ʻO ka ʻeli ʻana, ka huki ʻana, ka reaming, ka ʻoluʻolu... He aha kā lākou manaʻo? E aʻo mai kēia iā ʻoe e hoʻomaopopo maʻalahi i ka ʻokoʻa ma waena o kēia mau manaʻo.

Ke hoʻohālikelike ʻia me ka hoʻoili ʻana o ka ʻili o waho, ʻoi aku ka maikaʻi o nā kūlana o ka hoʻoili ʻana o ka lua, a ʻoi aku ka paʻakikī o ka hana ʻana i nā lua ma mua o ka hana ʻana i nā pōʻai waho. ʻO kēia no ka mea:

1) ʻO ka nui o ka mea hana i hoʻohana ʻia no ka hole machining e kaupalena ʻia e ka nui o ka lua e hana ʻia ai ka mīkini, a ʻilihune ka rigidity, kahi e kūlou ai i ka deformation a me ka vibration;

2) I ka hana ʻana i ka lua me kamea paʻa-nui, Hoʻoholo pinepine ʻia ka nui o ka lua e ka nui kūpono o ka mea hana, a ʻo ka hewa o ka hana ʻana a me ka ʻaʻahu ʻana o ka mea hana e hoʻopili pololei i ka pololei o ka mīkini o ka lua;

3) I ka hana ʻana i nā lua, ʻo ka ʻoki ʻoki i loko o ka mea hana, ʻaʻole maʻalahi ka wehe ʻana o ka chip a me nā kūlana wela, a ʻaʻole maʻalahi ka mālama ʻana i ka pololei o ka mīkini a me ka maikaʻi o ka ʻili.

1. ʻO ka wili ʻana a me ka reaming

1. Ka wili ana

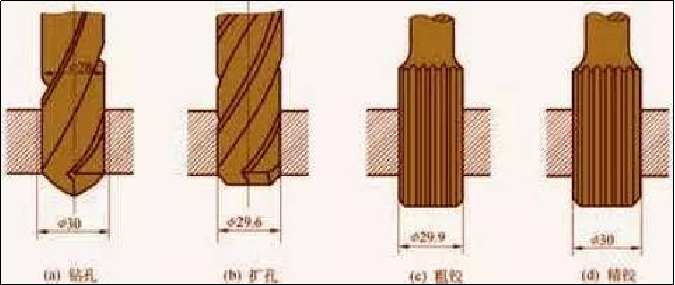

ʻO ka wili ʻana ke kaʻina hana mua o ka hana ʻana i nā lua i nā mea paʻa, a ʻo ke anawaena o nā puka ma lalo o 80mm. ʻElua ala o ka wili ʻana: ʻo ka hoʻololi ʻana o ka drill; ʻo ka hoʻololi ʻana o ka mea hana. ʻOkoʻa nā hewa i hana ʻia e nā ʻano hana ʻelua ma luna. Ma ke ʻano o ka wili ʻana me ka wili ʻana o ka drill bit, i ka wā e hoʻokaʻawale ʻia ai ka drill bit ma muli o ka asymmetry o ka ʻoki ʻoki a me ka lawa ʻole o ka rigidity o ka drill bit, e skewed a hoʻololi paha ka laina waena o ka lua mīkini. ʻAʻole pololei, akā ʻaʻole i loli ke anawaena o ka puka; akā, ma ke ʻano o ka hoʻowili ʻana i ka mea hana, ʻo ka ʻae ʻana o ka puʻupuʻu e hoʻololi i ke anawaena o ka puka, ʻoiai ʻo ka laina waena o ka puka e pololei.

ʻO nā mea hana wili maʻamau i hoʻohana ʻia: wili wili, wili waena, hohonu hole drill, a pēlā aku.

Ma muli o nā palena o ke kūkulu ʻana, ua haʻahaʻa ʻia ka rigidity wili a me ka torsional rigidity o ka drill bit, i hui pū ʻia me ke kikowaena maikaʻi ʻole, haʻahaʻa ka pololei o ka wili ʻana, ma ke ʻano maʻamau a hiki i IT13 ~ IT11; ka roughness ili nui no hoi, a me Ra mea maʻamau 50 ~ 12.5μm; akā, ʻoi aku ka nui o ka hoʻoneʻe metala o ka wili ʻana, a ʻoi aku ka maikaʻi o ka ʻoki ʻana. Hoʻohana nui ʻia ka wili ʻana no ka hana ʻana i nā lua me nā koi haʻahaʻa haʻahaʻa, e like me nā lua bolt, nā lua lalo i hoʻopaʻa ʻia, nā lua aila, a me nā mea ʻē aʻe. machining hope. 2. Reaming

ʻO Reaming ka hana hou aʻe o nā lua i wili ʻia, hoʻolei ʻia a hoʻopaʻa ʻia paha me kahi drill reaming e hoʻonui i ka puka a hoʻomaikaʻi i ka maikaʻi o ka hana ʻana o nā lua.Mīkini hope loao na lua koi emi. Ua like ka reaming drill me ka twist drill, akā ʻoi aku ka nui o nā niho a ʻaʻohe ʻaoʻao chisel.

Ke hoʻohālikelike ʻia me ka hoʻoheheʻe ʻana, loaʻa i ka reaming nā hiʻohiʻona penei: (1) nui ka helu o nā niho drill reaming (3 ~ 8 niho), maikaʻi ke alakaʻi, a paʻa ka ʻoki ʻana; (2) ʻaʻohe kihi o ka reaming drill, a maikaʻi nā kūlana ʻoki; (3) He liʻiliʻi ka haʻawina mīkini, hiki ke hoʻopaʻu ʻia ka ʻeke chip, hiki ke hoʻonui ʻia ke kumu drill, a ʻoi aku ka maikaʻi o ka ikaika a me ka paʻakikī o ke kino ʻoki. ʻO ka pololei o ka hole reaming ka mea maʻamau ʻo IT11 ~ IT10, a ʻo ka roughness ʻili Ra he 12.5 ~ 6.3μm. Hoʻohana pinepine ʻia ʻo Reaming i nā lua mīkini me ke anawaena liʻiliʻi ma mua o . Ke wili ʻana i kahi lua me kahi anawaena nui aʻe (D ≥ 30mm), hoʻohana pinepine ʻia kahi puʻu liʻiliʻi (ʻo 0.5 ~ 0.7 mau manawa ke anawaena o ka lua) e hoʻohana mua i ka lua, a laila ka nui like o ka reaming drill. hoʻohana ʻia e ream i ka lua, hiki ke hoʻomaikaʻi i ka maikaʻi o ka lua. ʻO ka maikaʻi o ka hana ʻana a me ka maikaʻi o ka hana.

Ma waho aʻe o ka hoʻoponopono ʻana i nā lua cylindrical, hiki i ka reaming ke hoʻohana i nā ʻano hoʻoheheʻe reaming kūikawā (ʻike ʻia ʻo countersinks) e hana i nā lua noho countersunk a me ka countersinking. He kolamu alakaʻi ka ʻaoʻao mua o ka countersink, i alakaʻi ʻia e ka lua mīkini.

2. Reaming

ʻO Reaming kekahi o nā ala hoʻopau o nā lua, i hoʻohana nui ʻia i ka hana ʻana. No nā puka liʻiliʻi, ʻoi aku ka maikaʻi o ka reaming ma mua o ka wili ʻana i loko a me ka ʻoluʻolu maikaʻi.

1. Reamers

Hoʻokaʻawale ʻia nā reamers i ʻelua ʻano: reamers lima a me reamers mīkini. ʻO ka lima o ka reamer lima he lima pololei, ʻoi aku ka lōʻihi o ka hana, a ʻoi aku ka maikaʻi o ka hana alakaʻi. ʻElua mau hale o ka ʻano hoʻohui a me ke anawaena o waho hiki ke hoʻololi ʻia. ʻElua ʻano o ka mīkini reamers, ʻano shank a me ke ʻano lima. ʻAʻole hiki i nā Reamers ke hana wale i nā puka pōʻai, akā hiki ke hana ʻia nā puka lipi me nā reamers lipi. 2. ʻO ke kaʻina hana Reaming a me kāna noi

He hopena nui ka haʻawina reaming i ka maikaʻi o ka reaming. Inā ʻoi aku ka nui o ka haʻawina, ʻoi aku ka nui o ka ukana o ka reamer, e ʻoki koke ʻia ka ʻoki ʻoki, ʻaʻole maʻalahi ka loaʻa ʻana o ka ʻili mīkini ʻoluʻolu, a ʻaʻole maʻalahi ka hoʻomanawanui ʻana o ka dimensional; inā he liʻiliʻi loa ka haʻawina, inā ʻaʻole hiki ke wehe ʻia nā hōʻailona mea hana i waiho ʻia e ka hana mua, ʻaʻole ia e hoʻomaikaʻi i ka maikaʻi o ka hoʻoili ʻana i ka lua. ʻO ka maʻamau, ʻo 0.35 ~ 0.15mm ka ʻāpana hinge, a ʻo ka hinge maikaʻi ʻo 01.5 ~ 0.05mm.

No ka pale ʻana i ke kūkulu ʻia ʻana o ka lihi i kūkulu ʻia, hana maʻamau ka reaming ma nā wikiwiki ʻoki haʻahaʻa (v <8m/min no nā reamers kila kiʻekiʻe no ke kila a me ka hao). ʻO ka waiwai o ka hānai e pili ana i ka aperture e hana ʻia. ʻO ka nui o ka puka, ʻoi aku ka nui o ka waiwai o ka hānai. I ka wā e hana ai ka reamer kila kiʻekiʻe i ke kila a me ka hao, ʻo ka meaʻai maʻamau ka 0.3 ~ 1mm/r.

I ka wā e hana hou ai i nā lua, pono e hoʻoluʻu, lubricated a hoʻomaʻemaʻe ʻia me ka wai ʻoki kūpono e pale ai i ka lihi i kūkulu ʻia a wehe i nā ʻāpana i ka manawa. Ke hoʻohālikelike ʻia me ka wili ʻana a me ka hōʻoluʻolu, ʻoi aku ka nui o ka reaming a maʻalahi e hōʻoia i ka pololei o ka lua; akā naʻe, ʻaʻole hiki i ka reaming ke hoʻoponopono i ka hewa kūlana o ka axis hole, a pono e hōʻoia ʻia ka pololei o ke kūlana o ka lua e ka hana mua. ʻAʻole pono ka hana ʻana i nā puka heʻe a me nā puka makapō.

ʻO ka pololei o ka nui o ka lua reaming ma ke ʻano he IT9 ~ IT7, a ʻo ka ʻili o ka ʻili Ra he 3.2 ~ 0.8 μm. No nā puka liʻiliʻi me nā koi kikoʻī kiʻekiʻe (e like me IT7-level precision hole), ʻo ke kaʻina hana wili-hoʻonui-reaming he papa hana maʻamau i hoʻohana mau ʻia i ka hana.

3. Luuluu

ʻO Boring kahi ʻano hana e hoʻohana ana i nā mea hana ʻoki e hoʻonui i nā lua i hana mua ʻia. Hiki ke hana ʻia ka hana ʻoluʻolu ma luna o ka mīkini hoʻoheheʻe a i ʻole ka lathe.

1. ʻO ke ʻano hōʻoluʻolu

ʻEkolu mau ʻano mīkini ʻokoʻa no ka ʻoluʻolu.

(1) Kawili ka mea hana a hanai ka mea hana. ʻO ka hapa nui o ka hoʻoluhi ʻana ma ka lathe no kēia ʻano hana ʻoluʻolu. ʻO nā hiʻohiʻona o ke kaʻina hana: ʻo ka laina axis o ka lua ma hope o ka mīkini e kūlike me ka rotation axis o ka mea hana, ʻo ka pōʻai o ka puka e hilinaʻi nui ʻia i ka pololei o ka rotation o ka mīkini mea hana spindle, a ʻo ka hewa geometry axial o ka lua e hilinaʻi nui ʻia. ma ke kuhikuhi hanai o ka mea paahana e pili ana i ka axis rotation o ka mea hana. pololei kūlana. He kūpono kēia ʻano hana ʻino no ka hana ʻana i nā lua i loaʻa nā koi coaxiality me ka ʻili o waho.

(2) Hoʻololi ka mea hana a hana ka mea hana i kahi neʻe hānai. ʻO ka milo o ka mīkini hoʻoluliluli e hoʻohuli i ka mea hana ʻoluʻolu e hoʻohuli, a na ka papa hana e hoʻokele i ka mea hana e hana i kahi neʻe hānai.

(3) Ke hoʻololi ka mea hana a hana i kahi neʻe hānai, hoʻohana ʻia ke ʻano hoʻoluhi no ka hoʻoluhi. Hoʻololi ʻia ka lōʻihi o ka pahu hoʻoluhi, a ua hoʻololi pū ʻia ka hoʻololi ʻana o ka pahu hoʻoluhi. He liʻiliʻi ke anawaena o ka puka, e hana ana i puka liʻiliʻi. Eia kekahi, ke piʻi aʻe ka lōʻihi o ka pahu hoʻoheheʻe, a me ka hoʻololi ʻana o ka deformation o ke kumu nui ma muli o kona kaumaha ponoʻī e hoʻonui ʻia, a e kūlou ʻia ke koʻi o ka lua mīkini. He kūpono wale kēia ʻano hana hōʻoluʻolu no nā puka pōkole.

2. Luuluu daimana

Ke hoʻohālikelike ʻia me ka hōʻoluʻolu maʻamau, hōʻike ʻia ka hōʻeha daimana e kahi ʻoki liʻiliʻi o ke kua, hānai liʻiliʻi, a me ka wikiwiki ʻoki kiʻekiʻe. Hiki iā ia ke kiʻi i ka pololei machining kiʻekiʻe (IT7 ~ IT6) a me ka maʻemaʻe loa (Ra ʻo 0.4 ~ 0.05 μm). Ua hana mua ʻia ka hoʻoheheʻe daimana me nā mea hana hoʻoheheʻe daimana, a i kēia manawa ua hana ʻia me ka carbide cemented, CBN a me nā mea hana daimana synthetic. Hoʻohana nui ʻia no ka hana ʻana i nā mea hana metala non-ferrous, akā no ka hana ʻana i ka hao a me ke kila.

ʻO ka nui o ka ʻokiʻoki maʻamau no ka hoʻoheheʻe daimana: ʻo ka nui o ka ʻoki hope ʻana o ka pre-boring he 0.2 ~ 0.6mm, a ʻo ka hōʻeha hope he 0.1mm; ʻO ka helu hānai he 0.01 ~ 0.14mm / r; ʻO ka wikiwiki o kaʻokiʻana he 100 ~ 250m / min i ka hanaʻana i ka hao, a me ka mīkini 150 ~ 300m / min no ke kila, 300 ~ 2000m / min no ka hanaʻana i nā metala non-ferrous.

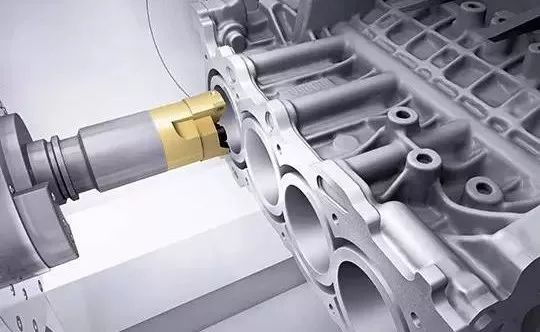

I mea e hōʻoia ai i hiki ke hoʻokō i ka pololei machining kiʻekiʻe a me ka maikaʻi o ka ili, ka mīkini mīkini (Diamond boring machine) i hoʻohana ʻia he kiʻekiʻe geometric pololei a me ka rigidity. Kākoʻo pinepine ʻia ke kumu nui o ka mīkini e nā bearings angular contact ball bearing a i ʻole hydrostatic sliding bearings, a me nā ʻāpana wili kiʻekiʻe. Pono e kaulike pono; Eia kekahi, pono e paʻa loa ka neʻe ʻana o ka mīkini hana hānai e hōʻoia i ka hiki i ka papa hana ke hana i ka neʻe hānai paʻa a haʻahaʻa.

He maikaʻi ka hana ʻana o ka Diamond boring a me ka hana kiʻekiʻe o ka hana ʻana, a hoʻohana nui ʻia i ka hoʻoponopono hope ʻana o nā puka kikoʻī i ka hana nui, e like me nā lua cylinder engine, nā piston pin, a me nā puka spindle ma nā pahu spindle machine tool. Eia nō naʻe, pono e hoʻomaopopo ʻia i ka wā e hoʻohana ai i ka diamond boring e hana i nā huahana ferrous metala, hiki ke hoʻohana wale ʻia nā mea hana ʻino i hana ʻia me ka carbide cemented a me CBN, a ʻaʻole hiki ke hoʻohana ʻia nā mea hana ʻawaʻawa i hana ʻia me ke daimana, no ka mea, he nui ka pilina o nā kalapona kalapona i ke daimana. me nā mea hui hao. , haʻahaʻa ke ola mea hana.

3. Mea hana luuluu

Hiki ke hoʻokaʻawale ʻia nā mea hana ʻoluʻolu i hoʻokahi ʻaoʻao hoʻoluʻu mea hana a me ʻelua ʻaoʻao hoʻoluʻu mea hana.

4. ʻO nā hiʻohiʻona ʻenehana a me ka hoʻohana ʻana o ka ʻoluʻolu

Ke hoʻohālikelike ʻia me ke kaʻina hana drilling-expanding-reaming, ʻaʻole i kaupalena ʻia ke anawaena o ka lua e ka nui o ka hāmeʻa, a he ikaika ka hoʻoponopono hewa ʻana i ka ʻeha. Mālama nā ʻili ʻoluʻolu a me ka hoʻonohonoho ʻana i ka pololei kūlana kiʻekiʻe.

Ke hoʻohālikelike ʻia me ka pōʻai o waho o ka lua ʻeha, ma muli o ka rigidity maikaʻi ʻole a me ka deformation nui o ka ʻōnaehana paʻa paʻa, ʻaʻole maikaʻi ka dissipation wela a me nā kūlana hoʻohemo chip, a ʻoi aku ka nui o ka deformation thermal o ka workpiece a me ka mea paahana. ʻAʻole kiʻekiʻe ke kiʻekiʻe o ka maikaʻi o ka mīkini a me ka hana ʻana o ka lua hoʻoluhi e like me ka pōʻai waho o ke kaʻa. .

Ma muli o ka loiloi ma luna, hiki ke ʻike ʻia he ʻano hana ākea ka boring, a hiki ke hana i nā lua o nā ʻano nui a me nā pae pololei like ʻole. No nā puka a me nā ʻōnaehana puka me nā anawaena nui a me nā koi kikoʻī kiʻekiʻe a me ke kūlana kūlana, ʻo ka hoʻoluhi wale nō ka hana. ʻano hana. ʻO ka pololei machining o ka ʻoluʻolu ʻo IT9 ~ IT7. Hiki ke hana ʻia ka hoʻoheheʻe ʻana ma luna o nā mea mīkini e like me nā mīkini hoʻoheheʻe, nā mīkini wili, a me nā mīkini wili. Loaʻa iā ia nā pono o ka maʻalahi a hoʻohana nui ʻia i ka hana. I ka hana nui, i mea e hoʻomaikaʻi ai i ka maikaʻi o ka hōʻoluʻolu, hoʻohana pinepine ʻia ka boring make.

4. honing puka

1. Honing principle a honing poo

ʻO ka Honing ke ʻano o ka hoʻopau ʻana i ka lua me ke poʻo honing me kahi lāʻau wili (whitstone). I ka wā honing, hoʻopaʻa ʻia ka mea hana, a hoʻokele ʻia ke poʻo honing e ka spindle o ka mīkini e hoʻohuli a hana i kahi neʻe linear reciprocating. I ke kaʻina hana honing, hana ka pahu wili ma luna o ka ʻili o ka mea hana me kahi kaomi, a ʻoki i kahi ʻāpana lahilahi loa o nā mea mai ka ʻili o ka mea hana, a ʻo ka trajectory ʻoki ʻia he mesh kea. I mea e hana hou ʻole ai ka neʻe ʻana o nā ʻōpala abrasive o ka pā one, ʻo nā kipi i kēlā me kēia minuke o ka neʻe ʻana o ke poʻo honing a me ka helu o nā paʻi pānaʻi i kēlā me kēia minuke o ke poʻo honing he mau helu nui o kekahi.

Ua pili ka huina hui o ka track honing i ka wikiwiki reciprocating a me ka wikiwiki peripheral o ke poʻo honing. ʻO ka nui o ke kihi e pili ana i ka maikaʻi o ka hana a me ka maikaʻi o ka honing. ʻO ka mea maʻamau, ua lawe ʻia ʻo ia ma ke ʻano he ° no ka honing ʻino a no ka honing maikaʻi. I mea e maʻalahi ai ka hoʻokuʻu ʻia ʻana o nā ʻāpana abrasive a me nā chips, e hoʻemi i ka mahana ʻoki a hoʻomaikaʻi i ka maikaʻi o ka hana ʻana, pono e hoʻohana ʻia ka wai ʻoki i ka wā honing.

I mea e hana like ai ka paia o ka puka, pono ka hahau o ka pa one ma mua o ka nui ma na welau elua o ka lua. I mea e hōʻoiaʻiʻo ai i ka hāʻawi honing like ʻole a hōʻemi i ka mana o ka mīkini mea hana spindle rotation hewa ma ka mīkini pololei, ʻo ka hapa nui o nā poʻo honing a me nā spindles mea mīkini e hoʻopili ʻia e ka lana.

ʻO ka hoʻonui radial a me ka hoʻoponopono ʻana o ka honing head grinding bar he ʻano hana like ʻole e like me ka manual, pneumatic a me ka hydraulic.

2. Nā hiʻohiʻona kaʻina hana a me ka laulā noi o ka honing

1) Hiki i ka Honing ke loaʻa ka pololei kiʻekiʻe a me ka pololei o ke ʻano. ʻO ka pololei o ka mīkini ʻo IT7 ~ IT6, a hiki ke hoʻomalu ʻia ka pōʻai a me ka cylindricity hewa o nā lua i loko o ka laulā o ka , akā ʻaʻole hiki i ka honing ke hoʻomaikaʻi i ke kūlana pololei o nā lua machined.

2) Hiki i ka Honing ke loaʻa i ka maikaʻi o ka ʻili kiʻekiʻe, ʻo ka roughness ʻili Ra he 0.2 ~ 0.25μm, a ʻo ka hohonu o ka papa defect metamorphic o ka metala ʻili he liʻiliʻi loa 2.5 ~ 25μm.

3) Ke hoʻohālikelike ʻia me ka wikiwiki wili, ʻoiai ʻaʻole kiʻekiʻe ka wikiwiki peripheral o ke poʻo honing (vc = 16 ~ 60m / min), akā ma muli o ka nui o ka pilina ma waena o ke one a me ka mea hana, ʻoi aku ka kiʻekiʻe o ka wikiwiki reciprocating. (va=8~20m/min). min), no laila, ʻoi aku ka maikaʻi o ka honing.

Hoʻohana nui ʻia ʻo Honing i ka mīkini ʻana i nā lua cylinder engine a me nā lua precision i nā ʻano hydraulic like ʻole i ka hana nui. Eia naʻe, ʻaʻole kūpono ka honing no ka hana ʻana i nā lua ma nā mea hana metala non-ferrous me ka plasticity nui, ʻaʻole hiki ke hana i nā puka me nā kī kī, nā lua spline, etc.

5. Huki puka

1. ʻO ka hoʻopaʻa ʻana a me ka hoʻopaʻa ʻana

ʻO ka hole broaching kahi hana hoʻopau maikaʻi loa i hana ʻia ma ka mīkini broaching me kahi broach kūikawā. ʻElua ʻano o ka moena broaching: moe broaching horizontal a me ka moena broaching vertical, me ka moe broaching horizontal ka mea maʻamau.

Ke broaching, hana wale ka broach i ka holo laina haʻahaʻa (ka neʻe nui). ʻO ka nui o nā niho o ka broach e hana ana i ka manawa like ʻaʻole pono e emi iho ma mua o 3, i ʻole e holo mālie ka broach, a maʻalahi ka hana ʻana i nā annular ripples ma ka ʻili o ka mea hana. I mea e pale aku ai i ka haki ʻana o ka broach ma muli o ka ikaika broaching nui, i ka wā e hana ana ka broach, ʻaʻole pono ka nui o nā niho hana ma mua o 6 a 8.

ʻEkolu mau ʻano hana broaching no ka broaching, i wehewehe ʻia penei:

1) Layered broaching ʻO ke ʻano o kēia ʻano broaching, ʻo ia ka ʻoki ʻana o ka broach i ka papa haʻawina mīkini hana ma ka papa ma ke ʻano maʻamau. I mea e maʻalahi ai i ka haki ʻana i ka puʻupuʻu, hoʻomaloʻo ʻia nā niho ʻokiʻoki me nā awāwa hoʻokaʻawale chip. ʻO ka broach i hoʻolālā ʻia e like me ke ʻano broaching layered i kapa ʻia ʻo broach maʻamau.

2) Block broaching ʻO ke ʻano o kēia ʻano broaching, ʻo kēlā me kēia papa o ka metala ma ka ʻili i hana ʻia me ka hui o nā niho me ka nui o nā niho me ka nui like ʻole akā ʻo nā niho kuʻekuʻe (ʻo ka maʻamau o kēlā me kēia hui he 2-3 niho) i ʻoki ʻia. ʻOki wale nō kēlā me kēia niho i kahi ʻāpana o kahi papa metala. ʻO ka broach i hoʻolālā ʻia e like me ke ʻano broaching block i kapa ʻia he broach-cut broach.

3) ʻO ka broaching holoʻokoʻa Hoʻopili kēia ʻano hana i nā pono o ka broaching layered a me ka mahele. Hoʻohana ʻia ka ʻāpana niho ʻōpala i ka broaching ʻāpana, a ʻo ka ʻāpana niho maikaʻi e lawe i ka broaching layered. Ma kēia ala, hiki ke hoʻopōkole ʻia ka lōʻihi o ka broach, hiki ke hoʻonui i ka huahana, a hiki ke loaʻa ka maikaʻi o ka ʻili. Ua kapa ʻia ka broach i hoʻolālā ʻia e like me ke ʻano broaching ākea.

2. Nā hiʻohiʻona kaʻina hana a me ka laulā noi o ka huki ʻana o ka lua

1) ʻO ka broach he mea hana multi-blade, hiki iā ia ke hoʻopau i ka hoʻopau ʻana, hoʻopau a hoʻopau ʻana i ka lua i hoʻokahi pahu broaching, me ka hana kiʻekiʻe.

2) ʻO ka pololei o ka broaching ma muli o ka pololei o ka broach. Ma lalo o nā kūlana maʻamau, hiki i ka pololei broaching ke hiki i IT9 ~ IT7, a hiki i ka roughness ʻili Ra hiki ke hiki i 6.3 ~ 1.6 μm.

3) I ka huki ʻana i ka lua, hoʻonoho ʻia ka mea hana e ka lua mīkini ponoʻī (ʻo ka ʻaoʻao mua o ka broach ka mea hoʻonohonoho o ka mea hana), a ʻaʻole maʻalahi ka hōʻoia ʻana i ka pololei o ke kūlana o ka lua a me nā mea ʻē aʻe; I ka hana ʻana i nā ʻāpana kino, huki mua ʻia nā lua, a laila hana ʻia nā ʻaoʻao ʻē aʻe me ka hoʻohana ʻana i nā lua e like me ke kuhikuhi kūlana. 4) ʻAʻole hiki i ka broach ke hana wale i nā puka pōʻai, akā hana pū kekahi i nā lua a me nā lua spline.

5) ʻO ka broach kahi mea paʻa paʻa me ke ʻano paʻakikī a me ke kumukūʻai kiʻekiʻe, ʻaʻole kūpono ia no ka mīkini ʻana i nā lua nui.

Hoʻohana maʻamau ʻia nā puka huki i ka hana nui e hana ma o nā puka ma nā ʻāpana liʻiliʻi a me ke anawaena o Ф10 ~ 80mm a me ka hohonu o ka lua ʻaʻole iʻoi aku ma mua o 5 mau manawa ke anawaena o ka lua.

Ka manawa hoʻouna: ʻAukake-29-2022