CNC machining kev pabcuam

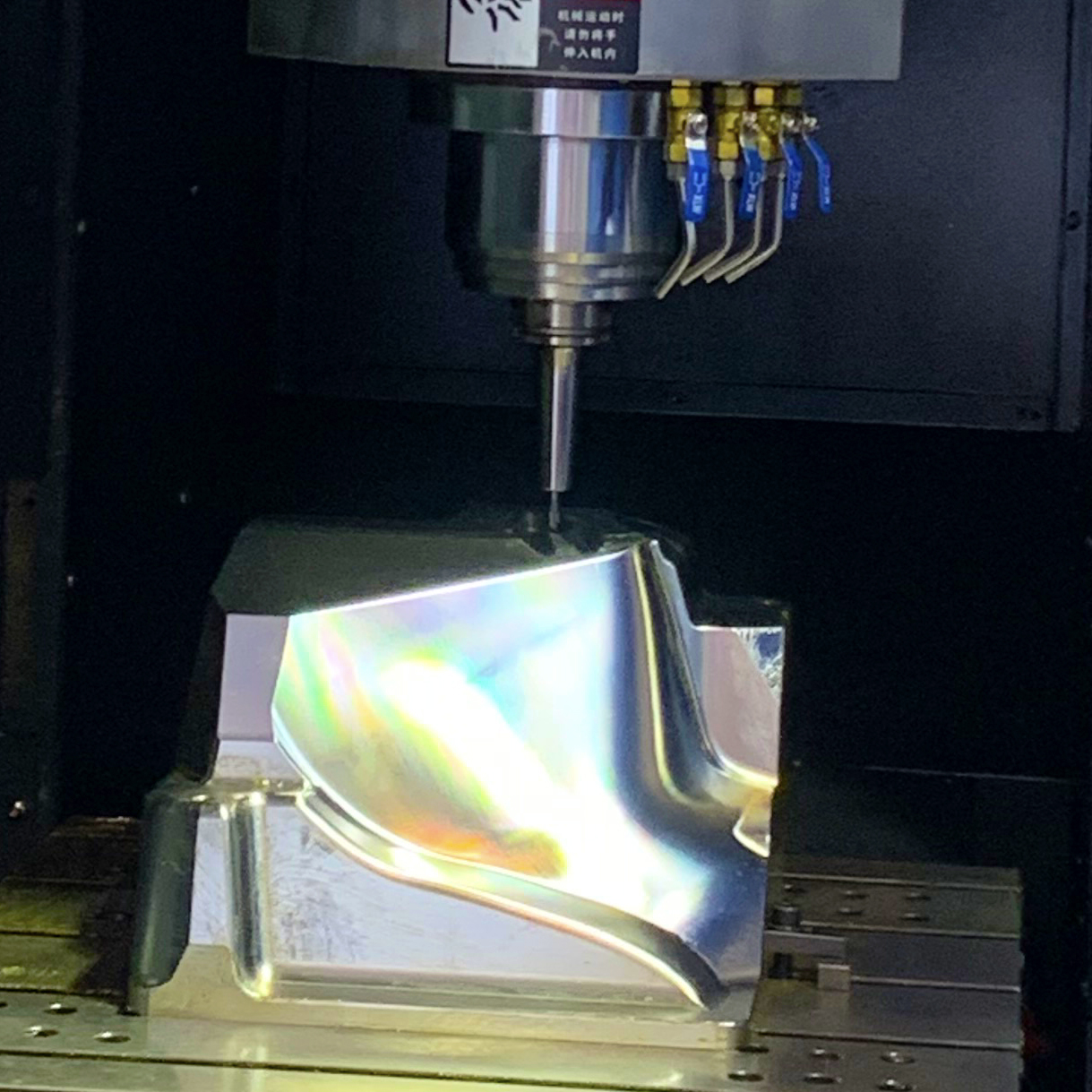

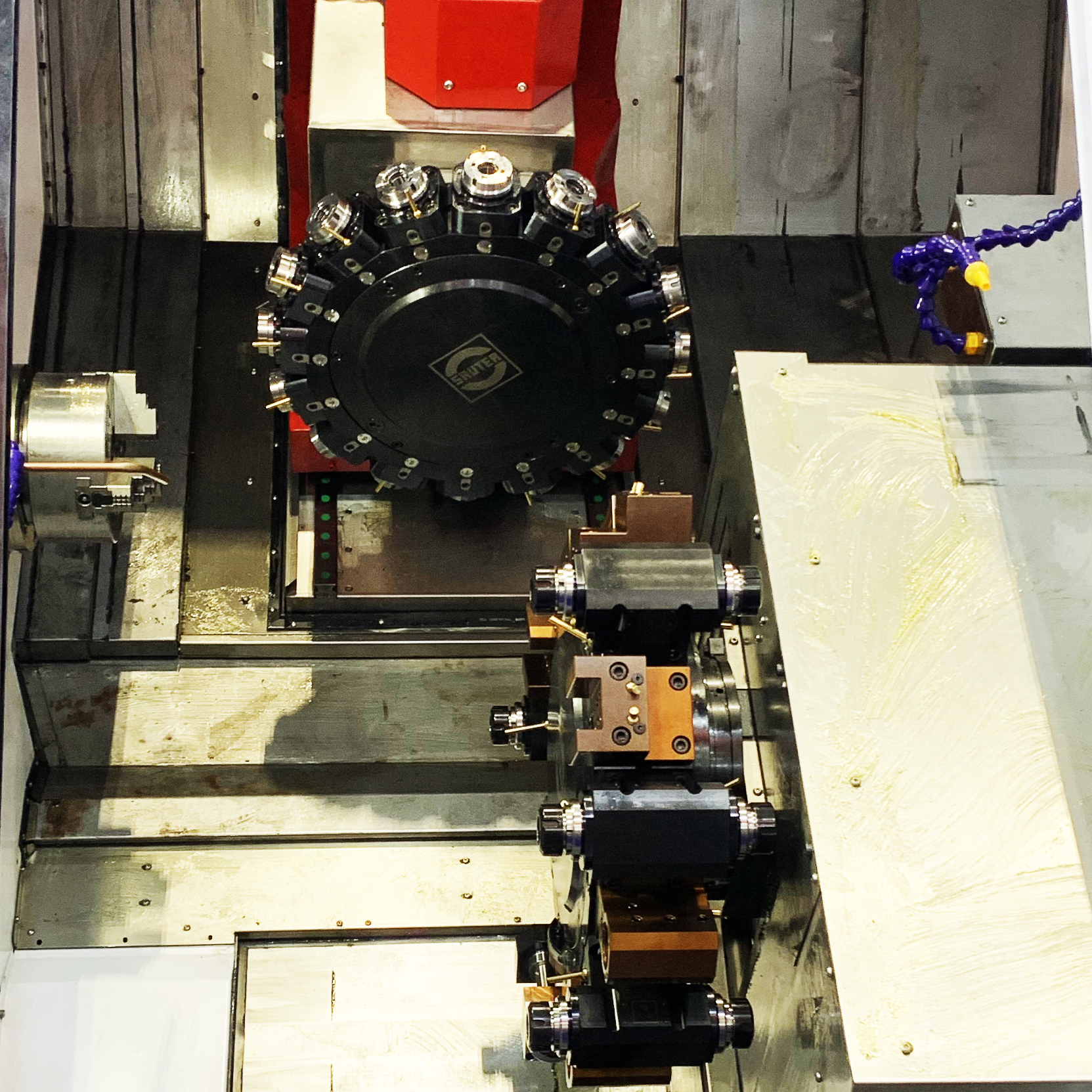

Anebon muaj cov cuab yeej siv siab heev los muab koj ntau yam ntawm CNC machining cov kev pab cuam, suav nrog milling, tig, EDM, hlau txiav, nto sib tsoo thiab lwm yam. Peb siv imported 3, 4 thiab 5-axis CNC machining chaw los muab koj zoo precision, amazing saj zawg zog, thiab ib tug dlej tso zis rau yuav luag txhua yam machining project. Peb tsis tsuas yog muaj cov tshuab sib txawv, tab sis kuj yog ib pab neeg ntawm cov kws tshaj lij, uas tau cog lus los muab kev pabcuam zoo tshaj plaws nyob rau hauv Suav teb rau koj. Peb cov kws kho tsheb txawj siv tau ntau yam khoom siv yas thiab hlau los tsim cov khoom tig thiab milling.

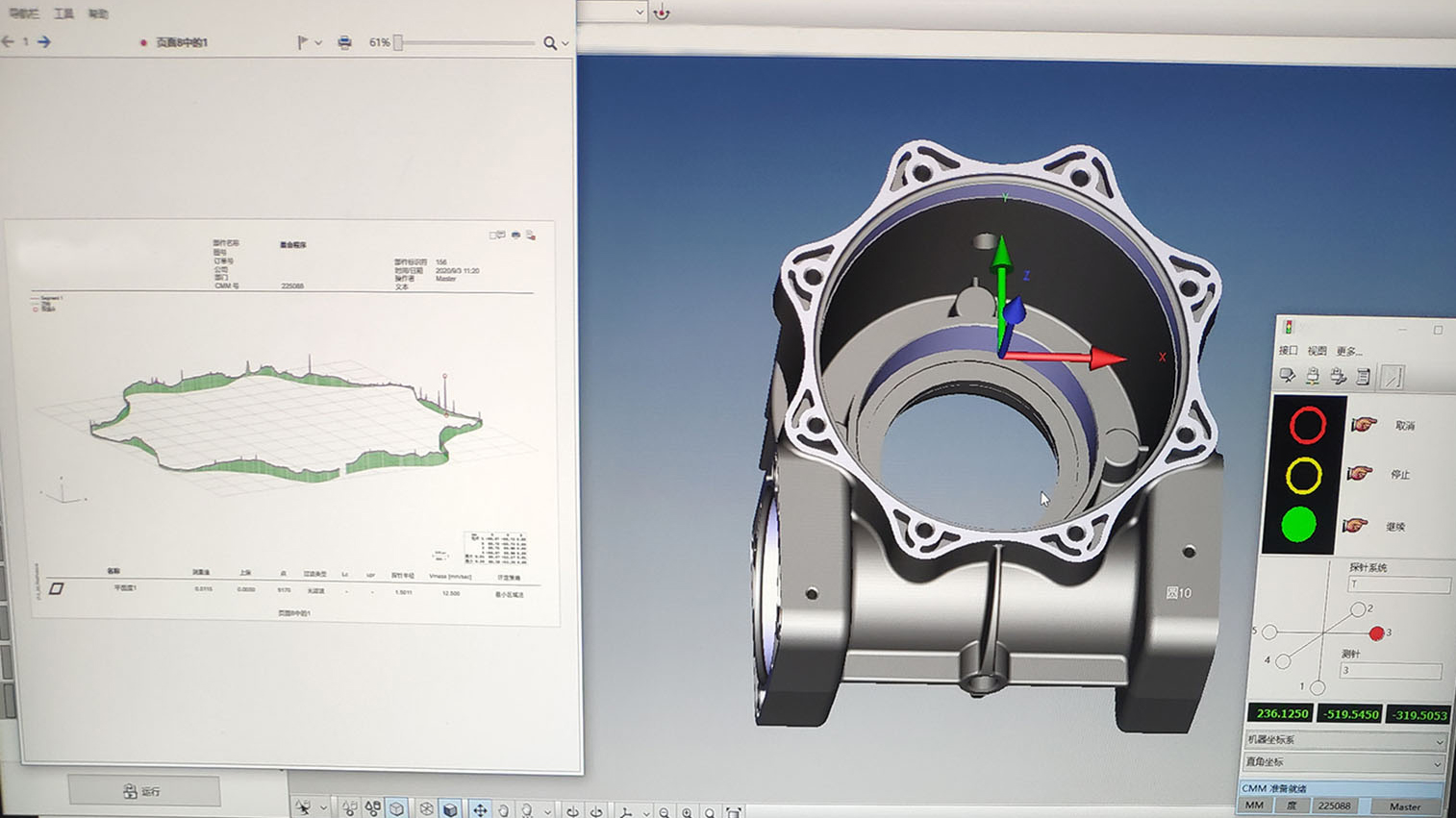

Peb lees paub koj tias txawm tias qhov loj ntawm txoj haujlwm, peb cov kws tshaj lij kho nws zoo li nws yog lawv tus kheej. Peb tseem tuaj yeem muab cov qauv CNC machining cov kev pabcuam uas yuav pab tau koj kom tau txais daim duab meej ntawm cov khoom kawg.

Vim li cas thiaj xaiv peb?

Anebon tau ua tus thawj coj hauv kev tsim cov khoom tshiab. Specialty Integrated Services tau hwm nws cov kev txawj ntse thiab cov txheej txheem. Lub Tuam Txhab tsim yuav luag txhua lub ntiaj teb cov khoom siv hlau. Peb cov engineers yuav ua hauj lwm nrog koj los xyuas kom meej qhov siab tshaj plaws tsim zoo rau kev tsim thiab sib dhos. Kev pabcuam zoo rau cov neeg siv khoom thiab kev txaus siab yog cov cim ntawm peb lub tuam txhab thiab lub hauv paus rau peb txoj kev lag luam vam meej.

Sijhawm Sijhawm - Peb nkag siab tias qee qhov ntawm peb txoj haujlwm muaj lub sijhawm ceev, thiab peb muaj cov kev txawj thiab cov txheej txheem los xyuas kom meej tias peb xa tuaj raws sijhawm yam tsis muaj kev cuam tshuam txog kev ua haujlwm uas peb ua.

Kev paub - Peb tau muab kev pabcuam CNC milling rau ntau tshaj 10 xyoo. Peb tau sib sau ua ke ntau yam ntawm cov tshuab milling siab heev rau ntau yam txheej txheem thiab muaj ib pab neeg ua haujlwm paub txog thiab cov neeg ua haujlwm los muab cov khoom zoo rau txhua tus neeg siv khoom.

Peev Xwm - Nrog rau ntau yam ntawm peb cov tshuab, peb muaj peev xwm lav tau qhov tseeb ntawm txhua yam khoom hauv txhua qhov ntau thiab tsawg.

CNC machining yog dab tsi?

CNC machining yog cov txheej txheem tsim tawm uas txiav cov ntaub ntawv raw los ntawm ntau yam precision txiav cov cuab yeej. Advanced software yog siv los tswj cov cuab yeej raws li qhov tshwj xeeb ntawm 3D tsim. Peb pab neeg ntawm engineers thiab mechanics cov kev pab cuam cov cuab yeej los optimize txiav lub sij hawm, nto tiav thiab zaum kawg kam rau ua kom tau raws li koj xav tau. Peb siv CNC machining tsis yog tsuas yog tsim cov khoom thiab cov qauv, tab sis kuj los ua cov cuab yeej pwm.

Cov Cai Tsim:

(1) Cov txheej txheem tsim tshwj xeeb yuav tsum ua kom muaj kev ua haujlwm zoo ntawm lub tshuab qhov chaw (lossis kev sib dhos zoo ntawm lub tshuab) thiab ua tau raws li cov kev cai uas tau teev tseg ntawm cov qauv tsim.

(2) Cov txheej txheem yuav tsum muaj kev tsim khoom siab thiab cov khoom yuav tsum tau muab tso rau hauv kev lag luam sai li sai tau.

(3) Sim txo cov nqi tsim khoom

(4) Ua tib zoo txo qis kev siv zog ntawm cov neeg ua haujlwm thiab ua kom muaj kev nyab xeeb ntawm kev tsim khoom.

Tsawg-Volume Manufacturing

Kev tsim khoom hauv cov ntim qis yog qhov kev daws teeb meem zoo tshaj plaws rau kev tswj hwm koj cov khoom muag thiab kuaj kev lag luam ua ntej tsim cov khoom loj. xaiv Low-Volume Manufacturing yog koj xaiv zoo tshaj.

Anebon yuav xaiv cov txheej txheem tsim nyog tshaj plaws raws li cov khoom siv, kev kho deg thiab kom muaj nuj nqis, tab sis kuj muab ntim thiab lwm yam kev pabcuam ib zaug.

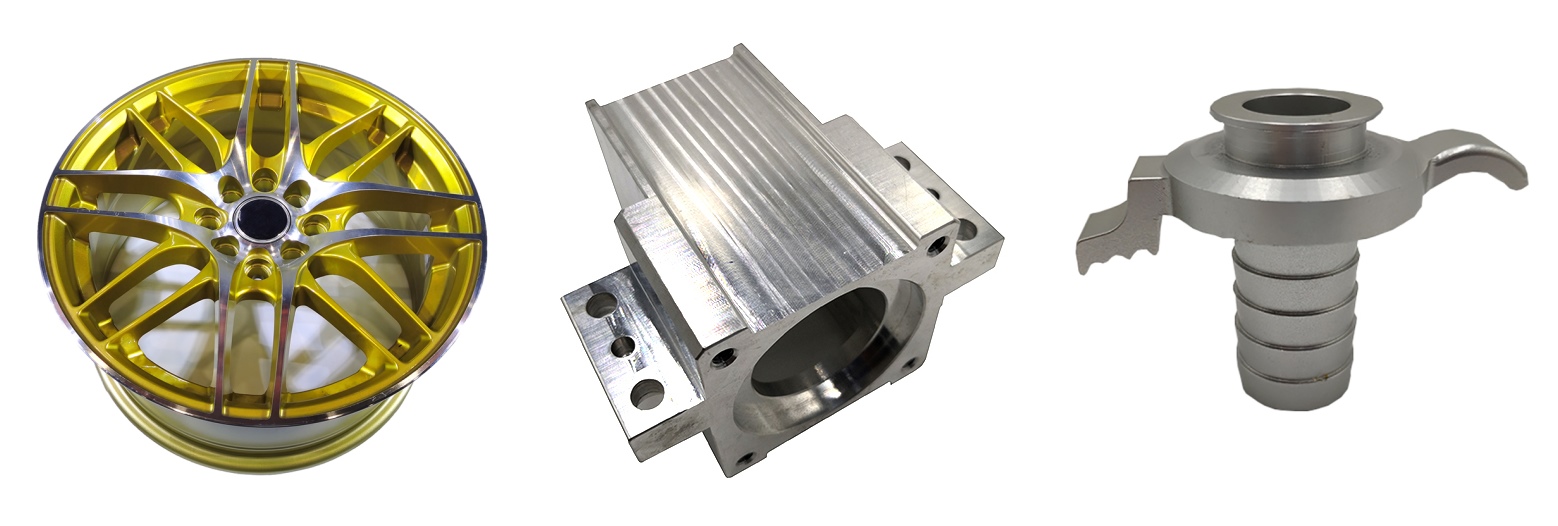

Peb CNC Machining, qauv sai thiab Tsawg-Volume Manufacturing haum rau ntau yam kev lag luam xws li Tsheb, Motorcycles, Machinery, dav hlau, tsheb ciav hlau, tsheb kauj vab, Watercraft, Electronic, Scientific equipment, Laser theatre, Robots, Oil & Gas Control Systems, Medical devices , Cov khoom siv hluav taws xob tau txais, Cov khoom siv kho qhov muag, Lub Koob Yees Duab & Duab, Cov khoom siv ncaws pob zoo nkauj thiab teeb pom kev zoo, Rooj tog.

Qhov zoo ntawm CNC machining

CNC machining yog qhov zoo tagnrho rau koj qhov kev xav tau ntawm cov khoom tsim kho. Nov yog qee qhov zoo ntawm precision machining:

• Mechanical processing of titanium alloys, superalloys, non-metals, etc., pwm tsim thiab tsim

• Cov khoom siv tsis yog qauv tsim thiab tsim khoom

• Machining txheej txheem: drilling, xov milling, broaching, tapping, spline, reaming, txiav, Profile, tiav, tig, threading, internal forming, dimples, knurling, countersunk, tho txawv, thim rov qab drilling, hobbing

• Tshem tawm cov khoom siv hlau loj heev sai sai

• Haum rau ntau hom substrates

• Tsawg peev hauv pwm thiab cov nqi npaj

• Muaj tseeb thiab rov ua tau dua

• Pwm tsim thiab tsim khoom

• Kev kam rau siab: ± 0.002mm

• Kev lag luam

R&D

Peb muaj ntau tshaj li kaum xyoo ntawm kev txawj ntse hauv 3D tsim. Peb pab neeg ua haujlwm nrog cov neeg siv khoom los tsim cov qauv tsim / qhov chaw uas ua tau raws li lawv cov kev xav tau, thaum txiav txim siab tus nqi, qhov hnyav thiab cov txheej txheem tsim khoom.Tom qab tsim tiav, peb teeb tsa tag nrho engineering thiab cov txheej txheem tsim khoom ntawm cov cuab yeej. Thiab peb tuaj yeem pib qhov kev sim tom ntej tsuas yog tom qab lub tuam tsev zoo tau pom zoo cov cuab yeej.

Peb tsom mus rau cov txheej txheem tseem ceeb hauv R & D txheej txheem:

Cov qauv tsim

Tool DFM

Cov cuab yeej / pwm tsim

Pwm Flow - Simulation

Kev kos duab

CAM

Hom kev ua cov cuab yeej

Muaj ntau ntau hom kev ua cov cuab yeej siv tau ib leeg los yog ua ke nrog lwm cov cuab yeej hauv ntau cov kauj ruam ntawm cov txheej txheem tsim khoom kom ua tiav qhov xav tau geometry. Cov txheej txheem tseem ceeb ntawm cov cuab yeej ua haujlwm:

• Cov cuab yeej tho txawv: Cov cuab yeej no feem ntau yog siv los ua cov khoom tiav los nthuav cov qhov uas tau txiav rau hauv cov khoom yav dhau los.

• Cov cuab yeej txiav: Cov cuab yeej xws li saws thiab txiab yog cov cuab yeej sawv cev rau cov cuab yeej txiav. Lawv feem ntau yog siv los txiav cov khoom uas muaj qhov loj me me, xws li cov ntawv hlau, rau hauv cov duab uas xav tau.

• Cov cuab yeej Drilling: Cov qeb no suav nrog ob-edged swivel uas tsim ib lub voj voog lub voj voog mus rau lub axis ntawm kev sib hloov.

• Cov cuab yeej sib tsoo: Cov cuab yeej no siv lub log tig rau kev ua haujlwm zoo lossis txiav me me ntawm cov khoom ua haujlwm.

• Cov cuab yeej milling: Cov cuab yeej milling siv qhov sib hloov ntawm qhov chaw uas muaj ntau qhov ntxig los tsim ib lub qhov uas tsis yog lub voj voog lossis txiav cov qauv tsim tshwj xeeb ntawm cov khoom siv.

• Cov cuab yeej tig: Cov cuab yeej no tig lub workpiece ntawm lub ncej thaum lub cuab yeej txiav nws.

Khoom siv

| Hlau | Carbon Steel, 4140, 20 #, 45 #, 4340, Q235, Q345B, thiab lwm yam |

| Stainless hlau | SS303, SS304, SS316, SS416 thiab lwm yam. |

| Aluminium | Al6063, AL6082, AL7075, AL6061, AL5052, A380 thiab lwm yam. |

| Hlau | 12L14, 1215, 45 #, A36, 1213, thiab lwm yam. |

| tooj dag | HSn62-1, HSn60-1, HMn58-2, H68, HNi65-5, H90, H80, H68, H59 thiab lwm yam |

| Tooj | C11000, C12000, C12000, C26000, C51000 thiab lwm yam. |

| Yas | Delrin, Nylon, Teflon, PP, PEI, ABS, PC, PE, POM, Peek.Carbon Fiber |

Kev kho saum npoo

| Mechanical Surface Treatment | Xuab zeb blasting, txhaj tshuaj blasting, sib tsoo, dov, polishing, txhuam, tshuaj tsuag, pleev xim, roj pleev xim thiab lwm yam. |

| Tshuaj kho qhov muag | Bluing thiab Blackening, Phosphating, Pickling, Electroless Plating ntawm Ntau Hlau thiab Alloys thiab lwm yam. |

| Electrochemical Surface Treatment | Anodic Oxidation, Electrochemical Polishing, Electroplating thiab lwm yam. |

| Niaj hnub nimno kho deg | CVD, PVD, Ion implantation, Ion Plating, Laser Surface Treatment ect. |

| Xuab zeb Blasting | Qhuav Sand Blasting, ntub Sand Blasting, Atomized Sand Blasting thiab lwm yam. |

| Txau | Electrostatic Spraying, Fame Spraying, Powder Spraying, Plastic Spraying, Plasma Spraying |

| Electroplating | Copper Plating, Chromium Plating, Zinc Plating, Nickel Plating |

Khoom

CNC Precision Wheels

CNC Aluminium Milling tshuab

CNC Machining Prototyping

5 Axies CNC Machining

Kev cai CNC Machining Iav

CNC tig Machining