Hoʻohana nui ʻia ka machining precision e ʻike i ka fineness o nā huahana, e like meʻāpana huli ʻo CNCaʻāpana wili CNC, a he huaʻōlelo i hoʻohana ʻia no ka loiloi ʻana i nā ʻāpana geometric o nā ʻili mīkini. Ana ʻia ka pololei o ka mīkini e ka māka hoʻomanawanui. ʻOi aku ka liʻiliʻi o ka helu helu, ʻoi aku ka kiʻekiʻe o ka pololei.

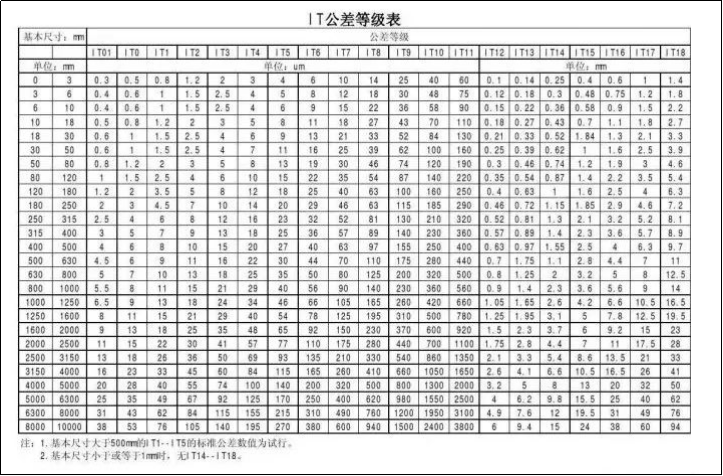

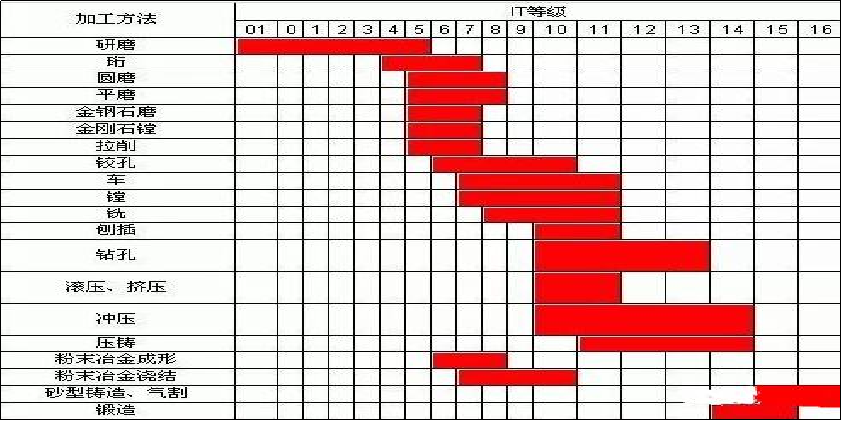

Aia he 20 mau papa hoʻomanawanui mai IT01, IT0, IT1, IT2, IT3 a hiki i IT18, nona ka IT01 e hōʻike ana i ka pololei o ka hoʻoponopono kiʻekiʻe loa o ka ʻāpana, IT18 ke hōʻike nei i ka haʻahaʻa haʻahaʻa haʻahaʻa o ka ʻāpana, nā mīkini mining maʻamau no IT7, a me ka mahiʻai maʻamau. No IT8 ka mīkini. E like me nā hana like ʻole o nā ʻāpana huahana, ʻokoʻa ka pololei o ka mīkini e hoʻokō ʻia a ʻokoʻa hoʻi ke ʻano hana a me ke kaʻina hana i koho ʻia. Hōʻike kēia pepa i ka pololei o ka mīkini ʻana o ka huli ʻana, ka wili ʻana, ka hoʻolālā ʻana, ka wili ʻana, ka ʻeli ʻana, ka ʻoluʻolu, a me nā ʻano mīkini maʻamau ʻē aʻe.

CNC Huli

ʻO ke kaʻina ʻokiʻoki kahi e hoʻohuli ai ka mea hana a neʻe ka mea hoʻohuli i kahi laina pololei a i ʻole ka pihi ma ka mokulele. Hoʻohana ʻia ka huli ʻana ma luna o kahi lathe, i hoʻohana ʻia no ka hoʻoponopono ʻana i ka ʻili o loko a me waho o ka cylindrical surfaces, nā alo hope, nā ʻili conical, nā papa hana, a me nā kaula o nā mea hana.

ʻO ka pololei o ka huli ʻana he IT8-IT7, a ʻo ka roughness ʻili he 1.6-0.8 μm.

1) E hoʻohana ka hoʻohuli ʻino i ka hohonu o ka ʻoki ʻana a me ka helu hānai nui e hoʻomaikaʻi ai i ka pono o ka huli ʻana me ka ʻole e hōʻemi i ka wikiwiki ʻoki. Eia nō naʻe, hiki i ka pololei o ka mīkini ke hiki i IT11 wale nō, a ʻo ka roughness ʻili he R α 20—10 μm.

2) E ʻae ʻia ka wikiwiki kiʻekiʻe, ka haʻahaʻa haʻahaʻa, a me ka hohonu o ka ʻoki ʻana i ka hiki no ka huli semi-finish a me ka huli hoʻopau. Hiki i ka pololei machining ke hiki i IT10-IT7, a ʻo ka ʻili o ka ʻili he R α 10—0.16 μm.

3) Kiekie-wikiwiki huli ana o nonferrous mea metala me ka daimana huli mea hana finely polie ma luna o ka kiʻekiʻe-precision lathe hiki ke hana i ka machining pololei hiki IT7-IT5, a me ka roughness ili R α 0.04—0.01 μm. ʻO kēia ʻano huli ʻana i kapa ʻia ʻo "mirror turning."

CNC Milling

ʻO ka Milling e pili ana i ka hoʻololi ʻana i nā mea hana multi-edge e ʻoki i nā mea hana, kahi ʻano hana ʻoi loa. He kūpono ia no ka hana ʻana i nā mokulele, grooves, nā ʻano like ʻole (e like me ka spline, gear, a me ke kaula), a me nā ʻāpana kū hoʻokahi o ka make. Hiki ke hoʻokaʻawale ʻia i ka milling i mua a me ka wili hoʻohuli e like me ka ʻaoʻao like a i ʻole ka ʻaoʻao o ka wikiwiki o ka neʻe nui a me ke kuhikuhi ʻana i ka mea hana i ka wā wili.

ʻO ka pololei machining o ka milling hiki ke hōʻea i IT8 ~ IT7, a ʻo ka roughness ʻili he 6.3 ~ 1.6 μm.

1) ʻO ka pololei o ka mīkini ʻana i ka wā wili liʻiliʻi ʻo IT11 ~ IT13, a ʻo ka roughness ʻili he 5 ~ 20 μm.

2) Mīkini pololei IT8 ~ IT11 a me ka roughness ili 2.5 ~ 10 ma semi-precision wili μ m.

3) ʻO ka pololei o ka mīkini i ka wā wili pololei ʻo IT16 ~ IT8, a ʻo ka ʻili o ka ʻili he 0.63 ~ 5 μm.

Hoʻolālā

ʻO ka hoʻolālā kahi ʻano ʻokiʻoki e hoʻohana ana i kahi planer e hana i ka neʻe ʻana o ka laina laina pili ma luna o ka mea hana, i hoʻohana nui ʻia no ka hana contour o nā ʻāpana.

Hiki i ka machining pololei o ka hoʻolālā ke hiki maʻamau i IT9 ~ IT7, a ʻo ka roughness ʻili he Ra6.3 ~ 1.6 μm.

1) Hiki ke hōʻea i ka pololei ʻo Roughing machining i IT12 ~ IT11, a ʻo ka roughness ʻili he 25 ~ 12.5 μm.

2) Hiki i ka pololei semi-finishing machining ke hiki i IT10 ~ IT9, a ʻo ka roughness ʻili he 6.2 ~ 3.2 μm.

3) Hiki i ka pololei o ka hoʻolālā hoʻopau ke hiki i IT8 ~ IT7, a ʻo ka roughness ʻili he 3.2 ~ 1.6 μm.

wili

ʻO ka grinding e pili ana i ke ʻano hana o ka hoʻohana ʻana i nā mea hana abrasive a me nā mea hana abrasive e ʻoki i nā mea keu ma luna o ka mea hana, nona ka hoʻopau ʻana a hoʻohana nui ʻia i ka ʻoihana hana mīkini.

Hoʻohana pinepine ʻia ka wili no ka semi-finishing a me ka hoʻopau ʻana, me ka pololei o IT8 ~ IT5 a i ʻole ke kiʻekiʻe aʻe, a ʻo ka roughness o ka ʻili he 1.25 ~ 0.16 μm.

1) ʻO 0.16 ~ 0.04 μm ka roughness ili o ka wili pololei.

2) ʻO 0.04-0.01 μm ka nui o ka wili ʻana i ka ʻili.

3) Hiki i ka roughness ili o ka wili aniani ke hiki i ka 0.01 μM ma lalo.

Ka wili ʻana

ʻO ka wili ʻana he ʻano koʻikoʻi o ka hana ʻana i nā lua. Hoʻohana pinepine ʻia ka wili ʻana ma ka wili a me ka lathes a i ʻole nā mīkini wili a wili paha.

He haʻahaʻa loa ka pololei o ka hana ʻana o ka wili ʻana, ma ke ʻano he IT10, a ʻo ka roughness ʻili he gtypically12.5 ~ 6.3 μm. Ma hope o ka wili ʻana, hoʻohana pinepine ʻia ka reaming a me ka reaming no ka semi-finishing.

Luuluu

ʻO ka boring kahi kaʻina ʻoki anawaena o loko e hoʻohana ana i kahi mea hana e hoʻonui ai i ka lua a i ʻole nā contur poepoe ʻē aʻe. ʻO ka laulā o kāna noi mai ka mīkini semi-rough a hiki i ka hoʻopau ʻana. ʻO ka mea hana maʻamau he mea hoʻoheheʻe hoʻokahi ʻaoʻao (i kapa ʻia ʻo kahi pahu ʻawaʻawa).

1) Hiki ke hōʻea i ka IT9 ~ IT7 ka pololei o nā mea kila, a ʻo ka roughness ʻili he 2.5 ~ 0.16 μm.

2) Hiki i ka machining pololei o ka precision boring hiki ke hōʻea i IT7 ~ IT6, a ʻo ka roughness ʻili he 0.63 ~ 0.08 μm.

Ka manawa hoʻouna: Nov-22-2022