardness thiab hnav tsis kam, yog li nws yog haum rau kev ua cov non-ferrnonferrous thiab ntau yam ntaub ntawv hlau. Tsis tas li ntawd, vim nws cov tshuab ua suab nrov, nws yog qhov zoo tagnrho rau kev tsim cov cuab yeej sib sau ua ke, tshwj xeeb tshaj yog cov hmoov metallurgy high-speed steel, uas muaj anisotropic mechanical zog thiab txo quenching deformation; nws yog tsim nyog rau manufacturing precision thiab complex forming cuab yeej.

Hard alloy

Cemented carbide muaj siab hardness thiab hnav tsis kam. Thaum txiavCNC tig qhov chaw, nws qhov kev ua tau zoo yog qhov zoo dua li cov hlau kub ceev. Nws durability yog ob peb mus rau kaum ob lub sij hawm ntawm high-ceev steel, tab sis nws cov cuam tshuam toughness yog tsis zoo. Vim nws txoj kev ua tau zoo heev, nws yog dav siv los ua cov khoom siv.

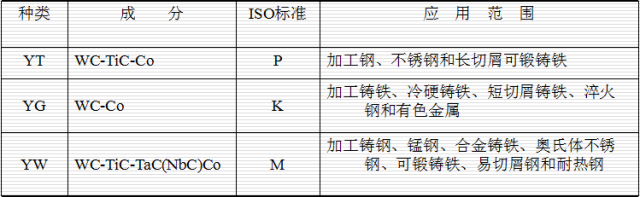

Kev faib tawm thiab cim cov cemented carbide rau cov cuab yeej txiav

Coated hniav

1) Cov khoom siv txheej txheej ntawm CVD txoj kev yog TiC, uas ua rau kom muaj zog ntawm cov cuab yeej cemented carbide los ntawm 1-3 zaug. Txheej thickness: Lub txiav ntug yog blunt thiab conducive rau kev txhim kho ceev lub neej.

2) Cov ntaub ntawv txheej txheej ntawm PVD lub cev vapor deposition txoj kev yog TiN, TiAlN, thiab Ti (C, N), uas txhim kho lub durability ntawm cemented carbide cov cuab yeej los ntawm 2-10 zaug. Txheej nyias; Ntse ntug; Nws muaj txiaj ntsig zoo rau kev txo qis txiav quab yuam.

★ Maximum thickness ntawm txheej ≤ 16um

CBN thiab PCD

Cubic boron nitride (CBN) Lub hardness thiab thermal conductivity ntawm cubic boron nitride (CBN) yog qis dua pob zeb diamond, thiab nws muaj thermal thiab tshuaj stability. Yog li ntawd, nws yog tsim rau machining hardened steel, nyuaj cam khwb cia hlau, superalloy, thiab cemented carbide.

Polycrystalline pob zeb diamond (PCD) Thaum PCD siv los ua cov cuab yeej txiav, nws yog sintered ntawm cemented carbide substrate. Nws tuaj yeem ua tiav hnav-tiv taus, siab hardness, tsis yog-hlau, thiab nonferrononferrousaterials xws li cemented carbide, ceramics, thiab siab silicon aluminium alloy.

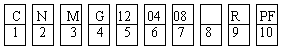

★ ISO tshuab clamp hniav khoom faib ★

Hlau qhov chaw: P05 P25 P40

Stainless hlau: M05 M25 M40

Cam khwb cia hlau: K05 K25 K30

★ Tus naj npawb tsawg dua, cov hniav ntau dua, qhov zoo dua qhov hnav tsis kam ntawm cov cuab yeej, thiab qhov cuam tshuam tsis zoo.

★ Tus lej loj dua, cov hniav yog softer, qhov zoo dua cov cuab yeej cuam tshuam thiab tsis zoo hnav tsis kam.

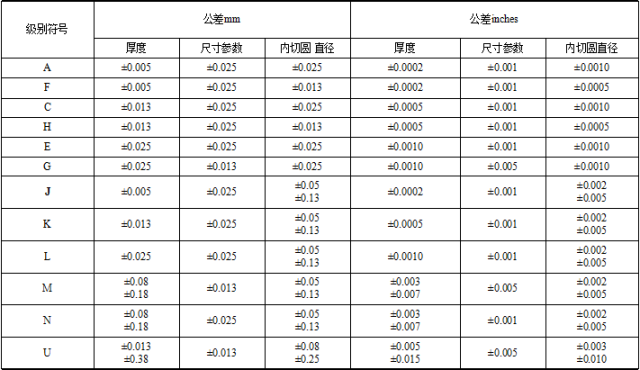

Hloov pauv mus rau cov qauv hniav thiab ISO cov cai sawv cev

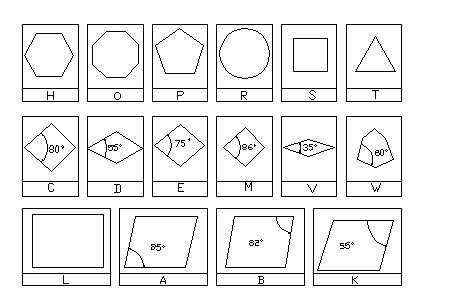

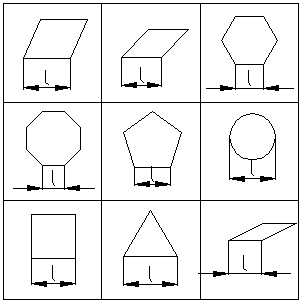

1. Code sawv cev rau cov duab ntawm cov hniav

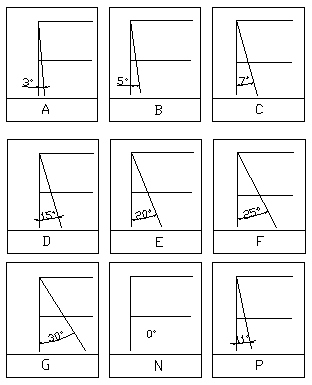

2. Code sawv cev rau lub kaum sab xis ntawm txoj kev txiav ntug

3. Code sawv cev rau qhov ntev ntev ntawm cov hniav

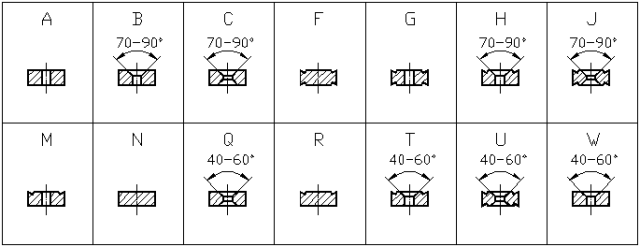

4. Code sawv cev rau cov nti tawg thiab clamping daim ntawv ntawm cov hniav

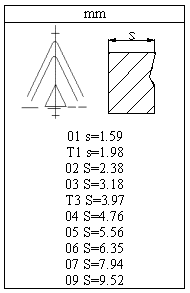

5. Sawv cev los ntawm qhov ntev ntawm kev txiav ntug

6. Code sawv cev rau lub thickness ntawm cov hniav

7. Code sawv cev rau polishing ntug thiab R lub kaum sab xis

Lub ntsiab lus ntawm lwm cov duab

Yim yog hais txog txoj cai qhia txog kev xav tau tshwj xeeb;

9 sawv cev rau cov cai ntawm kev coj noj coj ua; Piv txwv li, code R sawv cev rau txoj cai pub, code L sawv cev rau sab laug pub, thiab code N sawv cev rau qhov nruab nrab pub;

10 sawv cev rau cov cai ntawm nti tawg groove hom;

11 sawv cev rau cov khoom siv ntawm lub tuam txhab cuab yeej;

txiav ceev

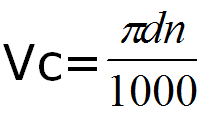

Kev suav cov mis ntawm kev txiav ceev Vc:

Hauv cov qauv:

D - rotary txoj kab uas hla ntawm workpiece los yog tooltip, unit: mm

N - rotational ceev ntawm workpiece los yog cuab tam, unit: r / min

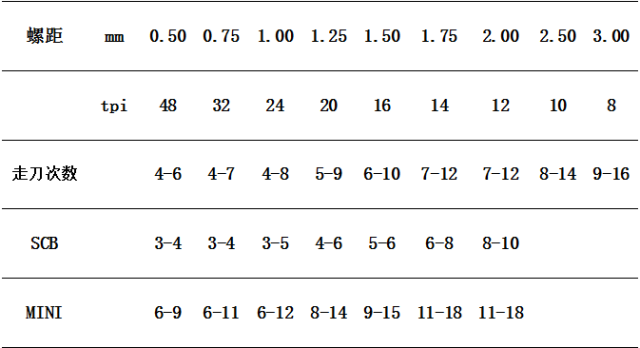

Qhov ceev ntawm Machining Xov nrog Ordinary Tshuab dhos

Spindle ceev n rau txoj xov. Thaum txiav xov, spindle ceev ntawm lub tshuab dhos yog cuam tshuam los ntawm ntau yam, xws li qhov loj ntawm cov xov suab (los yog cov hlau lead) ntawm lub workpiece, nqa thiab txo cov yam ntxwv ntawm lub tshuab tsav, thiab qhov ceev ntawm xov interpolation. Yog li ntawd, qhov sib txawv tshwj xeeb muaj nyob rau hauv spindle ceev rau txoj kev xa xov rau cov tshuab CNC sib txawv. Cov hauv qab no yog cov qauv rau kev xam cov spindle ceev thaum tig threads ntawm dav CNC lathes:

Hauv cov qauv:

P - xov suab los yog txhuas ntawm workpiece xov, unit: mm.

K - kev tuav pov hwm coefficient, feem ntau 80.

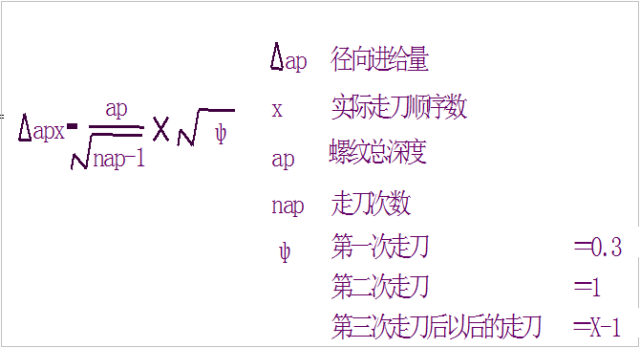

Kev suav ntawm txhua qhov pub qhov tob rau machining xov

Number of threading tool paths

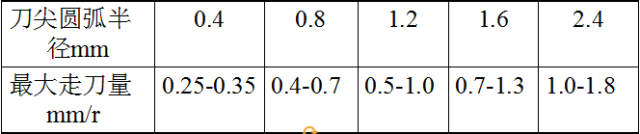

1) Rough machining

Empirical xam mis ntawm ntxhib machining pub: f ntxhib = 0.5 R

Qhov twg: R ------ cov cuab yeej taub arc vojvoog mm

F ------ ntxhib machining cuab tam pub mm

2) Kev ua tiav

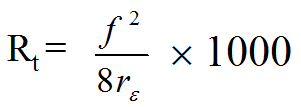

Hauv cov mis: Rt ------ contour tob µ m

F ------ Pub tus nqi mm/r

r ε ------ Radius ntawm tooltip arc mm

Sib txawv ntxhib thiab tiav tig raws li tus nqi pub thiab nti-tawg zawj

F ≥ 0.36 ntxhib machining

0.36 > f ≥ 0.17 semi-finishing

F < 0.17 tiav machining

Nws tsis yog cov khoom siv ntawm cov hniav tab sis cov nti-tawg zawj uas cuam tshuam rau qhov ntxhib thiab tiav machining ntawm cov hniav. Cov ntug txiav yog ntse yog tias lub chamfer tsawg dua 40um.

Post lub sij hawm: Nov-29-2022