Koj paub ntau npaum li cas txog kev ua cov ntsia hlau?

Cov txheej txheem ua cov ntsia hlau feem ntau muaj ntau yam ntawm cov kauj ruam, pib nrog cov khoom siv raw thiab xaus nrog cov khoom kawg. Nov yog cov lus piav qhia ua tiav ntawm cov txheej txheem kev ua cov ntsia hlau feem ntau:

Xaiv cov khoom siv:

Cov txheej txheem xaiv pib nrog kev xaiv cov khoom tsim nyog rau kev tsim cov screws. Cov khoom siv feem ntau yog carbon steel, stainless hlau tooj dag, tooj liab, los yog lwm yam alloys ntawm cov hlau, uas yuav tsum tau muaj zog thiab corrosion kuj thiab lwm yam yuav tsum tau rau daim ntawv thov.

Lub taub hau txias:

Nyob rau hauv cov txheej txheem no, cov ntsia hlau dawb paug yog tsim los ntawm txias forging los yog nqe lus. Lub taub hau txias yog cov txheej txheem ntawm kev ua tus pas nrig lossis xaim rau hauv cov duab uas xav tau rau lub hau ntswj los ntawm kev siv lub taub hau tshuab. Lub taub hau tshuab exerts siab los tsim koj cov dawb paug rau ib puag ncig zoo siv lub taub hau elongated.

Xov Txiav:

Nyob rau hauv cov qauv no siv lub tshuab dhos rau txiav screws, ib tug ntsia hlau yog siv los txiav threads los yog helical grooves nyob rau hauv lub dawb paug ntawm cov ntsia hlau. Lub qhov khoob yog tom qab ntawd tuav hauv chuck, thaum lub cuab yeej txiav tau txav mus los ntawm qhov axis los ua lub qhov. Cov txheej txheem no yog tsim los ua cov ntsia hlau uas muaj ntau qhov ntev thiab hom xov.

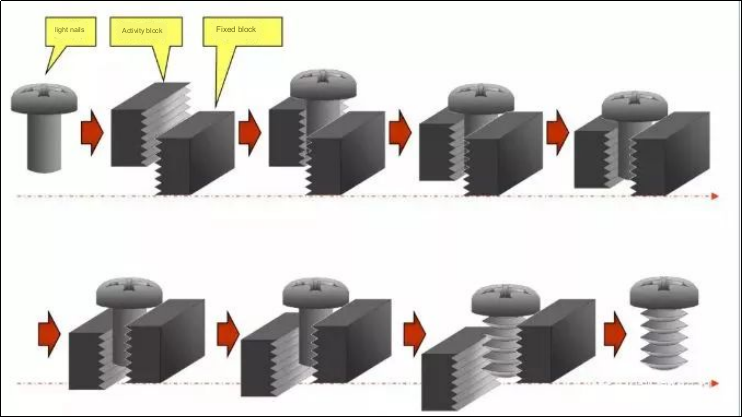

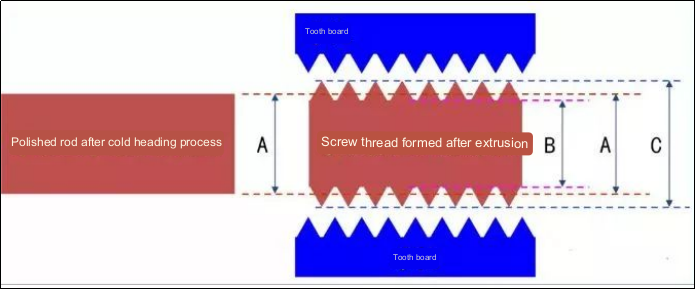

Xov Rolling:

Xov dov yog ib txoj kev sib txawv ntawm kev ua threads rau screws. Cov ntsia hlau khoob yog muab tso rau nruab nrab ntawm ob qhov tuag uas yog threaded thiab ces lub siab yog siv los deform cov ntaub ntawv thiab tsim threads. Xov dov tsim muaj zog threads uas yog ntau leej thiab feem ntau siv nyob rau hauv high-volume ntau lawm.

Kev kho cua sov:

Cov txheej txheem kev kho cua sov zoo li tempering thiab quenching yog nquag siv los txhim kho nws cov yam ntxwv ntawm cov ntsia hlau. Cov txheej txheem no nce hardness, lub zog thiab durability uas cov ntsia hlau muaj, ua kom nws muaj peev xwm tiv taus ntau yam kev ntxhov siab thiab kev thauj khoom.

Nto Finishing:

Ntau txoj kev ua tiav saum npoo yog siv los txhim kho qhov zoo thiab kev ua haujlwm ntawm cov ntsia hlau. Cov txheej txheem saum npoo muaj xws li zinc plating, nickel plating, galvanizing, dub oxide txheej, lossis passivation. Cov khoom tiav no tiv thaiv corrosion, ua kom cov khoom siv tau ntev, thiab tseem ntxiv tus nqi zoo nkauj.

Kev tshuaj xyuas thiab kev tswj xyuas zoo:

Kev tswj xyuas kev ua tau zoo yog ua tiav thoob plaws hauv cov txheej txheem kom paub tseeb tias cov ntsia hlau ua tau raws li qhov yuav tsum tau ua rau cov lus qhia tshwj xeeb thiab cov qauv. Kev ntsuam xyuas, xws li xov txoj kab uas hla, lub suab ntev, txoj kab uas hla, thiab qhov zoo ntawm qhov tiav, yog siv los xyuas qhov sib xws thiab qhov tseeb.

Kev xa khoom thiab ntim khoom:

Tom qab cov ntsia hlau tau raug tshuaj xyuas kom zoo tom qab uas lawv tau ntim thiab npaj xa tuaj. Kev ntim khoom tuaj yeem ua rau hauv cov thawv ntim ntau tsim los siv rau kev lag luam, lossis cov thawv me me los muag cov khw muag khoom, nyob ntawm lub khw uas lawv npaj siab.

Koj puas paub cov ntsiab lus hais txog cov screws?

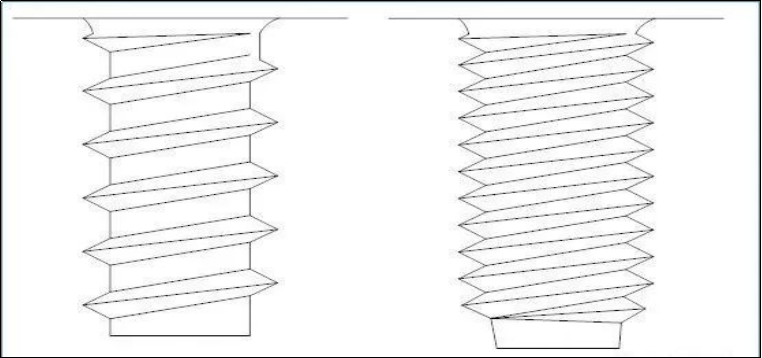

1. Qhov sib txawv ntawm cov ntsia hlau, txiv ntseej lossis bolts screws, thiab studs Cov qauv kab lus yog tias tsis muaj txiv ntseej lossis cov ntsia hlau. Cov ntsia hlau feem ntau raug xa mus los ntawm lawv lub npe rau cov ntsia hlau, thiab cov uas muaj cov xov sab nraud tuaj yeem raug hu ua "screws". Nws cov duab feem ntau yog hexagonal. Qhov qhib sab hauv yog ib qho xov sab hauv uas ua haujlwm nrog lub ntsia liaj qhov rooj thiab ua kom nrujcov khoom siv machining. Txiv ntseej yog lub npe nrov, thiab ntau lub npe yuav tsum yog "txiv ntseej".

Nws lub taub hau feem ntau yog hexagonal, thaum lub shank yog nruab nrog cov xov sab nraud. Cov ntsia hlau yog me me, thiab lub taub hau yog lub taub hau elongated los yog hla lub taub hau, thiab lwm yam. Lub shank yog threaded externally. Studs yuav tsum hu ua "ob-kawg studded". Ob qhov kawg yog nruab nrog cov xov sab nraud thiab qhov nruab nrab feem ntau yog ua los ntawm cov pas nrig polished. Qhov ntev tshaj plaws ntawm tus pas nrig txuas nrog lub qhov nyob hauv nruab nrab, thaum lub sijhawm luv luv txuas nrog cov txiv ntseej.

2. Lus Askiv sawv cev: Screw / Bolt / Fastener (ntsia hlau / ntsia hlau) (bolt) (fastener)

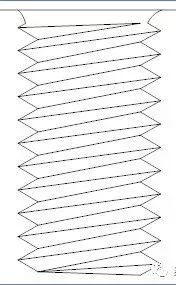

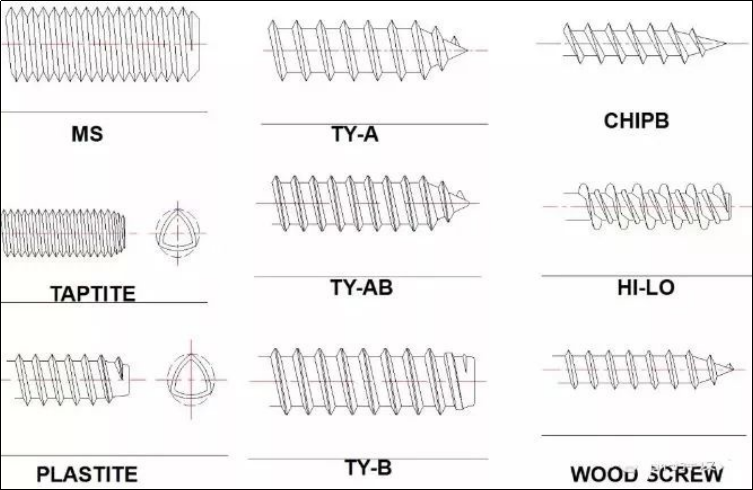

3. Cov ntsiab lus xov: nws yog cov duab uas muaj homogeneous helical protrusions uas nyob rau sab hauv lossis sab nrauv ntawm ib qho khoom.

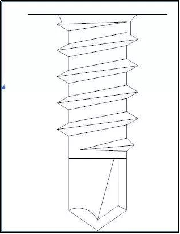

Tus kheej tapping xov: laum qhov hauv lub rooj sib dhos thaum sib dhos, tsis tas tapping cov xov hauv siv lub zog loj dua los sib sau ua ke.

Self-drilling xov: Siv ncaj qha rau ntawm lub rooj sib txoos, lub hau ntswj yog laum thiab coj mus rhaub ib txhij.

Txoj kev ua cov ntsia hlau

1. tig

Tsim koj cov khoom raws li qhov koj xav tau los ntawm kev noj cov khoom

Qhov zoo: siab precision hauv machining thiab tsis muaj pwm txwv

Tsis zoo: cov nqi ntau lawm thiab ua haujlwm qeeb

2. Forging

Extrude cov khoom nrog rau sab nraud quab yuam, ua rau nws deform nyob rau hauv thiaj li yuav tsim cov yam xav tau.

Cov txiaj ntsig: Kev tsim khoom ceev ceev thiab tus nqi qis, haum rau kev tsim khoom loj

Tsis txaus: Daim ntawv yog txwv los ntawm cov pwm thiab pwm cov nqi rau cov khoom siv ntau dua yog siab heev.

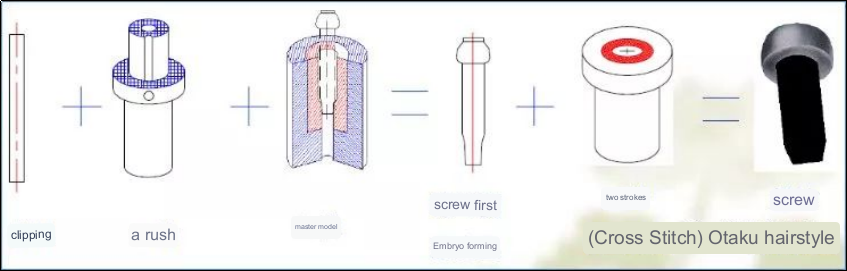

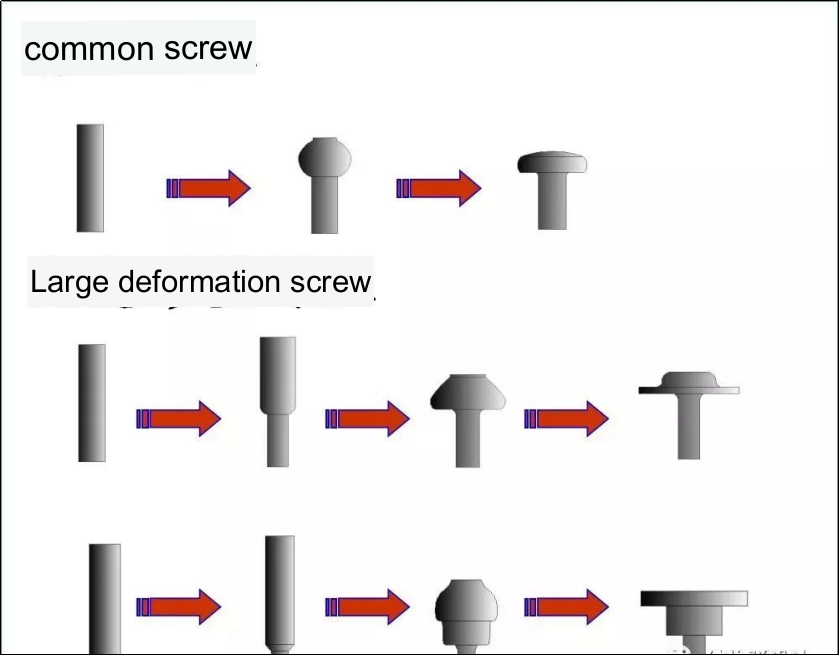

3. Lub taub hau txias

Nws yog cov txheej txheem ntawm extruding thiab tsim cov hlau hlau los ntawm kev quab yuam sab nraud, nyob rau hauv cov xwm txheej uas cov hlau hlau tsis kub. Cov txheej txheem txias-heading yog ib hom txheej txheem rau kev ua forgings.

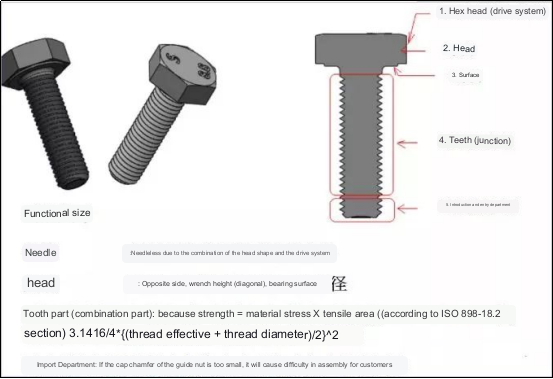

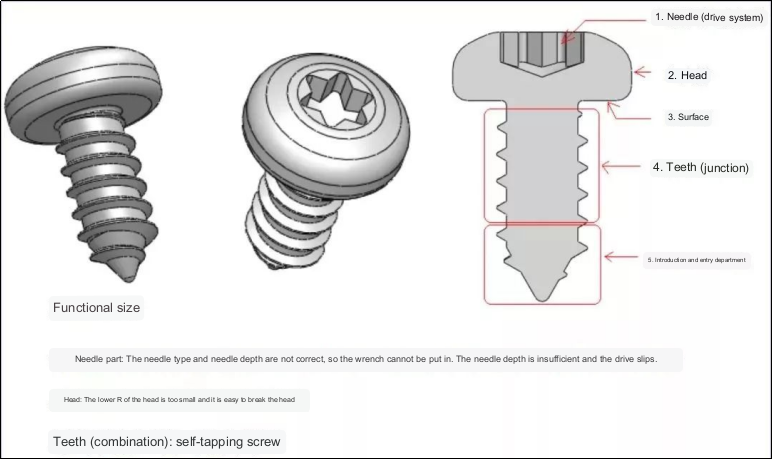

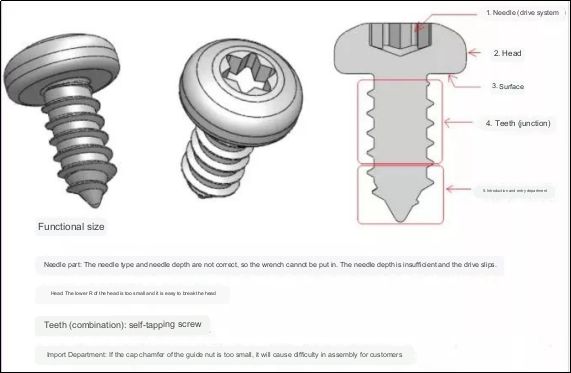

Kev taw qhia txog lub hauv paus configuration ntawm screws

Yuav kom nkag siab tag nrho cov bolts thiab screws ua ntej, koj yuav tsum paub txog lawv hom, nta thiab lawv txoj haujlwm.

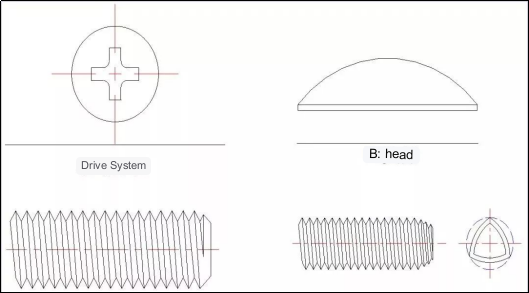

Ib tug tsav system

B taub hau

C: Cov hniav sib txuas

D Department of Import thiab Attack

Tshuab ntsia hlau

Self tapping ntsia hlau

Daim duab peb sab hniav ntsia hlau

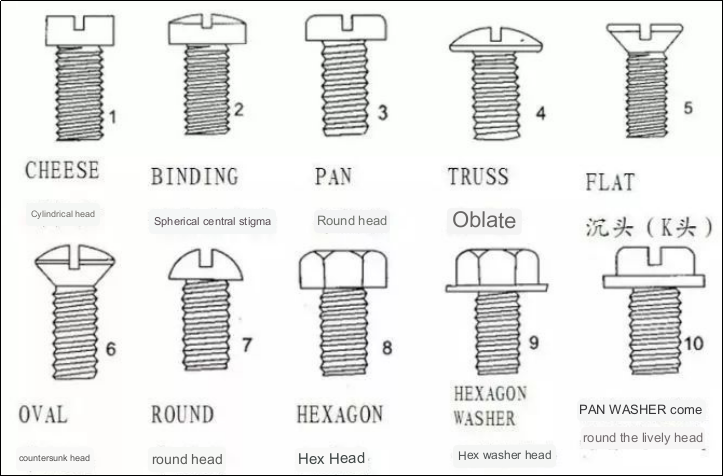

Ntsia taub hau hom

Ntsia hlau profile

Ntsia hlau txheej txheem

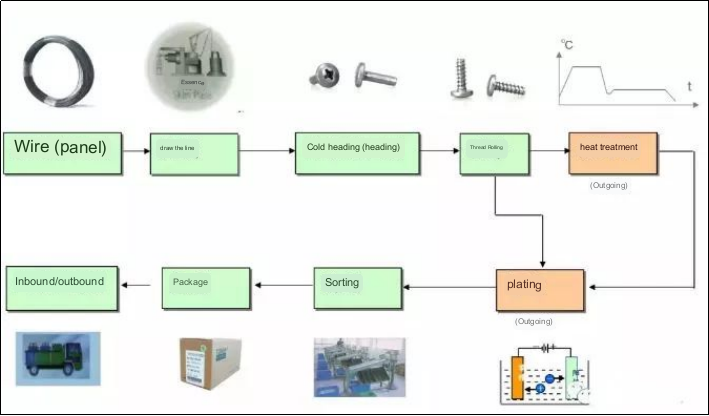

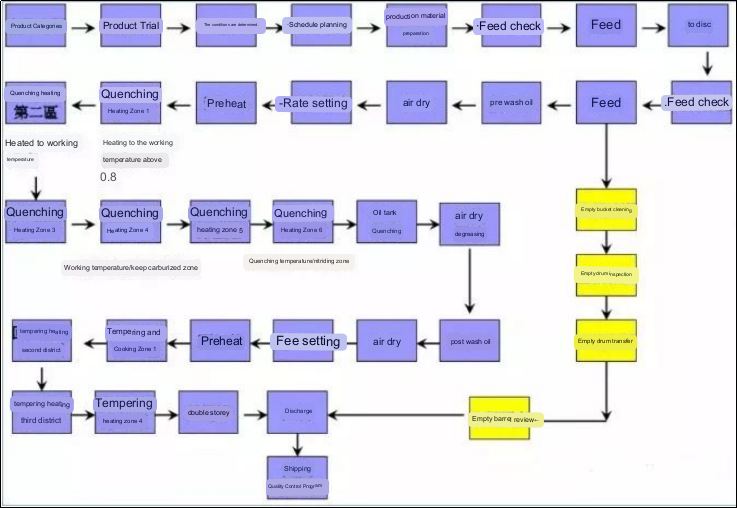

Flow chart's general format yog raws li nram no:

Disk unit txheej txheem

Tus thawj xaim pas nrig uas tau yuav los ntawm tus neeg muag khoom ntawm cov khoom siv raw. Ib co coil feem ntau muaj cov hauv qab nocnc machined qhov chawsuav nrog: A, hom npe BC, lub npe khoom, specification D cov khoom E, lub cub tawg tus naj npawb, batch tooj, qhov ntau lossis qhov hnyav. Cov ntsiab lus tseem ceeb ntawm carbon steel discs yog: C Mn, P Si Cu thiab Al Qhov me me ntawm Cu thiab Al yog qhov zoo dua.

Kev kos duab

Txhawm rau kom ua tiav cov kab kab uas hla peb xav tau (xws li mus rau 3.5mm kos hlau).

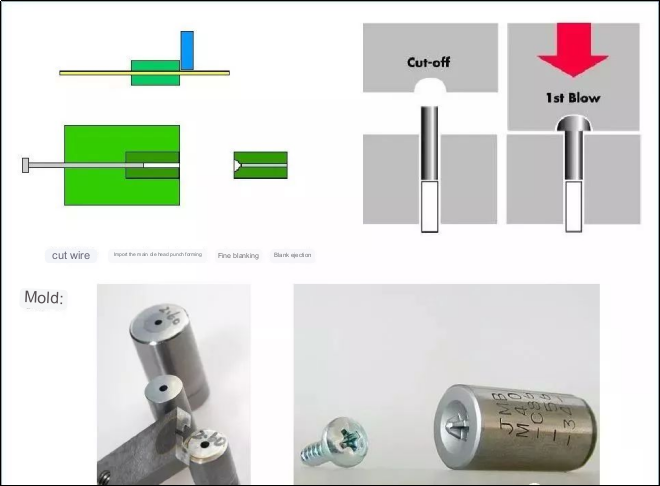

Cold heading (heading) txheej txheem

Los ntawm kev sib cuam tshuam ntawm cov pwm, nws yog tsim. Ua ntej, cov hlau raug txiav tawm thiab chim siab rau hauv cov ntsia hlau dawb los tsim lub taub hau, hla qhov zawj (los yog lwm lub taub hau hom) xov dawb kab uas hla thiab pas nrig ntev, thiab sib npaug ntawm cov ces kaum hauv qab lub taub hau.

Kev piav qhia: Nws muaj peev xwm tsim tau raws li cov neeg siv khoom xav tau. Hom taub hau feem ntau muaj xws li P taub hau, B taub hau, F taub hau, T taub hau, thiab lwm yam. Hla grooves, plum blossom grooves, hexagonal grooves, thiab slotted grooves yog txhua hom zawj.

Kev piav qhia: Nws muaj peev xwm tsim tau raws li cov neeg siv khoom xav tau. Hom taub hau feem ntau muaj xws li P taub hau, B taub hau, F taub hau, T taub hau, thiab lwm yam. Hla grooves, plum blossom grooves, hexagonal grooves, thiab slotted grooves yog txhua hom zawj.

Hloov ua ntej thiab tom qab txhuam hniav

Cov hniav txhuam hniav tshuab

Rub board (template)

Kev kho cua sov txheej txheem

1. Lub hom phiaj: Ua kom cov ntsia hlau tau siab dua hardness thiab lub zog tom qab lub taub hau txias.

2. Muaj nuj nqi: Paub txog tus kheej-tapping locking ntawm hlau, txhim kho cov khoom siv ntawm cov hlau, xws li torsion tsis kam, tensile kuj thiab hnav tsis kam. 3. Classification: A. Annealing: (700 ° C x 4hr): elongated qauv - tsis tu ncua polygon.

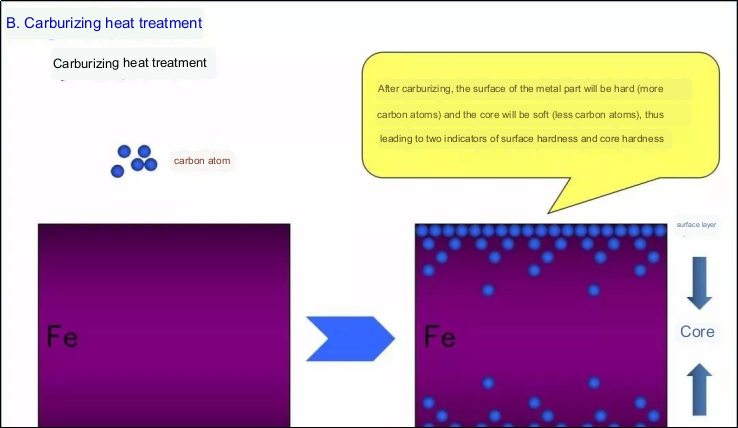

Cov qauv ua haujlwm txias B. Kev kho cua sov ntawm carburizing (ntxiv cov pa roj carbon rau cov hlau los txhim kho lawv cov tawv tawv) rau cov khoom uas muaj cov ntsiab lus carbon tsawg.

C. quenching thiab tempering kub kev kho mob (tsis txhob ntxiv cov ntsiab lus rau cov hlau, hloov cov qauv sab hauv ntawm cov hlau los ntawm kev hloov qhov kub thiab txias kom tau txais cov khoom zoo dua qub).

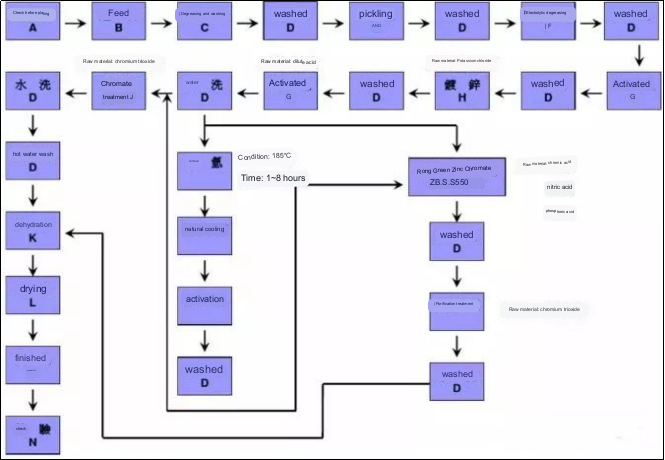

Cov txheej txheem electroplating

Tom qab electroplating, qhov saum npoo ntawm cov khoom tuaj yeem coated nrog cov xim xav tau thiab cov nyhuv oxidation.

Anebon lub hom phiaj yog kom nkag siab zoo heev disfigurement los ntawm kev tsim khoom thiab muab cov kev txhawb nqa sab saum toj rau cov neeg siv khoom hauv tsev thiab txawv teb chaws rau 2022 Zoo siab Stainless Hlau Aluminium High Precision Custom MadeCNC tig, Milling, Machining Spare Part for Aerospace, Yuav kom nthuav peb lub lag luam thoob ntiaj teb, Anebon tsuas yog muab peb cov neeg siv khoom txawv teb chaws Sab saum toj zoo kev ua haujlwm zoo tshaj plaws, milled qhov chaw thiab cnc tig kev pabcuam.

Tuam Tshoj lag luam wholesale Tuam Tshoj Machinery Parts thiab CNC Machining Service, Anebon upholds tus ntsuj plig ntawm "innovation, kev sib raug zoo, pab neeg ua hauj lwm thiab sib koom, txoj kev, pragmatic kev vam meej". Muab sijhawm rau peb thiab peb yuav mus ua pov thawj peb lub peev xwm. Nrog koj txoj kev pab zoo, Anebon ntseeg tias peb tuaj yeem tsim lub neej yav tom ntej nrog koj ua ke.

Post lub sij hawm: Aug-08-2023