Mea Hana Huli

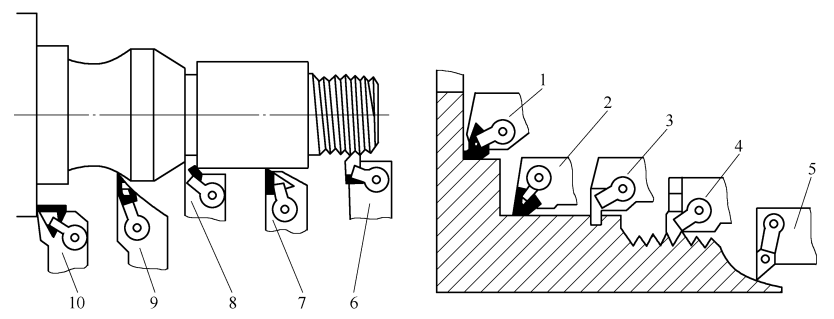

ʻO ka mea hana maʻamau i ka ʻoki metala ʻo ia ka mea hoʻohuli. Hoʻohana ʻia nā mea hana hoʻohuli e ʻoki i nā pōʻai i waho, nā lua ma waenakonu, nā milo, nā ʻauwaha, nā niho, a me nā ʻano ʻano ʻē aʻe ma ka lathe. Hōʻike ʻia kona mau ʻano nui ma ke Kiʻi 3-18.

Kiʻi 3-18 ʻAno nui o nā mea hana hoʻohuli

1. 10—Mea hana hoohuli hope 2. 7—Poai iwaho (mea paahana huli puka o loko) 3. 8—Mea hana hoololi 4. 6—Mea hoololi i ka milo 5. 9—Mea hana hoohuli i ka palapala.

Hoʻokaʻawale ʻia nā mea hana hoʻohuli ma muli o ko lākou ʻano i ka huli ʻana paʻa, ka hoʻohuli ʻana i ka wili, ka huli ʻana o ka mīkini, a me nā mea hana hiki ke kuhikuhi ʻia. ʻOi aku ka kaulana o nā mea hana huli ʻōlelo ma muli o kā lākou hoʻohana nui ʻana. Ke kālele nei kēia ʻāpana i ka hoʻokomo ʻana i nā loina hoʻolālā a me nā ʻenehana no ka indexable a me ka welding turn tool.

1. Mea hana wiliwili

Hana ʻia ka mea hoʻohuli kuʻi ʻana me kahi lau o kahi ʻano kikoʻī a paʻa i hoʻopili ʻia e ka wili. Hana ʻia nā ʻāpana mai nā ʻano like ʻole o nā mea carbide. ʻO ke kila kila ma ke ʻano he 45 a hoʻokala ʻia e kūpono i nā koi kikoʻī i ka wā e hoʻohana ai. ʻO ka maikaʻi o nā mea hana hoʻohuli a me kā lākou hoʻohana ʻana e hilinaʻi ʻia i ka pae o ka lau, ke kumu hoʻohālike, nā ʻāpana geometric mea hana a me ke ʻano a me ka nui o ka slot. ʻO ka maikaʻi wili, etc. ʻO ka maikaʻi wili, etc.

(1) Loaʻa nā pōmaikaʻi a me nā pōʻino i nā mea hana hoʻohuli

Hoʻohana nui ʻia ma muli o kona ʻano maʻalahi a paʻa; ʻoʻoleʻa mea hana kiʻekiʻe; a me ke kū'ē haʻalulu maikaʻi. Nui nō hoʻi nā hemahema, ʻo ia hoʻi:

(1) He ʻilihune ka hana ʻoki ʻana o ka maka. E hoʻemi ʻia ka hana ʻoki ʻana o ka maka ma hope o ka welded ʻana i kahi wela kiʻekiʻe. ʻO ka wela kiʻekiʻe i hoʻohana ʻia no ke kuʻi ʻana a me ka hoʻokala ʻana e hoʻokau ʻia ka pahi i ke koʻikoʻi kūloko. No ka mea, ʻo ka helu hoʻonui laina o ka carbide he hapalua ia o ke kino mea hana, hiki i kēia ke hana i nā māwae i ka carbide.

(2) ʻAʻole hiki ke hoʻohana hou ʻia ka mea paʻa. Hoʻopau ʻia nā mea maka no ka mea ʻaʻole hiki ke hoʻohana hou ʻia ka mea paʻa.

(3) He lōʻihi loa ka manawa kōkua. ʻO ka hoʻololi ʻana a me ka hoʻonohonoho ʻana o ka mea hana e lawe i ka manawa nui. ʻAʻole kūpono kēia me nā koi o nā mīkini CNC, nā ʻōnaehana machining maʻalahi, a i ʻole nā mea hana mīkini.

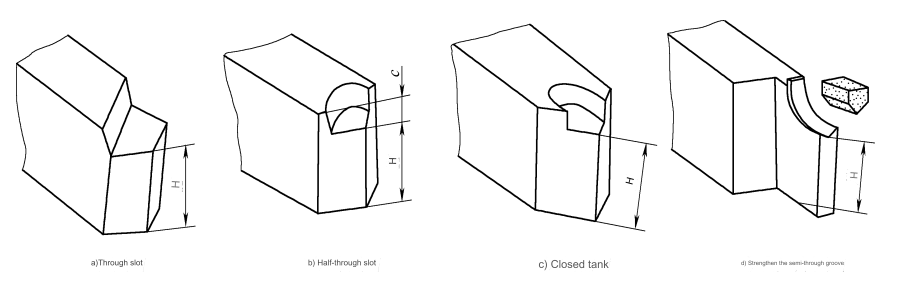

(2) Ke ʻano o ka mea paʻa paʻa paʻa

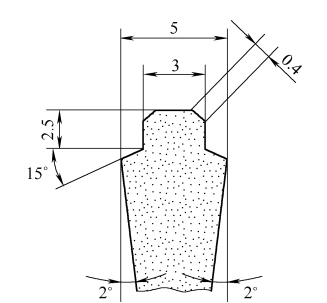

No nā mea hana hoʻohuli welded, pono e hana ʻia nā ʻauwaʻa shank mea hana e like me ke ʻano a me ka nui o ka maka. Aia i loko o nā ʻāwīwīwīwī i loko o nā ʻāwīwī, nā ʻūhā semi-ma, nā ʻāwī paʻa, a me nā ʻāpana semi-through i hoʻoikaika ʻia. E like me ka hōʻike ʻana ma ke Kiʻi 3-19.

Kiʻi 3-19 Geometry mea paʻa

Pono e hoʻokō ka groove paʻa mea hana i kēia mau koi e hōʻoia i ka wili maikaʻi:

(1) E hoʻomalu i ka mānoanoa. (1) E hoʻomalu i ka mānoanoa o ke kino ʻoki.

(2) E hoʻomalu i ka ʻokoʻa ma waena o ka ʻili a me ka mea paʻa paʻa. ʻAʻole nui a liʻiliʻi paha ka ʻokoʻa ma waena o ka pahi a me ka mea paʻa paʻa, ʻo 0.050.15mm maʻamau. Pono ka hui arc e like me ka mea hiki a ʻaʻole pono e ʻoi aku ka nui o ke āpau kūloko ma mua o 0.3mm. A i ʻole, e hoʻopilikia ʻia ka ikaika o ka weld.

(3) E hoʻomalu i ka waiwai o ka paʻa paʻa paʻa. Loaʻa ka ʻili o ka ʻili o ka mea paʻa paʻa o Ra=6.3mm. Pono ka ʻili o ka ʻili e palahalaha a pahee. Ma mua o ke kuʻi ʻana, pono e hoʻomaʻemaʻe ʻia ke awāwa o ka mea paʻa paʻa inā he ʻaila. No ka hoʻomaʻemaʻe ʻana i ka ʻili o ka wahi wili, hiki iā ʻoe ke hoʻohana i ka sandblasting a i ʻole ka waiʻona a i ʻole ka ʻaila e palaki ai.

E hoʻomalu i ka lōʻihi o ka maka. I nā kūlana maʻamau, ʻo kahi pahi i hoʻokomo ʻia i loko o ke awāwa mea hana pono e hoʻopuka ʻia e 0.20.3mm e ʻae ai i ka ʻoi. Hiki ke lō'ihi ka lō'ihi o ka 0.20.3mm ma mua o ka lau. Ma hope o ka wili ʻana, wili ʻia ke kino mea hana. No ka ʻike maʻemaʻe, e wehe i nā mea keu.

(3) Ke kaʻina hana brazing blade

Hoʻohana ʻia ka solder paʻakikī e wili i nā lau carbide cemented (he mea refractory a i ʻole nā mea brazing ka mea hoʻoheheʻe ʻoi aʻe ma mua o 450degC). Hoʻomaʻamaʻa ʻia ka solder a hiki i kahi kūlana hoʻoheheʻe, ʻo ia ka mea maʻamau 3050degC ma luna o ka helu heheʻe. Mālama ka flux i ka solder mai ke komo ʻana a me ka laha ʻana ma ka ʻili o kaʻāpana mīkini. Hiki nō hoʻi i ka launa pū ʻana o ka solder me ka mea welded. ʻO ka hana hoʻoheheʻe ʻana e hoʻopaʻa paʻa i ka pahi carbide i loko o ka slot.

Nui nā ʻenehana hoʻomehana brazing, e like me ka welding flame gas a me ka welding frequency kiʻekiʻe. ʻO ka wiliwili pili uila ke ʻano hoʻomehana maikaʻi loa. ʻO ke kū'ēʻana ma kahi o ka pilina ma waena o ka'āpana keleawe, aʻo ke poʻoʻokiʻoki ka mea kiʻekiʻe loa, a ma laila kahi e hanaʻia ai kahi wela kiʻekiʻe. E ʻulaʻula mua ke kino ʻoki a laila hoʻoili ʻia ka wela i ka maka. ʻO kēia ka mea e wela mālie ai ka lau a piʻi mālie ka mahana. He mea nui ka pale ʻana i nā māwae.

ʻAʻole "hoʻopau ʻia" ka maka no ka mea ua pani ʻia ka mana i ka wā e heheʻe ai ka mea. Ua hōʻike ʻia ka wiliwili pili uila e hōʻemi i nā māwae o ka ʻili a me ka desoldering. He maʻalahi a paʻa ka brazing, me ka maikaʻi maikaʻi. ʻOi aku ka maikaʻi o ke kaʻina hana brazing ma mua o nā welds kiʻekiʻe, a he paʻakikī ke hoʻopaʻa i nā mea hana me nā ʻaoʻao he nui.

Hoʻopili ʻia ka maikaʻi o ka brazing e nā kumu he nui. Pono e koho pono ʻia ke ʻano brazing, flux a me ke ʻano wela. No ka mea paahana carbide brazing, pono e loaʻa i ka mea hoʻoheheʻe kahi kiʻekiʻe ma mua o ka mahana o ka ʻoki ʻana. He mea maikaʻi ia no ka ʻoki ʻana no ka mea hiki iā ia ke mālama i ka ikaika hoʻopaʻa ʻana o ka lau me ka mālama ʻana i kona wai, pulu a me ka conductivity wela. Hoʻohana maʻamau ʻia kēia mau mea hoʻoheheʻe ʻia i ka wā e hoʻopaʻa ai i nā ʻōpala cemented-carbide:

(1) ʻO ka mahana hoʻoheheʻe o ke keleawe maʻemaʻe a i ʻole ka copper-nickel alloy (electrolytic) ma kahi o 10001200degC. ʻO nā mahana hana i ʻae ʻia ʻo 700900degC. Hiki ke hoʻohana ʻia kēia me nā mea hana i loaʻa nā haʻahaʻa hana.

(2) Copper-zinc a i ʻole 105 # filler metala me kahi mahana hoʻoheheʻe ma waena o 900920degC & 500600degC. He kūpono no ka mea paahana haʻahaʻa haʻahaʻa.

ʻO ka helu hoʻoheheʻe o ka hui kālā-keleawe he 670820. ʻO kona mahana hana kiʻekiʻe he 400 degere. Eia nō naʻe, kūpono ia no ka wiliwili ʻana i nā mea hana hoʻohuli me ka cobalt haʻahaʻa a i ʻole ka titanium carbide kiʻekiʻe.

Hoʻopili nui ʻia ka maikaʻi o ka brazing e ke koho a me ka hoʻohana ʻana i ka flux. Hoʻohana ʻia ka flux e wehe i nā oxides ma ka ʻili o kahi mea hana e hoʻopaʻa ʻia, hoʻonui i ka wettability a pale i ka weld mai ka oxidation. Hoʻohana ʻia ʻelua mau kahe e hoʻopaʻa ai i nā mea hana carbide: Borax Na2B4O2 dehydrated a i ʻole Borax dehydrated 25% (massfraction) + boric Acid 75% (massfraction). He 800 a hiki i ka 1000degC ka wela wela. Hiki ke hoʻoheheʻe ʻia ʻo Borax ma ka hoʻoheheʻe ʻana i ka borax, a laila e ʻoki ʻia ma hope o ka hoʻoluʻu ʻana. kānana. I ka hoʻopaʻa ʻana i nā mea hana YG, ʻoi aku ka maikaʻi o ka borax dehydrated. Hiki iā ʻoe ke loaʻa nā hopena ʻoluʻolu i ka wā e hoʻopaʻa ai i nā mea hana YT me ka hoʻohana ʻana i ka formula dehydrated borax (massfraction) 50% + boric (massfraction) 35% + dehydrated potassium (massfraction) fluoride (15%).

ʻO ka hoʻohui o ka potassium fluoride e hoʻomaikaʻi i ka wettability a me ka hoʻoheheʻe ʻana o ka titanium carbide. I mea e hōʻemi ai i ke koʻikoʻi wili i ka wā e hoʻopaʻa ai i nā alloys kiʻekiʻe-titanium (YT30 a me YN05), hoʻohana mau ʻia kahi haʻahaʻa haʻahaʻa ma waena o 0.1 a me 0.5mm. Ma ke ʻano he gasket uku ma waena o nā lau a me nā mea paʻa, hoʻohana pinepine ʻia ke kila kalapona a i ʻole ka hao-nickel. No ka ho'ēmiʻana i ke kaumaha wela, pono e hoʻokaʻawaleʻia ka pahi. ʻO ka mea maʻamau e hoʻokomo ʻia ka mea hoʻohuli i loko o kahi umu me ka mahana o 280 ° C. Insulate no ʻekolu hola ma 320degC, a laila hoʻomaha mālie i loko o ka umu ahi, a i ʻole i loko o ka asbestos a i ʻole ka pauka lehu mauʻu.

(4) Hoʻopaʻa hoʻopaʻa kino

Hoʻohana ka hoʻopaʻa paʻa ʻole i ka solution phosphoric a me ka pauka keleawe ʻole, ka mea e hui pū ai i ke kemika, mechanics, a me ka physics i ka hoʻopaʻa ʻana i nā lau. ʻOi aku ka maʻalahi o ka hoʻohana ʻana i ka paʻa inorganic ma mua o ka brazing a ʻaʻole e hoʻokau i ke koʻikoʻi o loko a i ʻole nā māhā o ka maka. He mea pono loa kēia ʻano no nā mea ʻili paʻakikī e wili, e like me nā seramika.

Nā hana kūikawā a me nā hihia kūpono o ka mīkini

4. Ke koho ʻana i ke kihi o ka ʻae ʻana a me ka ʻoki ʻana i ka bevel

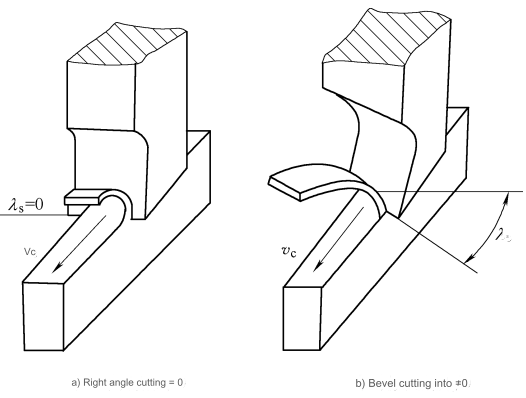

(1)ʻO ka ʻoki ʻana i ka bevel kahi manaʻo i loaʻa no ka manawa lōʻihi.

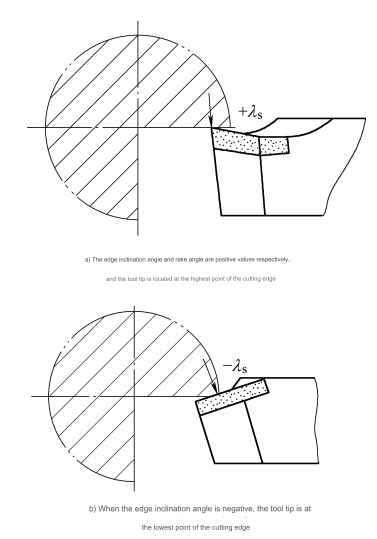

ʻOki ʻana ka ʻoki kihi ʻākau kahi e like ai ka ʻoki ʻoki o ka mea paahana me ke ʻano o ka ʻoki ʻana. ʻO ka ʻoki ʻana i ka bevel ke kū pololei ʻole ka ʻoki ʻoki o ka mea hana me ke kuhikuhi o ka ʻoki ʻana. Ma keʻano he maʻalahi, hiki ke nānāʻole i ka hopena o ka hānai. ʻO ka ʻoki ʻoki ʻana i kū pololei me ka wikiwiki o ka neʻe ʻana a i ʻole nā kihi kihi kihi lss=0 i manaʻo ʻia he ʻoki kihi ʻākau. Hōʻike ʻia kēia ma ke Kiʻi 3-9. ʻO ka ʻoki ʻana ʻaʻole kū pololei me ka wikiwiki o ka neʻe ʻana a i ʻole nā kihi inclination lss0, ua kapa ʻia ʻo oblique angle-cutting. No ka laʻana, E like me ka mea i hōʻike ʻia ma ke Kiʻi 3-9.b, ke ʻoki ʻoki hoʻokahi wale nō ʻoki, ʻike ʻia kēia ʻo ka ʻoki manuahi. ʻO ka ʻoki ʻana i ka bevel ka mea maʻamau i ka ʻoki metala.

Kiʻi 3-9 ʻOki ʻoki kihi ʻākau a me ka ʻoki ʻana i ka bevel

(2) Ka hopena o ka ʻoki ʻana i ka bevel i ke kaʻina ʻoki

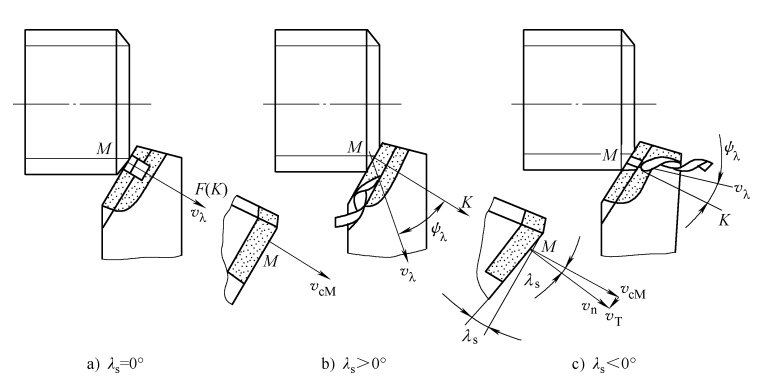

1. Hoʻololi i ke kuhikuhi o ka chip outflow

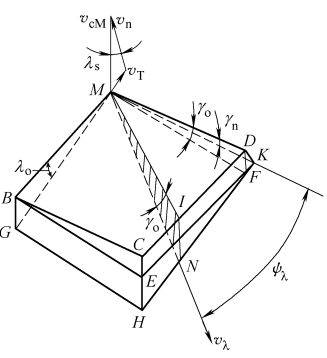

Hōʻike ke kiʻi 3-10 e hoʻohana ʻia kahi mea hoʻohuli waho e hoʻohuli i kahi paipu paipu. Ke komo wale ka ʻoki ʻoki nui i ka ʻoki ʻana, ʻo kahi ʻāpana M i ka papa ʻokiʻoki (manaʻo ʻia ʻo ia ke kiʻekiʻe like me ke kikowaena o ka ʻāpana) lilo i puʻupuʻu ma lalo o ka extrusion i mua o ka mea hana a kahe i waho ma mua. ʻO ka pilina ma waena o ka ʻaoʻao kahe o ka chip a me ke kihi inclination o ka ʻaoʻao, ʻo ia ke aʻe ʻana i kahi kino ʻāpana MBCDFHGM me ka mokulele orthogonal a me ka mokulele ʻoki a me nā mokulele ʻelua e pili ana iā lāua ma ke kiko M.

Kiʻi 3-10 Ka hopena o nā λs ma ke kuhikuhi puʻupuʻu kahe

ʻO MBCD ka mokulele kumu ma ke Kiʻi 3-11. Ke ls=0, ʻo MBEF ka mua ma ke Kiʻi 3-11, a ʻo ka mokulele MDF he ʻōpono a me ka mokulele maʻamau. Ua kū pololei ka lae M i ka ʻoki ʻoki. Ke hoʻokuʻu ʻia nā ʻāpana, ʻo M kahi ʻāpana o ka wikiwiki ma ke ala o ka ʻoki ʻoki. Pili ka MF me ka ʻoki ʻoki. E like me ka mea i hōʻike ʻia ma ka Figure 3-10a, i kēia manawa, ua ʻāwili ʻia nā Chips i kahi ʻano like me ka punawai a i ʻole ke kahe ʻana i kahi laina pololei. Inā he waiwai maikaʻi ko ls a laila aia ka mokulele MGEF ma mua a ʻaʻole like ka neʻe nui o ka wikiwiki ʻoki vcM me ka MG lihi ʻoki. ʻO ka māmā M velocitynā mea hoʻohuli cncvT pili i ka mea hana ma ke ala o na kiko oki i ka MG. Ke hoʻololi ʻia ke kiko M i ʻāpana e kahe ana i mua a hoʻopilikia ʻia e ka vT e haʻalele ka wikiwiki o ka chip mai ka mokulele maʻamau MDK ma kahi kihi chip o psl. Ke loaʻa ka waiwai nui o ls, e kahe nā ʻāpana i ke ala o ka hana ʻana i ka ʻili.

ʻO ka mokulele MIN, e like me ka mea i hōʻike ʻia ma nā Kiʻi 3-10b a me 3-11, ʻike ʻia ʻo ka kahe chip. Ke loaʻa ka ls i ka waiwai ʻino, ua hoʻohuli ʻia ka ʻāpana velocity vT i ka ʻaoʻao o ka ʻoki ʻoki, e kuhikuhi ana i ka GM. Hoʻokaʻawale kēia i nā ʻāpana mai ka mokulele maʻamau. Aia ke kahe ma ka ʻaoʻao ʻē aʻe i ka ʻili o ka mīkini. E like me ka hoike ana ma ke Kii 3-10.c. ʻO kēia kūkākūkā e pili ana i ka hopena o ls i ka wā ʻoki manuahi. ʻO ke kahe ʻana o ka mea metala ma ka piko o ka mea hana, ka ʻoki ʻoki liʻiliʻi, a me ka ʻāʻī puʻupuʻu e loaʻa i ka hopena i ke ala o ka puka ʻana o nā ʻāpana i ka wā o ka hana mīkini maoli o ka hoʻohuli ʻana i nā pōʻai waho. Hōʻike ke Kiʻi 3-12 i ka paʻi ʻana o nā puka puka a me nā puka pani. Ka hopena o ka ʻoki ʻoki ʻana i ke kahe ʻana o ka chip. Ke paʻi ʻana i kahi milo puka ʻole, maikaʻi ka waiwai ls, akā i ka paʻi ʻana i kekahi me ka lua, he waiwai ʻino ia.

Kiʻi 3-11 ʻO ka ʻoki ʻoki ʻoki ʻoki ʻana i ke ala kahe kahe

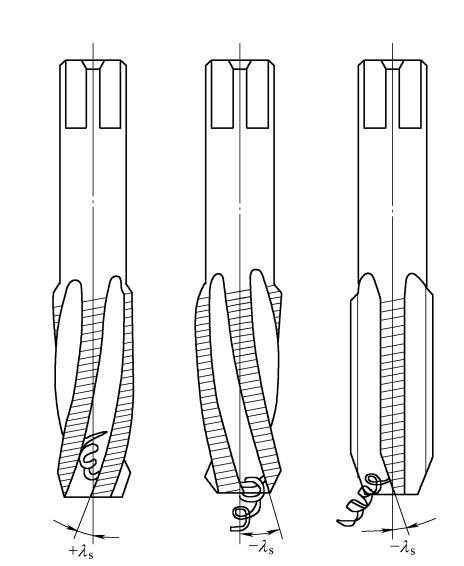

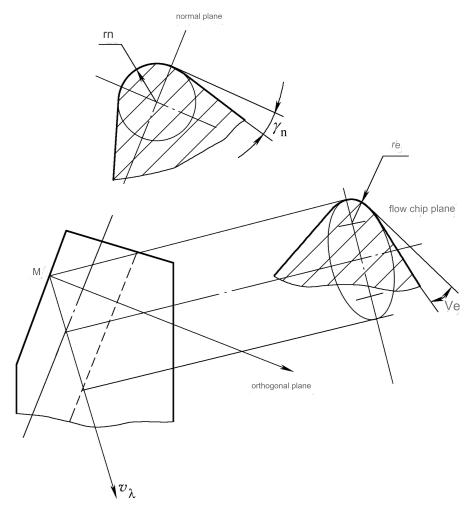

2. Hoʻopili ʻia ka rake maoli a me ka radii obtuse

I ka ls = 0, ma ka oki noa, ua like like na kihi rake ma ka mokulele orthogonal a me ka mokulele kahe. Inā ʻaʻole ʻole ka ls, hiki iā ia ke hoʻopilikia maoli i ka ʻoki ʻoki a me ka pale ʻana i ka friction i ka wā e kiola ʻia ai nā ʻāpana. I loko o ka mokulele lele, pono e ana ʻia nā kihi rake kūpono a me ka ʻoki ʻana i nā radii obtuse. Hoʻohālikelike ka Kiʻi 3-13 i ka geometry o kahi mokulele maʻamau e hele ana ma ka lae M o ka lihi nui me ka radii obtuse o ka mokulele kahe chip. I ka hihia o ka ʻoi ʻoi, hōʻike ka mokulele maʻamau i kahi arc i hana ʻia e ka radius obtuse rn. Eia nō naʻe, ma ka ʻaoʻao o ka kahe chip, ʻo ka ʻoki ʻana he ʻāpana ellipse. ʻO ka radius o ka curvature ma ke koʻi lōʻihi, ʻo ia ka ʻoki ʻoki ʻana obtuse radius re. Hiki ke helu ʻia ke kumu hoʻohālikelike ma lalo mai nā huahelu pili geometric ma nā Kiʻi 3-11 a me 3-13.

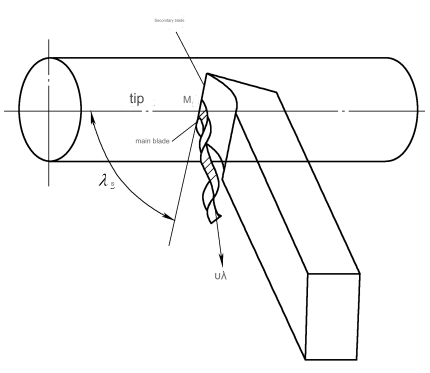

Hōʻike ke kumu ma luna nei e piʻi hou ana i ka piʻi ʻana o ka waiwai kūʻokoʻa ls, ʻoiai e emi ana ka ge. Inā ls=75deg, a me gn=10deg me rn=0.020.15mm a laila hiki ke like ka nui me ka 70deg. hiki ke liʻiliʻi e like me 0.0039mm. ʻOi loa kēia i ka ʻoki ʻoki, a hiki iā ia ke hoʻokō i ka ʻoki ʻoki liʻiliʻi (ap0.01mm) me ka hoʻohana ʻana i kahi ʻoki liʻiliʻi. Hōʻike ke kiʻi 3-14 i ke kūlana ʻoki o kahi mea hana waho ke kau ʻia ʻo ls ma 75deg. ʻO nā ʻaoʻao nui a me nā ʻaoʻao ʻelua o ka mea hana i hoʻopaʻa ʻia i kahi laina pololei. ʻOi loa ka ʻoki ʻoki o ka mea hana. ʻAʻole paʻa ka ʻoki ʻoki i ka wā o ka ʻoki ʻana. Ua pili pū me ka ʻili cylindrical waho. He maʻalahi ka hoʻonohonoho a me ka hoʻoponopono. Ua hoʻohana maikaʻi ʻia ka mea hana no ka hoʻopau ʻana i ka hoʻohuli kiʻekiʻe o ke kila kalapona. Hiki ke hoʻohana ʻia e hoʻopau i ka hana ʻana i nā mea paʻakikī i ka mīkini e like me ke kila ikaika kiʻekiʻe.

Kiʻi 3-12 ʻO ka mana o ke kihi inclination lihi ma ka ʻaoʻao kahe o ka puʻupuʻu i ka wā e paʻi ana i ka milo

Kiʻi 3-13 Hoʻohālikelike o rn a me re geometries

3. Hoʻopilikia ʻia ka hopena a me ka ikaika o ka piko o ka mea hana

Inā ʻino ka ls, e like me ka mea i hōʻike ʻia ma ke Kiʻi 3-15b, ʻo ka piko o ka mea hana ka lae haʻahaʻa ma ka ʻoki ʻoki. Ke ʻoki ʻia nā kihi ʻoki i loko o kaʻāpana prototypeʻO ka helu mua o ka hopena me ka mea hana, ʻo ia ka tooltip (i ka wā e loaʻa ai kahi waiwai maikaʻi) a i ʻole ka mua (inā maikaʻi ʻole) ʻaʻole wale kēia e pale a hoʻoikaika i ka piko, akā kōkua pū nō hoʻi e hōʻemi i ka pōʻino. Nui nā mea hana me ke kihi rake nui e hoʻohana i ka inclination lihi maikaʻi ʻole. Hiki iā lāua ke hoʻonui i ka ikaika a hoʻemi i ka hopena ma ka piko o ka mea hana. Ke piʻi nei ka ikaika hope Fp i kēia manawa.

Kiʻi 3-14 ʻO ka mea hoʻohuli i ka ʻaoʻao ākea nui me ka ʻole o ka piko paʻa

4. Hoʻopilikia i ka paʻa o ka ʻoki ʻana i loko a i waho.

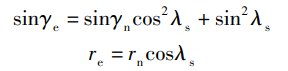

Ke ls = 0, ʻoki ka ʻoki ʻoki i loko a i waho o ka mea hana i ka manawa like, hoʻololi koke ka ʻoki ʻoki, a nui ka hopena; inā ʻaʻole ʻole ka ls, ʻoki mālie ka ʻoki ʻoki i loko a i waho o ka mea hana, liʻiliʻi ka hopena, a ʻoi aku ka maʻalahi o ka ʻoki ʻana. No ka laʻana, ʻoi aku ka ʻoi o ka ʻoki ʻoki a me ka ʻoki maʻalahi ma mua o nā ʻoki wili maʻamau kahiko. Hoʻonui ʻia ka maikaʻi o ka hana ʻana e 2 a 4 mau manawa, a hiki i ka waiwai o ka roughness ʻili Ra hiki ke emi ma lalo o 3.2 mm.

5. ʻO ke ʻano ʻokiʻoki

ʻO ke ʻano ʻoki ʻoki o ka hāmeʻa kekahi o nā mea maʻamau o nā ʻāpana geometric kūpono o ka hāmeʻa. Hoʻololi ke ʻano o ka lau o ka mea hana i ke ʻano oki. ʻO ka mea i kapa ʻia ʻoki ʻoki e pili ana i ka hoʻonohonoho a me ke ʻano i hoʻoneʻe ʻia ai ka papa metala e hana ʻia e ka ʻoki ʻoki. Hoʻopili ia i ka nui o ka ukana ʻoki ʻoki, nā kūlana koʻikoʻi, ke ola mea hana a me ka maikaʻi o ka ʻili mīkini. kali. Nui nā mea hana holomua e pili pono ana i ke koho kūpono o nā ʻano lau. Ma waena o nā mea hana holomua, hiki ke hōʻuluʻulu ʻia nā ʻano o ka lau i nā ʻano aʻe:

(1) Hoʻonui i ke ʻano o ka maka o ka ʻoki. ʻO ke ʻano o ka pahi ka mea nui e hoʻoikaika i ka ikaika o ka ʻoki ʻoki, hoʻonui i ke kihi ʻoki ʻoki, hoʻemi i ka ukana ma ka lōʻihi o ka ʻāpana o ka ʻoki, a hoʻomaikaʻi i nā kūlana dissipation wela. Ma waho aʻe o kekahi mau ʻano hiʻohiʻona mea hana i hōʻike ʻia ma ke Kiʻi 3-8, aia pū kekahi mau hiʻohiʻona ʻaoʻao (arc edge hobbing tools, arc edge hobbing face milling cutters, arc edge drill bits, etc. ), he nui nā ʻano kihi kihi ʻoi (drill bits. , etc.) )kali;

(2) He ʻano lihi e hōʻemi ana i ke koena. Hoʻohana nui ʻia kēia ʻano ʻaoʻao no ka hoʻopau ʻana i nā mea hana, e like me nā mea hana huli ʻai nui a me nā mea ʻoki wili maka me nā wipers, nā mea hana hoʻoluʻu lana a me nā mea hana hoʻoluhi maʻamau me nā wipers cylindrical. Reamers, etc.;

Kiʻi 3-15 Ka hopena o ke kihi inclination lihi ma kahi hopena i ka wā e ʻoki ai i ka mea hana

(3) He ʻano maka e puʻunaue pono i ka ʻāpana ʻokiʻoki a hoʻokuʻu mālie i nā ʻāpana. ʻO ka hiʻohiʻona o kēia ʻano o ke ʻano o ka lau, ʻo ia ka puʻunaue ʻana i ka ʻāpana ʻoki ākea a lahilahi i loko o nā ʻāpana liʻiliʻi, ʻaʻole wale ia e ʻae i ka hoʻokuʻu ʻia ʻana o nā chips me ka maʻalahi, akā e hoʻonui pū i ka helu mua. Hāʻawi i ka nui a hoʻemi i ka mana ʻoki ʻāpana. No ka laʻana, ke hoʻohālikelike ʻia me nā pahi ʻoki ʻaoʻao maʻamau maʻamau, e puʻunaue nā pahi ʻoki ʻaoʻao pālua i ka ʻoki ʻoki nui i ʻekolu mau ʻāpana, e like me ka hōʻike ʻana ma ke Kiʻi 3-16. Hoʻokaʻawale ʻia nā ʻāpana i ʻekolu mau ʻāpana e like me ia. Hoʻemi ʻia ka paio ma waena o nā ʻāpana a me nā pā ʻelua, kahi e pale ai i ka paʻa ʻana o nā ʻāpana a hoʻemi nui i ka ikaika ʻoki. Ke piʻi aʻe ka hohonu o ka ʻoki ʻana, piʻi ka emi ʻana, a ʻoi aku ka maikaʻi o ka hopena. I ka manawa like, hoʻemi ʻia ka mahana ʻoki a hoʻomaikaʻi ʻia ke ola mea hana. Nui nā mea paahana no kēia ʻano ʻano o ka maka, e like me nā ʻoki wili wāwae, nā ʻoki wili wili, nā ʻili ʻili kuʻekuʻe, nā bit drill chip, nā ʻoki wili kulina niho, a me nā wili hopena nalu. A me nā broaches ʻoki huila, etc.;

Kiʻi 3-16 ʻO ka pahi ʻoki ʻaoʻao kaulua

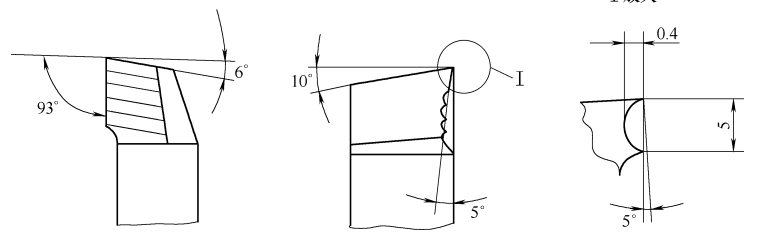

(4) Nā kiʻi kūikawā ʻē aʻe. ʻO nā hiʻohiʻona o ka pahi kūikawā he mau hiʻohiʻona maka i hoʻolālā ʻia e hoʻokō i nā kūlana hana o kahi ʻāpana a me kona ʻano ʻokiʻoki. Hōʻike ka Figure 3-17 i ke ʻano o ka papa holoi mua i hoʻohana ʻia no ka hana ʻana i ke kēpau keleawe. Hoʻohālikelike ʻia ka lihi ʻoki nui o kēia maka i loko o nā pio ʻekolu. Loaʻa i kēlā me kēia kiko ma ka ʻoki ʻoki kahi kihi inclination e piʻi aʻe mai ka maikaʻi ʻole, a i ʻole a laila i ka maikaʻi. ʻO kēia ke kumu e ʻoki ʻia ai ka ʻōpala i loko o nā ʻāpana lipine.

Ke kākoʻo mau nei ʻo Anebon i ka manaʻo o "E No. E hoʻomau ʻo Anebon i ka lawelawe mua a me nā mea hou mai ka home a me nā ʻāina ʻē me ka wela piha no ka Ordinary Discount 5 Axis Precision Custom Rapid Prototype5 axis cnc millingʻO ka hoʻololi ʻana i ka mīkini, ma Anebon me ke ʻano kiʻekiʻe e hoʻomaka me kā mākou motto, hana mākou i nā huahana i hana ʻia ma Iapana, mai ke kūʻai ʻana i nā lako a hiki i ka hana ʻana. Hāʻawi kēia i nā mea kūʻai mai nā ʻāina āpau e hoʻohana me ka maluhia o ka noʻonoʻo.

ʻO nā kaʻina hana hana Kina, nā lawelawe wili metala a me ka lawelawe prototyping wikiwiki. Manaʻo ʻo Anebon i nā "kumukūʻai kūpono, ka manawa hana kūpono a me ka lawelawe ma hope o ke kūʻai aku" e like me kā mākou kumu. Manaʻo ʻo Anebon e hui pū me nā mea kūʻai aku no ka hoʻomohala ʻana a me nā pono. Aloha mākou i nā mea kūʻai aku e hoʻopili iā mākou.

Ka manawa hoʻouna: Dec-14-2023