ʻO ke kila kila kahi koho kaulana no ka hanaʻana i nā mea kani. Hiki i ke aʻo ʻana e pili ana i ke kila kila kila ke kōkua i nā mea hoʻohana e lilo i mea akamai i ke koho ʻana a me ka hoʻohana pono ʻana i nā mea kani.

ʻO ke kila kila, i hoʻopau pinepine ʻia e like me SS, hiki ke pale i ka ʻike ʻana i ka ea, ka mahu, ka wai, a me nā mea ʻino ʻē aʻe. I kēia manawa, ʻo ke kila i hiki ke pale aku i nā hopena o ka ʻino kemika mai nā mea like me ka waikawa, ka alkali, ka paʻakai, a me nā mea etchants kemika ʻē aʻe, ua ʻike ʻia ʻo ke kila kūpaʻa waikawa.

Hiki ke kū i ka ea, ka mahu, ka wai, a me nā mea ʻino ʻino. Eia naʻe, he mea nui e hoʻomaopopo ʻaʻole hiki i nā kila kuhili ke kū i ka ʻino kemika. Ma ka ʻaoʻao ʻē aʻe, ua hoʻolālā ʻia ke kila ʻakika e kūʻē i nā hopena o ka media kemika e like me ka waikawa, alkali, a me ka paʻakai. Hoʻoholo ʻia ke kūpaʻa ʻino o ke kila kila e nā mea hoʻohui i loko o ke kila.

Hoʻokaʻawale maʻamau

Hoʻokaʻawale pinepine ʻia e ka hui metallographic:

Ma ke aupuni o ka hui metallographic, hoʻokaʻawale ʻia ke kila kuhiliʻole maʻamau i ʻekolu pūʻulu: Austenitic stainless steel, ferritic stainless steel, a me martensitic stainless steel. Hoʻokumu ʻia kēia mau pūʻulu, a mai laila mai, ua hoʻomohala ʻia ke kila biphase, ke kila kila i hoʻopaʻa ʻia i ka ua, a me ke kila kila kiʻekiʻe i loaʻa ma lalo o 50% ka hao no ka hoʻokō ʻana i nā pono kikoʻī a lawelawe i nā kumu kūikawā.

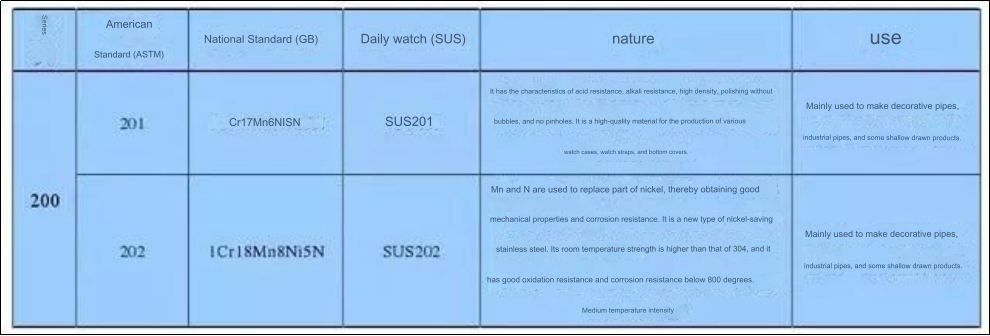

1, ʻAʻole Magnetic Kuhili ʻole

ʻO kēia ʻano ʻano kila kila he ʻano aniani i kapa ʻia ʻo austenitic, i hoʻoikaika nui ʻia ma o ka hana anu. ʻAʻole ia he magnetic, akā ʻo nā helu 200 a me 300, e like me 304, hoʻohana mau ʻia e ka American Iron and Steel Institute e ʻike i kēia kila.

2, Ke kila kila i hana ʻia me ka hao

ʻO kēia ʻano kila kuhili ʻole ka nui o ka hale aniani i hoʻomalu ʻia e ka ferrite (phase A), ʻo ia ka magnetic. ʻAʻole hiki ke hoʻopaʻakikī ʻia ma ka hoʻomehana ʻana, akā hiki ke hoʻonui iki ʻia ka ikaika ma ka hana anu. Hoʻohālikelike ka American Iron and Steel Institute i ka 430 a me 446 i mau hiʻohiʻona.

3, Ke kila kila ʻole

ʻO kēia ʻano ʻano kila kila he ʻano aniani i kapa ʻia ʻo martensitic he magnetic. Hiki ke hoʻololi ʻia kona ʻano mechanical ma o ka mālama ʻana i ka wela. Ke kuhikuhi nei ka American Iron and Steel Institute iā ia he 410, 420, a me 440. Hoʻomaka ʻo Martensite me kahi ʻano austenitic i nā wela kiʻekiʻe a hiki ke hoʻololi i martensite (ʻo ia hoʻi, e paʻakikī) ke maʻalili ʻo ia i ka wikiwiki kūpono i ka lumi wela.

4, Duplex Stainless Steel

ʻO kēia ʻano ʻano kila kila he hui ʻana o nā hale austenitic a me ka ferritic. ʻOi aku ka nui o ka hapa liʻiliʻi o ka hana ma mua o 15%, e hana ana i ka magnetic a hiki ke hoʻoikaika ʻia ma o ka hana anu. ʻO 329 kahi laʻana kaulana o kēia ʻano kila kila. Ke hoʻohālikelike ʻia me ke kila kila austenitic, ʻoi aku ka ikaika o ke kila duplex a me ka piʻi nui ʻana o ke kūʻē ʻana i ka intergranular corrosion, chloride stress corrosion, a me point corrosion.

5, Ke kila kila me ka hiki ke paakiki ka ua

ʻO kēia ʻano kila kuhili ʻole he matrix austenitic a i ʻole martensitic a hiki ke paʻakikī ma o ka paʻakikī o ka ua. Ka Hao Amerika

aHāʻawi ʻo Steel Institute i nā helu 600 i kēia mau kila, e like me 630, ʻo ia hoʻi ʻo 17-4PH.

Ma keʻano laulā, ma waho aʻe o nā alloys, hāʻawi ka austenitic stainless steel i ke kūpaʻa kūʻokoʻa. No nā kaiapuni liʻiliʻi liʻiliʻi, hiki ke hoʻohana ʻia ke kila kila ferritic, ʻoiai ma nā wahi e pono ai ka ikaika kiʻekiʻe a i ʻole ka paʻakikī, ʻo ke kila kuhiliʻole martensitic a me ka ua paʻakikī paʻakikī nā koho kūpono.

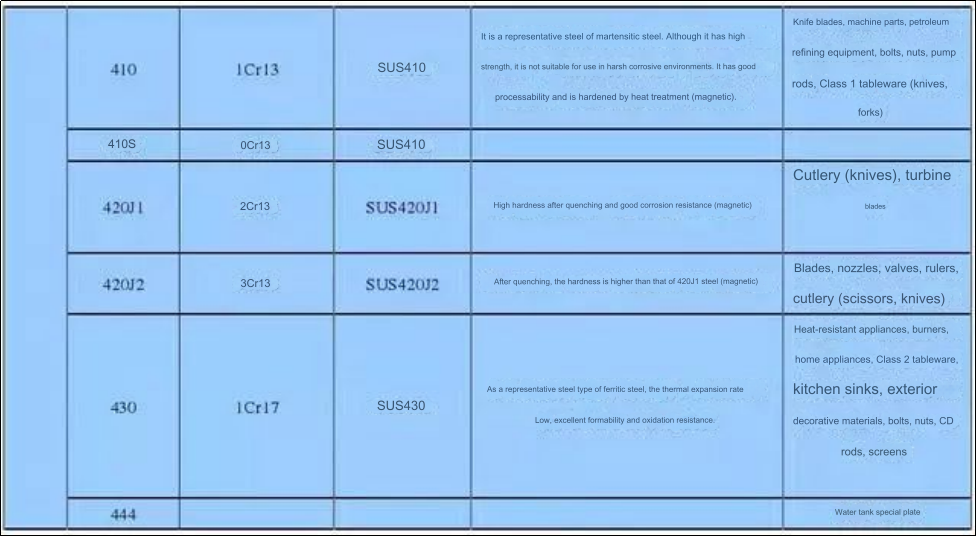

Nā hiʻohiʻona a me nā wahi noi

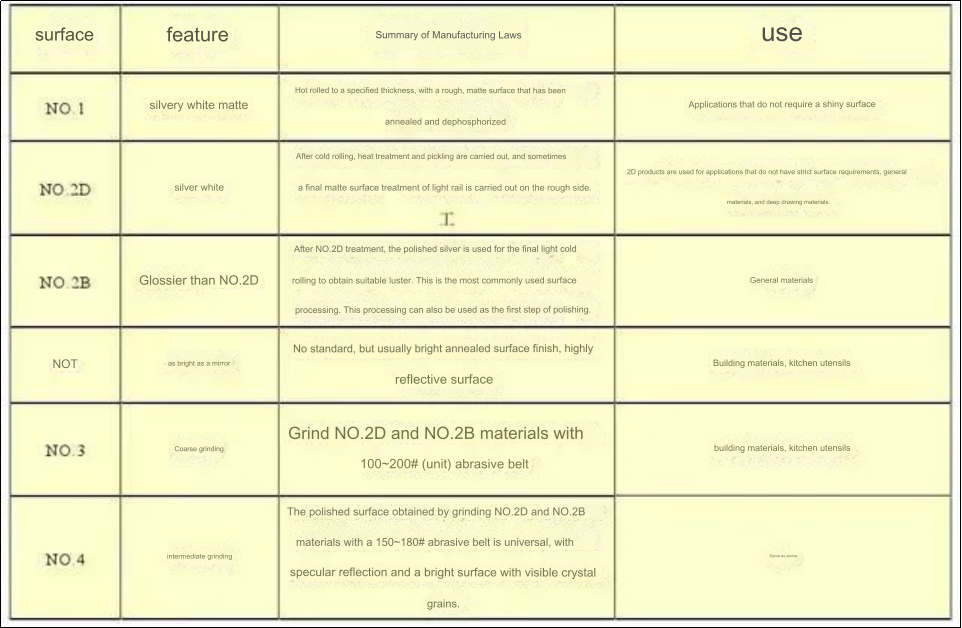

ʻenehana ʻili

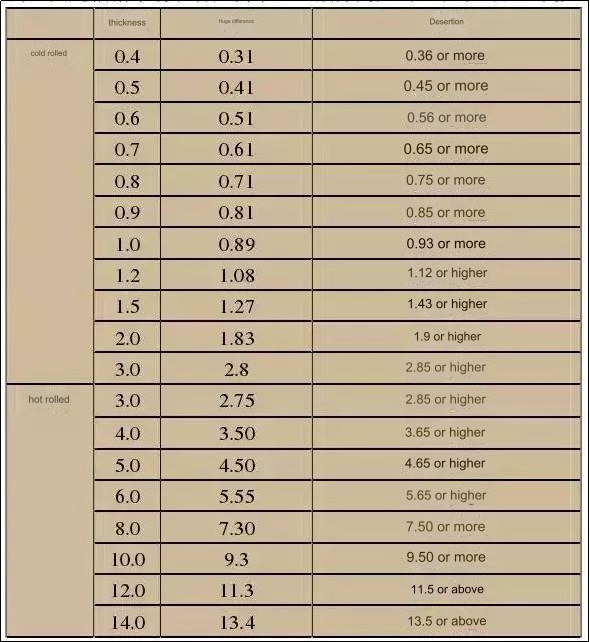

ʻokoʻa mānoanoa

1, no ka mea, o ka mīkini wili kila i ke kaʻina hana, ʻike ʻia ka wela o ka ʻōwili i ka liʻiliʻi o ka deformation, ka hopena i ka mānoanoa o ka neʻe ʻana o ka papa i ʻōwili ʻia, maʻamau ka mānoanoa ma nā ʻaoʻao ʻelua o ka lahilahi. Ke ana ʻana i ka mānoanoa o ka papa, ʻōlelo ka mokuʻāina e ana ʻia ka ʻāpana waena o ke poʻo o ka papa.

2, ʻo ke kumu o ka hoʻomanawanui e like me ka mākeke a me ka koi o ka mea kūʻai aku, maʻamau i māhele ʻia i nā tolerances nui a me nā ʻae liʻiliʻi: no ka laʻana,

He aha ke ʻano o ke kila kila ʻaʻole maʻalahi ka ʻōpala?

ʻEkolu mau kumu nui e pili ana i ka ʻino ʻana o ke kila kila:

1, ka maʻiʻo o nā mea hoʻohuihui.

ʻO ka hopena o nā mea hoʻohui ʻia Ma ka laulā, hōʻike ke kila me ka liʻiliʻi o 10.5% chromium i ke kūʻē ʻana i ka ʻōpala. Eia kekahi, ʻo ke kila kila me nā pae kiʻekiʻe o ka chromium a me ka nickel, e like me ka mea i loaʻa ma 304 kila me 8-10% nickel a me 18-20% chromium, hōʻike i ka hoʻoikaika ʻana i ka corrosion a hiki ke kū i ka pala i nā kūlana maʻamau.

2. Ka hopena o ke kaʻina hana hoʻoheheʻe ma luna o ka pale ʻana i ka corrosion

Hiki ke hoʻopili ʻia ka pale ʻana o ke kila kila ma ke kaʻina hoʻoheheʻe ʻana i nā hale hana. Hiki ke hoʻopaʻa i ka maikaʻi o ka huahana paʻa a hilinaʻi hoʻi ma o ka hoʻomalu pono ʻana o nā mea hoʻohuihui, ka wehe ʻana i ka haumia maikaʻi, a me ka hoʻokele pololei ʻana i nā mahana hoʻoluʻu billet. ʻO kēia ka hopena i ka maikaʻi o loko a hoʻemi ʻia i ka pala. ʻO ka mea ʻē aʻe, paʻakikī paha nā wili kila liʻiliʻi me nā lako kahiko a me ka ʻenehana i ka wehe ʻana i nā haumia i ka wā e hoʻoheʻe ʻia ai, e alakaʻi ana i ka ʻeleʻele hiki ʻole o kā lākou huahana.

3. ʻo ke kaiapuni o waho, maloʻo ke aniau a ʻaʻole maʻalahi ka ʻōpala.

ʻO ke ʻano o ke kaiapuni o waho, ʻo ia hoʻi kahi ea maloʻo a maikaʻi hoʻi, ʻaʻole ia e paipai i ka hoʻokumu ʻana o ka ʻōpala. ʻO ka mea ʻē aʻe, hiki i nā pae kiʻekiʻe o ka haʻahaʻa o ka ea, ka ua lōʻihi, a i ʻole nā kaiapuni me nā pae kiʻekiʻe o ka pH hiki ke alakaʻi i ka hana ʻino. ʻO ka 304 stainless steel e ʻōpala inā hoʻopilikia ʻia nā kūlana kūlohelohe.

ʻO ke kila kila ʻole pehea e hana ai?

1. Nā ʻano hana kemika

E hoʻohana i nā ʻano kemika e like me ka pickling paste a i ʻole e hoʻomaʻamaʻa i ka passivation hou o nā wahi ʻōpala, e hana ana i kahi kiʻiʻoniʻoni chromium oxide e hoʻihoʻi hou i ka pale ʻana. Ma hope o ka ʻohi ʻana, pono ka holoi ʻana me ka wai e wehe i nā mea haumia a me nā koena waikawa. E hoʻopau i ke kaʻina hana ma ka hoʻomaʻamaʻa hou ʻana me nā lako kūpono a me ka sila ʻana me ka wax. No nā wahi ʻōpala liʻiliʻi liʻiliʻi, hiki ke hoʻopili ʻia kahi hui ʻana o ka ʻaila a me ka ʻaila me kahi lole maʻemaʻe e wehe i ka ʻōpala.

2. Mechanical ala

ʻO ka hoʻohana ʻana i ka puhi ʻana i ke one, ke aniani a i ʻole ka pāpaʻi ʻana i nā ʻōpala, ka abrading, ka palaki ʻana, a me ka hoʻoliʻiliʻi ʻana i nā ʻano hana kino no ka wehe ʻana i ka haumia i waiho ʻia e nā hana polishing a i ʻole nā hana abrading. Hiki ke alakaʻi i ka ʻino, ʻoi aku ka maʻemaʻe o nā ʻano ʻino, ʻoi aku ka nui o nā mea hao haole. No laila, pono e hoʻokō i ka hoʻomaʻemaʻe kino o nā ʻili ma lalo o nā kūlana maloʻo. He mea nui e hoʻomaopopo i ka hoʻohana ʻana i nā ʻano hana kino hiki ke wehe wale i nā haumia o ka ʻili a ʻaʻole e hoʻololi i ke kūpaʻa corrosion kūlohelohe o ka mea. No laila, ʻoi aku ka maikaʻi e hoʻopau i ke kaʻina hana ma ka hoʻomaʻamaʻa hou ʻana me nā mea pono kūpono a me ka sila ʻana me ka wax polishing.

Mea hana maʻamau i hoʻohana ʻia i ke kila kila kila a me ka hana

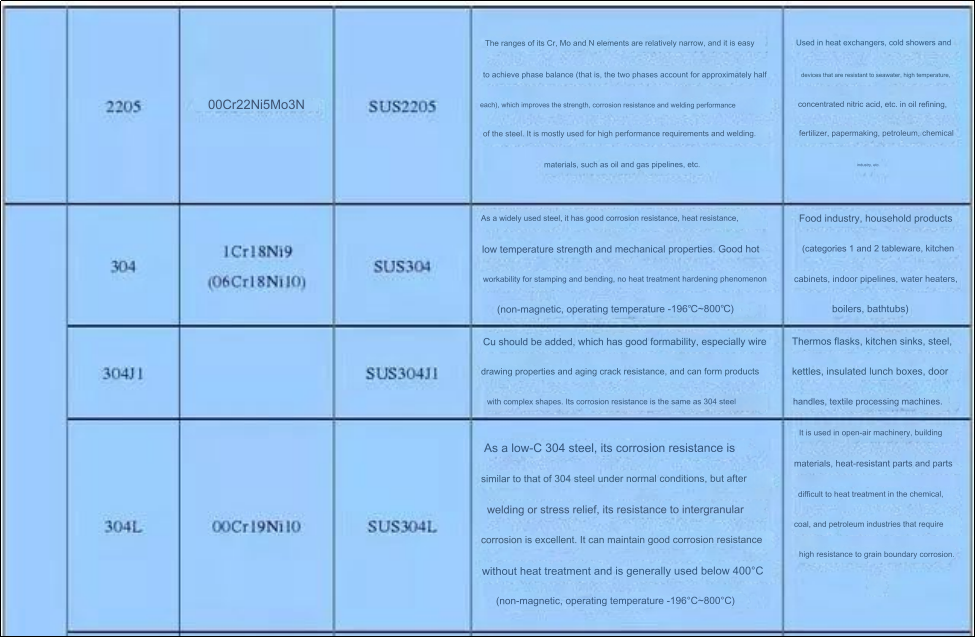

ʻO 1, 304 kila kila he kila austenitic i hoʻohana nui ʻia, kūpono no ka hana ʻana i ka hohonu hohonu.nā ʻāpana mīkini cnc, nā paipu waika, nā ipu, nā ʻāpana hana, a me nā kino mea kani like ʻole. Eia hou, hiki iā ia ke hana i nā mea hana a me nā mea hana non-magnetic a haʻahaʻa haʻahaʻa.

Hoʻohana ʻia ʻo 2, 304L stainless steel no ka hoʻoponopono ʻana i ka maʻalahi o ka corrosion intergranular o 304 stainless steel ma muli o ka ua Cr23C6 ma lalo o nā kūlana kikoʻī. ʻO ke kūlana sensitized o kēia ultra-low carbon austenitic stainless steel hāʻawi i ka hoʻomaikaʻi maikaʻi ʻana i ke kūpaʻa intergranular corrosion i hoʻohālikelike ʻia me 304 stainless steel. Eia kekahi, ʻoiai e hōʻike ana i ka ikaika haʻahaʻa haʻahaʻa, ua kaʻana like ia i nā waiwai like me 321 stainless steel a hoʻohana mua ʻia no ka wili. He kūpono ia no ka hana ʻana i nā ʻano mea kani a me nā lako pale a me nā ʻāpana ʻaʻole hiki ke hana i ka lāʻau hoʻonā paʻa.

3, 304H kila kila. ʻO ka lālā kūloko o 304 stainless steel, carbon mass fraction o 0.04% -0.10%, ʻoi aku ka maikaʻi o ka hana wela ma mua o 304 stainless steel.

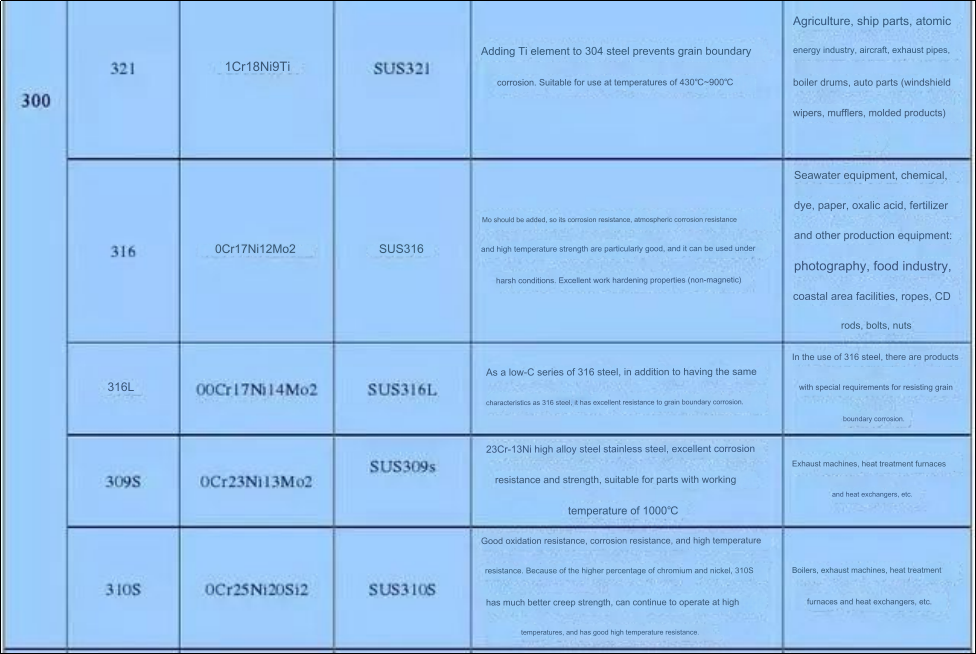

4, 316 kila kila. ʻO ka hoʻohui ʻana o ka molybdenum ma ke kumu o ke kila 10Cr18Ni12 e hoʻoikaika maikaʻi ai ke kila i ka hoʻēmi ʻana i ka media a me ka corrosion point. I ka wai kai a me nā mea hoʻolaha ʻē aʻe, ʻoi aku ka maikaʻi o ka corrosion ma mua o 304 stainless steel, i hoʻohana nui ʻia no ka pitting material resistance.

5, 316L kila kila. ʻO ke kila kalapona haʻahaʻa haʻahaʻa, me ke kūpaʻa maikaʻi i ka sensitized intergranular corrosion, kūpono no ka hana ʻana i nā ʻāpana welded a me nā mea hana me ka nui o nā ʻāpana ʻāpana mānoanoa, e like me nā mea pale i ka corrosion i nā lako petrochemical.

6, 316H kila kila. 316 kuhiliʻole kila lala i loko, kalapona ka hapa hapa o 0.04% -0.10%, kiʻekiʻe wela hana i oi aku mamua o 316 kuhiliʻole kila.

7, 317 kila kila. ʻOi aku ka maikaʻi o ka pitting a me ka creep resistance ma mua o ka 316L stainless steel, i hoʻohana ʻia i ka hana ʻana i nā mea hoʻoheheʻe petrochemical a me nā mea hoʻonaninani.

ʻO 8, 321 ke kila kila he austenitic stainless steel me ka titanium stabilization. ʻO ka hoʻohui ʻana o ka titanium e kuhikuhi ana i ka hoʻonui ʻana i ke kū'ē i ka intergranular corrosion, a ke hōʻike pū nei hoʻi i nā waiwai mechanical maikaʻi i nā wela kiʻekiʻe. Ma lalo o ka nui o nā kūlana, ʻaʻole ʻōlelo ʻia no ka hoʻohana ʻana, koe wale nō nā hiʻohiʻona kikoʻī e like me ka loaʻa ʻana o nā wela kiʻekiʻe a i ʻole nā huahana hydrogen-induced.

ʻO 9, 347 ke kila kila he austenitic stainless steel i hoʻopaʻa ʻia me ka niobium. ʻO ka hoʻohui ʻana o ka niobium e hoʻoikaika i kona kū'ē i ka intergranular corrosion a me kona hiki ke kū i ka corrosion i loko o ka acidic, alkaline, paʻakai, a me nā wahi kemika koʻikoʻi ʻē aʻe. Hōʻike ia i nā hiʻohiʻona wiliwili maikaʻi loa, kūpono ia no ka hoʻohana ʻana ma ke ʻano he mea pale a me ke kila wela. Hoʻohana nui ʻia kēia ʻano kila i ka mana wela a me nā ʻoihana petrochemical no nā noi like ʻole e like me ka hana ʻana i nā ipu, nā paipu, nā mea hoʻololi wela, nā shafts, a me nā paipu umu i loko o nā kapuahi ʻoihana, a me nā thermometers tube furnace.

ʻO 10, 904L ke kila kila he kila kila austenitic kiʻekiʻe loa i hoʻomohala ʻia e OUTOKUMPU (Finland) me kahi ʻano nickel mai ka 24% a hiki i ka 26% a me kahi maʻi kalapona ma lalo o 0.02%. Hāʻawi ʻo ia i ke kūpaʻa corrosion kūʻokoʻa a hana maikaʻi i nā waikawa non-oxidizing e like me ka sulfuric acid, acetic acid, formic acid, a me ka phosphoric acid. Eia kekahi, hōʻike ia i ke kūpaʻa ikaika i ka corrosion crevice a me ka corrosion stress. He kūpono ia no ka hoʻohana ʻana me ka sulfuric acid ma nā ʻano ʻokoʻa ma lalo o 70 ℃ a hāʻawi i ke kūpaʻa corrosion kiʻekiʻe i ka acetic acid a me nā ʻakika hui ʻia o ka waikawa formic a me ka waikawa acetic i kēlā me kēia neʻe a me ka mahana ma lalo o ke kaomi maʻamau. Ua helu mua ʻia ma ke ʻano he nickel-based alloy ma lalo o ke kūlana ASMESB-625, i kēia manawa ua hoʻokaʻawale ʻia ʻo ia ma ke ʻano he kila kila. ʻOiai ʻo Kina 015Cr19Ni26Mo5Cu2 kila e like me 904L, hoʻohana kekahi mau mea hana ʻEulopa i ka 904L stainless steel ma ke ʻano he kumu mua no kā lākou.ʻāpana cnc, e like me ka E+ H mass flow meter ana paipu a me ka pahu wati Rolex.

11, 440C kila kila. ʻO ke kila kila ʻole Martensitic, ʻo ka paʻakikī kiʻekiʻe loa i ke kila kila paʻakikī, ke kila kila, ka paʻakikī ʻo HRC57. Hoʻohana nui ʻia e hana i nā nozzles, bearings, valve spool, noho, lima lima, kumu a pēlā aku.

12, 17-4PH ke kila kila ma ke 'ano he martensitic precipitation-hardened stainless steel me ka Rockwell hardness o 44. Hāʻawi ia i ka ikaika kūikawā, ka paʻakikī, a me ka pale ʻana i ka corrosion, ʻoiai ʻaʻole kūpono ia no ka hoʻohana ʻana i nā mahana ma mua o 300 ° C. Hōʻike kēia kila i ke kūpaʻa maikaʻi i nā kūlana o ka lewa, a me nā waikawa diluted a i ʻole ka paʻakai. Hoʻohālikelike ʻia kona kūpaʻa corrosion me ka 304 stainless steel a me 430 stainless steel. ʻO nā noi no kēia kila me kona hoʻohana ʻana i ka hana ʻana i nā paepae o waho, nā turbine blades, valve spools, noho, lima lima, valve stems, a me nā mea hou aku.

Ma ke kahua o ka ʻoihana mea kani, ua hoʻoholo ʻia ke koho ʻana o ke kila kila austenitic maʻamau e nā kumu e like me ka versatility a me ke kumukūʻai. ʻO ke kaʻina hana maʻamau no ke koho kila kila ʻo 304-304L-316-316L-317-321-347-904L. ʻO ka mea nui, ʻaʻole i hoʻohana pinepine ʻia ʻo 317, ʻaʻole makemake ʻia ʻo 321, makemake ʻia ʻo 347 no ka pale ʻana i ka corrosion kiʻekiʻe, a ʻo 904L ka mea paʻamau no nā mea kikoʻī i hana ʻia e kekahi mau hui. ʻAʻole maʻamau ka 904L stainless steel ka koho maʻamau i nā noi hoʻolālā.

I ka hoʻolālā mea hana a me ke koho, e hālāwai pinepine i nā ʻano ʻōnaehana like ʻole, series, grades of stainless steel, pono e koho ʻia ma luna o ka media kaʻina kikoʻī, ka mahana, ke kaomi, nā ʻāpana koʻikoʻi, corrosion, kumukūʻai a me nā ʻano ʻē aʻe o ka noʻonoʻo.

ʻO ka ʻimi ʻana o Anebon a me ka pahuhopu ʻoihana ʻo "E hoʻomaʻamaʻa mau i kā mākou mea kūʻai aku". Ke hoʻomau nei ʻo Anebon i ka hoʻokumu ʻana a me ka hoʻolālā a me ka hoʻolālā ʻana i nā waiwai kiʻekiʻe o ka maikaʻi no kā mākou mau mea kahiko a me nā mea hou a ʻike i kahi manaʻo lanakila-lanakila no kā mākou mea kūʻai aku e like me kā mākou hana ʻana i nā profile extrusion kiʻekiʻe,cnc hoʻohuli i nā ʻāpana aluminiaʻāpana wili aluminino nā mea kūʻai aku. ʻO Anebon me nā lima hāmama, kono i nā mea kūʻai hoihoi āpau e kipa i kā mākou pūnaewele a i ʻole e kelepona pololei iā mākou no ka ʻike hou aku.

Factory Customized China CNC Machine a me CNC Engraving Machine, ʻike nui ʻia a hilinaʻi ʻia ka huahana a Anebon e nā mea hoʻohana a hiki ke hoʻokō mau i ka hoʻomohala ʻana i nā pono waiwai a me ka nohona. Hoʻokipa ʻo Anebon i nā mea kūʻai hou a kahiko mai nā ʻano like ʻole o ke ola e hoʻokaʻaʻike mai iā mākou no nā pilina ʻoihana e hiki mai ana a me ka loaʻa ʻana o ka kūleʻa like!

Ka manawa hoʻouna: Jan-23-2024