1. Nā hanana kino o ka mīkini titanium

ʻOi aku ka kiʻekiʻe o ka ʻoki ʻana o ka hana ʻana o ka titanium alloy ma mua o ke kila me ka paʻakikī like. Eia nō naʻe, ʻoi aku ka paʻakikī o ke ʻano kino o ka hoʻoili ʻana i ka titanium alloy ma mua o ka hoʻoili ʻana i ke kila, kahi e hana ai ka hana ʻana o ka titanium alloy i nā pilikia nui.

He haʻahaʻa loa ka conductivity thermal o ka hapa nui o nā alloys titanium, ʻo 1/7 wale nō o ke kila a me 1/16 o ka alumini. No laila, ʻaʻole e hoʻoneʻe koke ʻia ka wela i hana ʻia i ka wā e ʻoki ai i nā alloys titanium i ka mea hana a lawe ʻia paha e nā chips. Eia nō naʻe, e hōʻiliʻili ʻia ma ka ʻāpana ʻokiʻoki, a hiki ke kiʻekiʻe ke kiʻekiʻe e like me 1,000 °C a ʻoi aʻe paha, kahi e ʻaʻahu ai ka ʻoki ʻoki o ka mea hana, ʻokiʻoki, a pohā wikiwiki. ʻO ka hoʻokumu ʻana i kahi lihi i kūkulu ʻia a me ka ʻike wikiwiki ʻana o kahi lihi kahiko e hoʻonui i ka wela ma ka ʻāpana ʻoki, e hoʻopōkole ana i ke ola o ka mea hana.mīkini hana titanium

ʻO nā wela kiʻekiʻe i hana ʻia i ka wā o ke kaʻina hana e hoʻopau ai i ka pono o ka ʻili o nā ʻāpana titanium alloy, ka hopena i ka emi ʻana o ka pololei geometric o nā ʻāpana a me ka hana paʻakikī e hōʻemi loa i ko lākou ikaika luhi.

He mea pono paha ka elasticity o nā alloys titanium no ka hana ʻāpana, akā i ka wā o ka ʻoki ʻana, ʻo ka deformation elastic o ka mea hana ke kumu nui o ka haʻalulu. ʻO ke kaomi ʻoki ʻana i ka mea hana "elastic" e neʻe aku mai ka mea paahana a paʻa, no laila ʻoi aku ka nui o ka paio ma waena o ka mea hana a me ka mea hana ma mua o ka hana ʻoki. ʻO ke kaʻina hana friction e hoʻoulu i ka wela, e hoʻonui ana i ka pilikia o ka conductivity thermal maikaʻi ʻole o nā alloys titanium.

ʻOi aku ka koʻikoʻi o kēia pilikia i ka hana ʻana i nā ʻāpana ʻāpana lahilahi a i ʻole ke ʻano apo. ʻAʻole maʻalahi ka mīkini ʻana i nā ʻāpana ʻāpana titanium me ka paia lahilahi i ka pololei o ke ana i manaʻo ʻia. Ke hoʻokuke aku ka mea hana i ka mea hana, ʻoi aku ka deformation kūloko o ka pā lahilahi ma mua o ka lauwili elastic; hiki mai ka deformation plastic, a hoʻonui nui ka ikaika a me ka paʻakikī o ka ʻoki ʻoki. ʻOi aku ka kiʻekiʻe o ka mīkini ʻoki ʻana i ka māmā i hoʻoholo mua ʻia, e hopena i ka ʻaʻahu ʻana i nā mea hana ʻoi.

ʻO "Hot" ka "culprit" i mea paʻakikī i ka hana ʻana i nā alloys titanium!

2. ʻIke ʻenehana no ka hana ʻana i ka titanium CNC

Ma muli o ka hoʻomaopopo ʻana i ke ʻano hana o ka titanium alloys a me ka hoʻohui ʻana i ka ʻike, ʻo ke kaʻina hana mua no ka hana ʻana i nā alloys titanium penei:

(1) Hoʻohana ʻia nā mea hoʻokomo me ka geometry maikaʻi e hōʻemi i ka ikaika ʻoki o ka mea hana, ʻoki i ka wela, a me ka deformation.

(2) E mālama i ka hānai mau e pale i ka paʻakikī o ka mea hana. Pono ka mea hana i loko o ka moku hānai i ka wā o ka ʻoki ʻana, a ʻo ka nui o ka ʻoki radial he 30% o ka radius i ka wā wili.

(3) Hoʻohana ʻia ka wai ʻoki kiʻekiʻe a me ke kahe nui e hōʻoia i ka paʻa ʻana o ka wela o ke kaʻina hana mīkini a pale i ka degeneration ʻili o ka mea hana a me ka pōʻino o ka mea hana ma muli o ka wela nui.

(4) E hookiekie i ka lihi o ka maka; ʻO nā mea hana blunt ke kumu o ke kūkulu ʻana a me ka ʻaʻahu ʻana o ka wela, e alakaʻi koke ana i ka hemahema o ka mea hana.

(5) ʻO ka mīkini ʻana i ke kūlana palupalu o ka titanium alloy e like me ka mea hiki ke lilo i mea paʻakikī i ka mīkini ma hope o ka paʻakikī, a hoʻonui ka hoʻomaʻamaʻa wela i ka ikaika o ka mea a me ke komo ʻana o ka mea hoʻokomo.

(6) E hoʻohana i ka radius ihu nui a i ʻole chamfer e ʻoki i ka mea hiki i ka ʻoki ʻoki. Hoʻemi kēia i ka ikaika ʻoki a me ka wela i kēlā me kēia wahi a pale i ka haki kūloko. I ka wili ʻana i nā alloys titanium, ma waena o nā ʻāpana ʻokiʻoki, ʻo ka wikiwiki o ka ʻoki ʻana i ka mana nui loa i ke ola mea hana vc, a ukali ʻia e ka hoʻopili radial (hohonu milling) ae.

3. E hoʻomaka me ka pahi e hoʻoponopono i ka pilikia hana titanium

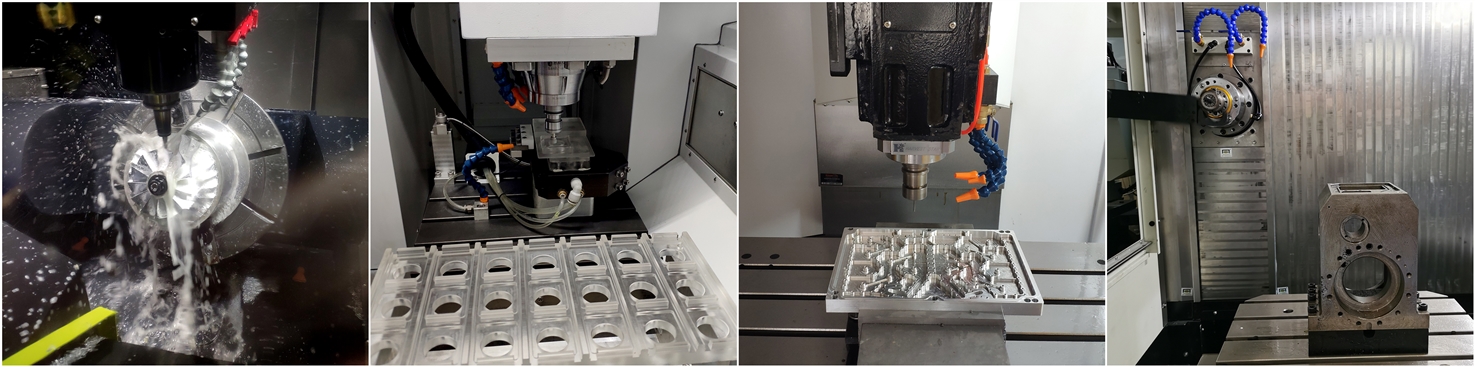

ʻO ka ʻaʻahu o ka insert groove i ka wā o ka hana ʻana i nā alloys titanium ʻo ia ka lole kūloko o ke kua a me mua i ke kuhikuhi o ka hohonu o ka ʻokiʻoki, i hana pinepine ʻia e ka papa paʻakikī i waiho ʻia e ka hana mua. ʻO ka hopena kemika a me ka hoʻopuehu ʻana o ka mea hana a me ka mea hana ma kahi mahana hana ʻoi aku ma mua o 800 °C he kumu hoʻi ia no ka hoʻokumu ʻana i ke kapa komo. No ka mea, i ka wā o ka mīkini hana, hōʻuluʻulu ʻia nā molekala titanium o ka mea hana i mua o ka maka a "welded" i ka ʻaoʻao o ka lau ma lalo o ke kiʻekiʻe kiʻekiʻe a me ke kiʻekiʻe kiʻekiʻe, e hana ana i kahi kihi i kūkulu ʻia. Ke ʻili ka ʻaoʻao i kūkulu ʻia i ka ʻoki ʻoki, lawe ia i ka uhi carbide o ka mea hoʻokomo, no laila pono ka mīkini titanium i nā mea hoʻokomo kūikawā a me nā geometries.cCustomprecision machining

4. ʻO ke ʻano mea hana kūpono no ka mīkini titanium

ʻO ka manaʻo o ka hana ʻana o ka titanium alloy he wela, a ʻo ka nui o ka wai ʻokiʻoki kiʻekiʻe e pono e hoʻoheheʻe ʻia ma ka ʻoki ʻoki a me ka pololei e wehe koke i ka wela. Aia nā hoʻonohonoho kūʻokoʻa o nā mea ʻoki milling kūikawā no ka machining titanium.

Hiki iā Anebon Metal Products Limited ke hāʻawi i ka CNC Machining, Die Casting, Sheet Metal Fabrication service, e ʻoluʻolu e kelepona mai iā mākou.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Ka manawa hoʻouna: Jan-18-2022