Brass Turning Parts

Product Detail:

| Precision ntawm workpiece: | +/- 0.005 ~ +/- 0.002 hli | ||

| Roughness ntawm workpiece: | Ra≤0.1 | ||

| Cov qauv zoo: | DIN, ASTM, GOST, GB, JIS, ANSI, BS; | ||

| Daim duab hom: | JPEG, PDF, AI, PSD, DWG, DXF, IGS, STEP.CAD | ||

| Cov khoom pov thawj: | ISO9001: 2015, CE, RoHS, SGS; | ||

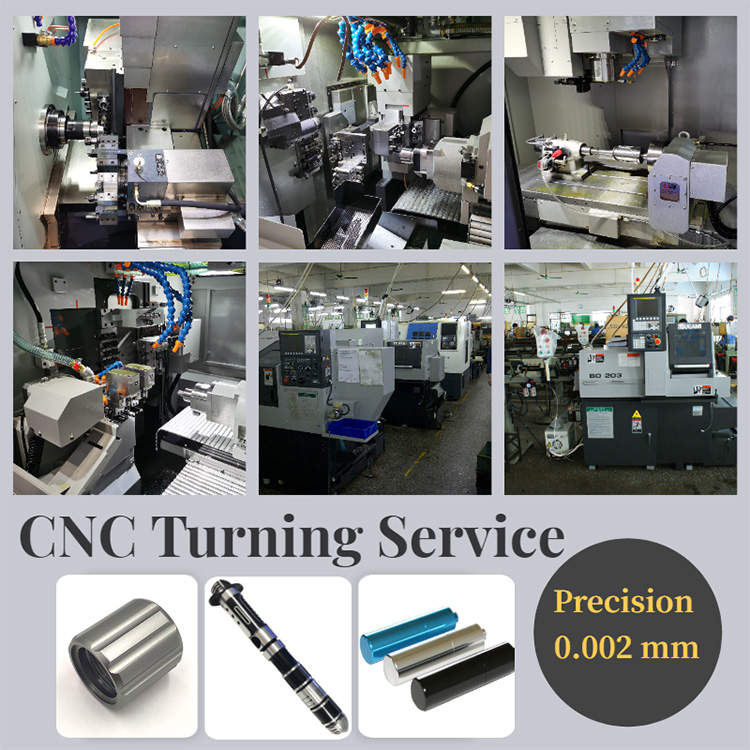

| Processing equipments: | DMG tsib-axis machining chaw / DMG sib xyaw ua chaw / chaw ua haujlwm / CNC ntsug tshuab dhos / CNC tshuab dhos / CNC milling tshuab / CNC sib tsoo tshuab / tig-txiav / laser txiav / hlau-electrode txiav / CNC sib koom tshuab | ||

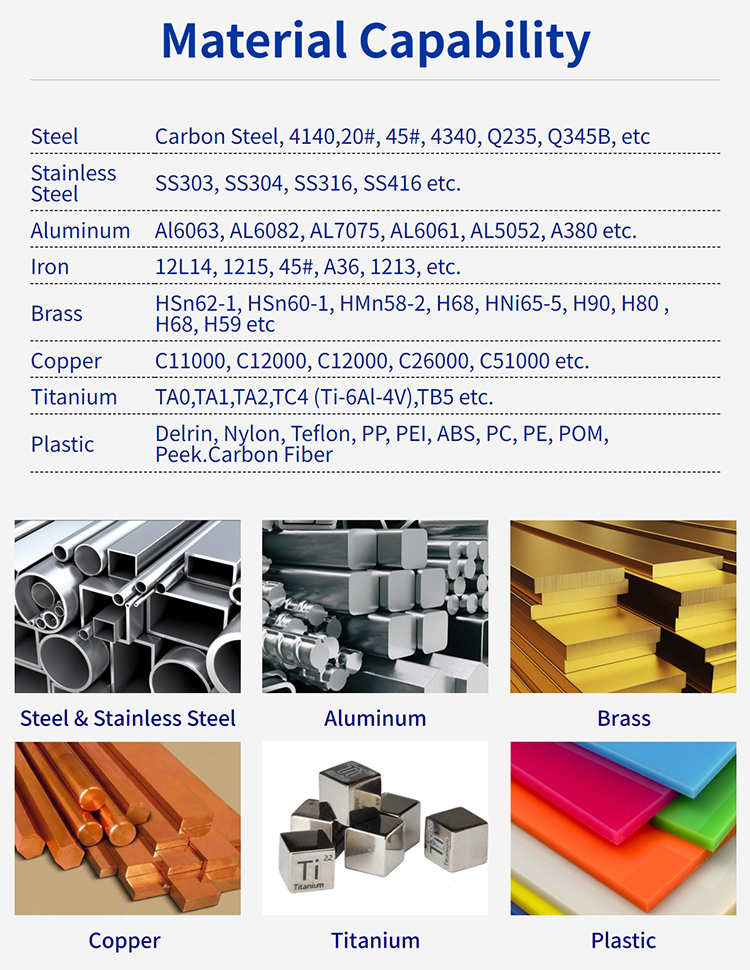

| Xaiv cov khoom siv | Hlau: steel, carbon steel, M3, 4340, 20 #, 45 #, 40Cr, 20Cr, thiab lwm yam | ||

| Aluminium: AL6061, AL6063, AL6082, AL7075, AL5052 thiab lwm yam. | |||

| Stainless hlau: 201SS, 301SS, 304SS, 316SS thiab lwm yam. | |||

| Copper: C37700, C28000, C11000, C36000 thiab lwm yam | |||

| Engineering plastics: PBI, PI, PAI, PTFE, PEEK, PPS, PPSU, PEI, PSU, PC, PETP, POM, PA, UHMW-PE | |||

| Kev kho deg: | Hlau qhov chaw | Stainless hlau qhov chaw | Aluminium qhov chaw |

| Galvanization | Polishing | Oxidized dawb | |

| Dub oxidation | Passivation | Sandblast anodization | |

| Nickel plating | Laser engraving | Tshuaj lom neeg zaj duab xis | |

| Chromeplate | Xuab zeb tawg | Txhuam txheej | |

| Kev kho cua sov | Polishing | ||

| Hmoov txheej | Chromeplate | ||

Peb qhov kev pabcuam:

1. 100% chaw tsim tshuaj paus

Peb lub Hoobkas nyob hauv Qingxi nroog, Dongguancity, Guangdong xeev, Suav teb nrog 100 tus neeg ua haujlwm uas muaj kev lees paub zoo tshaj plaws, kev ntseeg siab ntawm koj cov lus cog tseg. Peb muaj ntau xyoo kev tsim khoom thiab export kev.

2. Kev xaiv cov khoom zoo tshaj plaws.

Tag nrho peb cov khoom yog ua los ntawm cov ntaub ntawv zoo tshaj plaws los ntawm cov neeg muag khoom zoo tshaj plaws.

3. Kev pabcuam zoo

Peb yeej tsim txhua yam khoom los ntawm peb tus kheej. Nws yog cov kev pabcuam saum toj kawg nkaus los ntawm cov hlau rods pub, txheej, hlau kos duab, sib sau, xov, passivating, tshuaj xyuas, ntim, xa khoom, yog li qhov zoo yog 100% paub tseeb.

4. Kev tswj kom zoo

Txhua txhua daim ntawm cov khoom, txhua tus txheej txheem ntau lawm yog soj ntsuam thiab tswj ua ntej packing cov khoom rau hauv export thawv.

Peb xyuas kom meej tias txhua yam khoom xa tuaj yog qhov zoo.

5. Kev pab cuam tom qab muag

Tsis tas li ntawd, kev pab cuam tom qab muag yog tsim nyog rau kev nkag siab ntau ntxiv rau koj cov kev xav tau. Peb khaws kev txhawj xeeb ze

| Tshuab dhos | Milling | Tig |

| Cnc Machining Terms

| Cnc Milling Titanium

| Cnc tig ceev thiab pub

|

| Cnc Machining Terminology | Cnc Milling Cov Lus Qhia

| Cnc tig Software

|

| Cnc Machining Technology | Cnc Milling Tips Thiab Tricks

| Cnc tig Simulation

|

1. Lo lus nug: Qhov kev pabcuam tseem ceeb ntawm koj lub Hoobkas yog dab tsi?

Teb: Peb tsom rau OEM & ODM cnc tig qhov chaw rau ntau tshaj 10 xyoo! Peb yog cov kws tshaj lij hauv CNC machining qhov chaw.

2. Lo lus nug: Kuv tuaj yeem tau txais qhov kev txiav txim yam tsawg kawg nkaus thiab cov ntaub ntawv hais txog tus nqi?

Teb: Peb qhov kev txiav txim yam tsawg kawg nkaus yog nyob ntawm qhov tshwj xeeb ntawm koj qhov kev txiav txim. Koj tuaj yeem xa koj cov duab kos rau peb thaum qhia txog cov khoom siv, qhov ntev, yuav tsum tau ua siab ntev, thiab kho qhov chaw ntawm qhov chaw.

3. Lo lus nug: Kuv puas tuaj yeem tuaj xyuas koj lub Hoobkas thaum mus xyuas cov txheej txheem tsim khoom?

Teb: Koj tuaj yeem tuaj xyuas peb lub Hoobkas txhua lub sijhawm. Peb yuav tuaj tos koj ntawm tshav dav hlau lossis chaw nres tsheb ciav hlau. Nyob rau tib lub sijhawm, peb yuav niaj hnub tua peb cov yeeb yaj kiab ntau lawm rau koj qhov kev siv ntawm peb cov txheej txheem tsim khoom